Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

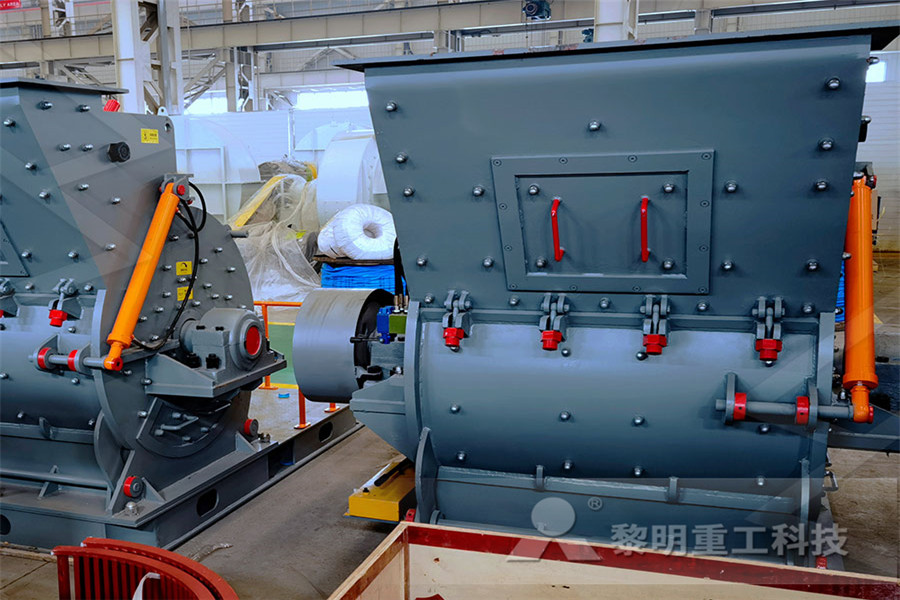

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

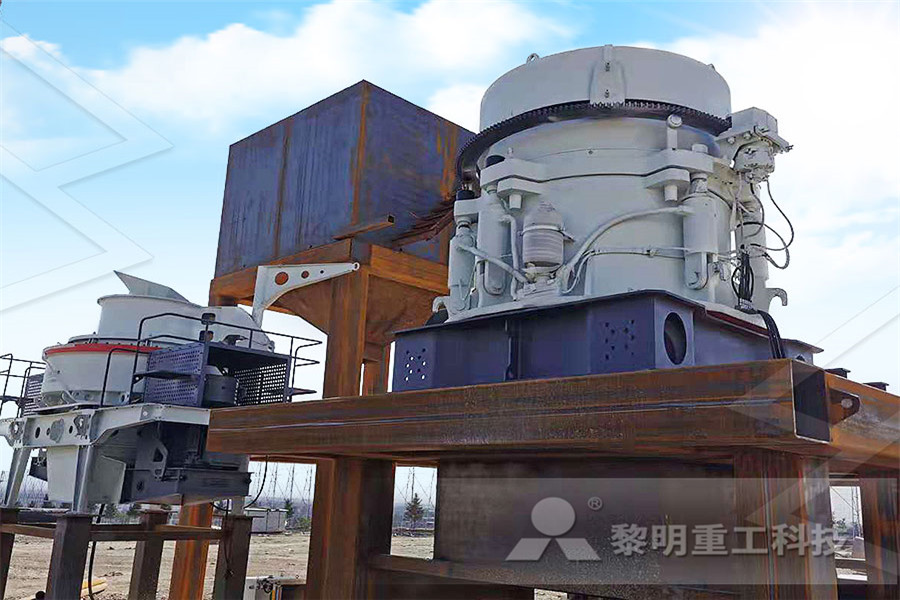

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

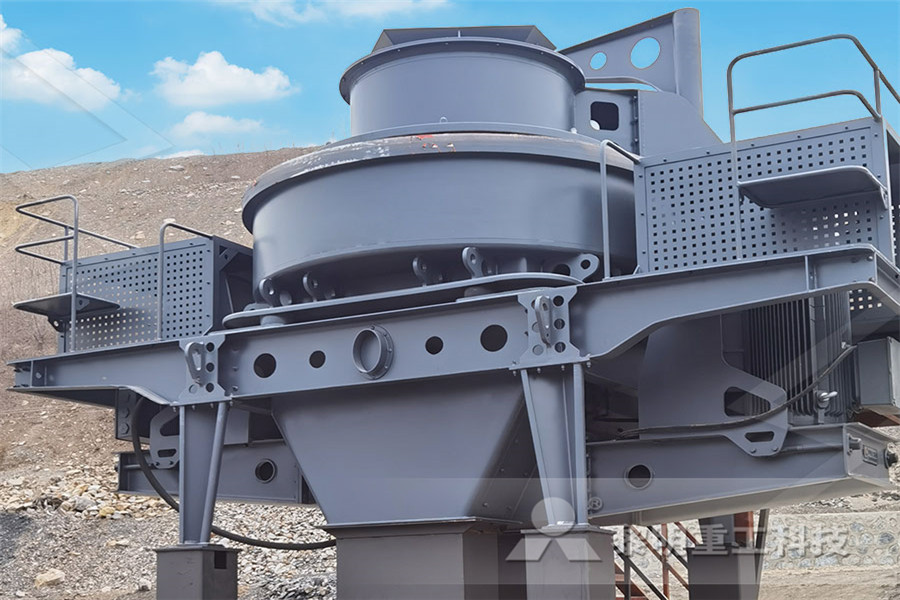

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Pulverizers 101: Part I POWER Magazine

Aug 01, 2011 The design "capacity" of that same pulverizer is 135,000 pounds per hour with fuel that is 55 HGI, 3/4inch raw coal maximum size, and 7% moisture The pulverizer Jun 15, 2020 The effect of moisture content on the pulverization of lignite in the Hardgrove mill was noted to be a highly important factor respecting grinding energy consumption and in pulverized coal production The grinding energy efficiency increased markedly as the feed moisture decreasedEffect of moisture on energysize reduction of lignite ber removes unwanted moisture and transports the pulverized coal dust up through the top of the pulverizer and out the exhaust pipes directly to the burner The more recent coal pulverizer designs are Vertical Roller Mills Figure 2 shows a cutaway view of a Babcock and Wilcox MPS Pulverizer RingRoll and BallRace MillsImproving Coal Pulverizer Performance and ReliabilityThe vertical spindle mill is a medium speed pulverizer and maintains a considerable amount of fuel in the mill system when operating Coal collects on the grinding table, in the classifier, in the pyrite collection sec tion below the grinding table, and at the fan exit for exhauster systems These are the prime locations of firesFire Detection Methods for Coal Pulverizer SystemsCoal pulverizes are designed to achieve the maximum rated capacity grinding a design coal with a grindability of 55 HGI and 812 percent moisture and achieving a discharge fineness of 70 per cent passing a 200 mesh screen (74 micron) and 995 per cent passing a 50 mesh screen Variation of the coal hardness and/or moisture content will effect COAL PULVERIZER ZK Ball Mill Rotary Kiln Grinding

The Storm Approach to Coal Pulverizer Optimization

The design “capacity” of the same pulverizer will grind 135,000 pounds per hour with fuel that is 55 HGI (Hardgrove Grindability Index) coal, ¾” raw coal top size, 7% moisture and produces pulverized coal that is 70% passing 200 mesh fineness (red line) This is pretty standardPulverizing fan is a unit which is simultaneously functioning as a grinding device and a fan conveying the finished pulverized coal by gas flow Hot gases drawn off from furnace and coal from which the surface moisture is removed (this moisture decreases drying agent temperature at mill inlet) enter the upper part of gas intake mine simultaneouslyPulverizing fan of MV type TyazhmashReliable coal pulverizer performance is essential for sustained fullload operation of today's power plants An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW BW's pulverizers, found at power stations throughout the worldPulverizers / Mills Babcock WilcoxEffect of fineness Maximum Mill capacity vs PF fineness at 12 % Raw coal moisture and at Coal HGI 100110 3300 3400 3500 3600 3700 3800 3900 4000 4100 65 70 75 80 85 Mill output at raw coal moisture and at Coal HGI 100110 31Pulverizer Plant OM AspectsRaw coal diverter chute BW provides a raw coal diverter chute to direct the incoming coal towards the center of the pulverizer, or inboard of the grinding elements Installation of a diverter chute will reduce the inventory of coal inside the pulverizer resulting in a reduction in pressure drop and increased fineness Boltthrough housing unitsPS410 E and EL Pulverizer Modifications for Optimum

Improving Coal Pulverizer Performance and Reliability

ber removes unwanted moisture and transports the pulverized coal dust up through the top of the pulverizer and out the exhaust pipes directly to the burner The more recent coal pulverizer designs are Vertical Roller Mills Figure 2 shows a cutaway view of a Babcock and Wilcox MPS Pulverizer RingRoll and BallRace MillsPulverizing fan is a unit which is simultaneously functioning as a grinding device and a fan conveying the finished pulverized coal by gas flow Hot gases drawn off from furnace and coal from which the surface moisture is removed (this moisture decreases drying agent temperature at mill inlet) enter the upper part of gas intake mine simultaneouslyPulverizing fan of MV type TyazhmashFeb 01, 2015 The meaning of k 10 × M c is the part of pulverized coal through the mill grinding the raw coal in per unit time (1) M To analyze the optimization effect of pulverized coal moisture on the mill outlet temperature set point, the traditional control method is applied to maintain the set point of T out before the 1000sModelling and control of pulverizing system considering Raw coal diverter chute BW provides a raw coal diverter chute to direct the incoming coal towards the center of the pulverizer, or inboard of the grinding elements Installation of a diverter chute will reduce the inventory of coal inside the pulverizer resulting in a reduction in pressure drop and increased fineness Boltthrough housing unitsPS410 E and EL Pulverizer Modifications for Optimum The ATOX® Coal Mill handles feed materials with less than one percent moisture and up to 25 percent moisture, where abrasiveness and stickiness is not an issue for grinding Effect Of Moisture Content In Coal mauritania moisture effect on coal grinding

Modeling and outlet temperature control of coal mill using

Sep 09, 2020 Coal mills are used to grind and dry the raw coal containing moisture and to transport the pulverized coal air mixture to the boiler Poor dynamic performance of coal mill In the whole system, the preparation of pulverized coal is the most important step And the ideal equipment for preparation coal powder is LM series Large Vertical Roller Mill Due to its high demand and big capacity, LM largescale coal mill become the star equipment in preparation of pulverized coalcoal Mill,coal processing plant,coal pulverizerPulverizing fan is a unit which is simultaneously functioning as a grinding device and a fan conveying the finished pulverized coal by gas flow Hot gases drawn off from furnace and coal from which the surface moisture is removed (this moisture decreases drying agent temperature at mill inlet) enter the upper part of gas intake mine simultaneouslyPulverizing fan of MV type TyazhmashFeb 01, 2015 The meaning of k 10 × M c is the part of pulverized coal through the mill grinding the raw coal in per unit time (1) M To analyze the optimization effect of pulverized coal moisture on the mill outlet temperature set point, the traditional control method is applied to maintain the set point of T out before the 1000sModelling and control of pulverizing system considering Sep 09, 2020 Coal mills are used to grind and dry the raw coal containing moisture and to transport the pulverized coal air mixture to the boiler Poor dynamic performance of coal mill Modeling and outlet temperature control of coal mill using

Modeling and Control of Coal Mill NTNU

and pulverized coal flow at desired set point value 1 INTRODUCTION Coal mill is an important component of the thermal power pla nt It is used to grind and dry the moisturized raw coal and transport the pulverized coal ± air mixture to the boiler Poor dynamic performance of coal mill will Jan 2, 2014 Variation of the coal hardness and/or moisture content will effect, up or crusher search effect of moisture in cement grinding mill to find yourget price Coal Preparation Ash content: 17%; but now the level has gone up to 19 to 21%effect of moisture content in coal in crusherRaw material, final products: soft coal, MTM160, 200mesh, D90; MTM130, 200mesh, D90 Customer Evaluation: Since 2003 cooperated with , we have purchased 16 sets of grinding mill, included MTW series grinding mill and MTM series milling machines The high quality equipment and high level service of were the important guarantee for our coal Mill,coal processing plant,coal pulverizercauses less feeder hopper bridging and plugging problems Coal feeders provide coal to the coal pulverizers (mills) where the coal is pulverized and dried Dryer coal is easier to pulverize, and less mill power is needed to achieve the same coal fineness Additionally, with less fuel moisture, more complete drying of coal can be achieved in the Coal Drying Improves Performance and Reduces EmissionsIn addition to raising the coal temperature inside the mill for drying and better grinding, the same air works as the transport medium to move the pulverized coal out of the mill: it travels through the annular space between the fixed trunnion tubes and the rotating hot air tube onwards to the classifierPulverizer Wikipedia

Coal grinding systems Safety considerations PEC

Sep 10, 2015 Coal grinding systems safety considerations Most rotary kilns use solid fuels as the main heat source to produce cement clinker A training program should be developed and extensive training for coal mill system operators provided on a regular basis Safety considerations, such as the prevention of fire or COAL MILL OPTIMIZATION CONTENTS • Raw Coal Size • Mill Throughput • Coal Fineness • Coal moisture • Fuel Hardgrove Gridability (HGI) • Pulverizes Input Horsepower • Coal reject • False Air Infiltration RAW COAL SIZE This is the first and a huge factor on capacity and throughput, especially with spot market coal and no controlCoal Mill Optimization Coal Energy Production Free The main purpose of the coal mill is to dry and pulverize the coal The primary air flow is used to dry and carry the pulverized coal to the furnace It is therefore important that the primary air has sufficient energy at all loads During a load increase of the power plant the coal flow is increased together with the primary air flow When Aalborg Universitet Estimation of Moisture Content in Coal The more recent coal pulverizer designs are Vertical Roller Mills Figure 2 shows a cutaway view of a Babcock and Wilcox MPS Pulverizer RingRoll and BallRace Mills A ball or roller between two races or rings provides the grinding surfaces on which pulverization occurs One or both of the races may rotate against a ball or roll (in a Ring Coal Pulverizer Pall CorporationFeatures of Coal grinding mill/coal mill pulverizer/coal pulverizing machine 1 High capacity, 120t/h 2 The fineness can be adjusted between 50 and 325 mesh (31545 micron) 3 Fixed with 10001500kg pressure springs, and its capacity increase 20% to 30%; When the grinding roller and grinding ring, stable capacity and fineness can be China Coal Grinding Mill/Coal Mill Pulverizer/Coal

TPS Coal Mills and Fan Performance

May 08, 2019 Mill Energy Balance Hot air Coal Dry pulverized coal + Air + Moisture Puliverizer frictional dissipation Motor Power Input Heat loss Tempering Air, Tatm 5/8/2019 Manohar Tatwawadi 24 25 Pulverizer Heat Balance • To perform the necessary pulverizer heat and mass balance calculations, the following parameters are required: • Primary air