Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

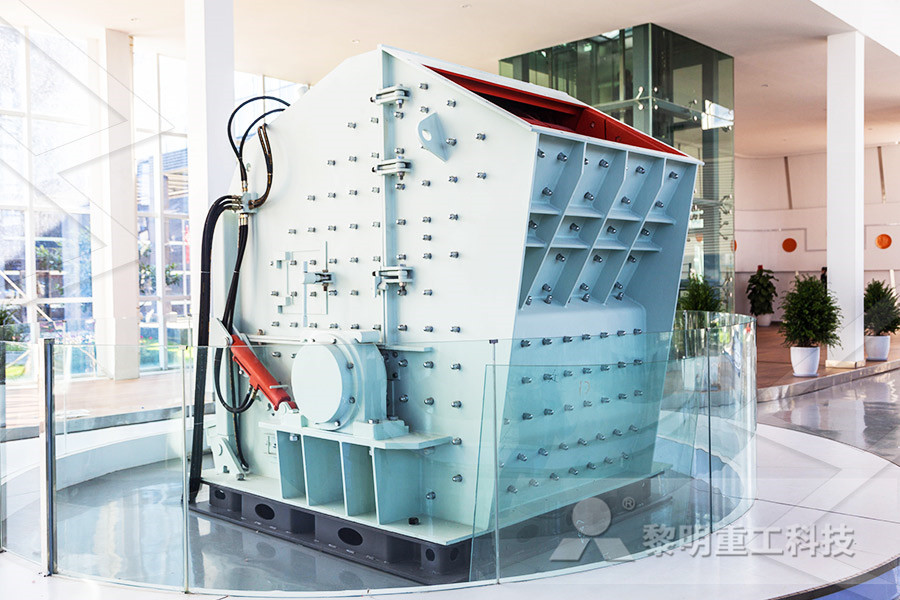

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Tips to maximize crushing efficiency Pit Quarry : Pit

May 13, 2019 Many modern impact crusher installations have a variable speed drive arrangement that allows an increase in the rotor speed to compensate for wear on the impact hammers In many impact crushers, a third curtain or crushing chamber can be HS impact crusher VS impact crusher Screening equipment YKRH/SK series circular screen A Handson Approach to Improve Productivity but the experience is that even a small deviation from the optimum CSS has a significant impact on revenue One should be aware of that for a production process that operates over many hours even a Crusher Performance Optimization – A Handson Approach to Primary crushing with impact crushers The primary impact crusher offers high capacity and is designed to accept large feed sizes The primary impact crushers are used to process from 200 t/h up to 1900 t/h and feed sizes of up to 1830 mm (71") in the largest modelCrushers All crusher types for your reduction needs Aug 15, 2012 The word impact makes sense that in this particular type of crusher some impaction is being used for crushing of rocks In normal types of crusher pressure is generated for the crushing of rocks But, impact crushers involve an impact method There is a hopper one side that takes the crushing material into the machineImpact Crusher Description Advantages Types of ® NP Series™ horizontal shaft impact (HSI) crushers ® NP Series™ HSI crushers consist of heavy rotor, wear resistant materials, and an optimal crusher chamber design This combination has proven revolutionary in improving capacity and product quality, as well as in reducing operating and wear costsHorizontal shaft impact (HSI) crushers

Impact Crushers For Sale MyLittleSalesman

Dec 15, 2020 Shop Impact Crushers For Sale by owners dealers near you Browse 30 new and used Impact Crushers by FABO, EvoQuip, JCI, Pegson, Texas Crusher, and more“The impact crusher’s ability to handle steelreinforced concrete, along with custom options, such as plastics and woodwaste removal systems, washing systems and more, has enabled recyclers to create much higher quality end products, and crush and process materials previously deemed only waste, or too difficult to process”The rise of mobile impact crushers for recycling HS impact crusher VS impact crusher Screening equipment YKRH/SK series circular screen A Handson Approach to Improve Productivity but the experience is that even a small deviation from the optimum CSS has a significant impact on revenue One should be aware of that for a production process that operates over many hours even a Crusher Performance Optimization – A Handson Approach to Great Wall impact crusher is under the international quality certificate of CE and ISO9001:2008, our main stone crushers contain impact crusher, jaw crusher, cone crusher, roll crusher , hammer crusher and diesel engine crusher If you are interested in our mining machinery or have any questions on stone crusher prices, please feel free to contact with our online serviceHow to improve impact crusher efficiency in crushing plant?The production capacity of jaw crusher directly affects the economic profits of investors And the production capacity of jaw crusher is affected by many factors, such as the properties of raw material (hardness, size, and bulk density), type size of jaw crusher, operation condition of jaw crusher Solutions To Improve The Production Capacity Of Jaw Crusher

Horizontal shaft impact (HSI) crushers

® NP Series™ HSI crusher is an excellent choice especially if your output and productivity demands are stringent In addition to the stationary crushers presented on this page, some HSI crusher models are also available as mobile or portable versions The crusher configuration can be adjusted for your requirementsA crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher WikipediaME Elecmetal — a global supplier of integrated wear solutions for mining, construction and industry — is among the first companies to benefit from Rocky DEM’s latest technology: the Tavares breakage modelThe industrial supplier chose Rocky software specifically for this capability, which accurately shows how particle breakage affects crusher liner equipment, in an effort to improve ME Elecmetal improves crusher liner performance with Rocky Jan 01, 2019 The particle size distribution curves of the products obtained using jaw and impact crushers are presented in Fig 4 The impact crusher led to a finer particle size distribution for the coarse fractions (above 48 mm), with little difference in the fine particle sizes Download : Download highres image (126KB) Download : Download fullsize imageConcrete aggregates properties crushed by jaw and impact 2 ) Impact crusher uses the motor drive to make the rotor rotate at high speed, the material on the rotor and the blow bar hit and break, and then bounce it onto the impact plate to make it break again This process is repeated until the material is broken to the desired particle size and discharged from the outletImpact Crusher VS Jaw Crusher:What Are the Differences?

Johnson Crushers International, Inc

Updates to the bowl float sensor and the addition of a labyrinth contact seal have continued to improve bearing life and reduce operating costs The modular plants, launched in 2016, have shown growth as JCI has continued to offer more options for jaw and impact crushers, as well as horizontal and incline screens on its simple modular structuresSUPERIOR JAW CRUSHER — double toggle machine, reinforced by thrurods Sizes from 36×24 to 84×60 in TYPE “B” BLAKE JAW CRUSHER — standard, reliable, double toggle crusher Has wide application in medium and small plants Five sizes, from 10″ x 7″ to 30″ x 18″Jaw Crushers for Sale Metallurgist Mineral Processing NP Series impact crushers have been designed to minimise maintenance and improve all adjustment operations NP Series impact crushers deliver unbeatable performances in primary, secondary, tertiary and recycling applications A history of quality NP Series impact crushers are built on the success of our 50 years of BP and Impact Crushers NP Series Impact CrushersBy understanding your business needs, we improve performance using technology and expertise LifeCycle Services Tailored service packages delivering performance outcomes Your goals are our goals The impact crusher parts are available for both horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushersCrusher parts spares and wears for cone, impact, jaw Durable impact crusher parts last longer and increase throughput Available for both horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers, 's comprehensive wear and spare parts offering contains standard parts offtheshelf and tailormade parts for any impact Impact crusher parts Outotec

4 Types of Stone Crushers' Maintenance and Efficient

Dec 12, 2020 Impact crusher Impact crusher When the impact crusher is working, the rotor rotates at high speed under the driving of the motorAfter the ores enter the action area of the hammer, it collides with the hammer on the rotor and is thrown to the impact device to crush again, and then rebound from the impact lining to the hammer action zone to continuous crushHS impact crusher VS impact crusher Screening equipment YKRH/SK series circular screen A Handson Approach to Improve Productivity but the experience is that even a small deviation from the optimum CSS has a significant impact Crusher Performance Optimization – A Handson Approach to Great Wall impact crusher is under the international quality certificate of CE and ISO9001:2008, our main stone crushers contain impact crusher, jaw crusher, cone crusher, roll crusher , hammer crusher and diesel engine crusher If you are interested in our mining machinery or have any questions on stone crusher How to improve impact crusher efficiency in crushing plant?The production capacity of jaw crusher directly affects the economic profits of investors And the production capacity of jaw crusher is affected by many factors, such as the properties of raw material (hardness, size, and bulk density), type size of jaw crusher, operation condition of jaw crusher Solutions To Improve The Production Capacity Of Jaw CrusherTo do this can improve the life of the impact crusher 1 Master the working principle of the impact crusher When the impact crusher works, the rotor is driven by an electric motor and rotates at a To do this can improve the life of the impact crusher

Impact Crushers Crush Rock, Minerals More Williams

Using an advanced impact method, impact crushers are the efficient and costeffective solution for industrial size reduction projects Impact Crushers have a wide range of industrial applications from crushing rock to delumping sand and whole lot more Browse Williams Crusher’s line of impact PF Impact Crusher PF Impact Crusher by its unique advantages, occupied the mining machinery market, It is because of back PF Impact Crusher with outstanding performance in energy saving and environmental protection, so in the mechanism of sand production line of sand system, PF impact crusher unique PF impact crusher,how to better improve impact ME Elecmetal — a global supplier of integrated wear solutions for mining, construction and industry — is among the first companies to benefit from Rocky DEM’s latest technology: the Tavares breakage modelThe industrial supplier chose Rocky software specifically for this capability, which accurately shows how particle breakage affects crusher liner equipment, in an effort to improve ME Elecmetal improves crusher liner performance with Rocky 2 ) Impact crusher uses the motor drive to make the rotor rotate at high speed, the material on the rotor and the blow bar hit and break, and then bounce it onto the impact plate to make it break again This Impact Crusher VS Jaw Crusher:What Are the Differences?Jan 01, 2019 An impact crusher was used in the concretes with lower strength to check if improvements in cement paste liberation were observedConcrete aggregates properties crushed by jaw and impact

Tips on Choosing a Concrete Crusher for Demolition

Nov 23, 2012 Impact crushers While jaw crushers use pressure to break up concrete, impact crushers rely on impact (as their name implies) Some impact crushers throw the rock against hard surfaces with such velocity that the rocks naturally break along internal fissures Other impact crushers