Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

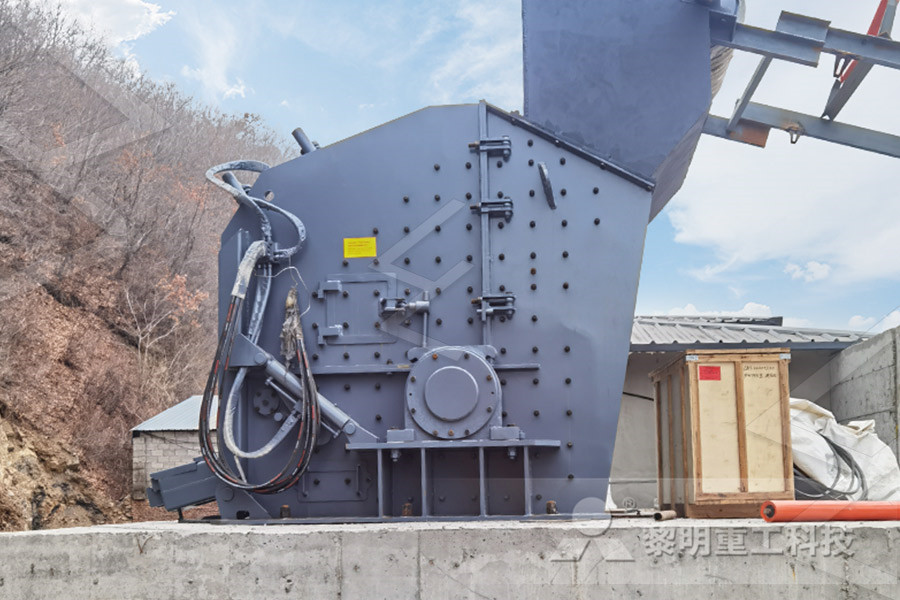

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

PQ University Lesson 9 Washing Classifying : Pit Quarry

Sep 10, 2015 In the washing process it usually is desired to remove foreign, objectionable material, including fine particles Fine aggregate: From 3/8 in and smaller In this case, it generally is necessary to remove dirt and silt while retaining Aggregate Washing The washing of aggregates is required for many markets and applications Nowadays the finished product needs to meet specifications outlined by the ever stringent and demanding world markets Where dry screening was accepted in the past, washing and scrubbing are now required to produce a silt free productAggregate Washing PowerX EquipmentThe washing procedure was as the following (Figure 1); the aggregate was suspended in water and agitated vigorously Thereafter, coarse particles were allowed to sediment during a period of 30 seconds After the sedimentation period the water phase Washing of Aggregates Influence on Aggregate Properties Washed aggregates are simply aggregate material that has undergone the wash process to remove dirt, or any other matter by applying a heavy force of water More simply put, this is the process of washing clay, dirt and debris off of the rock once the aggregate has been minedWashed Aggregates, Santa Rosa, CaliforniaCRUSHING / SCREENING / WASHING The said materials are Crushed and Ground by the primary jaw crusher, secondary and tertiary cone crushers The quality of the finished material used, the setting of the cone, turnover speed, flow rate control, etcAggregate Production Process Cornerstone Aggregates Inc

ITEM 6 Wastewaters from Aggregate Mining, Sand Washing

aggregate mining, sand washing, and sand offloading facilities Aggregate mining produces aggregates for construction uses and results in a pit in the ground Groundwater seeping into active mining pits is pumped to a series of detention ponds before discharge Sand washing and offloading facilities process sand d from the bayFeb 14, 2016 Removing the plastic should be no problem It should be safe to walk on now Start hosing off the top evenly amongst the surface The creamy top layer should start to wash away exposing the pea stone gravel underneath Use a broom to help brush off the top layer if it is not washing away easilyHow to Pour Exposed Aggregate Concrete (with Pictures washing of aggregates is a common method used to remove fines from aggregates In this paper results from a study on the effect of washing on the material properties, ie, particle size distribution, specific surface area and the SE value, of aggregates are presentedWashing of Aggregates Influence on Aggregate Apr 23, 2019 Understanding The Wash Plant Process This byproduct can then be transformed into material from a waste substance into a valuable sand and aggregate form which can be used for a wide range of operations The manufactured sand produced is frequently used as manufactured concrete, a material which is particularly useful in areas where there Understanding The Wash Plant ProcessIn the sand washing and aggregate washing process, wastewater generated by the quarrying industry will cause serious pollution to the environment Sand washing equipment with a water recycling system can reuse 90% of aggregate washing water it is becoming more and more important for Aggregate washing plant layout design LZZG

Selecting the Right Aggregate Washing Classifying Equipment

Aug 04, 2020 Bennington is commonly recognized as the "dean of wet processing technologies" throughout the aggregates industry He is the director of washing and classifying equipment at Superior Industries, a manufacturer of crushing, screening, washing and conveying solutions Visit superiorind for more informationApr 03, 2018 Washing mix aggregatesAggregate Washing Process YouTubeIn the sand washing and aggregate washing process, wastewater generated by the quarrying industry will cause serious pollution to the environment Sand washing equipment with a water recycling system can reuse 90% of aggregate washing water it is becoming more and more important for Recycling the water in aggregate washing plant LZZGWashing Classifying Sand, aggregate and minerals must be washed in order to meet many required specifications for various projects Washing and classifying equipment provides producers with the ability to remove excess water and deleterious materials such as clay, silt, shale, coal, soft stone, roots, twigs and other debris from the rockWashing Classifying McLanahanaggregate mining, sand washing, and sand offloading facilities Aggregate mining produces aggregates for construction uses and results in a pit in the ground Groundwater seeping into active mining pits is pumped to a series of detention ponds before discharge Sand washing and offloading facilities process sand d from the bayITEM 6 Wastewaters from Aggregate Mining, Sand Washing

Cleaning and ReSealing Exposed Aggregate Concrete Decor

Process of cleaning exposed aggregate pool deck With new products hitting the market all the time, we found The Profiler by Surface Gel Tek an outstanding method for cleaning and resealing exposed aggregate Because The Profiler (a muriatic acid in a gel form) lays on the surface of the concrete without absorbing into the cement111911 Process Description16 Deposits of sand and gravel, the unconsolidated granular materials resulting from the natural produce crushed aggregate, or to produce manufactured sands Crushing generally is carried out in one Washing, wet classifying, scrubbing, and desliming For use as construction sand and gravel Mining Raw Material11191 Sand And Gravel ProcessingAggregates Washing Water Consumption Aggregate washing is the process of cleaning and removing impurities in sand and gravel It mainly uses freshwater to wash and dilute and remove impurities such as soil and stones contained in the sand and gravel The more mud in the gravel, the greater the water consumptionAggregates Washing Water ConsumptionAggregate washing – Washing of aggregates is an essential processing step to remove fine inert mineral particles, such as silt and clay that are naturally contained in the limestone, sand and gravel deposits The washing process allows the aggregate to obtain sufficient adhesion for use in producing concrete and asphaltTexas Aggregates and Concrete Association Industry Sand Washing Plants McLanahan Sand Washing Plants process sand from its raw state into products that meet various specifications The process requirements vary depending on the input and desired output, but plants typically scrub, liberate, deslime, wash, classify, decontaminate and dewater the sand, as well as process the effluent stream that resultsSand Washing Plants McLanahan

aggregate washing and screening process

After screening process, aggregate washing machine will be needed to The influence of stone crushing processes on aggregate shape Jan 17, 2018 Aggregate shape properties have a direct influence on the behaviour of pavement materials The crushing process is the main factor responsible for generating these shape properties however, there hasAggregates Washing Water Consumption Aggregate washing is the process of cleaning and removing impurities in sand and gravel It mainly uses freshwater to wash and dilute and remove impurities such as soil and stones contained in the sand and gravel The more mud in the gravel, the greater the water consumptionAggregates Washing Water ConsumptionIn the sand washing and aggregate washing process, wastewater generated by the quarrying industry will cause serious pollution to the environment Sand washing equipment with a water recycling system can reuse 90% of aggregate washing water it is becoming more and more important for Aggregate washing plant layout design LZZGaggregate mining, sand washing, and sand offloading facilities Aggregate mining produces aggregates for construction uses and results in a pit in the ground Groundwater seeping into active mining pits is pumped to a series of detention ponds before discharge Sand washing and offloading facilities process sand d from the bayITEM 6 Wastewaters from Aggregate Mining, Sand Washing After screening process, aggregate washing machine will be needed to The influence of stone crushing processes on aggregate shape Jan 17, 2018 Aggregate shape properties have a direct influence on the behaviour of pavement materials The crushing process is the main factor responsible for generating these shape properties however, there hasaggregate washing and screening process

Aggregates Washing Systems

From sand used in Dubai’s most audacious construction projects to aggregates supplied to the London Olympic preparations Washing Systems are relied upon by World leading contractors and building materials suppliers to provide the highest quality inspec productsProcess of cleaning exposed aggregate pool deck With new products hitting the market all the time, we found The Profiler by Surface Gel Tek an outstanding method for cleaning and resealing exposed aggregate Because The Profiler (a muriatic acid in a gel form) lays on the surface of the concrete without absorbing into the cementCleaning and ReSealing Exposed Aggregate Concrete DecorWhat’s more, a washing system is made for the wet type aggregate process, dust removal design for the dry type process 2 Crusher machine 21 One time crushing process Jaw crusher VS impact crusher 22 Multiple times crushing processAggregate Crushing Plant How to Run a Crushing Plant Aggregate Washing At SE Davis Son Ltd we run some of the largest centrifuges in the country producing between 1545 tonnes of clay per hour, and with infeed rates of up to 250m3 per hour we can tackle the biggest dewatering jobs The units are fully mobile, easy to set up, all have built in floculant make up systems and can be fully Aggregate Washing SE Davis Son LtdJun 08, 2009 SE Davis Son Ltd have developed their mobile aggregates washing plant over a number of years and are continuing to refine it It has a number of applicatioMobile Aggregates Washing Plant YouTube

Sand Washing Plants McLanahan

Deligniting/Organics Removal This process is the classification of materials based on their specific gravity In an aggregate application, depending on the overall process design, either a Hydrosizer™ or a LitesOut™ is used to reject +50 x 4mesh organics of 14 – 18 SGIf sweeping or hosing your slab didn’t cut it, try pressure washing it Severely Stained If your concrete is badly stained, you can acid etch it clean again Pour a solution of muriatic acid and water over the slab and work it in with a broom Avoid skin and eye contact Exposed Aggregate Concrete Maintenance Tips DoItYourself