Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

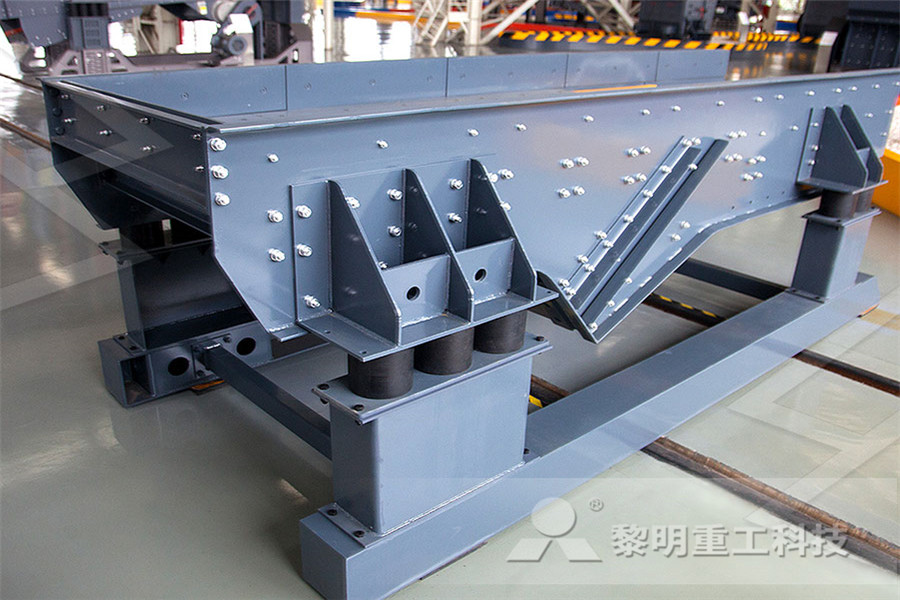

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

material balance calculations in vertical roller mill

Vertical Mill Calculations Mill (Grinding) Nozzle Vertical mill calculations Power consumption The theoretical power consumption of a vertical roller mill is expressed by the formula: N = KT A z v p [kW(net)] For the vertical mill the following applies: KT: Typically 500 700 A = Droller W roller Droller =06Do W roller = 02 DO Do = Millget priceThe advantages of the vertical roller mill include a high level of grinding efficiency combined with reduced energy consumption For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product Vertical Roller Mills Optimization of Vertical Raw Mill Operation Scribd Jul 3, 2012 Optimization of Vertical Raw Mill Operation Free download as PDF File (pdf), Text file Power Consumption Mill Drive Calculation of Specific Roller Force Ball Mill Optimization Help FAQ Press Purchase help Get Pricecalculation of specific power consumption of ball mill • Roller press in semi finish and finish grinding mode • Vertical roller mill (VRM) power consumption at mill shaft with this charge as 4110 kW the mill has increased to 160 t/h with an specific power consumption of 3360 Kwh/ t OPC at blaine of 2700 cm 2/gmCalculation Of Specific Power Consumption Of Roller Mill HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology It features in a combination of drying, grinding, classifying and conveying HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process HLM Vertical Roller Mill newhcmilling

Analysis of installation and maintenance of vertical

The vertical roller mill has the advantages of high grinding efficiency, low power consumption and high automation It has been widely used in cement production The grinding roller is the main grinding component of the vertical roller mill The roller shaft supports the roller body through the double row spherical roller bearing and the Vertical Roller Mills Calculation of Fan Motor Power P shaft = Valid for Fan without Damper Losses Only Flow (am3/h) X Static Pr (mbar) X F dust X F dyn Efficiency X 981 X 3600 Typical: Efficiency 08 F dust 10 – 102 F dyn 102 – 103Optimization of VRM Operation RUCEMRUpower consumption vertical rolling ball cement Inicio; power consumption vertical rolling ball cementpower consumption vertical rolling ball cementThe advantage of the vertical roller mill for cement (comparison with the tube mill) 1) Highly efficient grinding is possible with considerably low electrical power consumption 2) The residence time of cement grinding in the vertical roller mill is much shorter than that of tube mill Since system operational control response is superior,Vertical roller mill for cement grindingRaymond Mill Adopting many advantages from various mills, and the ideal substitute of the Raymond Mill Vertical Roller Mill Automatic control system makes remote control, low noise, and integrate sealing device stop dust spill and pollute the environment READ MORE Sand Making Machine grinding mills power consumption grinding mills power consumption

Optimization of VRM Operation RUCEMRU

Vertical Roller Mills Calculation of Fan Motor Power P shaft = Valid for Fan without Damper Losses Only Flow (am3/h) X Static Pr (mbar) X F dust X F dyn Efficiency X 981 X 3600 Typical: Efficiency 08 F dust 10 – 102 F dyn 102 – 103The vertical roller mill has the advantages of high grinding efficiency, low power consumption and high automation It has been widely used in cement production The grinding roller is the main grinding component of the vertical roller mill The roller shaft supports the roller body through the double row spherical roller bearing and the Analysis of installation and maintenance of vertical compared with tube mills These days, the vertical roller mills have been widely adopted A)Structure (1) The rollers are hydraulically pressed against a disc table and the feed is ground between the rollers and the disc table (2) The classifier is housed above the rollers B)Feature (1) The power consumption level for grindingVertical roller mill for raw Application p rocess materials• Roller press in semi finish and finish grinding mode • Vertical roller mill (VRM) power consumption at mill shaft with this charge as 4110 kW the mill has increased to 160 t/h with an specific power consumption of 3360 Kwh/ t OPC at blaine of 2700 cm 2/gmCalculation Of Specific Power Consumption Of Roller Mill HLM vertical mill has become the mainstream equipment in the pulverizing industry with the following advantages: efficient grinding, lower power consumption, larger feeding size, adjustable fineness, simple process flow, spacesaving, lower noise, smaller air pollution, easy maintenance, lower operation cost, longer working life of wearing HLM Vertical Roller Mill

4 methods to reduce vertical mill power consumption on

4 methods to reduce vertical mill power consumption on GGBFS producction line News Date: 09:43:56 Mineral powder vertical mill is a kind of machine used in slag production line which can be regards as an energy saving machine The maximum load of the vertical mill system mainly comes from the main motor and the circulating air blower, which approximately takes up 70% power consumptionpower consumption vertical rolling ball cement Inicio; power consumption vertical rolling ball cementpower consumption vertical rolling ball cementVertical roller mills can typically handle an aggregate moisture of up to 20% in raw materials and consumes about 30% less power in grinding Hence it is commonly preferred for grinding operation in new plants of higher capacitiesRaw Material DryingGrinding Cement Plant OptimizationThe vertical raw mill has several advantages over previouslyused mill systems including: • lower power consumption • less part wear/consumption • incorporation of drying with waste heat Previous technologies included ball mills with higher power consumption and part wear rates, and were not capable of higher levels of raw material dryingVRM optimisation International Cement ReviewRaymond Mill Adopting many advantages from various mills, and the ideal substitute of the Raymond Mill Vertical Roller Mill Automatic control system makes remote control, low noise, and integrate sealing device stop dust spill and pollute the environment READ MORE Sand Making Machine grinding mills power consumption grinding mills power consumption

Calculation Of Specific Power Consumption Of Ball Mill

Calculation Of Specific Power Consumption Of Ball Mill With Roller Press Ball mills are now an obsolete technology for the global cement industry mainly on account of high specific power consumption limitations on the throughput rates as the modern and the latest stateoftheart technology is not only for lower specific power consumption very low noise level and comparatively lower space The vertical roller mill (VRM) is popular and widely used for grinding of coal and raw materials The vertical mill is energy efficient with low specific wear rate increases the surface friction and effective grinding area and help to improve the grinding efficiency and reduces the power consumption Design Vertical Roller Mill Parts EcorporatesThe power consumption of vertical mill system is 20% lower than ball mill For many cement enterprises, the high energy consumption of ball mill system is such a big headache But the new type of vertical mill is a kind of energysaving and environmentfriendly grinding equipmentSteel Slag Vertical Mill Great Wall CorporationVertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the features of simple structure and low cost of manufacture and use Vertical roller mill has many different forms, but it works basically the sameVertical roller mill WikipediaHow Calculate Power Of Roller Mill Vertical Roller Mills Calculate to shaft power Influenced by: Grindability of Raw Material •Grinding Fineness •Classifier Design •Grinding Bed Height / Variations •Dam Ring Height •Air Flow •Temperature Level •Condition of Grinding Elements Power Consumption Mill How Calculate Power Of Roller Mill

EnergyEfficient Technologies in Cement Grinding IntechOpen

Oct 23, 2015 Vertical roller mills are developed to work as airswept grinding mills Roller mills are operated with throughput capacities of more than 300 t/h of cement raw mix (Loesche mill, Polysius® double roller mill, Pfeiffer® MPS mill) Loesche roller mill and Polysius® roller mills are widely applied in cement raw material pared with tube mills These days, the vertical roller mills have been widely adopted A)Structure (1) The rollers are hydraulically pressed against a disc table and the feed is ground between the rollers and the disc table (2) The classifier is housed above the rollers B)Feature (1) The power consumption level for grindingVertical roller mill for raw Application p rocess materialsCalculation Of Specific Power Consumption Of Ball Mill With Roller Press Ball mills are now an obsolete technology for the global cement industry mainly on account of high specific power consumption limitations on the throughput rates as the modern and the latest stateoftheart technology is not only for lower specific power consumption very low noise level and comparatively lower space Calculation Of Specific Power Consumption Of Ball Mill power consumption vertical rolling ball cement Inicio; power consumption vertical rolling ball cementpower consumption vertical rolling ball cementVertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the features of simple structure and low cost of manufacture and use Vertical roller mill has many different forms, but it works basically the sameVertical roller mill Wikipedia

VRM optimisation International Cement Review

The vertical raw mill has several advantages over previouslyused mill systems including: • lower power consumption • less part wear/consumption • incorporation of drying with waste heat Previous technologies included ball mills with higher power consumption and part wear rates, and were not capable of higher levels of raw material dryingRaymond Mill Adopting many advantages from various mills, and the ideal substitute of the Raymond Mill Vertical Roller Mill Automatic control system makes remote control, low noise, and integrate sealing device stop dust spill and pollute the environment READ MORE Sand Making Machine grinding mills power consumption grinding mills power consumption252 Replacing a Ball Mill with a Vertical Roller Mill, HighPressure Grinding Rolls, Figure 10: Power Consumption of Fan Installations with Different Control Methods 24 Figure 11: Measurement and Manipulation Points in a Process Control System 25 Figure 12: HighPressure Roller Press IMPROVING THERMAL AND ELECTRIC ENERGY Main equipment’s that involved in grinding process are roller mill, sifter and purifier Thus, reducing the number of use of these equipment items subsequently reduce the electrical energy cost Measuring the electric or energy power consumption should be related to the production rate or wheat groundEnergy management in flour plants Miller MagazineThe Design Principle of Vertical Roller Mill Posted: The past two years, the popularity of vertical roller mill is growing Vertical roller mill, is vertical mill for short, is a grinding processing equipment dealing with raw material such as cement, cement clinker, slag and cinderThe Design Principle of Vertical Roller Mill

Vertical Roller Mill Parts Ecorporates

The vertical roller mill (VRM) is popular and widely used for grinding of coal and raw materials The vertical mill is energy efficient with low specific wear rate increases the surface friction and effective grinding area and help to improve the grinding efficiency and reduces the power consumption Design Mill type Power consumption (kWh/t) Power plant coal 208 074 Ball mills 21 Cement plant coal 60 045 Vertical roller mills 12 The experimental results in Table 3 show that the fractions of particles sized greater than 74 m are 208% and 60% in the screening of the power plant coal and the cement plant coal, respectively The dataGrinding process within vertical roller mills: , LYNCH A J This innovative drive concept will have an available total drive power of 11 500 kW This amount of power cannot be implemented with conventional drive systems for vertical roller mills The individual drives will be synchronized by frequency converters which will also allow the speed to be adapted to the various product qualitiesGebr Pfeiffer to supply the world’s largest vertical