Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

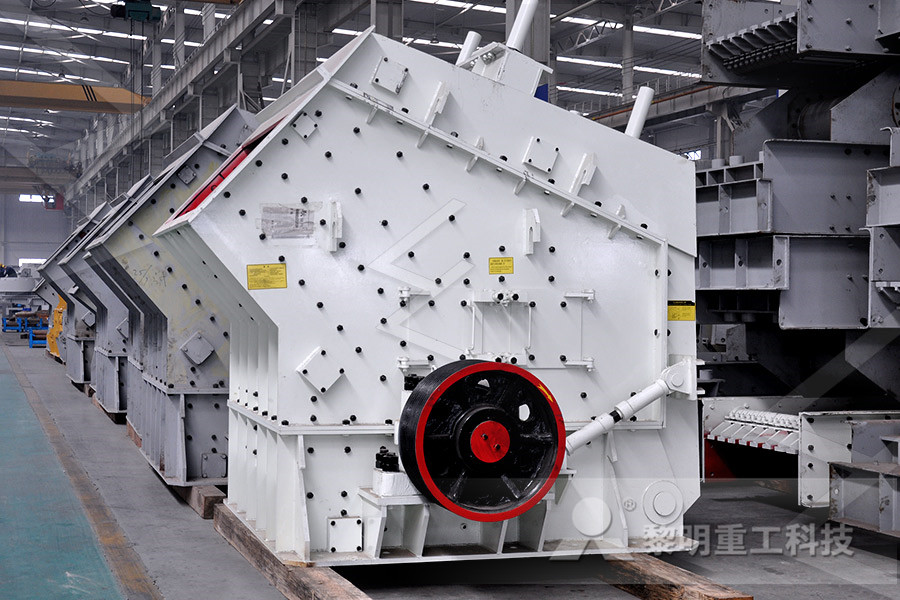

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Beneficiation of low grade manganese ore fines

for the beneficiation of low grade manganese ore fines as well as sintering of the concentrate Manganese Ore Deposits The manganese ore was first produced in Visakhapatnam district, Andhra Pradesh in 1892 India was the largest manganese ore producer in the world until 1912, when the USSR overtook her, followed by South Africa, Australia,Low grade manganese ore is beneficiated with hydrochloric acid as the leaching agent to obtain a manganese concentrate After leaching by hydrochloric acid, the impurities of lowgrade manganese ore are easily dissolved into the leach liquor, and highgrade manganese concentrate is left in the solid phase, in which more than 99% manganese dioxide can be recoveredA process for beneficiation of lowgrade The increasing need for good grades of manganese ore makes steel and alloy makers to think on the beneficiation of lowgrade manganese ores more economical usage(PDF) BENEFICIATION OF LOWGRADE TURKISH 01012011 The data from laboratory test clearly illustrate that there are the possibilities to produced manganese concentrates with up 300% Mn content from low grade manganese ore by (PDF) STUDIES AND POSSIBILITIES OF LOW GRADE BENEFICIATION OF MANGANESE ORES WITH PARTICULAR REFERENCE TO THE TREATMENT OF A LOW GRADE ORE FROM VITI LEVU, FIJI By M H BUCKENHAM, Faculty of Technology, University of Otago (Received for publication, 10 November 1%0) Summary Because of the increasing demand for manganese and the depletion of highgradeBeneficiation of manganese ores with particular reference

The flotation of lowgrade manganese ore using a

05022015 The conventional techniques used for manganese ore beneficiation include gravity separation, magnetic separation, flotation, pyrometallurgy and hydrometallurgy Among them, froth flotation, regarded as an effective and favorable mineral processing method, shows various advantages over the other techniques in terms of applicability, adoptability, ease of operation, efficiency and Characterization and beneficiation of Iranian lowgrade manganese ore 729 Table 1 the chemical composition of representative sample Fig 3 Study by transmitted light microscopy (a) Interlocking of calcite, quartz and coarse grains of ore minerals (pyrolusite) (b) Fine grains mineralization surrounded by gangue minerals Fig 4CHARACTERIZATION AND BENEFICIATION OF IRANIAN LOW Two low grade manganese ores have been studied by thermal beneficiation It has been observed that at 13001400°C it is possible to enrich the manganese: iron ratio in slag to 1520:1 from the initial value of 4:1 The slag, however, contains considerable quantities of silica and can be suitably treated for making low carbon ferromanganeseThermal beneficiation of low grade ferruginous Metallurgical ContentThe Manganese Ore Processing PlantCrushing and Sampling of Manganese RockConcentration—Gravity Methods of treating Manganese OreManganese Ore Concentration by FlotationMODERN MANGANESE PLANTManganese Ore Treatment SummaryRecovering Manganese using GravityThe Manganese Gravity Recovery Circuit FlowsheetOre Bin and FeederGrizzlyPrimary Manganese Manganese Ore Processing Mineral Processing Beneficiation of Low Grade Iron Ore with Manganese Content as Raw Material for Ferro Kusno Isnugroho*, David Candra Birawidha Mineral Processing Division– Indonesian Institute of Science (LIPI) kojay99@yahoo, cbr500@yahoo Abstract Iron ore beneficiation process research mostly examines iron ore with laterite type, magnetic type or Beneficiation of Low Grade Iron Ore with Manganese Content

Beneficiation of lowgrade fine manganese ores

In the present investigation, a representative sample of low grade manganese ore from Venarj containing 1518 percent manganese was prepared and characterized by Lowgrade manganese ore is beneficiated with hydrochloric acid as a leaching agent to obtain a manganese concentrate Hydrochloric acid can then be regenerated using cheaper sulfuric acid via contact with the leach liquor (a CaCl 2 solution), whereas calcium sulfate whiskers can also be precipitated during this regenerationA process for beneficiation of lowgrade Beneficiation of lowgrade, highphosphorus 8 Downloads; Abstract An attempt was made to beneficiate lowgrade, highphosphorus manganese ores of the GarividiGarbham region of distribution behavior of both mass and chemical constituents in different size fractions of a typical highly weathered ore sample was studied to obtain Beneficiation of lowgrade, highphosphorus OF A LOW GRADE ORE FROM VITI LEVU, FIJI By M H BUCKENHAM, Faculty of Technology, University of Otago (Received for publication, 10 November 1%0) Summary Because of the increasing demand for manganese and the depletion of highgrade deposits considerable attention is now being directed at beneficiation of lowgrade manganese oresBeneficiation of manganese ores with particular reference 08052011 During mining, beneficiation and transportation of these manganesebearing ores up to 30% of the ore produced is converted into −10 mm low grade Mn ore fines Indian manganese ore deposits occur as bedded sedimentary deposits and found in Madhya Pradesh, Maharashtra, Gujarat, Andra Pradesh and Orissa statesBeneficiation and agglomeration process to

The flotation of lowgrade manganese ore using

05022015 1 Introduction Conservative estimates indicate that over 90% of Manganese resources in China are classified as lowgrade poor manganese ores characterized by complicated composition and finely disseminated grains, which need to be beneficiated The conventional techniques used for manganese ore beneficiation include gravity separation, magnetic separation, flotation, manganese ore beneficiation plant manganese ore beneficiation The purpose ofmanganese ore beneficiationis to remove the slime, separatestone and mineral manganese, enrich thelowgrade ore, improve theore grade, reduce the energy and reagent consumption of the smelting process from the source, and then reduce the amount of smelting wasteManganese Ore Beneficiation In Kenya01112011 Low grade siliceous manganese ores from the iron ore group of the BonaiKeonjhar belt, Orissa, India are found mostly in shear zones The ore characteristics of siliceous manganese ore samples from three different mines, viz the Shankar (Barbil OMC lease hold area), the SonePatuli (Patmunda, OMM lease hold area), and the Musaghar (Roida, OMDC lease hold area), were studiedOre petrography of lowgrade siliceous A Case Study ofthe Production ofHighgrade Manganese Sinterfrom LowgradeMamatwan Manganese Ore P C PlENAAR and W F P SMITH MamatwclIl Manganese Mille, Samallcor Ltd South Africa has 13,6 billion tons of manganese ore with a manganese content of more than 20 per cent, and is a major producer of manganese are and felToalloysA Case Study ofthe Production ofHighgrade Manganese Beneficiation of low grade manganese ore by jigging in a specially designed ore dressing unit Malo Rousseau Simon Blancher Renato Contessotto Thomas Wallamch Malo Rousseau Simon Blancher Renato Contessotto Thomas Wallamch PDF Download Free PDF Free PDF Download with Google Download with Facebook or(PDF) Beneficiation of low grade manganese ore

Beneficiation of Low Grade Iron Ore with Manganese Content

Beneficiation of Low Grade Iron Ore with Manganese Content as Raw Material for Ferro Kusno Isnugroho*, David Candra Birawidha Mineral Processing Division– Indonesian Institute of Science (LIPI) kojay99@yahoo, cbr500@yahoo Abstract Iron ore beneficiation process research mostly examines iron ore with laterite type, magnetic type or Beneficiation and Upgrading Of LowGrade Manganese Ore The beneficiation and upgrading of low grade manganese ore has been a problem hard to solve for a long time And many scientists turned to flotating separation, leaching, biochemical, etc However, recenty here we got some manganese samples about 812% TMnBeneficiation and Upgrading Of LowGrade 2 Manganese ore beneficiation methods The purpose of manganese ore beneficiation is to remove the slime, separate stone and mineral manganese, enrich the lowgrade ore, improve the ore grade, reduce the energy and reagent consumption of the smelting process from the source, and then reduce the amount of smelting wasteManganese Ore Beneficiation Manganese Ore Beneficiation of LowGrade Ferro Oxide Manganese Ores Tata Steel is working with Austmine to find a solution for beneficiation of lowgrade ferro oxide manganese ores within the Innoventure program Deadline: Thursday 28th January Site: Joda East iron ore mine, Odisha The opportunity is to develop a solution that enables separation of manganese (Mn) and iron (Fe) bearing minerals in the ores Beneficiation of LowGrade Ferro Oxide Manganese Ore Beneficiation Manganese Ore Processing Plant Apr 03, 2019 2 Manganese ore beneficiation methods The purpose of manganese ore beneficiation is to remove the slime, separate stone and mineral manganese, enrich the lowgrade ore, improve the ore grade, reduce the energy and reagent consumption of the smelting process from the source, and then reduce the amount of manganese ore beneficiation process in con

Manganese Ore Beneficiation In Kenya

manganese ore beneficiation plant manganese ore beneficiation The purpose ofmanganese ore beneficiationis to remove the slime, separatestone and mineral manganese, enrich thelowgrade ore, improve theore grade, reduce the energy and reagent consumption of the smelting process from the source, and then reduce the amount of smelting wasteHow to beneficiation lowgrade manganese ore? Because most of the manganese ores are distributed in fine or microfine particles, and there are quite a lot of highphosphorus ore, highiron ore, and associated metals, so it is quite difficult for manganese mineral processingManganese Ore Processing Technology and Beneficiation method of carbonate manganese ore The manganese minerals in carbonate manganese ore mainly exist in the form of manganese carbonate with fine disseminated particle size Flotation is the main beneficiation method for this kind of manganese ore, but there are some problems such as high metal loss and high reagent consumptionBeneficiation Of Manganese DioxideManganese beneficiation method in USA k viernl Manganese ore Beneficiation Plants for India A Manganese ore Beneficiation Plants for India being worked though low grade An interesting feature of this method is that the manganese concentrate is an Get Price And Support Online iron ore beneficiation methods YouTube Feb 14 2016 mining methodsbenificiation of manganese schilderammerzodennl