Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

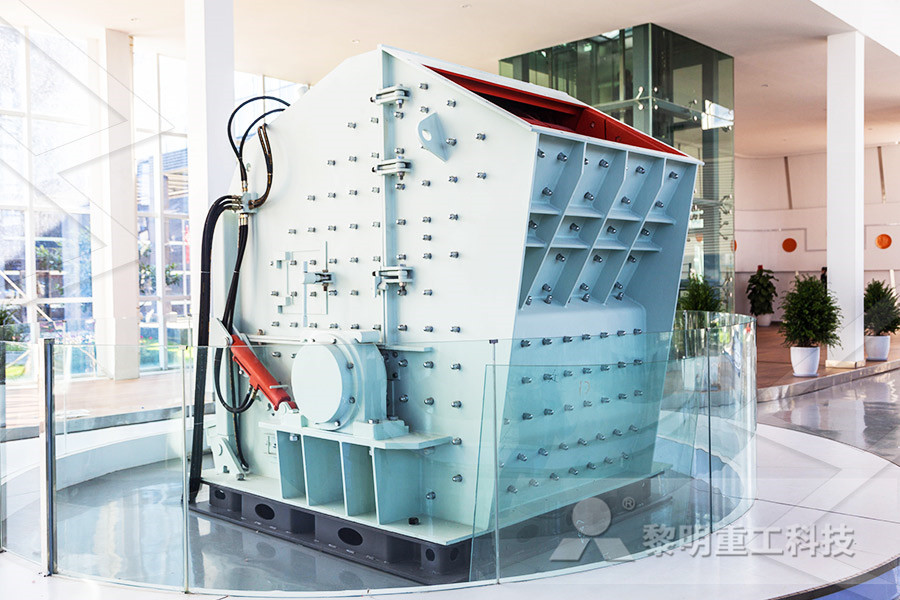

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Coking Process an overview ScienceDirect Topics

232 Coking Coking processes are processes in which the feedstock is thermally decomposed into lower boiling products The major subforms of the coking process are (1) the delayed coking process and (2) the fluid coking processJan 26, 2019 Ammonium Sulphate – A Byproduct of Coal Coking Process Ammonium sulphate is produced as a byproduct during removal of ammonia (NH3) from the raw coke oven gas generated during the coking of the metallurgical coal in byproduct coke ovensAmmonium Sulphate – A Byproduct of Coal Coking Process • Some of the byproducts of the coke making process include the following: naptha, nitric acid, benzene, and cyanogens Use a variety of resources to find out what the byproducts can be used to make Identify some of the products and explain what they can be used for • Create a visual display of the coking processCoal Mines and the Coking Process Rivers of SteelTo produce quality metallurgical coke, a hightemperature carbonization process is used Hightemperature carbonization, which takes place above 900°C (1650°F), involves chemical conversion of coal into a mostly gaseous product122 Coke ProductionCoking coal must also have low Sulphur and phosphorous contents Almost all metallurgical coal is used in coke ovens COKE • The coking process consists of heating coking coal ProcessesinobtainingByproductsofCoalpptx

Steelmaking: The Coke Oven ByProduct Plant

In the process of converting coal into coke using the byproduct coke oven, the volatile matter in the coal is vaporized and driven off This volatile matter leaves the coke oven chambers as hot, raw coke oven gas After leaving the coke oven chambers, the raw coke oven gas is cooled which results in a liquid condensate stream and a gas streamCoke, solid residue remaining after certain types of bituminous coals are heated to a high temperature out of contact with air until substantially all of the volatile constituents have been driven off The residue is chiefly carbon, with minor amounts of hydrogen, nitrogen, sulfur, and oxygenCoke coal product Britannica1221 General Metallurgical coke is produced by the destructive distillation of coal in coke ovens Prepared coal is heated in an oxygenfree atmosphere (–coked–) until most volatile components in the coal are removed The material remaining is a carbon mass called coke122 Coke ProductionThe coke oven byproduct plant is an integral part of the byproduct cokemaking process In the process of converting coal into coke using the byproduct coke oven, the volatile matter in the coal is vaporized and driven off This volatile matter leaves the coke Steelmaking: The Coke Oven ByProduct Plantresulting coke, to optimize the quality and quantity of byproducts, and to avoid the expansion exhibited by types of coal that may cause excessive pressure on the oven walls during the coking process Coal is usually received on railroad cars or barges Conveyor belts transfer the coal as needed to122 Coke Production

Coal utilization Carbonization (coke making) Britannica

Coal utilization Coal utilization Carbonization (coke making): Coke is the solid carbonaceous residue that remains after certain types of coal are heated to a high temperature out of contact with air The process of heating coal in this manner is referred to as carbonization or coke making Hightemperature carbonization, with which this section is concerned, is practiced to produce a coke Nov 29, 2020 The Coking Coal market report covers a comprehensive market analysis by product types, enduser applications, sales channels, and geographical location It offers detailed insights on the market drivers, restraints, opportunities, threats, challenges, and Global Coking Coal Market – Revenue, Opportunity, Segment COKE • Coking coal is converted to coke by driving off impurities to leave almost pure carbon The physical properties of coking coal cause the coal to soften, liquefy and then resolidify into hard but porous lumps when heated in the absence of air Coking coal must also have low Sulphur and phosphorous contents Almost all metallurgical coal is used in coke ovensProcessesinobtainingByproductsofCoalpptx It was during the industrial revolution that methods were developed which allowed iron smelting to be carried out using coal rather than wood as the ultimateBYPRODUCT COKING Steel Production Taylor Francis Group3 COAL COKING BYPRODUCTS The byproducts of the coal coking process, including the coke oven gas and tar, represent about 2025 wt% of the parent coal The coke oven gas (mainly permanent gas), which accounts for ~ 1520 wt% of the coking process, is stored in gas containers and used as fuel to heat the cokeChemicals from Coal Coking Digital CSIC

What You Should Know About Metallurgical Coal

Aug 21, 2020 Metallurgical coal, also known as coking coal, is used to produce coke, the primary source of carbon used in steelmakingCoal is a naturally occurring sedimentary rock formed over millions of years as plants and other organic materials are buried and subjected to geological forcesCoking coal must also have low sulphur and phosphorous contents Almost all metallurgical coal is used in coke ovens The coking process consists of heating coking coal to around 10001100ºC in the absence of oxygen to drive off the volatile compounds (pyrolysis) This process results in a How is Steel Produced? World Coal AssociationApr 03, 2020 Steam coal is primarily used in power generation, while coking coal is used mainly in steel production The five largest users of coal are China, India, the United States, Japan and Russia These coal users make up 76 percent of worldwide coal usage, although Asia accounts for 67 percent of worldwide coal usageWhat Is a List of Things Made From Coal?Crude Coal Tar is a by product of the Coking process Coking is the process of heating coal in coke ovens to drive volatile matter from it Metallurgical Coke is used as a fuel and reducing agent in the production of iron, steel, ferroalloys, elemental phosphorus, calcium carbide and How is Crude Coal Tar Derived 1Coke Oven Coking Process Brief: The coke pusher car takes raw coal from the coal tower, stamps and presses them to coal cakes, then pushes the coal cakes into the coking chamber The coal cakes are coked in the coking chamber for a coking cycle’s high temperature carbonizationCoke oven coking process introduction

Industrial coal coke briquette making process, briquetting

What is the industrial coal coke briquette The industrial coke is made of pulverized coal as raw material, processed by coals blending (or single coal) and then briquetting to briquette, after that through the coking process gets the coke and coketype coal productsGlobal Coking Coal Market Product Type Analysis Global Coking Coal Market overview: By Product Type Global Coking Coal Market share, By Product Type,2019 and 2026 The process of market research at Syndicate Market Research is an iterative in nature and usually follows following path Information from secondary is used to build data models Global Coking Coal Market by Product Type (Hard Coking Coking plant by products Merox sells and markets recycled and byproducts of coke oven, blast furnace, steel mill, rolling mills and own processing units Byproducts from coke oven are coagulants, tar, benzene and sulfur Subsequent process steps result Coking plant by products MeroxAug 21, 2020 Metallurgical coal, also known as coking coal, is used to produce coke, the primary source of carbon used in steelmaking Coal is a naturally occurring sedimentary rock formed over millions of years as plants and other organic materials are buried and subjected to geological forcesWhat You Should Know About Metallurgical CoalNov 15, 2020 Direct coal liquefaction is a promising approach for producing clean liquid fuels and valuable chemicals Noticeably, direct coal liquefaction residue (DCLR) is the main byproducts which accounts over 30 wt% of raw coal,,,Coking behavior and mechanism of direct coal liquefaction

Chemicals from Coal Coking Digital CSIC

3 COAL COKING BYPRODUCTS The byproducts of the coal coking process, including the coke oven gas and tar, represent about 2025 wt% of the parent coal The coke oven gas (mainly permanent gas), which accounts for ~ 1520 wt% of the coking process, is stored in gas containers and used as fuel to heat the cokeGlobal Coking Coal Market Product Type Analysis Global Coking Coal Market overview: By Product Type Global Coking Coal Market share, By Product Type,2019 and 2026 The process of market research at Syndicate Market Research is an iterative in nature and usually follows following path Information from secondary is used to build data models Global Coking Coal Market by Product Type (Hard Coking It was during the industrial revolution that methods were developed which allowed iron smelting to be carried out using coal rather than wood as the ultimateBYPRODUCT COKING Steel Production Taylor Francis GroupCoke Oven Equipment Coke Oven Coking Process Brief: The coke pusher car takes raw coal from the coal tower, stamps and presses them to coal cakes, then pushes the coal cakes into the coking chamber The coal cakes are coked in the coking chamber for a coking cycle’s high temperature carbonizationCoke oven coking process introductionPyrolysis product distribution of the typical subbituminous coal and bituminous coal under ultrahigh temperature conditions Energy Sources, Part A: Recovery, An integrated process of coal gasification and coking to methanol production Energy 2019, 177 , 304318Chemicals from Coal Coking Chemical Reviews

Metallurgical coal BHP

Metallurgical (met) coal (sometimes referred to as coking coal) is a naturally occurring sedimentary rock found within the Earth’s crust Categories of met coal include hard coking coal, semihard cokingcoal, semisoft coking coal and pulverized coal for injection (PCI)Apr 03, 2020 Steam coal is primarily used in power generation, while coking coal is used mainly in steel production The five largest users of coal are China, India, the United States, Japan and Russia These coal users make up 76 percent of worldwide coal usage, although Asia accounts for 67 percent of worldwide coal usageWhat Is a List of Things Made From Coal?Coal is a mineral consisting mainly of sedimentary fossilized carbon with smaller amounts of other elements, such as sulfur, hydrogen, oxygen, nitrogen and mSteel Manufacturing Process: Coal Coke YouTubeIn 2010, world crude steel production was 14 billion tonnes, requiring 721 million tonnes of coking coal The most commonly applied process for steelmaking is the integrated steelmaking process via the Blast Furnace – Basic Oxygen Furnace Around 06 tonnes (600 kg) of coke produces 1 tonne (1000 kg) of steel, which means that around 770 Coking Coal CRM AllianceOct 18, 2015 • The main function of Coke Ovens is to convert coal into coke which is used as a fuel and reducing agent in the Blast Furnace Its secondary function is to recover Volatile Matter and CO gas from coal and extract chemicals known as Coal Chemicals CO gas produced is used for heating purposes in the plantPPT ON COKE PREPARATION SlideShare

Coking Coal for steel production and alternatives Front

Metallurgical coal, also called metcoal or coking coal, is a type of coal that is used in the production of steel It is of a higher purity than thermal coal which is used in energy generation To make steel, metcoal is heated at around 1100 degrees C to remove water and other chemicals This is done without the presence of oxygen