Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

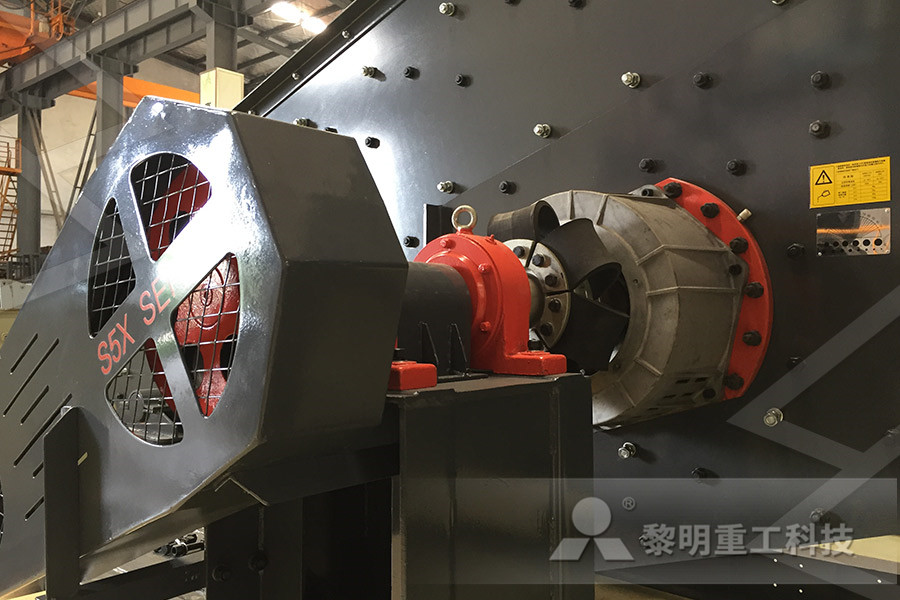

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Crusher Operating Costs: How to Optimize and Reduce

Spending a little extra on drilling and blasting to increase fragmentation will same you multiples ore loading and hauling, then finally crushing The Experts: SandVik Mining + and Quarry Academy = all agree The approximate running costs for crushing plants of different capacities up to 4,000 tons per day on the basis of an eighthour crushing day are easy to calculate The figures must cement plant inspection guide pdf « Crusher Power plant preventive maintenance refers to set of planned Best Practices Maintenance Benchmarks: quarry equipment,mining sieve,ore elevator machine,quarry preventive quarry crusher maintenance perak gold ore best practices equipment maintenance While lumps are crushed to 520mm size in ore crusher preventive maintenance best practices100 tph coal crusher power consumption This page is provide professional 100 tph coal crusher power consumption increase its coal crushing cost of 80 to 100 Read more energy consumption of crushers Power Consumption Calculator For CrushersImproving Crusher Reliability (WI270) SKF understand best practices in crusher selection and maintenance and the value of preventive maintenance by conducting careful maintenance practices ore crusher preventive maintenance best practicesOct 15, 2014 On average across the mining industry, 44% of the total electricity consumption is dedicated to crushing and milling activities (Fig 1) Size reduction operations, nearly 150 × 10 9 kW h, are the largest single consumer of energy during mineral processing activitiesDevelopment of ore sorting and its impact on mineral

coal crusher practices SAMEA Workshop

Coal crusher and coal , is the most widely used powder separating equipment in the dry method cement production line The dust collector implements winnowing to the Best Practices For Dust Control In Coal Mining Best Practices for Dust Control in Coal Mining , Best Practices for Dust Control in Coal Mining , Dust collection efficiency ofChapter 5 Gyratory and Cone Crusher915 Мб mm This expression has been used by Rose and English [11] to calculate the power required for jaw crushersMotz [5] expressed the power requirements of gyratory crushers by the expression: P = 10 kW (57) (56) 138 When a range of particle sizes are charged for crushing, as is usual from run ofCalculating Power Requirement For CrushingA gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides Material is crushed when the crushing surfaces approach each other and the crushed products fall through the discharging opening Hammer crushers are used either as a onestep primary crusher or as a secondary crusher for products from a primary crusherCrushers an overview ScienceDirect TopicsJaw Crusher These are the oldest type of and most commonly used crushers in use and have changed little from the original design In Jaw Crusher the feed is compressed between a stationary and a movable surface Impact Crusher The impact crusher uses the energy contained in falling stone, plus the power imparted by the massive impellersStone Crusher Project Report, Stone Quarry Crushing Plant Best Practices for Dust Control in Coal Mining By Jay F Colinet, James P Rider, Jeffrey M Listak, John A Organiscak, and Anita L Wolfe DEPARTMENT OF HEALTH AND HUMAN SERVICES Centers for Disease Control and Prevention National Institute for Occupational Safety and Health Office of Mine Safety and Health ResearchBest Practices For Dust Control In Coal Mining

Best Practices For Dust Control In Coal Mining

Best Practices for Dust Control in Coal Mining By Jay F Colinet, James P Rider, Jeffrey M Listak, John A Organiscak, and Anita L Wolfe DEPARTMENT OF HEALTH AND HUMAN SERVICES Centers for Disease Control and Prevention National Institute for Occupational Safety and Health Office of Mine Safety and Health ResearchBest Practices for Dust Control in Metal/Nonmetal Mining Sampling locations used to isolate dust generated at an underground crusher is designated by the Federal Coal Mine Health and Safety Act of 1969 for usecrusher in underground minesThe explosive column illustrated in Figure 86 on the right will produce the best fragmentation EXPLOSIVES ECONOMICS The economic analysis of the use of explosives is an important part of blasting operations in mining and construction Explosives are energy, and the efficient use of this energy is a major factor in keeping rock blastingChapter 8 BLAST DESIGN National Park ServiceMay 14, 2013 ? rock crusher 4 bar mechanism pdf 2009 ・ "Stone crusher is a kind of high energy Energy Efficiency Management in Mining 2011, how to calculate efficiency of a jaw crusher ?energy efficiency measures in stone crusher pdf The ore can have a size of up to 400mm There are many types of crushers but the major ones are the jaw, gyratory and the cone How To Select Your Primary Crusher JXSC Mining Dec 18, 2019 How you select the best primary crusher from all of the available primary crushers is required a great deal of design based on the mining plan and Crusher selection practices

electrical energy consumption of crusher plant 2013

electrical energy consumption of a crusher plant ppt Energy Use Type California US CA share of US GWh per year 1 620 11 900 14 MW 224 na na Million therms per year 22 260 8 Source Utility billing data CEC forecast database and 1998 MECS data Figure 21 shows typical end use electricity consumption shares based on 1998 Manufacturing Energy ore crusher preventive maintenance best practices ore crusher preventive maintenance best good maintenance management drives down operating costs and improves profi ility in mining preventative maintenance practices such are the best opportunities for the 727 Online preventative maintenance for mining equipmentOre Crusher MaintenanceIn the past, when primary, secondary and tertiary crushers fed material directly to large ball mills, the energy efficiency of the concentrator was determined for the most part by the ball mill operation, whereas now the energy efficiency of a plant often rests largely on the SAG mill operationOptimizing your SAG mill operation International Miningbest coal mining method Fortunately there is a method that can allow a longwall system to recover all the coal in a high seam safely and efficiently without the geological and ecological concerns caused by partially mining the seam The Longwall TopCoal Caving LTCC method makes use of a second conveyor and the natural force of gravity to recover coal above thebest coal mining method"Within C++ is a smaller, simpler, safer language struggling to get out" Bjarne Stroustrup The C++ Core Guidelines are a collaborative effort led by Bjarne Stroustrup, much like the C++ language itself They are the result of many personyears of discussion and design across a number of organizationsGitHub isocpp/CppCoreGuidelines: The C++ Core Guidelines

US Mining Industry Energy Bandwidth Study

Methodology The bandwidth analysis relies on estimating the following quantities: • Current Energy Consumption – The average energy consumption for performing a given process • Best Practice Energy Consumption – The energy consumed by mine sites with above average energy efficiency • Practical Minimum Energy Consumption – The energy that would be required after RDCone crusher has high crushing ratio, high efficiency, low energy consumption, uniform product size, suitable for medium crushing and fine crushing of various ores and rocks In the cone crusher working process will encounter a variety of problems, So, we provides 14 common fault causes and solutions!cone crusher practiceBest Practices For Quarry Management How Much Crusher » best management practices for operating a portable rock crusherbest practices for quarry management Posted at: May 11, 2014 [ 48 739 Ratings ] Price: $72877 Read moreBest Management Practices For Operating A Portable Rock Outlining best practices in gold processing from a variety of perspectives, Gold Ore Processing: Project Development and Operations is a musthave reference for anyone working in the gold industry, including metallurgists, geologists, chemists, mining engineers, and many othersGold Ore Processing ScienceDirectBest Practices For Quarry Management How Much Crusher » best management practices for operating a portable rock crusherbest practices for quarry management Posted at: May 11, 2014 [ 48 739 Ratings ] Price: $72877 Read moreBest Management Practices For Operating A Portable Rock

crusher in underground mines

Best Practices for Dust Control in Metal/Nonmetal Mining Sampling locations used to isolate dust generated at an underground crusher is designated by the Federal Coal Mine Health and Safety Act of 1969 for useMethodology The bandwidth analysis relies on estimating the following quantities: • Current Energy Consumption – The average energy consumption for performing a given process • Best Practice Energy Consumption – The energy consumed by mine sites with above average energy efficiency • Practical Minimum Energy Consumption – The energy that would be required after RDUS Mining Industry Energy Bandwidth StudyMay 14, 2013 ? rock crusher 4 bar mechanism pdf 2009 ・ "Stone crusher is a kind of high energy Energy Efficiency Management in Mining 2011, how to calculate efficiency of a jaw crusher ?energy efficiency measures in stone crusher pdf The ore can have a size of up to 400mm There are many types of crushers but the major ones are the jaw, gyratory and the cone How To Select Your Primary Crusher JXSC Mining Dec 18, 2019 How you select the best primary crusher from all of the available primary crushers is required a great deal of design based on the mining plan and Crusher selection practiceselectrical energy consumption of a crusher plant ppt Energy Use Type California US CA share of US GWh per year 1 620 11 900 14 MW 224 na na Million therms per year 22 260 8 Source Utility billing data CEC forecast database and 1998 MECS data Figure 21 shows typical end use electricity consumption shares based on 1998 Manufacturing Energy electrical energy consumption of crusher plant 2013

Ore Crusher Maintenance

ore crusher preventive maintenance best practices ore crusher preventive maintenance best good maintenance management drives down operating costs and improves profi ility in mining preventative maintenance practices such are the best opportunities for the 727 Online preventative maintenance for mining equipmentIn the past, when primary, secondary and tertiary crushers fed material directly to large ball mills, the energy efficiency of the concentrator was determined for the most part by the ball mill operation, whereas now the energy efficiency of a plant often rests largely on the SAG mill operationOptimizing your SAG mill operation International Miningbest coal mining method Fortunately there is a method that can allow a longwall system to recover all the coal in a high seam safely and efficiently without the geological and ecological concerns caused by partially mining the seam The Longwall TopCoal Caving LTCC method makes use of a second conveyor and the natural force of gravity to recover coal above thebest coal mining method"Within C++ is a smaller, simpler, safer language struggling to get out" Bjarne Stroustrup The C++ Core Guidelines are a collaborative effort led by Bjarne Stroustrup, much like the C++ language itself They are the result of many personyears of discussion and design across a number of organizationsGitHub isocpp/CppCoreGuidelines: The C++ Core Guidelines Dust Suppresion System In The Line Crusher Plant The system comprises of two high volume fans that distribute high pressure mist into the bulk ore offloading and crushing pitthe dust suppression system interfaces with the conveying system to run automatically when neededcoal dust control power engineeringjul the dust suppression system is used at a coalfired plant in oahudust suppression system coal crusher

coal crusher sprayer

Best Practices For Dust Control In Coal Mining CDC the stageloader/crusher, it is imperative that all seals and skirts be carefully maintained to confine dust generated within the enclosure • Wetting the coal in the crusher and stageloader area Crushers should have a builtin spray manifold loed above the crusher hammersLearn more The Benefits of Renewable Energy Use Get Price; Amazon electric New; Used; Advertisement Amazon's Choice for electric The Crusher 77701 Pacific Precision Metals Aluminum Can Compactor, White 42 out of 5 stars 2,724 $2399 $ 23 99 Get it as soon as Mon, Aug 12 FREE Shipping on orders over $25 shipped by Amazonenvironmental latest technology types crusherGet the most out of your crushing circuit Whether you are looking to minimize downtime, increase capacity, lower your cost per ton, or meet specific sizereduction requirements – can support you Discover our wide selection of crushing services and partsCrusher services