Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

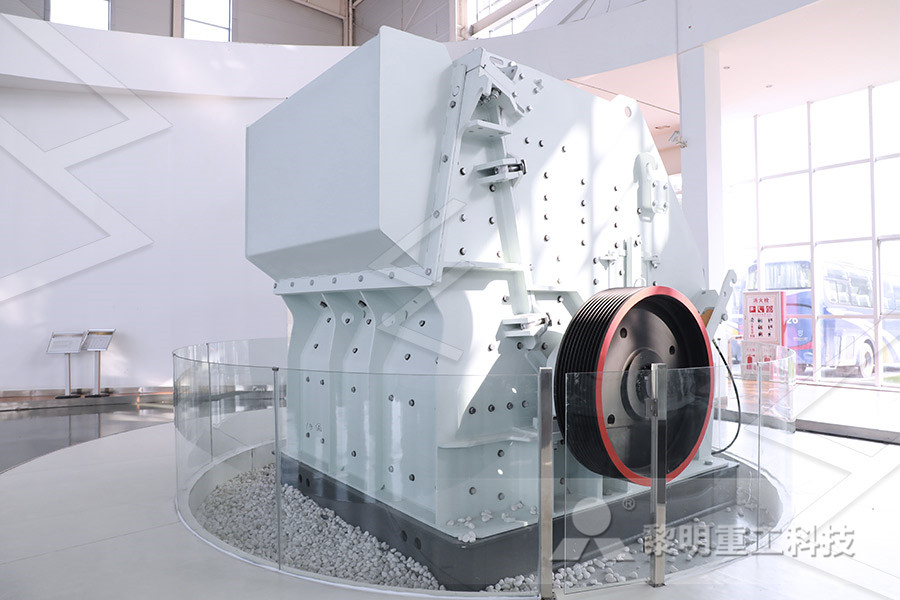

CI5X series impact crusher

-

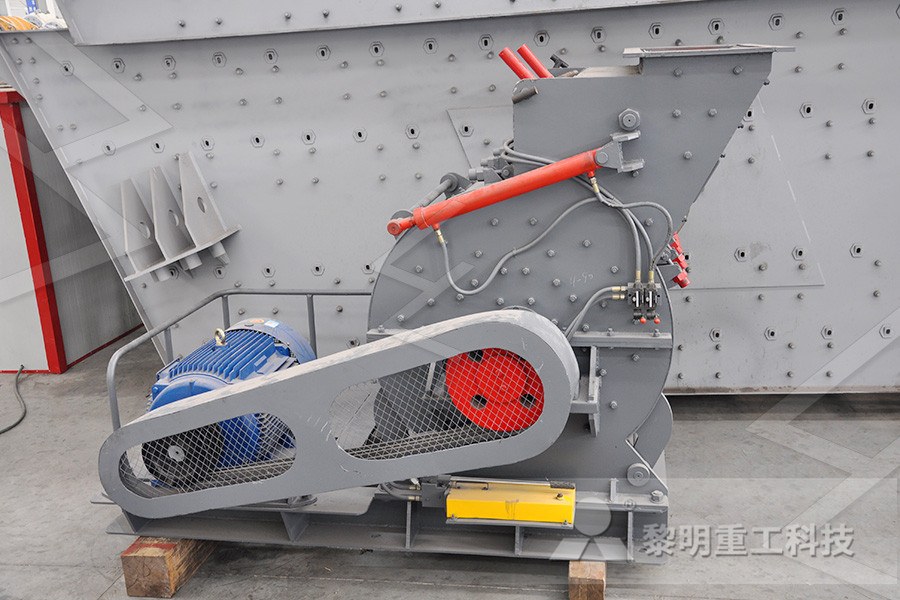

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Cone crusher basics in 4 minutes — Sandvik Mining and Rock

As the feed is crushed, it falls and exits the crusher through the space at the bottom The eccentric gyration of the mantle means that at any moment this space is narrowest at one point, and widest at the opposite point The widest distance is known as the open side Cone crusher is a compression type of rock size reducing machine that crushes rock stone material by the physical compression force forming by the fixed steel and the moving steel The final discharge particle size is determined by the interval between Cone Crusher, Stone Rock Crusher Machine JXSC MiningA cone crusher can crush a variety of rocks, from medium to hard The way a cone crusher operates is similar to how a gyratory crusher does, but in a cone crusher the slope in the breaking space is not as steep Although it is known for its ability to crush hard and abrasive ores and rocks, the cone crusher is better suited for secondary crushingTypes of Crushing Equipment Jaw, Cone Impact Tricon Oct 09, 2019 Cone crusher is one of the most widely used mining equipment This paper makes a description and comparison between the 5 types of cone crushers, to help you choose the right one JXSC engineer team does help you to buy the cone crusher, and design a complete crushing circuit5 Types of Cone Crushers Comparison JXSC Machine2 Single cylinder cone crusher Single cylinder cone crusher adopts the laminated crushing principle and has a variety of standard crushing cavity types, which has a better crushing effect on granite and makes the finished granite has uniform grain size and better grain shape The structure of single cylinder cone crusher is simple and can be operated by one buttonWhich Type of Crusher Should be Used for Granite Crushing

DOVE Cone Crushers

22 rows CONE CRUSHERS DOVE Cone Crushers are designed for efficient application of Sandvik Group is encouraging circularity in the mining industry through the recycling of steel from used cone crusher parts to make new crushing equipment While extractive industries such as mining are responsible for 50% of global carbon dioxide (CO2) emissions, recycling steel from mining equipment could make all the difference, according to cone crushers Archives International MiningFeb 19, 2011 Safety issues with crushers on a mine Crushers like jaw crushers and cone crushers crushing equipment and jaw crushers in mining crushing and screening rock crushers as mining equipmentcrushers jaw crushers in mining YouTubeCone crusher is a compression type of rock size reducing machine that crushes rock stone material by the physical compression force forming by the fixed steel and the moving steel The final discharge particle size is determined by the interval between Cone Crusher, Stone Rock Crusher Machine JXSC MiningOct 09, 2019 Cone crusher is one of the most widely used mining equipment This paper makes a description and comparison between the 5 types of cone crushers, to help you choose the right one JXSC engineer team does help you to buy the cone crusher, and design a complete crushing 5 Types of Cone Crushers Comparison JXSC Machine

Cone Crusher Nesans Mining and Automation Private Limited

The crushing chamber differs for a coarse cone crusher used in the secondary stage to that of a fine cone crusher used in the tertiary stage The coarse crushing chamber is deep and narrow whereas the fine crushing chamber is shallow and wide The crusher Cone Crusher is a crushing machine designed considering the secondary stage crushability for materials such as rock, mineral, ROM and building rubble Cone crusher design focuses on compression type crushing with feed of material being received from the top in crushing chamber that consist of concave and mantle made up of high manganese alloyCone Crusher – Manufacture of Crushing Screening DOVE Cone Crushersare designed for efficient application of crushing in mining industry, for efficient down sizing of various types of ores, prior to grinding operation and for efficient recovery of various minerals, as well as various quarry, aggregate and construction applications DOVE Cone Crushers are proven in various secondary and tertiary crushing applications, including limestone DOVE Cone CrushersSandvik Group is encouraging circularity in the mining industry through the recycling of steel from used cone crusher parts to make new crushing equipment While extractive industries such as mining are responsible for 50% of global carbon dioxide (CO2) emissions, recycling steel from mining equipment could make all the difference, according to cone crushers Archives International MiningFeb 19, 2011 Safety issues with crushers on a mine Crushers like jaw crushers and cone crushers crushing equipment and jaw crushers in mining crushing and screening rock crushers as mining equipmentcrushers jaw crushers in mining YouTube

Cone Crushers McLanahan

Cone Crushers A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest pointCone crushers Cone crushers resemble gyratory crushers from technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary, and quaternary crushing stages Sometimes, however, the grain size of the processed material is small enough by nature and the traditional primary crushing stage is not neededCrushers All crusher types for your reduction needs Cone crusher has high crushing ratio, high efficiency, low energy consumption, uniform product size, suitable for medium crushing and fine crushing of various ores and rocks In the cone crusher working process will encounter a variety of problems, So, we provides 14 common fault causes and solutions!14 Cone Crusher Common Problems And How To Fix Them MCThe 911MPETMLCC21 Laboratory Cone Crusher grinds 19 mm feed to 10 mesh and grinding fineness can be precisely calibrated by easily rotating the adjusting ring Custom cones are available in materials to suit specific applications The Laboratory Cone Crusher is typically used in applications where there are space limitations or flat (platelike) rocks are being crushed It weighs 273 kilos Laboratory Cone Crusher 911MetallurgistJun 23, 2020 Cone Crushers were developed more than a century ago to provide secondary, tertiary and even quaternary material reduction Like other compression crushers, Cone Crushers feature a crushing chamber or cavity where the rock is crushed to a smaller sizeThe crushing chamber in a Cone Crusher is the space created between the mantle (the moving piece of steel) and concaves Cone Crusher Liners: How to Select and When to Change

Crusher Machine/Mining Crusher Equipment//Rock Crusher

HPY cone crusher can achieve high crushing ratio and low cycle load, and the yield is higher, achieving superior continuous crushing and effectively reducing energy consumption HPY cone crusher particle size curve (HPY400 ) HPY400 cone crusher (medium crush) operation curve HPY400 cone crusher (Fine crush) operation curve Note: 1® MP1000 cone crusher still does provide the highest crushing power for any cone crusher in similar size Advanced crushing dynamics leads to more work per cycle ® MP1000 cone crusher increases power draw so that will lead to an increase in capacity, and a higher powertoproduction ratio giving energy efficiency too® MP1000™ cone crusher OutotecCone crusher is a compression type of rock size reducing machine that crushes rock stone material by the physical compression force forming by the fixed steel and the moving steel The final discharge particle size is determined by the interval between Cone Crusher, Stone Rock Crusher Machine JXSC MiningCone Crusher is a crushing machine designed considering the secondary stage crushability for materials such as rock, mineral, ROM and building rubble Cone crusher design focuses on compression type crushing with feed of material being received from the top in crushing chamber that consist of concave and mantle made up of high manganese alloyCone Crusher – Manufacture of Crushing Screening Cone crusher provides a high capacity and more efficient option compared to cone crushers of similar size Compact design allows less floor space, but no sacrifice when it comes to productivity® MP1000™ cone crusher Outotec

Cone Crusher Nesans Mining and Automation Private Limited

The crushing chamber differs for a coarse cone crusher used in the secondary stage to that of a fine cone crusher used in the tertiary stage The coarse crushing chamber is deep and narrow whereas the fine crushing chamber is shallow and wide The crusher is fitted with a hydraulic css adjustment system through which the setting can be adjusted Cone Crushers for Mining: Cone Crusher Bowl Liners and Mantles for Extreme Conditions Because of the extreme crushing conditions experienced by the crushers used in mining operations, special attention must be paid to the materials used in producing these castingsCone Crushers for Mining The Frog, Switch