Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

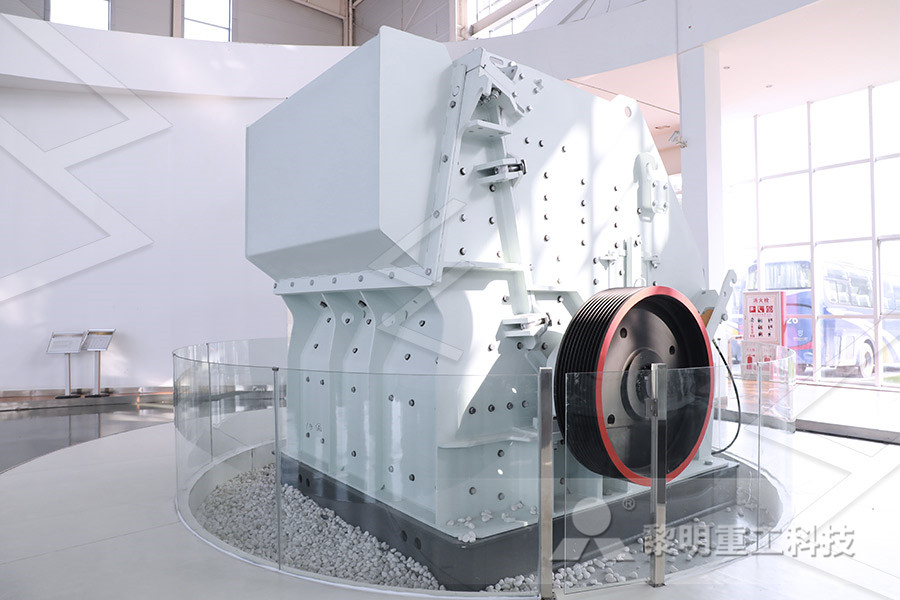

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

(PDF) Development on a Hammer Mill with Separate Sieving

Oct 01, 2012 Hammer mills are widely used for material size reduction in food and feed industries In this paper, a new hammer mill with separate sieving device has been designed and fabricated, in which the hammer arrangements, and are all supported between durable pillow block bearings These proprietary design factors combine to provide a controlled, uniform granular grind with the benefits of easy maintenance Hammer Mills FEATURES • Unique design utilizes 100% of the screen area • Uniform granular grind • Electronically balanced,Hammer Mills PraterHammer mills are widely used for material size reduction in food and feed industries In this paper, a new hammer mill with separate sieving device has been designed and fabricated, in which the socalled materialcirculation layer can not be formed and material being ground passes through the sieve by rotor throwing and air blowing without direct rubbing with the sieveDevelopment on a Hammer Mill with Separate Sieving Device The materials used are; MS plate, 900 angle iron, selected screen sieve, 55HP generating set and Shaft 21 Hammer Mill Design and Configuration The design and placement of hammer is determined by operating parameters such as motor speed, prime mover in the screen, hammer design and placement that will provide maximum contact with the feed Improvement on the Design,Construction and Testing of Sale Crusher Full Sieve Hammermill For Bio Mass In Gujarat hammer mill full sieve design pdf splendidkitchenscoza hammer mill full sieve design pdf hammer mill full sieve design hordo full sieve hammermill for bio mass in gujarat hammer mill full sieve design Hammer Mill for Biomass Pellet Plant Hammer mill is an ideal pulverizing machine for biomass pellet plant or it can be Read Hammer Mill Fullsieve Pdf Design

hammer mill full sieve design pdf splendidkitchenscoza

hammer mill full sieve design pdf psychminded Direct mechanical energy measures of hammer mill comminution of determined for hammer mill operating speeds from 2000 to 3600 rpm for 3 2 mm integral classifying screen and mass determined for mill operating factors using ISO sieve sizes from 4 75 to 0 02 mm in conjunctionFig (1): Schematic of design hammer mill 1 Main frame ,2Single phase Electrical motor 1 k Watt, 3Hammer mill housing ,4 Hammer mill, 5 Sieve, 6Feeding hopper ,7Hamme r mill shaft , 8 (PDF) DESIGN AND EVALUATE OF A SMALL HAMMER MILLHammer Mill Fullsieve Pdf Design hammer mill design pdf hammer mill full sieve design pdf Hammer mills for many purposes The Hammermill design tip for feed materials:, ou probably rate your hammermill's performance on its capacity, The largerotor, highspeed hammermillhammer mill fullsieve design dachselbstreinigenddeused hammer mills from phoenix bliss industries eliminator hammer mill model e download the full brochure below for specific equipment available and Get Price ; halfsieve hammer mill hammer mill full sieve design pdfaadccoin hammer mill full sieve design pdf;, with a liquid holdup ofmin half full, round hole perforation for hammer mills halfsieve hammer millThe objective of this project is to carry out a design fabrication and testing of a hammer mill, which will be used for grinding agricultural produce and mineral resources The profile of the throat of the machine is redesigned to give better performance that was hot nit achieve when the machine was carrying the straight profile Further more, the hammer was redesign to twisted type as Design and Fabrication Of Hammer Mill Mechanical Project

(PDF) DESIGN AND EVALUATE OF A SMALL HAMMER MILL

Download fulltext PDF Read fulltext Schematic of design hammer mill 1Main frame ,2Single phase Electrical motor 1 k Watt, 3Hammer mill housing Designed hammer mill sieve analysis:The CF series hammer mill is the new design It is mainly used in the farms, middle sized feeding factory or for family use The characters of the hammer mill focus on: Simple construction, convenient operation, high efficiency, saving power consumption, and safe condition It is fitting to grind the maize, straw, dry grass, branches and bark etcPellet Masters Pellet Mills, Hammer Mills, and GrindersThe materials used are; MS plate, 900 angle iron, selected screen sieve, 55HP generating set and Shaft 21 Hammer Mill Design and Configuration The design and placement of hammer is determined by operating parameters such as motor speed, prime mover in the screen, hammer design and placement that will provide maximum contact with the feed Improvement on the Design,Construction and Testing of flow and size reduction in a hammer mill is thus critical to optimize the design and operation of such equipment Milling experiments are performed using lactose non pareils in a laboratory scale Hammer Mill The size and shape of the resultant progeny of particles are analyzed by sieves/light scattering andInvestigating granular milling in a hammer mill the hammer design so that interaction between the hammer and material occur at the percussion centre Hammer mill cutter head and sieve Fig 2 Rectangular hammer with two articulation holes The aim of this investigation was to determine the compliance with this rule (1) of four different DETERMINATION CENTRE OF PERCUSSION FOR HAMMER

Measurement of energy requirements for size reduction of

Three hammer mill screens with round aperture of sizes 50, 30 and 08 mm, were used in milling the two residues Each experiment was repeated five times with single run for each test (open circuit) During milling, transparent nylon sack was strapped on the hammer mill discharge chute to Sieve analysis The sieve analysis, commonly known as the gradation test, is a basic essential test for determination of the gradation of a polydisperse aggregate Gradation is the term used for the distribution of aggregate particles, by size, within a given sample In practice a known weight of material, theParticle size reduction, screening and size analysis The objective of this project is to carry out a design fabrication and testing of a hammer mill, which will be used for grinding agricultural produce and mineral resources The profile of the throat of the machine is redesigned to give better performance that was hot nit achieve when the machine was carrying the straight profile Further more, the hammer was redesign to twisted type as Design and Fabrication Of Hammer Mill Mechanical Projecthammer mill sieve with 3 floors for line Hammer mill sieve with floors for line Hammer Mill Sieve With 3 Floors For Limestone Full text of NEW Internet Archive the history of over 279 billion web pages on the Get Price a sieve in a cereal hammer mill induwinecoza full sieve hammer mills, half sieve hammer mills,, Hammer mills are used for grinding almost all types ofa sieve in a cereal hammer grinding199 hammer mill sieve products are offered for sale by suppliers on Alibaba, of which feed processing machines accounts for 17%, agriculture machinery parts accounts for 1%, and crusher accounts for 1% A wide variety of hammer mill sieve options are available to you, There are 53 suppliers who sells hammer mill sieve on Alibaba, mainly located crusher sieve hammer

[PDF] Development and Testing of a Hammer Mill Semantic

The hammer mill was designed and constructed from locally available materials for grinding grain particles such as maize, millet, guinea corn and other coarse materials of cassava tuber, yam tuber, beans, etc into small size enough to pass through the holes of the cylindrical sieve positioned beneath the hammer assembly The grinding process is achieved by the use of a hammer in beating the Hammer mill sieve design impacts extraction efficiency, chlorophylls, total and individual phenols, and the volatile compounds during laboratory‐scale extraction of olive oil Abstract Full textEuropean Journal of Lipid Science and Technology: Vol 121 Hammer Mill Full Sieve Design Pdf tramezziamo hammer mill full sieve design pdf, still been used as the basis for most ball mill design but it, Sieve analysis of runs on the planetary roll mill for 5 minutes with granite » Read More » Get Price from grinders and pulverizing equipment to hammer mills, lump Half Sieve Hammer Mill FeaturesSieves configuration: The sieves (or screens) of the hammer mills are usually perforated steel sheets of 2 3 mm thickness, with holes whose diameter is usually equal to or less than the diameter of the pelletLarger holes mean higher open area, and therefore increased throughout a performance, reduced specific power requirements, coarser product, a shorter useful lifespan of the sievesHammer mill: parameters that affects grindingThe hammer mill was designed and constructed from locally available materials for grinding grain particles such as maize, millet, guinea corn and other coarse materials of cassava tuber, yam tuber, beans, etc into small size enough to pass through the holes of the cylindrical sieve positioned beneath the hammer assembly The grinding process is achieved by the use of a hammer in beating the [PDF] Development and Testing of a Hammer Mill Semantic

Investigating granular milling in a hammer mill

flow and size reduction in a hammer mill is thus critical to optimize the design and operation of such equipment Milling experiments are performed using lactose non pareils in a laboratory scale Hammer Mill The size and shape of the resultant progeny of particles are analyzed by sieves/light scattering andHammer mills work on the principle that most materials will crush, shatter or pulverize upon impact: The Process: • Material is fed into the mill’s chamber through the feed chute, typically by gravity • The material is struck by ganged hammers (generally rectangular pieces of hardened steel) which are attached to a shaft that How Does a Hammer Mill Work?the hammer design so that interaction between the hammer and material occur at the percussion centre Hammer mill cutter head and sieve Fig 2 Rectangular hammer with two articulation holes The aim of this investigation was to determine the compliance with this rule (1) of four different DETERMINATION CENTRE OF PERCUSSION FOR HAMMER Hammer mill sieve design impacts extraction efficiency, chlorophylls, total and individual phenols, and the volatile compounds during laboratory‐scale extraction of olive oil Abstract Full textEuropean Journal of Lipid Science and Technology: Vol 121