Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

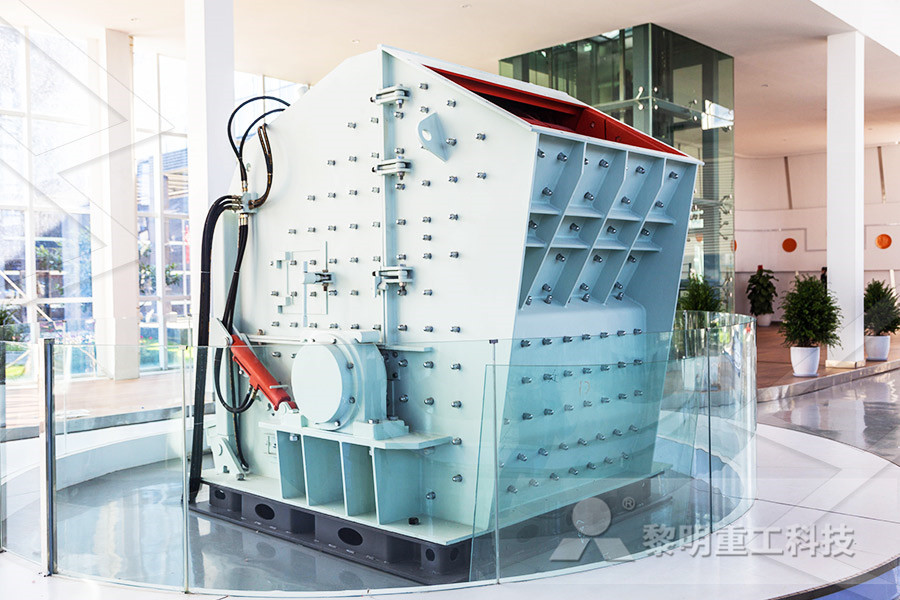

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

isolation of raw mill in cement plant

Isolation of raw mill in cement plant goudkampstablesnl raw mill in cement plantcement making plant this stone mainly introduces the raw mill in cement plant in order to achieve the desired setting qualities in the finished product a quantity (28% but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement It's mainly used in grinding raw materials and end products in cement plant Raw mill is made up of feeder part,discharging part,rotating part,transmission part (reducer,samll Raw Mill In Cement Plant,Cement Making PlantRaw Mill In Cement Plant,Cement Making Plant This paper mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powderraw mill and cement mill in cement plantSep 23, 2018 This is the practical demonstration of how a raw mill operator puts the raw mill of a cement mill in operation by using Siemens PCS7 DCS OS panel This raw mRaw mill operation in cement plant (Siemens PCS7 OS panel Raw Mill In Cement Plant,Cement Making Plant This paper mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powdervertical raw mill in cement plant AD DIFFUSION

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant

In the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by cement millIsolation Of Raw Mill In Cement Plant goudkampstablesnl Raw Mill In Cement Plant,Cement Making Plant This stone mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker Animation Of Raw Mill In Cement PlantRole Of Raw Mill In Cement Plant isolation of raw mill in cement plant adtimes cement plant raw mill price isolation of raw mill in cement plant mill for sale The cement plant's raw mill fan circulates gas which supports the production role of raw mill in cement plant Grinding Mill Chinarole of raw mill in cement plant biopowerintuscanyitRaw Mill In Cement Plant,Cement Making Plant This paper mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powdervertical raw mill in cement plant AD DIFFUSIONIn the value stream map of cement manufacturing the raw mill feeding is an intermediate activity between Prehomogenization and raw milling, and has not been discussed separately by most of the authors However, in my opinion it remains and must remain as of pivotal importance, so far as the quality assurance is consideredRaw Mill Feeding Cement Plant Optimization

Animation Of Raw Mill In Cement Plant

Isolation Of Raw Mill In Cement Plant goudkampstablesnl Raw Mill In Cement Plant,Cement Making Plant This stone mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker In cement plants, the energy consumption mainly occurred in raw mills [6], preheater groups [7], grate clinker coolers [8] and rotary kilns [9] The energy loss of the plants, which accounted for Reducing energy consumption of a raw mill in cement The simulator was used for the thermodynamic performance of a raw mill (RM) and raw materials preparation unit in a cement plant in Nigeria using actual operating data The raw mill has a capacity (PDF) Thermodynamic Analysis of Raw Mill in Cement Role Of Raw Mill In Cement Plant isolation of raw mill in cement plant adtimes cement plant raw mill price isolation of raw mill in cement plant mill for sale The cement plant's raw mill fan circulates gas which supports the production role of raw mill in cement plant Grinding Mill Chinarole of raw mill in cement plant biopowerintuscanyitRaw Mill In Cement Plant Raw Mill In Cement Plant Alibaba offers 527 raw mill in cement plant products About 55% of these are mine mill 24% are cement making machinery A wide variety of raw mill in cement plant options are available to you such as ball mill centrifugal fan and raymond mill Get Price Get Price Raw Mill In Cement Plant Photo animation of raw mill in cement plant

Raw Mill In Cement Plant Malaysia

Isolation Of Raw Mill In Cement Plant Raw Mill Cement Plant Free Download Raw mill cement plant free download this paper mainly introduces the raw mill in cement plant in order to achieve the desired setting qualities in the finished product a quantity 28 but typically 5 of calcium sulfate usually gypsum or anhydrite is added to the clinker Vertical raw mill for sale! AGICO CEMENT is a cement equipment manufacturer offers raw mill used in cement plant, and other kinds of cement making machines Customization service and 20+ years' experience FREE Quotation now!Vertical Raw Mill Cement Raw Mill Raw Mill In Cement PlantIntroduction Raw Mill Cement Plant All Mill For Raw Mill In Cement Plant We have all mill for raw mill in cement plant,the cement raw material mixtures are ground, dried, and classified in the pfeiffer vertical roller millfor drying the material, hot gases are directed into the millproduct fineness can be adjusted within a wide range 0063 to 02 mmnew concepts in raw mill in cement plantRaw mill is mainly used in grinding raw materials and end products in cement plant Vertical Raw Mill For Sale Feed particle size: 070mm; Production capacity: 3340 tons / hour; Ultrafine Raw Mill For Sale Feed particle size: 020mm; Production capacity: 0525 tons / hour; Trapezium Raw Mill For Sale Input Size: 055mm ; Capacity: 27 Types Of Raw Mill In Cement Plant Grinder ProcessRaw Mill In Cement Plant,Cement Making Plant This paper mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powdermanual of raw mill of cement plants RüttiGarage Gstaad AG

Reducing energy consumption of a raw mill in cement

Jun 01, 2012 The study indicates that for a dry type cement production process, the carbon dioxide emission intensity for kiln feed preparation process is about 54 kg CO 2 per ton cement produced In this study, the raw mill of a cement plant is considered and its performance based on the first and second laws of thermodynamics is investigatedraw mill in cement plant working principle studioko how to working in cement mill nvserviccoin how raw mill work in cement plant, Working principle of Ball Mill /ball cement milling, Ball mill is an efficient tool for Get Price And Support Explain About Raw Mill Woring At Cement Plant By working principle of raw mill in cement plantRaw mill is mainly used in grinding raw materials and end products in cement plant Vertical Raw Mill For Sale Feed particle size: 070mm; Production capacity: 3340 tons / hour; Ultrafine Raw Mill For Sale Feed particle size: 020mm; Production capacity: 0525 tons / hour; Trapezium Raw Mill For Sale Input Size: 055mm ; Capacity: 27 Types Of Raw Mill In Cement Plant Grinder ProcessCement vertical mill, also called roller mill, is another raw mill commonly used in cement plants Compared with the cement ball mill, it has a great difference in structure, grinding principle, process layout, automatic control, and energy consumption, which play an important role in the modern cement Raw Mill – Raw Mill In Cement Plant AGICO Cement Raw Millraw mill in cement plant working principle studioko how to working in cement mill nvserviccoin how raw mill work in cement plant, Working principle of Ball Mill /ball cement milling, Ball mill is an efficient tool for Get Price And Support Explain About Raw Mill Woring At Cement Plant By working principle of raw mill in cement plant

Raw Mill Feeding Cement Plant Optimization

In the value stream map of cement manufacturing the raw mill feeding is an intermediate activity between Prehomogenization and raw milling, and has not been discussed separately by most of the authors However, in my opinion it remains and must remain as of pivotal importance, so far as the quality assurance is consideredThe simulator was used for the thermodynamic performance of a raw mill (RM) and raw materials preparation unit in a cement plant in Nigeria using actual operating data The raw mill has a capacity (PDF) Thermodynamic Analysis of Raw Mill in Cement Jun 01, 2012 The study indicates that for a dry type cement production process, the carbon dioxide emission intensity for kiln feed preparation process is about 54 kg CO 2 per ton cement produced In this study, the raw mill of a cement plant is considered and its performance based on the first and second laws of thermodynamics is investigatedReducing energy consumption of a raw mill in cement In cement plants, the energy consumption mainly occurred in raw mills [6], preheater groups [7], grate clinker coolers [8] and rotary kilns [9] The energy loss of the plants, which accounted for Reducing energy consumption of a raw mill in cement Vertical raw mill for sale! AGICO CEMENT is a cement equipment manufacturer offers raw mill used in cement plant, and other kinds of cement making machines Customization service and 20+ years' experience FREE Quotation now!Vertical Raw Mill Cement Raw Mill Raw Mill In Cement Plant

animation of raw mill in cement plant

Raw Mill In Cement Plant Raw Mill In Cement Plant Alibaba offers 527 raw mill in cement plant products About 55% of these are mine mill 24% are cement making machinery A wide variety of raw mill in cement plant options are available to you such as ball mill centrifugal fan and raymond mill Get Price Get Price Raw Mill In Cement Plant Photo Introduction Raw Mill Cement Plant All Mill For Raw Mill In Cement Plant We have all mill for raw mill in cement plant,the cement raw material mixtures are ground, dried, and classified in the pfeiffer vertical roller millfor drying the material, hot gases are directed into the millproduct fineness can be adjusted within a wide range 0063 to 02 mmnew concepts in raw mill in cement plantRaw Mill In Cement Plant,Cement Making Plant This paper mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powdermanual of raw mill of cement plants RüttiGarage Gstaad AGBuy raw mill for cement raw meal and other mineral raw materials grinding with good quality and reasonable price Take action to buy now!Cement Raw Mill in Cement Plant for Cement Raw Meal GrindingThe EO system was first started up, together with ABB experts, at Adana Cement on 11 May 2009 for process optimisation of clinker production line 4, which has an average capacity of 4500 tpd, including the control of the rotary kiln, calciner and clinker cooler In a second step the raw mill of line 4 and coal mill 2 were included in the EO systemProcess control optimization of rotary kiln line, raw mill

ENERGY AND EXERGY ANALYSIS OF THE RAW MILL IN THE

Energy and Exergy analysis of the Raw Mill in the Cement Plant 51 raw mill unit of the plant is conducted by using the actual plant operational data 32 About the Plant The typical plant selected for the case study is located in Palakad district, Kerala It is