Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

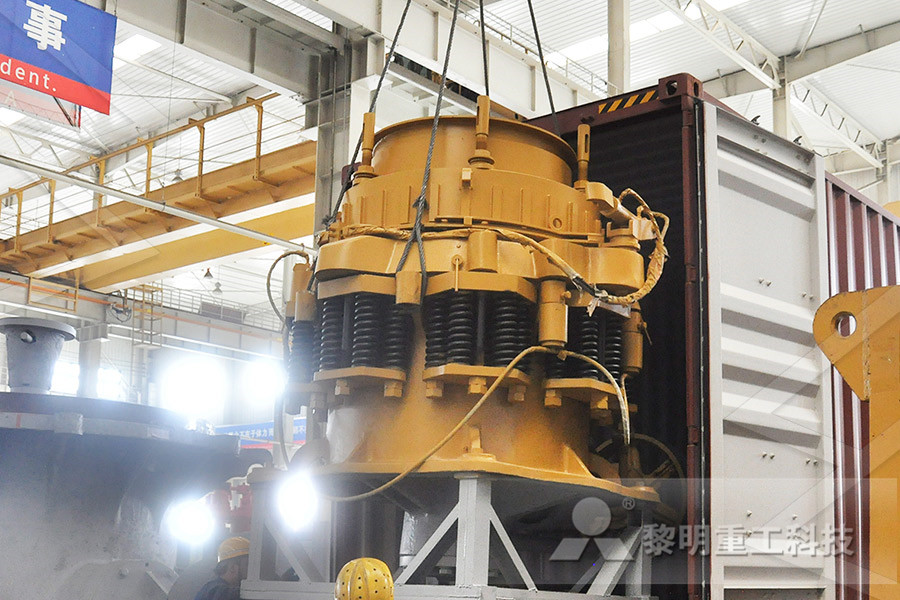

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Hydrocyclones an overview ScienceDirect Topics

Cyclones are also commonly used for dewatering of slurries given that they are much faster throughput than the alternatives, such as the traditional filter press The operating principle of the hydrocyclone is that of a conical vortexgenerating chamberFullText PDF Scientific Research Publishing wet high intensity magnetic separator and flotation to recover the iron bearing minerals scrubber, two stage classifier, spiral, and hydrocyclone from the desliming cyclone separation studies were col lected varying the slurry pH from 9 to 10, collector dosage from froth collection time 4 min were kept constant for allCyclones With Froth Flotation For Scrubber SlurryThe cyclone parameters consisted of a 6 mm spigot, Froth Flotation Experiments The procedure used for froth flotation experiments was consistent with the procedure given in progress report #6, where a conventional flotation cell with automated paddles was used This is a reverse flotation process where the limestone, one of the impurities, is beingSeparation of FlueGas Scrubber Sludge into Marketable cyclones with froth flotation for scrubber slurry cyclones with froth flotation for scrubber slurryand utilization of gypsum and line from scrubber A combined cyclonefroth flotation process has been foundFree chat Learn MoreCyclones With Froth Flotation For Scrubber SlurryFroth Flotation Cells Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a mineral/water slurryFroth Flotation Cells by Parnaby Cyclones

Hydrocyclones an overview ScienceDirect Topics

Cyclones are also commonly used for dewatering of slurries given that they are much faster throughput than the alternatives, such as the traditional filter press The operating principle of the hydrocyclone is that of a conical vortexgenerating chamberFroth Flotation Cells Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a mineral/water slurryFroth Flotation Cells by Parnaby CyclonesThe cyclone parameters consisted of a 6 mm spigot, Froth Flotation Experiments The procedure used for froth flotation experiments was consistent with the procedure given in progress report #6, where a conventional flotation cell with automated paddles was used This is a reverse flotation process where the limestone, one of the impurities, is beingSeparation of FlueGas Scrubber Sludge into Marketable The most common brand of cyclones found in the oil sands are the Krebs gMAX Cyclones, manufactured and distributed by APPLICATION The use of cyclones to break up emulsions in a naphthenic Froth Treatment process was patented by Suncor in 2006 and first commercialized at the Millennium NFT facility Cyclones are also used at HorizonHydrocarbon Cyclones Explained Oil Sands MagazineAn apparatus for extracting floatable minerals from a slurry (3) Slurry (3) is fed into a tank (2) via a feed inlet (25) and agitated and aerated so as to create an upper zone containing froth enriched with the floatable minerals The agitation and aeration are also regulated to create a lower zone (41) containing a relatively dense or coarse component of the slurry (3), and an intermediate USA Flotation method and apparatus for treatment

cyclone deironer slurry mud separation for construfroth

Sf Flotation Cell; Flotation Cell; XCF Air Inflation Flotation Cell; Jjf Flotation And Wemco Flotation; Magnetic Drum; Spiral Chute; Bf Flotation Cell; cyclone deironer slurry mud separation for constru Efficient Thickener Efficient Thickener Hydraulic Motor Driving Center ThickenerR Dunne, in Gold Ore Processing (Second Edition), 2016 62 Depression of Sulfide Minerals With Cyanide The depressing action of cyanide on pyrite during froth flotation is well known (Sutherland and Wark, 1955) and is widely exploited on many flotation plants to selectively separate copper minerals from pyriteDepression of pyrite by cyanide during froth flotation appears to take place in Flotation Froth an overview ScienceDirect TopicsA column flotation system including tailings recirculation The system includes a column for particle separation and a gas injected reactor providing the site for bubble generation within a treated slurry feed The reactor may contain a plurality of the spaced internal discs that cause shearing of the slurry to generate and entrain bubbles thereinUSA Recirculating column flotation apparatus Environmental Impact of Flotation Processing Valuable minerals in an ore can be separated from each other, and from worthless minerals, by the froth flotation process The need for a process to extract ore arose from major sulfide mineralization after the oxide ores had been depletedEnvironmental Impact of Flotation ProcessingTo participate in the 911Metallurgist Forums, be sure to JOIN LOGIN Use Add New Topic to ask a New Question/Discussion about Thickening, Filtering or Tailings and Water OR Select a Topic that Interests you Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent) Using Add Reply allows you to Attach Images or PDF files and provide a more complete input Use Add Comment Removal of Froth from Thickener Thickening, Filtering

Vertical Froth Pumps SALA Type

The Vertical Froth Pumps is specifically designed to solve pumping difficulties seen with froth or a highviscosity slurry Froth pumps are vertical shaft slurry pumps with integral sumps generally used on the output from froth flotation cells Centrifugal pumps cannot pump froths, and therefore require sufficient volume in the sump to hold the froth until broken down to a liquid The froth Flotation is the most widely used beneficiation method for fine materials, and almost all ores can be separated by flotation Another important application is to reduce ash in fine coal and to remove fine pyrite from coal The flotation machine is mechanical equipment for realizing the froth flotation process and separating target minerals from oreFlotation Machines Mineral Processing Machine Today froth flotation remains the separation process of choice for most sulphide deposits (eg Pyrite FeS 2), and an increasing number of other minerals Bench flotation test programmes are commonly designed to consider the following parameters: flotation kinetics, grind size, reagent selection and optimisation, selective flotationMineral Sands Process DevelopmentOur range of cyclones, spirals, magnetic separators, froth flotation equipment and industrial slurry pumps helps you lower your cost per ton Read more Mill Scrubber Linings Range of liners for your ball, SAG and AG mills and scrubbers Designed for maximum wear resistance to lower your mill maintenance downtimeMultotec AustraliaFroth Flotation Cells Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a mineral/water slurryFroth Flotation Cells by Parnaby Cyclones

Recovery and utilization of gypsum and limestone from

Much of the remaining impurities are hydrophobic, and can be removed by froth flotation A combined cyclone/froth flotation process has been found to be suitable for producing a highpurity product from scrubber sludge at low cost}, doi = {102172/}, journal = {}, number = , volume = , place = {United States}, year = {Fri Dec 31 00:00 An apparatus for extracting floatable minerals from a slurry (3) Slurry (3) is fed into a tank (2) via a feed inlet (25) and agitated and aerated so as to create an upper zone containing froth enriched with the floatable minerals The agitation and aeration are also regulated to create a lower zone (41) containing a relatively dense or coarse component of the slurry (3), and an intermediate USA Flotation method and apparatus for treatment small diameter cyclones prior to being fed to the apatite flotation circuit froth beds and to wash the froth was the main reasons cited for the air sparging through a porous bottom and horizontal slurry flow, in 1914 The first countercurrent column flotation device was designed and tested by Town and flynn in 1919 Crosscurrent pneumaticThe USe of ColUmn floTaTion for The reCovery ofThe source of the test material is from flotation gold ore tailings, the particle size is 200 mesh 537%, the feed concentration of the cyclone is 20%, and the feed pressure is adjusted by the frequency converter On the basis of the test conditions, the overflow pipes and grit nozzles needs to adjustedApplication of Hydrocyclone in Gold Ore TailingsSf Flotation Cell; Flotation Cell; XCF Air Inflation Flotation Cell; Jjf Flotation And Wemco Flotation; Magnetic Drum; Spiral Chute; Bf Flotation Cell; cyclone deironer slurry mud separation for constru Efficient Thickener Efficient Thickener Hydraulic Motor Driving Center Thickenercyclone deironer slurry mud separation for construfroth

USA Recirculating column flotation apparatus

A column flotation system including tailings recirculation The system includes a column for particle separation and a gas injected reactor providing the site for bubble generation within a treated slurry feed The reactor may contain a plurality of the spaced internal discs that cause shearing of the slurry to generate and entrain bubbles therein1 Froth Flotation – Fundamental Principles Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a mineral/water slurry The particles 1 Froth Flotation – Fundamental PrinciplesToday froth flotation remains the separation process of choice for most sulphide deposits (eg Pyrite FeS 2), and an increasing number of other minerals Bench flotation test programmes are commonly designed to consider the following parameters: flotation kinetics, grind size, reagent selection and optimisation, selective flotationMineral Sands Process DevelopmentTo participate in the 911Metallurgist Forums, be sure to JOIN LOGIN Use Add New Topic to ask a New Question/Discussion about Thickening, Filtering or Tailings and Water OR Select a Topic that Interests you Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent) Using Add Reply allows you to Attach Images or PDF files and provide a more complete input Use Add Comment Removal of Froth from Thickener Thickening, Filtering US Pat No 2,746,605 discloses a froth flotation device utilizing air injected into a pretreated slurry flowing into an open tank US Pat No 4,287,054 discloses another type of froth flotation device wherein air is aspirated into flowing water which is injected into the base of a cylindrical column wherein feedstock is charged at an Froth flotation ore beneficiation process utilizing

Production of High Grade Iron Ore Eriez Flotation

results in higher froth densities, and when coupled with a stabilizing water addition, permits froth depths of 1m 2m to be maintained The deep froth allows for better drainage and gives the operator more flexibility in controlling the grade/ recovery relationship Another advantage of the column geometry is that slurry naturally hydrophobic) Froth flotation cells then aggressively bubble air through the slurry The air bubbles attach to the hydrophobic particles in the slurry and float them to the surface creating a mineral froth at the top of the flotation cell This concentrated mineral froth is then collected from the surface of the flotation cellGold Recovery 101 Sepro SystemsFlotation Cell; XCF Air Inflation Flotation Cell; Jjf Flotation And Wemco Flotation; Magnetic Drum; Spiral Chute; Bf Flotation Cell; Submerged Slurry Pump Submerged Slurry Pump Agitation Tank For Chemical Reagent Agitation Tank For Chemical Reagent High Frequency Dewatering Screenmining machinery for bentonite ore hydrocyclonefroth