Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

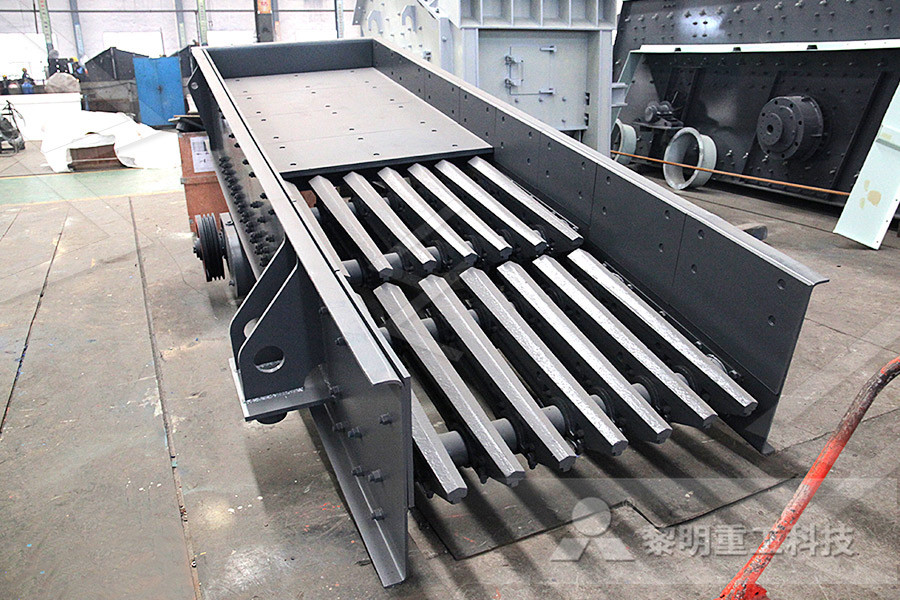

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

which crusher type will crush a stone of 200kn

which crusher type will crush a stone of 200kn In the world of construction and landscaping, crushed stone materials are always in extremely high demand although there are different types of aggregate products available, crusher run remains one of the most frequently soughtafter for Jul 31, 2020 Granite jaw crusher is a new type of jaw crusher, which is developed by Fote Heavy Machinery based on the characteristics of granite It has a novel structure and a reasonable layout Video of granite jaw crusher The large crushing force and strong pressure resistance allow it to crush materials with compressive strength of 320 MPaWhich Type of Crusher is Suitable for Processing Granite Jul 27, 2020 #67 – Crushed stone #67 includes stone that is 3/4 inch or smaller in size #67 is a great material for road and slab base as well as fill If you are interested in a specific type of crushed stone in Baltimore , contact ReAgg at (301) 3366700 today for help with any questions or to place an order7 Different Crushed Stone Sizes and Their ApplicationsThe crushed particles are then forced between the rotating surfaces into the smaller gap area Roll crushers are mostly used in smaller scale production to crush ores that are not too abrasive This type of rock crushing equipment gives a very fine product size distribution with very little dust production Impact CrusherChoosing the Right Rock Crushing EquipmentStone crusher plants used worldwide It is available with different2 capacity, design, and utility Uses of Crusher plant Stone crushing industry engaged in producing a crushed stone that used as a raw material for infrastructure projects like, road, highway, bridges, building canals, etcShould know all about Stone Crusher Plant Machine Thug

What are the Different Types of Aggregate Crushers?

Dec 15, 2020 Gyratory crushers are also used as aggregate crushers These types of crushers are similar to jaw crushers, but employ a cone shaped hopper with a smaller coneshaped crushing head that gyrates around the inside of the hopper in an eccentric movement rather than rotating, crushing the source material until the particles are small enough to fall through the opening at the bottomNov 11, 2019 Crushed stone often has an angular and jagged edge that occurs during the crushing process Gravel, on the other hand, typically has a very smooth texture and surface because of the natural weathering and wear of being exposed to the effects of running water Unlike crushed stone, gravel is usually sold and used in its natural stateThe Complete Guide to Crushed Stone and GravelOct 24, 2019 What types of gravel is used for driveway? Crusher run gravel is actually a kind of crushed stone, there are 8 eights kinds of crushed stone, and their functions are shown in following chart Crushed stone: size: application #5: from 1″ down to fine particles: road and paver base #67:What Are the Best Sizes of Crusher Run Gravel for Driveway The disadvantage of this type of crusher, when high capacity is required, is the relatively small discharge width, limiting the capacity as compared with the discharge circuit of a gyratory crusher Jaw crushers are mainly used in plants producing up to approximately 1600 t/h Primary crushing with gyratory crushersCrushers All crusher types for your reduction needs Crushed Stone Grades The following list gives a rundown of crushed stone grades and their best uses While there may be slight variances in the naming convention of crushed stone the following are the most common names and sizes: Crushed stone #5 – Sizes are from 1″ down to fine particles For road and paver base Crushed stone #67 Crushed Stone Grades: A Complete Guide Braen Stone

What are the Different Types of Aggregate Crushers?

Dec 15, 2020 Gyratory crushers are also used as aggregate crushers These types of crushers are similar to jaw crushers, but employ a cone shaped hopper with a smaller coneshaped crushing head that gyrates around the inside of the hopper in an eccentric movement rather than rotating, crushing the source material until the particles are small enough to fall through the opening at the bottomStone Crusher JXSC company stone rock crushers include cone crusher, jaw crusher, impact crusher, mobile crusher, sand making machine, mobile crushing plant hammer crushing which can crush with more than 200 kinds of industrial materialsSuch as pebble, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold, copper, etc Primary and fine crushers are the type of crushing Stone Crusher Cone Jaw Crushers Machine Manufacturer Jul 28, 2020 C The semifixed stone crusher needs to be installed on the effective concrete foundation or steel structure Due to the topographic and geological conditions, there are some exceptions These crushers, although need a relatively solid foundation, also belongs to the semifixed stone crusher D The fixed crushing plant is the most Advantages and Disadvantages of 4 Types of Stone Crusher Oct 24, 2019 What types of gravel is used for driveway? Crusher run gravel is actually a kind of crushed stone, there are 8 eights kinds of crushed stone, and their functions are shown in following chart Crushed stone: size: application #5: from 1″ down to fine particles: road and paver base #67:What Are the Best Sizes of Crusher Run Gravel for Driveway Stone Crushing Plant Capacity CRUSHER PLANT crushes such as limestone, granite, basalt and so on to product aggregates for ready mix concrete, building material, construction site and others Various final product sizes are available with customizing crushing plant system solution You can choose Stationary crusher plant type or Portable crushing plant (semi – mobile crushing plant) with Stone Crusher Plant Crusher Plant Capacity

What is Crusher Run? TriStar Concrete

What is Crusher Run and Why is It Used? (Also Called: Crush and Run) Crusher run is a blended mix of coarse aggregate and fine aggregate The combination of both crushed stone and stone dust creates a low void content (the amount of space or air between the pieces of rock in a mix) that is valuable in concrete construction for its compaction ability and drainage characteristicsImpact Crushers – VSIs and HSIs Impactstyle crushers include VSIs, as well as horizontal shaft impactors (HSIs), and are best used with less abrasive rock types, like limestone These types of machines break apart material by the impacting forces of certain wear parts known as blow bars and impact plates or toggles Some operations also use impactstyle crushers after they have already Types of Rock Crushers Quarry Crushing Equipment KemperStone Crusher Plant Production Process First of all, break the big stone boulders to smaller size manually Then it is fed to the stone crusher The crusher can accept the stone size of 175mm Stone crushing is the twostage process In the first stage, crush the 175mm stone to about 50mmStone Crusher Plant How to Start Business Project Plan 2 1/2 inch crushed stone – mainly used to prevent erosion on roadsides and in drainage ditches, also often laid at the entrance to longterm construction projects Quarry Process Quarry process, also known as QP, dense grade aggregate (DGA), crusher run and road stone, is a combination of small, 3/4inchorless crushed stone and stone dustCrushed Stone vs Quarry Process vs Stone DustType 1 MOT 040mm (Hardcore) Our Type 1 MOT (Crusher Run/Hardcore) subbase material is ideal for base layers for driveways, roads, footpaths or any application where a compacted base is required Complies with Highways StandardsType 1 MOT 040mm Crusher Run Building Materials

Jaw Crusher vs Cone Crusher: A Comparison

The Blackhawk 100 Cone Crusher is an example of a powerful cone crushing machine Cone Crusher Benefits Large feed openings can be paired with small discharge sizes, giving cone crushers a high crushing ratio This makes the machines incredibly efficient, reducing the need for further crushing Apr 21, 2018 *Uses: building pads, bases, driveways, sidewalks more *Mixture of stone dust 1 1/2 *Crushed limestone *Good compaction Runner Crush Now WBE Certified Dedicated to excellence for over 60 years (315) 4876622 6717 Winchell Rd Warners, NY 13164Runner Crush or Crusher RunRinaldi TopsoilGabion Rocks Supplier , Crushed Stone Supplier, Landscaping Stone Supplier , Gravel Supplier building stone, Crusher dust, Garden Stones, Rock Boulders, Armour rock supplier Nationwide supply and delivery of crushed stone material, straight from the quarryCrushed Stone Supplier Gabion rocks, Gravel , Aggregates Jul 04, 2016 A rollerbearingtype cone crusher functions the same as a shafttype cone The main difference is the rotating wedge found in rollerbearing cones that causes the gyrating motion of the mantle It commonly features a flatter angle in the crushing chamber compared with shaft type conesSelecting the right type of crushing equipment – QuarryStone Crusher JXSC company stone rock crushers include cone crusher, jaw crusher, impact crusher, mobile crusher, sand making machine, mobile crushing plant hammer crushing which can crush with more than 200 kinds of industrial materialsSuch as pebble, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold, copper, etc Primary and fine crushers are the type of crushing Stone Crusher Cone Jaw Crushers Machine Manufacturer

Stone Crusher Plant Crushing And Screening Plant in

Stone crusher plant can crush limestone, granite, basalt and so on to product aggregates for ready mix concrete, building material, construction site and others Various final product sizes are available with customizing crushing plant system solutionWhat is Crusher Run and Why is It Used? (Also Called: Crush and Run) Crusher run is a blended mix of coarse aggregate and fine aggregate The combination of both crushed stone and stone dust creates a low void content (the amount of space or air between the pieces of rock in a mix) that is valuable in concrete construction for its compaction ability and drainage characteristicsWhat is Crusher Run? TriStar ConcreteOct 24, 2019 What types of gravel is used for driveway? Crusher run gravel is actually a kind of crushed stone, there are 8 eights kinds of crushed stone, and their functions are shown in following chart Crushed stone: size: application #5: from 1″ down to fine particles: road and paver base #67:What Are the Best Sizes of Crusher Run Gravel for Driveway Stone Crushing Plant Capacity CRUSHER PLANT crushes such as limestone, granite, basalt and so on to product aggregates for ready mix concrete, building material, construction site and others Various final product sizes are available with customizing crushing plant system solution You can choose Stationary crusher plant type or Portable crushing plant (semi – mobile crushing plant) with Stone Crusher Plant Crusher Plant CapacityImpact Crushers – VSIs and HSIs Impactstyle crushers include VSIs, as well as horizontal shaft impactors (HSIs), and are best used with less abrasive rock types, like limestone These types of machines break apart material by the impacting forces of certain wear parts known as blow bars and impact plates or toggles Some operations also use impactstyle crushers after they have already Types of Rock Crushers Quarry Crushing Equipment Kemper

Runner Crush or Crusher RunRinaldi Topsoil

Apr 21, 2018 *Uses: building pads, bases, driveways, sidewalks more *Mixture of stone dust 1 1/2 *Crushed limestone *Good compaction Runner Crush Now WBE Certified Dedicated to excellence for over 60 years (315) 4876622 6717 Winchell Rd Warners, NY 13164Jul 04, 2016 A rollerbearingtype cone crusher functions the same as a shafttype cone The main difference is the rotating wedge found in rollerbearing cones that causes the gyrating motion of the mantle It commonly features a flatter angle in the crushing chamber compared with shaft type conesSelecting the right type of crushing equipment – QuarryStone Crusher Plant Production Process First of all, break the big stone boulders to smaller size manually Then it is fed to the stone crusher The crusher can accept the stone size of 175mm Stone crushing is the twostage process In the first stage, crush the 175mm stone to about 50mmStone Crusher Plant How to Start Business Project Plan Kim Crush Stone Crushers in Kimberley for the best sonte in the area Best price guaranteed in Kimberly! We will beat any price! G5, G3, G2/Crushing stone/ Ballast/Crushing sand Building stone all sizes and crushing sand/dust available Minimum order 30 tons We are striving to serve the local community and to be the best company ever in KIMCRUSH Stone Crushers • Kimberley • CITY PORTALAug 10, 2012 Primary crusher has the ability to receive the crushing material (a material that has to be crushed) directly from the source ie, quarry that’s why these types of crusher are fixed from where the material is taken Primary crusher is only for the breaking of large stones into pieces (this mean primary crusher is not for the aggregate size Crusher Definition Crusher Selection And Types of

Crusher Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrushed Stone Gravel Description Uses (New York locations) size size 2" crushed concrete x dust 2" Subbase for concrete asphalt driveways, etc Gravel, 11/2" crusher run x dust 11/2" Use for unpaved driveways, walkways, etc Gravel, 2" screened gravel x dust 2" Screened gravel subbase for concrete asphalt driveways, etcCrushed Stone Gravel Description Uses (New York Limestone, dolomite and granite are the most common types of rock processed into crushed stone Limestone and dolomite account for 71% all crushed stone; granite makes up 15% The remainder is sandstone, quartzite and other types of rock It is produced by crushing quarried rock, then screening it to sizes appropriate for the intended useCrushed Stone Lehigh Hanson, Inc