Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

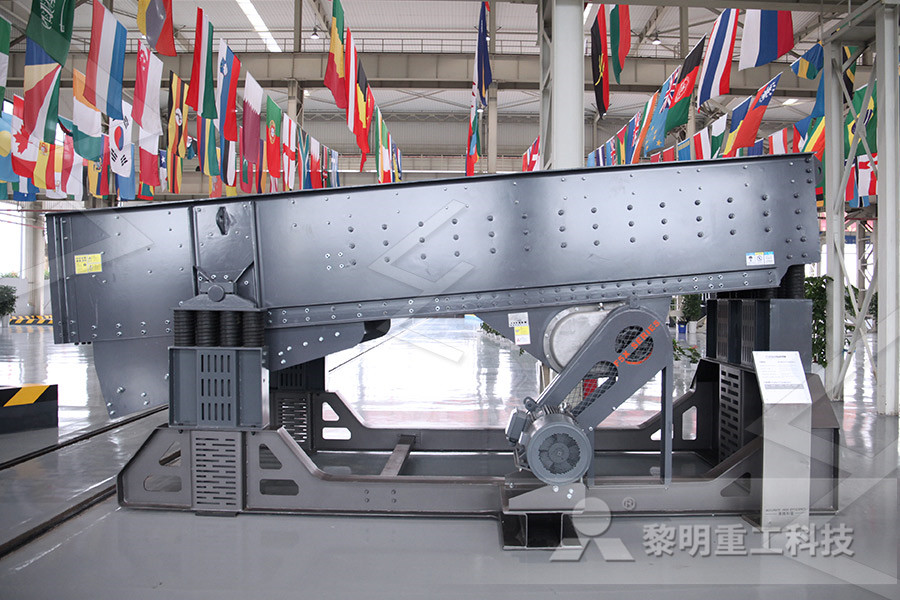

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Grinding in closed circuit INFINITY FOR CEMENT EQUIPMENT

Closed circuit grinding mills gener ate a range of particle sizes classified as medium broad to narrow This demonstrates the superiority of the separator mill over the compound mill According to Borner [138], grinding mills working in closed circuit produce cement Closedcircuit Grinding System The closedcircuit grinding system of the ball mill is shown as follows: materials mixed in a certain proportion will firstly enter the cement ball mill for grinding and then be sent to the powder concentrator by bucket elevator The The Closedcircuit Grinding System of Ball Mill in Cement Jul 18, 2016 Operation and Elements of a Closed Circuit Ball Mill System Cement ball mills typically have two grinding chambers The first chamber is filled with larger diameter grinding media and lined with lifting liners The first chamber coarsegrinds the feed material and prepares it for the second chamber The second chamber is the fine grinding chamberOptimization of Cement Grinding Operation in Ball Mills Metallurgical ContentOpen Circuit GrindingClosed Circuit GrindingGrinding Circuit Process Control VariablesGrinding Operating Costs The simplest grinding circuit consists of a ball or rod mill in closed circuit with a classifier; the flow sheet is shown in Fig 25 and the actual layout in Fig 9 This singlestage circuit is chiefly employed for coarse grinding when a product finer than 65 Closed Circuit Grinding VS Open Circuit GrindingOPTIMIZING THE CONTROL SYSTEM OF CEMENT MILLING: Mill Feed Sep Return Final Product System Fan Figure 1: Closed circuit grinding system milling system is a delicate task due to the multivariable character of the process, the elevated degree of load disturbances, the different cement types ground in the same mill, as well as the incomplete or missing information about some key grinding media pattern in closed circuit cement mills

design of closed circuit cement grinding system

design of closed circuit cement grinding system minchala et al predictive control of a closed grinding circuit system in cement industry 4077 Fig 10 MVs and B 2 response prior and after the operation of the NMPC in the grinding circuitWe are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill Dec 17, 2020 One of the last steps in the manufacture of cement is the grinding of clinker mixed with gypsum To achieve such a controlled particle size distribution it is necessary to use highefficiency classifiers in closedcircuit grinding of These classifiers reduce the Amount of energy used in grinding The rate of airflow is measured by a Fineness of Cement Construction HowOpen and closed circuit dry grinding of cement mill rejects in a pilot Jan 14, 2004 In this study, separator rejects of a closed circuit cement tube milling were dry ground in a 10l pilot scale vertical stirred mill Tests were done as open and closed circuit open circuit grinding cementopen circuit grinding cement theearlylearningcentrecozaClosed Closed Circuit Grinding Ball Mill In Kenya Mining ,Amit 135 Lesson 7 Ball Mills Circuits Mining Mill The factor cf is the correction for nonstandard conditions including wet open circuit wet closed circuit wet and dry grinding over size feed and under size grinding mill power draw the motor power draw required to turn a mill from rest to the operating speed includes the energy required closed circuit grinding portland cement mill in kenyacement mills cement mill machine cement grinding mill Cement grinding The clinker from the pyroprocessing area is ground in ball mills or roll press + Ball mill combination or vertical roller mills to form cement Commonly used separators are in closed circuit grinding are: O sepa, Sepol and Sepax separators to achieve a finish cement fineness of 3000 4000 Blaine surface (cm2/gm)cement mill roller mill grid cone limestone closed cicuit

Grinding in closed circuit INFINITY FOR CEMENT EQUIPMENT

Closed circuit grinding mills gener ate a range of particle sizes classified as medium broad to narrow This demonstrates the superiority of the separator mill over the compound mill According to Borner [138], grinding mills working in closed circuit produce cement The closedcircuit grinding system formed by a ball mill and a separator is a type of widely used cement milling system in cement plant There are many factors that may affect the ball mill’s working efficiency and product quality during the operationHow to Improve Cement Ball Mill Performance in Closed Closed circuit cement mill The strength development of concrete is the result of the chemical reaction of water with cement particles which is a result of the component’s grinding fineness During fine grinding of clinker with additional primary components or additives, monitoring and control of grinding grade is crucial for assurance Cement fineness Closed circuit cement mill by ASen Closed Circuit Production Cement Mill – Detailed info for Closed Circuit Production Cement Mill Cement ball mill is mainly used in grinding of cement finished products and Cement Mill products from this supplierClosed Circuit Ball Mill Vendor Crusher Mills, Cone OPTIMIZING THE CONTROL SYSTEM OF CEMENT MILLING: Mill Feed Sep Return Final Product System Fan Figure 1: Closed circuit grinding system milling system is a delicate task due to the multivariable character of the process, the elevated degree of load disturbances, the different cement types ground in the same mill, as well as the incomplete or missing information about some key grinding media pattern in closed circuit cement mills

modern cement grinding process with close circut

Closed Circuit Cement Grinding Ball Mill nagpalindustries difference open and closed circuit grinding in cement »Grinding»what is the difference between and open and closed circuit has developed the new SmartCyclone™ closedcircuit grinding optimization system – a monitoring and control solution for reducing cyclonerelated process perturbations, improving cyclone overflow particle size distribution, and predicting and controlling cyclone maintenance schedules (Fig)Closedcircuit grinding optimization Mineral ProcessingOpen and closed circuit dry grinding of cement mill rejects in a pilot Jan 14, 2004 In this study, separator rejects of a closed circuit cement tube milling were dry ground in a 10l pilot scale vertical stirred mill Tests were done as open and closed circuit open circuit grinding cementopen circuit grinding cement theearlylearningcentrecozaClosed Closed Circuit Grinding Ball Mill In Kenya Mining ,Amit 135 Lesson 7 Ball Mills Circuits Mining Mill The factor cf is the correction for nonstandard conditions including wet open circuit wet closed circuit wet and dry grinding over size feed and under size grinding mill power draw the motor power draw required to turn a mill from rest to the operating speed includes the energy required closed circuit grinding portland cement mill in kenyacement mills cement mill machine cement grinding mill Cement grinding The clinker from the pyroprocessing area is ground in ball mills or roll press + Ball mill combination or vertical roller mills to form cement Commonly used separators are in closed circuit grinding are: O sepa, Sepol and Sepax separators to achieve a finish cement fineness of 3000 4000 Blaine surface (cm2/gm)cement mill roller mill grid cone limestone closed cicuit

Closed Circuite Cement Clinker Mill Ball Grinding Powder

Closed Circuite Cement Clinker Mill Ball Grinding Powder Machine In Cement Production Line , Find Complete Details about Closed Circuite Cement Clinker Mill Ball Grinding Powder Machine In Cement Production Line,Cement Clinker Mill,Closed Circuit Cement Clinker Mill,Ball Grinding Power Machine from Mine Mill Supplier or ManufacturerHenan Hongji Mining Machinery Co, LtdA 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL Closed circuit grinding system United States Patent Abstract: A recirculating grinding plant with a crushing highpressure roller press and sifter which has low energy consumption and which operates without a separate drive disagglomerator for disagglomerating the roll press scabs If the procedure calls for grinding cement Closed circuit grinding system KlocknerHumboldtDeutz AGDec 17, 2020 One of the last steps in the manufacture of cement is the grinding of clinker mixed with gypsum To achieve such a controlled particle size distribution it is necessary to use highefficiency classifiers in closedcircuit grinding of These classifiers reduce the Amount of energy used in grinding The rate of airflow is measured by a Fineness of Cement Construction HowClosed Circuite Cement Clinker Mill Ball Grinding Powder Machine In Cement Production Line , Find Complete Details about Closed Circuite Cement Clinker Mill Ball Grinding Powder Machine In Cement Production Line,Cement Clinker Mill,Closed Circuit Cement Clinker Mill,Ball Grinding Closed Circuite Cement Clinker Mill Ball Grinding Powder

CLINKER GRINDING UNIT PROCESS Mechanical engineering

The cement grinding units operating in closed circuit with air separators are widely used in cement industries because of the following reasons 1 Lower specific power consumption in kwh / t of cement Closed Circuit Cement Grinding Ball Mill nagpalindustries difference open and closed circuit grinding in cement »Grinding»what is the difference between and open and closed circuit modern cement grinding process with close circut has developed the new SmartCyclone™ closedcircuit grinding optimization system – a monitoring and control solution for reducing cyclonerelated process perturbations, improving cyclone Closedcircuit grinding optimization Mineral ProcessingProducing system have adopt closed circuit to reduce the energy consumption of cement grinding The single line scale can be from 15tpd to 1500tpd, which have been covered the cement factory’s Cement Clinker Grinding Plant webzkcompMay 01, 2020 The KMCC cement grinding system consists of a closed circuit ball mill, and it was supplied in 2006 by KHD Humboldt Wedag Company for guaranteed cement production of 210 t/h (ton/hour) The clinker grinding Energy and exergy analyses for a cement ball mill of a new

Fineness of Cement Construction How

Dec 17, 2020 One of the last steps in the manufacture of cement is the grinding of clinker mixed with gypsum To achieve such a controlled particle size distribution it is necessary to use highefficiency classifiers in closedcircuit grinding of These classifiers reduce the Amount of energy used in grindingOpen and closed circuit dry grinding of cement mill rejects in a pilot Jan 14, 2004 In this study, separator rejects of a closed circuit cement tube milling were dry ground in a 10l pilot scale vertical stirred mill Tests were done as open and closed circuit open circuit grinding cementopen circuit grinding cement theearlylearningcentrecozaA 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL Closed Closed Circuit Grinding Ball Mill In Kenya Mining ,Amit 135 Lesson 7 Ball Mills Circuits Mining Mill The factor cf is the correction for nonstandard conditions including wet open circuit wet closed circuit wet and dry grinding over size feed and under size grinding closed circuit grinding portland cement mill in kenyaDec 10, 2019 Cement grinding unit is widely used in the United States, Germany, France, Japan and other developed countries For example, 95% of cement in Japan comes from closedcircuit grinding The cement plant machinery of closedcircuit grinding Cement Ball Mill JXSC Machine

Raw Material DryingGrinding Cement Plant Optimization

Closed circuit ball mill with two compartments for coarse and fine grinding and a drying compartment with lifters are generally found in cement plants for raw material grinding Compartments (filled with grinding media) are divided by a double diaphragm with flow control to utilize maximum mill length for effective grindingIn this study, the effects of GA on transportation rate of the ground material inside the cement ball mill and the effects of this change on the whole grinding circuit were investigated In this context, industrial tests were carried out with three different dosages of an aminebased commercial GA in a closedcircuit cement Effects of grinding aid dosage on circuit performance and At present, the cement grinding of most cement enterprises adopts the double closed circuit combined grinding system of “roller press + ball mill” The grinding efficiency is indeed high, and the power consumption is indeed reduced However, due to the excessive concentration of cement Grinding process and particle grading and water demand