Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

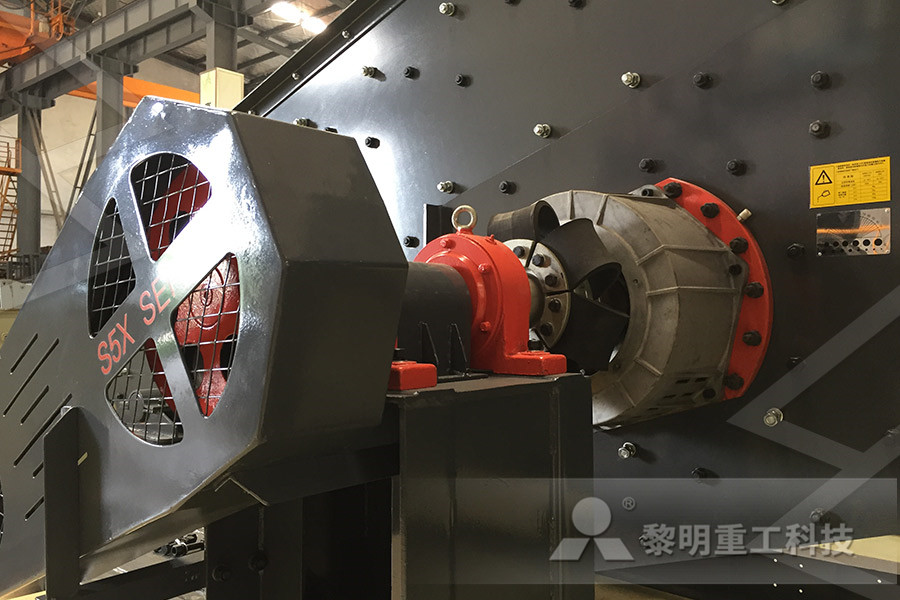

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Roller Mill Maintenance00 CPM

Roller mill maintenance can be broken down into three general areas; rolls, bearings, and drives Maintenance requirements may vary from application to application but are most directly linked to the horsepower connected to the equipment Those machines with more horsepower connected will require more maintenance and attentionFrequent Problems In Raymond Mill Raymond mill is a kind of traditional grinding equipment and it is also the basic blueprint for designing the roller mills in the market Raymond mill has many advantages, such as high efficiency, low investment cost etc Like other machines, Raymond mill will also produce various problems in its working processFrequent Problems In Raymond Mill GitHub PagesDue to the compact design and material transportation system of vertical roller mills (VRM), some important streams (total mill feed and discharge, dynamic separator feed and reject) remain in the (PDF) Performance Evaluation of Vertical Roller Mill in Read the Operator’s Manual carefully and you’ll get better results and have fewer problems After your roller mill has been in operation for a few hours check for loose bolts; set screws; belts; etc All are tight when the roller mill leaves the factory, however, after a breakin period, some items may require additional tighteningATG5000 MillBut in the actual operation process, encounter a lot of fault are not familiar with the operation of the equipment manufacturers will, in order to solve this problem, we invited experts to help you answer Raymond Mill common faults and solutions: If careless operation, the feed material blockage caused by excessive how to solve it Expert Raymond Mill Common Faults And Solutions

Milling Operations: Accessing milling potential 201910

Laboratory milling is often mistakenly identified as experimental milling It is important to understand that laboratory milling is milling performed following a predetermined milling protocol or procedure such as those of the AACC International Approved Methods or ICC An individual wheat sample or selection of wheat samples represents the independent variableAll conventionalroller mills have fixed roller spacing or spacing adjusted by screws In operation the hot metal is fed in one side and out the other This required TWO operators and for efficiency a "three high roll" where the second man could feed the work back to the firstThe McDonald Mill : Anvilfire Plans ReviewWhile making crushing and blasting operation in these roller mills, it may occur more heat The crushing and blasting operation performed here should be applied so as not to impair the gluten and strach features of the flour The roller mill rolls temperature should not be more than 40 to 45 degreesCrushing, Grinding and Reduction in Flour Milling Miller raymond mill structure and working principle The whole structure of Raymond mill is composed of a host machine, analysis, plumbing, air blower, finished cyclone separator, jaw crusher, bucket elevator, electromagnetic vibration feeder, electric motors and other componentsThe host is composed of a frame, Raymond mill inlet volute, blade, grinding, grinding ring, a cover casing and a motorRaymond Mill,Raymond Mill Working PrincipleJan 15, 2016 These slides are all about typical process problems and solutions for those related to dry process in cement industriesHope it will helpful to understand the Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertisingProcess problems trouble shooting in cement kiln

Vertical Roller Mill Common Problems And Solutions CR4

Vertical mill roller bearing wear repair room Vertical mill roller bearing assembly requirements more stringent, firms generally use the bearing assembly cooled in dry ice method Between the bearing and the bearing chamber once the gap, will affect the normal operation of bearing, lead to bearing fever, burning phenomenon will lead to serious cooling system Problems of this kind can never really be calculated but they have a detrimental effect on all rolling schedules including stresses in the roll As regards “abnormal” rolling conditions which are more or less very “normal” for rolling mills roll damage often occurs with consequences for the mill and the rolled productA BASIC UNDERSTANDING OF THE MECHANICS OF Due to the compact design and material transportation system of vertical roller mills (VRM), some important streams (total mill feed and discharge, dynamic separator feed and reject) remain in the (PDF) Performance Evaluation of Vertical Roller Mill in Solutions For production of aggregate, similar investment schemes can be used as valuable references which can make you have a rough idea of scheme design, model selection of machines, construction, operation and investment returns for your future projects Welcome field visits or factory visits, You can get Free Custom SolutionSolutions Vertical Roller Mill, Vertical Roller Mill Operation Material grinding process motor through reducer rotating drive disc, the material falls from the mill under the central entrance and exit, under the action of centrifugal force to the disc edge by the roller to move and the crushing, grinding out lap after the material was speed up the flow to and vertical mill with one of the separator, after the meal by the separator back to the Vertical roller mill Wikipedia

The McDonald Mill : Anvilfire Plans Review

The Solution: The manual closing of the rollers with the steel between them Its SO simple! But the best ideas are simple, and MANY others have worked on this problem and not come up with this brilliant but simple solution All conventional roller mills have fixed roller spacing or spacing adjusted by screws In operation the hot metal is fed The average lenght of the roller mill is based on the account of12mm / 100kg /24 hours This account is valid for standard flour mills It varies according to the ratio of the products in the passages ROLLER MILL SETTINGS Roller mill settings can be adjusted according to three basic principles • The first is a setting done by handCrushing, Grinding and Reduction in Flour Milling Miller Our versatile SD threeroll mills bring you high quality, high throughput and repeatable application for nearly any viscosity mass From inks and electronics to cosmetics and pharmaceuticals, this is the mill you can rely on, day in day outSD Threeroll Mill Grinding and Dispersing Mar 25, 2015 Hydraulic system vertical roller mill operation 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside Hydraulic system vertical roller mill operationJan 15, 2016 These slides are all about typical process problems and solutions for those related to dry process in cement industriesHope it will helpful to understand the Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertisingProcess problems trouble shooting in cement kiln

07 VRM Pregrinder Mill (Grinding) Dam

16 TikariaMill HGRS SEPT07 Workshop Problems Solutions Situation: During the operation of the Cartago raw mill, a capacity drop was observed over the time of wear of the dam ring (height was NOT affected) Experience: After the repair of the dam ring, theCustom Grain Handling Solutions for the Craft Brewer and Distiller Malt is the most important (and expensive) ingredient in your beer (with the exception of you, of course) Achieving and maintaining the optimum grist profile involves more than simply adjusting the gap setting on your roller mill and hitting the start button on your augerMalt Handling, LLC Custom Grain Handling Solutions5 CPM World Class Animal Feed Solutions Roller Mills Roskamp roller mills deliver a consistent, uniform grind for varied applications Engineered to support your need for energyefficient, precise particle size control, Roskamp roller mills are built on a strong foundation and equipped with solid rolls for long life and reliabilityCapabilities: Excellence every step of the way Your Today the airswept vertical roller mill is the standard solution for coal grinding installations And thanks to our continuous refinement of the ATOX coal mill over the years, today’s leading airswept vertical roller mill is the compact ATOX Offering high reliability, ATOX coal mill Vertical mill roller bearing wear repair room Vertical mill roller bearing assembly requirements more stringent, firms generally use the bearing assembly cooled in dry ice method Between the bearing and the bearing chamber once the gap, will affect the normal operation of bearing, lead to bearing fever, burning phenomenon will lead to serious Vertical Roller Mill Common Problems And Solutions CR4

A BASIC UNDERSTANDING OF THE MECHANICS OF

cooling system Problems of this kind can never really be calculated but they have a detrimental effect on all rolling schedules including stresses in the roll As regards “abnormal” rolling conditions which are more or less very “normal” for rolling mills roll damage often occurs with consequences for the mill and the rolled productSolutions For production of aggregate, similar investment schemes can be used as valuable references which can make you have a rough idea of scheme design, model selection of machines, construction, operation and investment returns for your future projects Welcome field visits or factory visits, You can get Free Custom SolutionSolutions Vertical Roller Mill, Vertical Roller Mill Operation Material grinding process motor through reducer rotating drive disc, the material falls from the mill under the central entrance and exit, under the action of centrifugal force to the disc edge by the roller to move and the crushing, grinding out lap after the material was speed up the flow to and vertical mill with one of the separator, after the meal by the separator back to the Vertical roller mill WikipediaThe air volume of the vertical roller mill is controlled by the fan, and the fan plays a vital role in the operation of the vertical roller mill There is a large damper on the pipeline at the discharge position Through these two places, the air volume of the vertical roller mill is adjusted, the air volume is large, the fineness is coarse, and the output is high; the air volume is small A Fan Can Efficient of Your Vertical Roller MillToday the airswept vertical roller mill is the standard solution for coal grinding installations And thanks to our continuous refinement of the ATOX coal mill over the years, today’s leading airswept vertical roller mill is the compact ATOX Offering high reliability, ATOX coal mill

Hydraulic system vertical roller mill operation

Mar 25, 2015 Hydraulic system vertical roller mill operation 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside There is a variety of things to take into consideration when selecting bentonite clay mill to best suit your needs To More; Energy Efficient And Productive Raymond Mill 1Performance Advantages Raymond mil has the characteristics of simple structure, convenient operation, high cost perf More; Coal Powder Making Vertical Roller Mill, Vertical Roller Mill Operation And 16 TikariaMill HGRS SEPT07 Workshop Problems Solutions Situation: During the operation of the Cartago raw mill, a capacity drop was observed over the time of wear of the dam ring (height was NOT affected) Experience: After the repair of the dam ring, the07 VRM Pregrinder Mill (Grinding) DamCustom Grain Handling Solutions for the Craft Brewer and Distiller Malt is the most important (and expensive) ingredient in your beer (with the exception of you, of course) Achieving and maintaining the optimum grist profile involves more than simply adjusting the gap setting on your roller mill and hitting the start button on your augerMalt Handling, LLC Custom Grain Handling SolutionsThe Szego Mill features unique, proprietary roller mill technology developed by General Comminution Inc and the University of Toronto over the past 30 years The mill has very high specific capacity and low energy consumption It can operate dry, with air sweeping, or wet, and can process slurries and thick pastes It is suitable for materials ofGeneral Comminution Inc, Szego Mill

Roller Compaction Products for the Pharmaceutical Industry

The size reduction unit: mills the compacted material to the desired particle size; Altogether, these components allow for the production of more precise and accurate pharmaceutical products The above qualities are among some of the reasons why most pharmaceutical companies employ roller compaction for their production operationsmill operation a major challenge Timken ball mill solutions include spherical roller bearings in pillow block housings used to support the pinion shafts and drive systems The full range of Timken® tapered roller bearing, cylindrical roller bearing and spherical roller bearing products provides the qualityTHE RIGHT MIX FOR THE CEMENT INDUSTRYEasy operation and maintenance; Maximum safety; Leadingedge control system; Four or eightroller mill Diorit MDDY MDDZ consistently and safely grinds wheat, corn, rye, barley, spelt and other grains; State of the art machine control, mobile access and an intuitive user interface make the roller mill more efficient than ever beforeRoller Mill Diorit Feed Grain Buyers Guide