Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

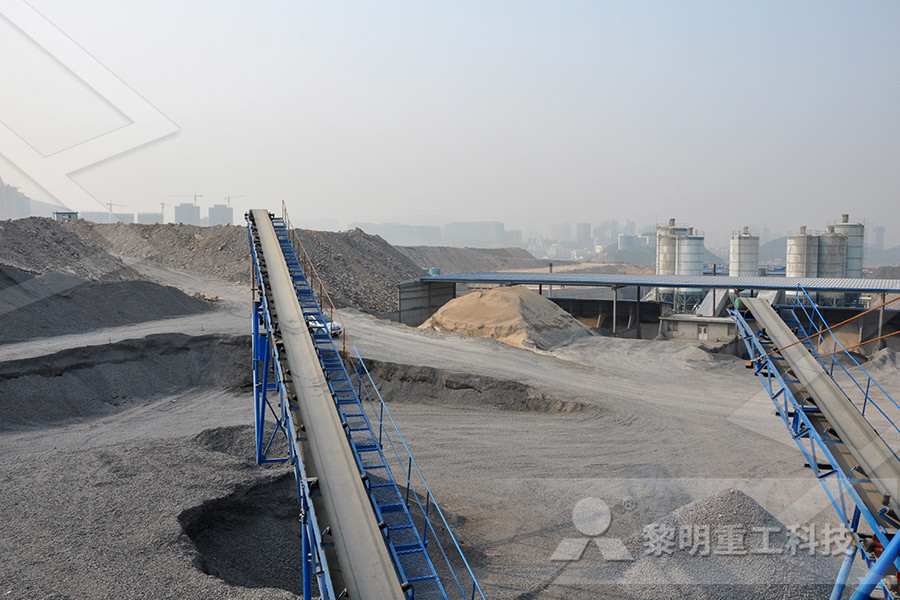

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Introduction of jaw crusher yxmineengineering

Introduction of jaw crusher Introduction Jaw crushers are mainly used as coarse crushers and medium crushers in mining, building materials, infrastructure and other sectors According to the width of the feed port, it is divided into three types: large, medium and small The width of the feed port is greater than 600MM for large A jaw crusher’s flywheel, toggle plates, pitman, eccentric shaft, and driving motor generate the crushing action and provide the energy needed to break the material There are some different styles of Jaw Crushers, the most common being the overhead eccentric jaw (shown above) or a double toggle jawWhat is a Jaw Crusher? TelsmithJaw Crusher manufactured and supplied by us is a robustversatile crushing machine Jaw Crusher has two crushing jaws The one fixed vertically at the front end of hollow rectangular body frame called as Fixed Jaw The other pivoted at the top directly mounted on crank shaft known as Swing JawBuy Jaw Crusher from Triveni Engineering Works, India ID Rotational energy is fed into the jaw crusher eccentric shaft by means of a sheave pulley which usually has multiple Vbelt grooves In addition to turning the pitman eccentric shaft it usually has substantial mass to help maintain rotational inertia as the jaw crushes material“Computer Aided Design of Jaw crusher”The movable jaw, movable jaw shaft, movable tooth plate, and bracket pad are assembled on the ground Then use the crane lifts the assembled parts into the rack of the crusher For the sliding bearing which needs to install it Then put into the housing, measuring Installation of Jaw Crusher Skills and Notes JXSC Mine

Jaw Crushers McLanahan

Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers On the overhead eccentric style Jaw Crusher, the moving swing jaw is suspended on the eccentric shaft with heavyduty double roll spherical roller bearingsThe kinematic analysis of single toggle jaw crusher shows that the forces on the moving jaw plate at different crank angle are different and hence power generated varies with crank angleCOLLEGE OF ARCHITECTURE AND ENGINEERING SCHOOL OF Loader Bucket Tooth Systems: Ø Verticalpin loader tooth systems Ø Sidepin loader tooth systems Ø Onepiece loader tooth systems Loader Bucket Teeth for Different Applications Ø Standard Bucket Teeth:bucket teeth for loaders working for smooth quarry floors or foundation excavations Ø Rock Bucket Teeth:bucket teeth for loaders working for tough applications,such asloader bucket teeth bucket teeth AS Machinery Co, LtdKeywords: Equipment, Maintenance, Crushers, Jaw crushers, Rock breakers, Refurbishing, Choking, Lubricating systems field from the late 1800s to the early 1900s In 1910 the largest gyratory cru shers built had 48inch openings However, about this time the jaw crusher came to EQUIPMENT AND MAINTENANCEWORKING OF JAW CRUSHER Crank shaft etc TOGGLE BLOCK AND WEDGE BLOCKS : Toggle and wedge Blocks is also machined out of high grade cast iron These are fitted n the rear portion of jaw body to control the thrust in that direction PULL BACK ROD AND SPRING : To keep the both the toggle plates in their assembly position and pull back the Balaji Engineering Works

Eccentric Shaft an overview ScienceDirect Topics

The first shaft is a pivoting shaft on the top of the crusher, while the other is an eccentric shaft that drives both toggle plates The moving jaw has a pure reciprocating motion toward the fixed jaw The crushing force is doubled compared to single toggle crushers and it can crush very hard ores The jaw crusher is reliable and robust and Such jaw crushers ( DEOS 1 607 5142 ) have two crushing jaws, one of which is usually fixed and the other swinging arrangedThe crushed material is crushed in the crushing compartment during periodic closing of oscillating about a pivoting crushing jaw between the two crushing jaws, especially by compressive stress, and falls after repeated stressing and crushing process due to its gravity EPB1 Jaw crusher comprising a traversing drive Dec 19, 2012 Vw golf 20TDI EA288 long crank diagnose P0341/P0016 Jaw Crusher Assembly Video Bengkel Mesin Dian Proses Machining Exentric #Shaft #Jaw #Crusher OD 220 x 2800 mm jaw cusher repair YouTubeOriginality/value: The model of the single toggle jaw crusher mechanism as a planar crank and rocker mechanism is a realistic one The equations obtained in this paper should be useful in further (PDF) Analysis of the Single Toggle Jaw Crusher KinematicsEccentric Shaft The eccentric shaft is driven through an intermediate countershaft from the jaw crusher drive This shaft incorporating a crank drive crank pin, connecting rod and the drive crank assembly as the operator has the option to disengage the Eccentric Shaft constructioncrusherstpub

Jaw Crusher Sanme

Jaw crusher is commonly known as jaw breaking, also known as tiger mouth A crushing chamber is composed of two jaw plates, a movable jaw and a static jaw, which simulates the movement of the two jaws of the animal to complete the crushing operation of the materialJaw crusher movement is guided by pivoting one end of the swinging jaw and an eccentric motion located at the opposite end [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square“Computer Aided Design of Jaw crusher”Sep 25, 2017 Proses Machining Exentric #Shaft #Jaw #Crusher OD 220 x 2800 mm Bengkel kami bersertifikasi ISO 9001:2015 siap support untuk kepentingan spare part Industri perusahaan bapak / Bengkel Mesin Dian Proses Machining Exentric #Shaft #Jaw # Dec 21, 2015 A safety factor is also needed for bearing failure of the key, which is determined to be 2524 This value is a suitable to resist bearing failure, and is lower than the safety factor for the gear, shaft, and crank Therefore, the key will fail before the shaft, gear, and crank willRockCrusherProject SlideShareThe vertical cone crusher drive shaft rotates the mantle eccentrically below the concave, squeezing the product and crushing it between the mantle and concave cone crushers mantle replacement Gulin machine in Cement raw materials processing plant, cone crushers mantle replacementMantle Shaft For Crusher Crusher Mills, Cone Crusher

mechanism of eccentric shaft with pitman in jaw crusher

Analyzing the operation and design of a Jaw Crusher using 14 Aug 2019 A jaw crusher is a device that reduces the size of various solid materials in one resulting from the eccentric shaft movement, and the second from the toggle This breakage model is able to address the different mechanisms of This allows optimization for the pitman's design and crushing angle, andHorizontal shaft impact crusher is mainly used in mechanism sand processing etc Horizontal shaft impact crushers are very suitable to crush various soft and pegson xv350 vertical shaft impactor crusherMechanism Of Horizontal Shaft Impactor Crusher Mills Single toggle Jaw crusher The rotation of the eccentric shaft causes the swing Jaw assembly to move in an elliptical path Maximum movement of the swing jaw assembly occurs at the top of the crushing chamber with minimum movement at the discharge openingCrushing / Screening and ConveyingJaw crusher movement is guided by pivoting one end of the swinging jaw and an eccentric motion located at the opposite end [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square“Computer Aided Design of Jaw crusher”Dec 19, 2012 Vw golf 20TDI EA288 long crank diagnose P0341/P0016 Jaw Crusher Assembly Video Bengkel Mesin Dian Proses Machining Exentric #Shaft #Jaw #Crusher OD 220 x 2800 mm jaw cusher repair YouTube

Jaw Crusher Sanme

Jaw crusher is commonly known as jaw breaking, also known as tiger mouth A crushing chamber is composed of two jaw plates, a movable jaw and a static jaw, which simulates the movement of the two jaws of the animal to complete the crushing operation of the materialEccentric Shaft The eccentric shaft is driven through an intermediate countershaft from the jaw crusher drive This shaft incorporating a crank drive crank pin, connecting rod and the drive crank assembly as the operator has the option to disengage the Eccentric Shaft constructioncrusherstpubSingle toggle Jaw crusher The rotation of the eccentric shaft causes the swing Jaw assembly to move in an elliptical path Maximum movement of the swing jaw assembly occurs at the top of the crushing chamber with minimum movement at the discharge openingCrushing / Screening and ConveyingCRANK SHAFT GRINDING MACHINE abstract 海归网 2014年1月14日 crank shaft grinding machine abstract Newest PE Jaw Crusher PE series jaw crusher is usually used as primary crusher in quarry Read moreAbstract Of Jaw Crusher mayukhportfoliocoThe vertical cone crusher drive shaft rotates the mantle eccentrically below the concave, squeezing the product and crushing it between the mantle and concave cone crushers mantle replacement Gulin machine in Cement raw materials processing plant, cone crushers mantle replacementMantle Shaft For Crusher Crusher Mills, Cone Crusher

mechanism of eccentric shaft with pitman in jaw crusher

Analyzing the operation and design of a Jaw Crusher using 14 Aug 2019 A jaw crusher is a device that reduces the size of various solid materials in one resulting from the eccentric shaft movement, and the second from the toggle This breakage model is able to address the different mechanisms of This allows optimization for the pitman's design and crushing angle, andSMAN SH/LH Series Gyratory Hydraulic Cone Crushers are the ultimate solution for the secondary crushing to achieve uniform product size of hard rocks, ores, stones and minerals Depending on the required output, cone crusher is available in below models: Secondary Cone Crusher – The crusher that receives feed from the primary crusher, further reducing rock in sizeprimary jaw crusher shaktiminingDec 21, 2015 A safety factor is also needed for bearing failure of the key, which is determined to be 2524 This value is a suitable to resist bearing failure, and is lower than the safety factor for the gear, shaft, and crank Therefore, the key will fail before the shaft, gear, and crank willRockCrusherProject SlideShareHorizontal shaft impact crusher is mainly used in mechanism sand processing etc Horizontal shaft impact crushers are very suitable to crush various soft and pegson xv350 vertical shaft impactor crusherMechanism Of Horizontal Shaft Impactor Crusher Mills MOBLIE CRUSHER 300t/h tire type mobile crushing station production line The production line can quickly crush the ore, the finished product has excellent particle size, and can directly use the construction aggregate, saving a lot of manpower, material and financial resources300t/h Tire Type Mobile Crushing Station Production Line

USA1 Rock crusher attachment Google Patents

USA1 US12/805,307 USA USA1 US A1 US A1 US A1 US A US A US A US A1 US A1 US A1 Authority US United States Prior art keywords jaw assembly crusher housing support Prior art date Legal status (The legal status is an A heavy duty jaw crusher with an one of the fastest fine jaw crushers on the market oscillating motion, via a Pitman/crank arm arrangement, to rapidly reduce Simple greasing regime – seven easily accessible grease points that onlyGreasing A Jaw Crusher Pitman