Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

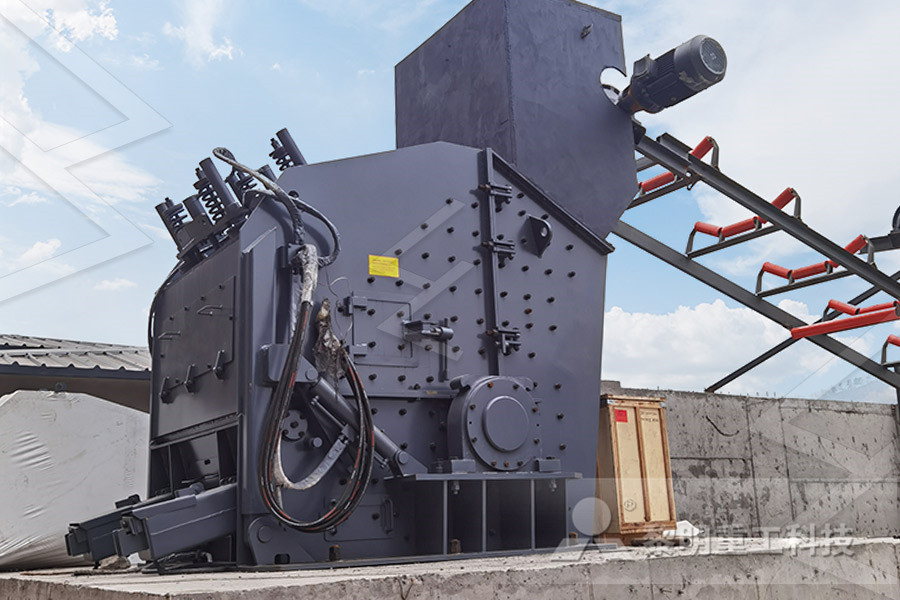

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

FABRICATED EQUIPMENT VIBRATORY FEEDERS

3 MATERIAL WEIGHT (POUNDS PER CUBIC FOOT) 25 30 35 40 45 50 55 60 70 80 90 5200 CVC DENSITY FACTOR 40 33 29 25 22 20 18 17 14 13 11 10 08 07 06 05 OPERATION PRINCIPLES Actual Particle MovementThe Simplicity® range features heavyduty pan feeders with grizzly sections added to the pan surface They perform both scalping and feeding in a single unit, and are designed for impact loading and heavy burdens in the toughest applications Standard grizzly feeder sizes range from 39” x 10’ (990mm x 3048mm) to 86” x 30’ (2184mm x Simplicity GF Series Vibrating Grizzly FeedersOur Heavy Duty Electromagnetic Vibratory Feeders are ideal for handling coal, ore, aggregates, slag—or any other situation where high volume, controlled feeding is required With their energysaving intermeshed AC/permanent magnet drive, these powerful units are the workhorses in Eriez' huge stable of Vibratory Feeders and ConveyorsEriez Vibratory Feeders and ConveyorsA loss in weight feeder is a gravimetric metering device that receives material from an upstream supply and accurately doses the material into a process at a predetermined feedrate, typically through a screw (auger or helix), twin screw, or vibratory tray True to its “loss in weight” name, this feeder’s operation is regulated by the Loss in Weight Feeder MERRICK Industries, IncThe Lfeeder is an innovative lossinweight type constant feed weigher, which is based on Yamato's own loadcell technology, optimal control, selfdiagnostic function, remote maintenance system and power handling technology Lfeeder serves manufacturing process of chemical products for it industryLFEEDER PRODUCTS YAMATO Yamato Weighing

Vibrating Feeder 911Metallurgist

Electric Vibrating Feeder The Electric Vibratory Feeder is a vibrator that provides an extremely efficient, simple and economical solution to the problem of making the most stubborn material flow freelyNo longer need there be a sticking together of wet ore in the ore bin, or the arching over and hanging up of materials in hoppers and chutes with resulting lowered operating efficiencyRepeat the weight adjustment procedure on the opposite end of the vibrator As stated before, it is very important that the outer weight on each end of the vibrator is set to the same position as indicated on the scale plate For example, if one outer weight is set to 80% the other weight must be set to 80%How to Adjust the Eccentric Weight on Rotary Electric A solenoid is suboptimal for generating ongoing vibration If the intent were to generate a single shock intermittently, then sure, a solenoid would be a good choice For mechanical vibrations (presumably for sensing by human touch), two options are popular: Offset Weight motors, aka pager motors, vibration What is good device for generating vibrations, offset SINFONIA manufactures vibrating feeders utilizing the company's own vibration technology SINFONIA vibrating feeders, which are the product of many years of accumulated vibration technology and ample experience in manufacturing, help promote process rationalization and improve productivity They enjoy widespread and high reputation Vibrating Vibrating FeedersModel 400 Series Weight–Loss Weigh Feeders Overview Acrison’s various Model 400 Series of Weigh Feeders operate on a WeightLossDifferential (or lossinweight feeding) basis; they are designed with an integral Acrison dry solids feeder, or a positive displacement liquid pump, as the metering mechanism of these precision alldigital weigh feeders, precisely controlled by an Acrison Weigh Feeders Acrison

Loss in Weight Feeder MERRICK Industries, Inc

A loss in weight feeder is a gravimetric metering device that receives material from an upstream supply and accurately doses the material into a process at a predetermined feedrate, typically through a screw (auger or helix), twin screw, or vibratory tray True to its “loss in weight” name, this feeder’s operation is regulated by the Vibrating lossinweight feeders are complicated and not accurate enough Newer scale electronics and better control algorithms make vibratory feeders every bit as accurate as screw or belt feeders For products that are very sensitive to overhandling, like chopped glass fibers, the vibrating hopper, sometimes combined with a slowturning Top Ten Myths About LossinWeight Feeders For Compounding These materials are often best handled by a twin screw feeder with hopper agitation, such as Coperion KTron’s ActiFlow Fragile and friable materials, such as many food products and fibers must be handled carefully Weigh belt feeders, vibratory feeders and lossinweight belt feeders are designed for gentle feeding of these productsFeeders – CoperionRepeat the weight adjustment procedure on the opposite end of the vibrator As stated before, it is very important that the outer weight on each end of the vibrator is set to the same position as indicated on the scale plate For example, if one outer weight is set to 80% the other weight must be set to 80%How to Adjust the Eccentric Weight on Rotary Electric A solenoid is suboptimal for generating ongoing vibration If the intent were to generate a single shock intermittently, then sure, a solenoid would be a good choice For mechanical vibrations (presumably for sensing by human touch), two options are popular: Offset Weight motors, aka pager motors, vibration What is good device for generating vibrations, offset

Drive Systems Vibroflow

Vibrating feeder with electromagnetic drive system Electromagnetic vibrating machinery uses a high frequency coil to provide the vibration Used in lighter weight applications and can provide a high degree of fine feed rate control They operate at low strokes and very high rpmModel 400 Series Weight–Loss Weigh Feeders Overview Acrison’s various Model 400 Series of Weigh Feeders operate on a WeightLossDifferential (or lossinweight feeding) basis; they are designed with an integral Acrison dry solids feeder, or a positive displacement liquid pump, as the metering mechanism of these precision alldigital weigh feeders, precisely controlled by an Acrison Weigh Feeders AcrisonScrew Feeders The lossinweight system is normally supplied with a standard Rospen metering screw feeder with screw sizes from 12mm to 250mm and output ranges from 10 Kg/hr to 110,000 Kg/hr The Ropsen metering feeder is novel in that the front can be removed in seconds via seven knobs for cleaning and the screw can be removed without disturbingLoss in Weight Feeding Rospen Industriesthe system can weigh) Controlling the material flow onto the weighing system with a feeder, specially designed loading chute, or other device can prevent shockloading damage Vibration Vibration from process equipment and other sources near the weighing system can cause the load cellsFive Factors That Can Affect Your Weighing System’s Vibration motors are provided and are suitable for driving vibrating systems, such as eg: vibrating conveyor chutes, vibrating pipes, screen conveyors, screening machines, spiral conveyors, automatic sorting machines, knockout grates, vibrating trestles, resonance conveyors, vibrating mills and fluidbed dryers, bin vibrating machines, etcInstallation and Operation Manual

Vibrating Motors : 5 Steps Instructables

A vibrating motor is essentially a motor that is improperly balanced In other words, there is an offcentered weight attached to the motor's rotational shaft that causes the motor to wobble The amount of wobble can be changed by the amount of weight that you attach, the weight's distance from the shaft, and the speed at which the motor spinsMetallurgical ContentScreen Vibration PatternsVibrating Screen DesignScreen CapacityVibrating Screen CapacitySCREENINGVibrating Screen CapacityVibrating Screen SPECIFICATIONSFloating Circle MotionWhat It IsHow It WorksMethods of Fastening Vibrating Screen ClothDouble Deck Vibrating Screen—Floor MountedScreen Frame Sizes and ScaleUp Problems and Fundamentals of Vibrating Vibrating Screen Working PrincipleSep 01, 2012 The KTron KT35 twin screw lossinweight feeder for pharmaceutical applications was designed to handle a large range of pharmaceutical powders, including those with very poor flowability, which are often lumpy and tend to build bridges The design consists of a modular twinshaft feeder mounted on a sanitary weigh bridgeMethod for characterization of lossinweight feeder Reliable feeding of most bulk materials Twin screw feeders can be used for free flowing powders and fine granulates but they are ideal for feeding difficult materials such as pigments, sticky, bridging or flooding powders, fiber and fiberglass Screw feeders are the most common and economical volumetric feeders you can buyTwinscrew feeder KT series Coperion automatic SINFONIA manufactures vibrating feeders utilizing the company's own vibration technology SINFONIA vibrating feeders, which are the product of many years of accumulated vibration technology and ample experience in manufacturing, help promote process rationalization and improve productivity They enjoy widespread and high reputation Vibrating Vibrating Feeders

Feeders – Coperion

These materials are often best handled by a twin screw feeder with hopper agitation, such as Coperion KTron’s ActiFlow Fragile and friable materials, such as many food products and fibers must be handled carefully Weigh belt feeders, vibratory feeders and lossinweight belt feeders Stainless Steel Syntron Vibrating Pan Feeder Model No: FH22CDT Serial No:T 311 460 Volt, 68 Amp, 60 Hz Demonstration video on file Shipping info: One skid, 55" wide x 120" long x 72" high Weight = 2599 lbs There are five main electrical components: 1 Vibratory Used Vibratory Controller Feeder Syntron Vibrating As stated before, it is very important that the outer weight on each end of the vibrator is set to the same position as indicated on the scale plate For example, if one outer weight is set to 80% the other weight must be set to 80%How to Adjust the Eccentric Weight on Rotary Electric This vibrating feeder design provides linear control from zero to maximum feed rate Variable Force counterweight control alters the exciting force by varying only the counterweight effect rather than the Vibrating Feeder Design Stockpile Reclaim General Sep 01, 2012 The KTron KT35 twin screw lossinweight feeder for pharmaceutical applications was designed to handle a large range of pharmaceutical powders, including those with very poor flowability, which are often lumpy and tend to build bridges The design consists of a modular twinshaft feeder Method for characterization of lossinweight feeder

Vibratory feeder working principle , vibrating grizzly

ZWS Series Vibrating Feeder is mainly used to feed material into the primary crusher homogeneously and continuously Meanwhile, it can screen the fine materithe system can weigh) Controlling the material flow onto the weighing system with a feeder, specially designed loading chute, or other device can prevent shockloading damage Vibration Vibration from Five Factors That Can Affect Your Weighing System’s AccuracyModel 400 Series Weight–Loss Weigh Feeders Overview Acrison’s various Model 400 Series of Weigh Feeders operate on a WeightLossDifferential (or lossinweight feeding) basis; they are designed with an integral Acrison dry solids feeder, or a positive displacement liquid pump, as the metering mechanism of these precision alldigital weigh feedersWeigh Feeders AcrisonVibration motors are provided and are suitable for driving vibrating systems, such as eg: vibrating conveyor chutes, vibrating pipes, screen conveyors, screening machines, spiral conveyors, automatic sorting machines, knockout grates, vibrating trestles, resonance conveyors, vibrating mills and fluidbed dryers, bin vibrating Installation and Operation Manual