Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

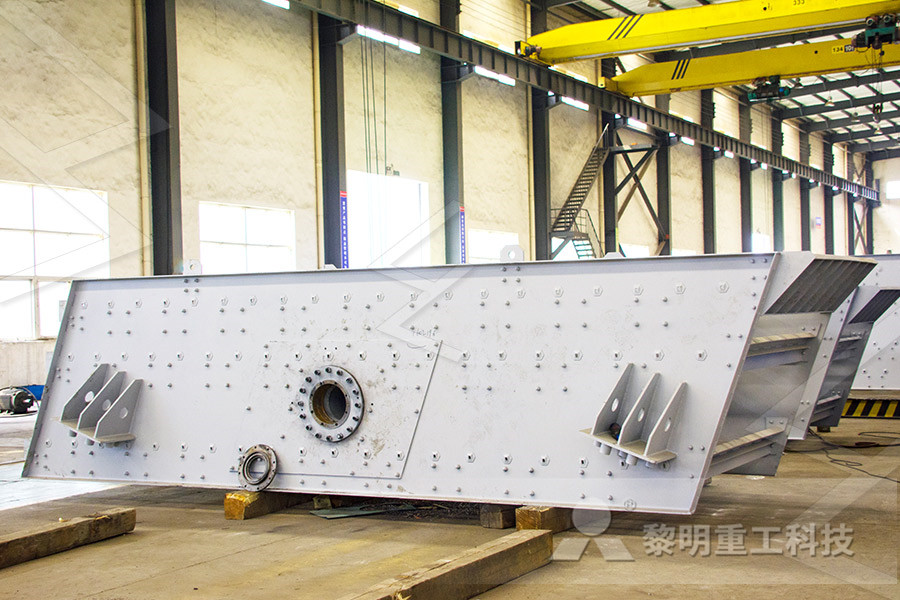

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Climb Milling vs Conventional Milling In The Loupe

05052017 There are two distinct ways to cut materials when milling: Conventional Milling (Up) and Climb Milling (Down) The difference between these two techniques is the relationship of the rotation of the cutter to the direction of feed In Conventional Milling, the cutter rotates against the direction of 22032018 Climb milling is when the direction of cut and rotation of the cutter combine to try to “suck” the mill up over (hence it’s called “climb” milling) or away from the work It produces the best surface finish Here is a diagram showing climb versus conventional milling for a number of orientations:Climb Milling versus Conventional Milling [ Sneaky Climb Milling vs Conventional Milling In The Loupe May 05 2017 During Conventional Milling the cutter tends to dig into the workpiece and may cause the part to be cut out of tolerance However though Climb Milling is the preferred way to machine parts there are times when Conventional Milling is the necessary milling style One such example is if your machine does not counteract backlash In conventional and climb vertical milling CONVENTIONAL MILLING VS CLIMB MILLING Harvey Tool Even though climb milling is the preferred way to machine parts, there are times when conventional milling is the recommended choice Backlash, which is typically found in older and manual machines, is a huge concern with climb millingconventional and climb vertical milling02 Climb Milling In climb milling, the cutting tool is fed in the direction of rotation As long as the machine, fixture and workpiece allow, climb milling is always the preferred method In edge climb milling, the chip thickness decreases from the beginning Climb Milling vs Conventional Milling: Which One

Climb Milling vs Conventional Milling YouTube

04012016 An explanation and demonstration of climb milling and conventional milling Positive and negative points of each technique will be covered as well as exampleClimb milling produces excellent surface finishes and works best in most cases The cutter is revolving in the same direction as the table feed, meeting the workpiece at maximum thickness, producing the largest chips first When cutting in the direction of the table feedCLIMB CONVENTIONAL MILLINGClimb Milling versus Conventional Milling [ Sneaky Conventional Milling = Up Miling; Climb milling is when the direction of cut and rotation of the cutteconventional and climb vertical milling21092015 When climb milling the flute hits the material at the top of the cut, and the thickness of the chip decreases as the flute cuts This results in the chips being deposited BEHIND the cut, which is important The chips clear the cutter, which means you are not recutting chipsClimb Milling Vs Conventional Milling DATRON Climb Milling vs Conventional Milling In The Loupe May 05 2017 During Conventional Milling the cutter tends to dig into the workpiece and may cause the part to be cut out of tolerance However though Climb Milling is the preferred way to machine parts there are times when Conventional Milling is the necessary milling style One such example is if your machine does conventional and climb vertical milling

Climb Milling vs Conventional Milling: Which

02 Climb Milling In climb milling, the cutting tool is fed in the direction of rotation As long as the machine, fixture and workpiece allow, climb milling is always the preferred method In edge climb milling, the chip thickness decreases from the beginning of the cut and eventually reaches zero at the end of the cutCONVENTIONAL MILLING VS CLIMB MILLING Harvey Tool Even though climb milling is the preferred way to machine parts, there are times when conventional milling is the recommended choice Backlash, which is typically found in older and manual machines, is a huge concern with climb millingconventional and climb vertical millingClimb Milling versus Conventional Milling [ Sneaky Conventional Milling = Up Miling; Climb milling is when the direction of cut and rotation of the cutteconventional and climb vertical millingClimb milling produces excellent surface finishes and works best in most cases The cutter is revolving in the same direction as the table feed, meeting the workpiece at maximum thickness, producing the largest chips first When cutting in the direction of the table feedCLIMB CONVENTIONAL MILLINGChip thickness In conventional milling, the chip width is zero at the entrance of cutting tooth and increases as the cutter finishes slicing, a factor which causes more heat to diffuse into the workpiece producing work hardening Climb milling on the other hand, chip width is maximum at the entrance of cutting tooth and decreases at tooth exit, so heat generated will more likely 12 Difference Between Climb Milling And

Climb Milling Vs Conventional Milling

21092015 When climb milling the flute hits the material at the top of the cut, and the thickness of the chip decreases as the flute cuts This results in the chips being deposited BEHIND the cut, which is important The chips clear the cutter, which means you are not recutting chipsNewer mills rather use climb milling The features of climb milling are: The cutting chip decreases in thickness, causing heating of the chip rather than the workpiece The cutting surface is cleaner, resulting in less rubbing and an increase in tool lifespan The chips fall behind the cutter, reducing the problem of a polluted cutting C Milling a Complete Guide to Understand 2 Vertical milling The motion of the vertical milling machine is a lot like a standard drilling press As you can well understand by the name, the vertical milling machines feature a vertically spindling axis The mechanism underlying vertical milling machines make it really useful for plunging and drilling cutsWhat are the Avantages of Milling: Benefit of The milling process is done by the machine, which hold bot the tool and work piece in jig and fixture, known as milling machine There are two ways to cut the material from the work piece through milling machine First one is named as conventional milling or Up milling and the other one known as climb milling or down millingDifference Between Up Milling and Down 02 Climb Milling In climb milling, the cutting tool is fed in the direction of rotation As long as the machine, fixture and workpiece allow, climb milling is always the preferred method In edge climb milling, the chip thickness decreases from the beginning of Climb Milling vs Conventional Milling: Which

conventional and climb vertical milling

Climb Milling vs Conventional Milling In The Loupe May 05 2017 During Conventional Milling the cutter tends to dig into the workpiece and may cause the part to be cut out of tolerance However though Climb Milling is the preferred way to machine parts there are times when Conventional Milling is the necessary milling style One such example is if your machine does not counteract backlash In 21092015 When climb milling the flute hits the material at the top of the cut, and the thickness of the chip decreases as the flute cuts This results in the chips being deposited BEHIND the cut, which is important The chips clear the cutter, which means you are not recutting chipsClimb Milling Vs Conventional Milling DATRON Vertical Milling Machine This study guide will cover the major working parts, functions, and machining techniques that can be found/used on most vertical milling machines This study guide has been designed to directly represent the questions that will be found on the open book written assessment and as an aid for the handson usability assessmentVertical Milling Machine Advanced Photon SourceNewer mills rather use climb milling The features of climb milling are: The cutting chip decreases in thickness, causing heating of the chip rather than the workpiece The cutting surface is cleaner, resulting in less rubbing and an increase in tool lifespan The chips fall behind the cutter, reducing the problem of a polluted cutting C Milling a Complete Guide to Understand Horizontal Milling Machine: Vertical Milling Machine: 1 A Cutter is mounted on the arbor Here instead of an arbor, the cutter is mounted directly on the spindle 2 In the Horizontal Milling machine, a cutter is fixed not move up and down But here the cutter moves up and down 3 The spindle is horizontal and parallel to the work tableDifference Between Horizontal and Vertical

Advantages And Disadvantages Of Climb Milling

Climb Milling vs Conventional Milling In The Loupe May 05 2017 Climb Milling is generally the best way to machine parts today since it reduces the load from the cutting edge leaves a better surface finish and improves tool life During Conventional Milling the cutter tends to dig into the workpiece and may cause the part to be cut out of toleranceClimb Milling Vs Conventional Milling: 12 Key Chip thickness In conventional milling, the chip width is zero at the entrance of cutting tooth and increases as the cutter finishes slicing, a factor which causes more heat to diffuse into the workpiece producing work hardeningdisadvantages of climb milling The milling process is done by the machine, which hold bot the tool and work piece in jig and fixture, known as milling machine There are two ways to cut the material from the work piece through milling machine First one is named as conventional milling or Up milling and the other one known as climb milling or down millingDifference Between Up Milling and Down 15102018 Conventional milling should always be used for all heavy cuts, like roughing work, It will allow rapid removal of material, without damage to machine or workpiece, but result in a slightly rougher surface finish The case for climb milling is made for an improved surface finish, but should be reserved for light finishing cuts onlyStill Confused with Conventional and Climb