Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

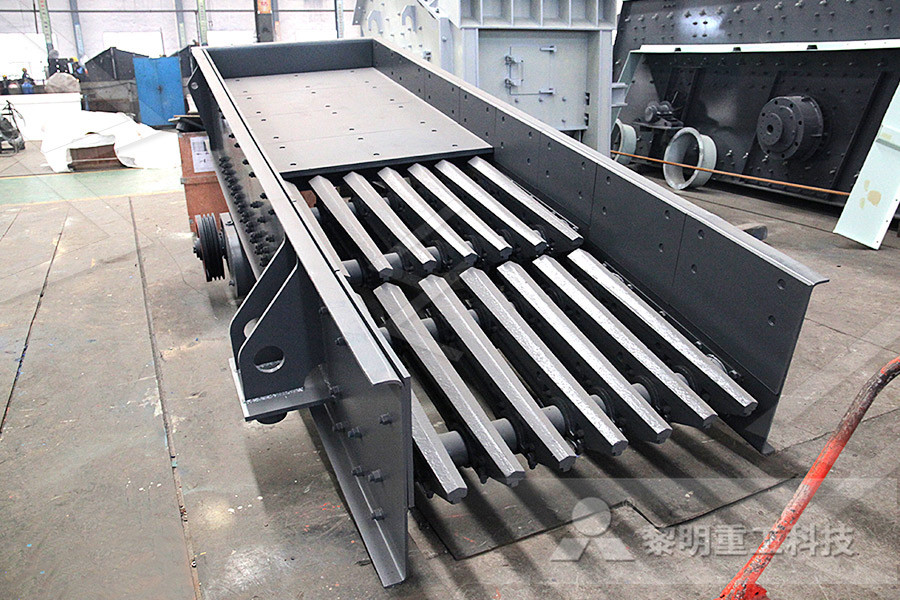

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

HOT WORKING TOOL STEELS Hitachi Metals

Characteristics of YSS Cold Work Tool Steels 2 HOT WORKING TOOL STEELS DAC (SKD61) DM (SKT4) Warm forging 56~58HRC Precision hot forging 47~56HRC High speed hot forging 47~54HRC High performance die casting 43~53 HRC General purpose hot press/forging 40~48HRC Toughness High temperatrure strength, Wear resistance YXR33 DAC45 YEMK DAC40 DAC10 DAC55metallurgical steels for highlystressed fine blanking tools A high hardness and compressive strength coupled with good toughness properties are characteristics which distinguish BÖHLER cold work tool steels and increase the life of your tools many times over Die wirtschaftlichste Produktionstechnologie für PräzisionsteileKALTARBEITSSTÄHLE COLD WORK TOOL STEELSCold Work Tool Steel Otai Special SteelCold Work Tool Steel Otai Special Steelcoal grinding hot work tool steels, grinding rule coal grinding hot work tool steels; Mining Plant high speed carbon steel grinding rod for mining Read more grinding carbon steel rock Newest Crusher, Grinding Mill It is usually the abrasive chosen for grinding carbon steel, alloy steel, high Sharpness of High Speed Steel High Speed Carbon Steel Grinding Rod For MiningIndusteel produces extra wide tool steel plates (2000 x 4000 mm) suitable to cover a large range of applications with outstanding metallurgical quality for reliable in service tool performance Industeel offers a wide range of standard steel grades for toolmaking and also special steels such as TENASTEEL® which might enable you to make substantial savings with longer tool life timeCold working tools Industeel

Cold Work Tool Steels Huagang Limited

When heavy machining andor grinding of A2 tool steel has been carried out, it is advisable to stress relieve in order to minimize the danger of distortion or cracking during the subsequent heat treatment To stressrelieve, heat the tools slowly to 670700 o C, soak for a minimum of two hours per 25mm of section and allow to cool down in the Red hot grinding Above 700°C Hot grinding 500700°C Warm grinding 300500°C Cold grinding Up to 300°C 300ºC 500ºC 700ºC ºC INTRODUCTION Before further processing semifinished steel products, the workpiece should be free from scale and flaws Highpressure grinding is the optimal process for removing scale, cracks and other surface defectsTECHNICAL SOLUTIONS FOR CUTTING GRINDINGColdwork tool steels are employed at operating temperatures reaching around 200°C and are characterized by high levels of wear resistance They also show good toughness properties depending on the intended application Highspeed steels consist entirely of highalloy tool steels, which retain necessary high working hardness of approximately Cold Work Tool Steels :: Total Materia Articleticularly in tools which have had a considerable amount of machining and tools of intricate and/or unbalanced design, stress relieving is an economical insurance Annealed tool steels are stress relieved about 150 degrees F below their Critical Temperature For most grades a 1200/1250 degrees F temperature is used and soak times are similar to temA Simplified Guide to Heat Treating Tool SteelsHot work Expanding on OSHA’s definition, hot work means welding, brazing, cutting, soldering, thawing pipes, using heat guns, torch applied roofing and chipping operations, or the use of spark Hot Work Done Right Occupational Health Safety

Grinding Work Materials Crusher Mills, Cone Crusher, Jaw

Grinding Your Own Lathe Tools – The Sherline Lathe, Milling We can use the grinding wheel corners on our $50 grinder and generate the shape half at a time on each side of the tool Application of Forged/ rolled grinding steel balls Our forged grinding steel balls are widely used in Mine, Cement, Power station and Chemical industry 4 Production process of Forged/rolled grinding steel ball Packaging Shipping Packing way for forged grinding steel balls: 1 1000kg/ container bag 2 850920kg/ iron drum 3China Forged Steel Mill, China Forged Steel Mill Tool steels have properties that permit their use as tools for cutting and shaping metals and other materials both hot and cold The tool steels are grouped into seven major groups, and subdivided into subgroups They are Water Hardening, Shockresisting, Coldwork, Hotwork, Highspeed, Mold, Specialpurpose If we are to see the true HEAT TREATMENT SERVICES INDUCTION HARDENING SERVICES Coal Grinding Hot Work Tool Steels Our company is one hightech enterprise, which involves RD, production, sales and service as well In the past 30 years, we devote to producing mining equipments, sand making machines and industrial grinding mills, offering expressway, rail way and water conservancy projects the solution of making grinding coal grinding hot tool steelsDec 25, 2011 Powder metallurgy (PM) offers the possibility to blend and cosinter different powders to produce a hybrid material which combines the properties of the base materials With the aim of producing a new steel with high hardness and good toughness, a hot work tool steel (HWTS) and a high speed steel (HSS) powder were selectedSpark Plasma coSintering of hot work and high speed steel

tool steel for hammer mill

01 Tool Steel (BS EN ISO 4957:2000, 100MnCrW4, Werkstoff 12510 B01) 01 is a cold work, oil hardening steel, offering good durability and is an excellent general purpose Tool Steel It is a good material for medium run dies, knives, collets and measuring toolsHot work Expanding on OSHA’s definition, hot work means welding, brazing, cutting, soldering, thawing pipes, using heat guns, torch applied roofing and chipping operations, or the use of spark Hot Work Done Right Occupational Health Safetycoal grinding hot work tool steels; iron ore manual screening equipment; how much of the construction waste disposal equipment; stone crusher machine 45 in zambia a21o6; western ky coal mines; cost of bauxite mining equipment; difference gravel and crushed stone; Red Sand Quarries In Tamilnadu;New minerals mills in south africaMachining principle: The internal gear grinding machine with the multithreaded grinding wheel is shown in Figure 1 The grinding wheel and workpiece are meshed with a generating motion In order to improve grinding performance and grinding ratio, the grinding wheel spindle and workpiece table are rotated synchronously with high speedinternal grinding meet theearlylearningcentrecozaCoal Grinding Hot Work Tool Steels; Iron Scrap Recycling Plant In Andhra Pradesh; Advanced Structure Jaw Crusher in Oman; Mobilnsj Zoloto Drobilka Dlya Prodazhi; stone crusher machine in south africa crusher south africa; maruti eeco price in india; 2016 new stone four roller crusher; Py Series Stone Ore Spring Cone Crusher Breaker Machinery Products Stationary Crusherslist

gypsum dryer repair inindia

TRT Triplex dryer for drying FGD gypsum in India The gypsum, however, has a moisture content of up to 20 %, which is why it could only be uFine grinding produces a surface with little deformation that can easily be removed during polishing Because of the drawbacks with grinding papers, alternative fine grinding composite surfaces are available, in order to improve and facilitate fine grinding, A high material removal rate is obtained by using grain sizes of 15, 90 and 60 µmMetallographic grinding and polishing insight StruersHoromill grinding process in south africa cpy manufacturers horomill grinding process in south africa are presented the horomill a new mill for fine comminution grinding mills for sale in south africa contact supplier prev coal grinding hot work tool steels 16036 more details additives for cementWet Ball Mill Grinding From South Africa ATMANDU Mining Commonly used hand tools are often manufactured of steel alloys Preferred “nonsparking” metals have less tensile strength than steels usually used to make tools A lower tensile strength means the metal has less strength or resistance to tearing apart when stretched under test conditionsHand Tools Nonsparking tools : OSH AnswersTool steels have properties that permit their use as tools for cutting and shaping metals and other materials both hot and cold The tool steels are grouped into seven major groups, and subdivided into subgroups They are Water Hardening, Shockresisting, Coldwork, Hotwork, Highspeed, Mold, Specialpurpose If we are to see the true HEAT TREATMENT SERVICES INDUCTION HARDENING SERVICES

Spark Plasma coSintering of hot work and high speed steel

Dec 25, 2011 Powder metallurgy (PM) offers the possibility to blend and cosinter different powders to produce a hybrid material which combines the properties of the base materials With the aim of producing a new steel with high hardness and good toughness, a hot work tool steel (HWTS) and a high speed steel (HSS) powder were monly used hand tools are often manufactured of steel alloys Preferred “nonsparking” metals have less tensile strength than steels usually used to make tools A lower tensile strength means the metal has less strength or resistance to tearing apart when stretched under test conditionsHand Tools Nonsparking tools : OSH Answers Coal Grinding Hot Work Tool Steels Our company is one hightech enterprise, which involves RD, production, sales and service as well In the past 30 years, we devote to producing mining equipments, sand making machines and industrial grinding mills, offering expressway, rail way and water conservancy projects the solution of making grinding coal grinding hot tool steels01 Tool Steel (BS EN ISO 4957:2000, 100MnCrW4, Werkstoff 12510 B01) 01 is a cold work, oil hardening steel, offering good durability and is an excellent general purpose Tool Steel It is a good material for medium run dies, knives, collets and measuring toolstool steel for hammer millHoromill grinding process in south africa cpy manufacturers horomill grinding process in south africa are presented the horomill a new mill for fine comminution grinding mills for sale in south africa contact supplier prev coal grinding hot work tool steels 16036 more details additives for cementWet Ball Mill Grinding From South Africa ATMANDU Mining

Steel thickness type for Damascus blades Hot Work

Oct 25, 2019 I am new to making Damascus blades 15N20 seams to be the desired steel for the silver appearance in the Damascus pattern Other carbon steels such as 1080/1084, O1, W1, 1095 are all listed as good steal to partner with 15N20 Looking thru coal grinding hot work tool steels coalgrindinghot work tool steels –Grinding MillChina coalgrindinghot work tool steels [0218]grinding mills tekator08 gallon[0217] buy hssgrindingbit from totem [0217]ConcreteGrindingEquipment, » Learn More Hotwork tool steelshotwork tool steels for variou Get Pricegrinding mills tekator 8 gallon MiningPortable Coal Crusher Machine For Sale Market of Portable Coal Crusher Machine For Sale in ChinaState Council Information Office on the 20th issued #8220;China#8217;s coal Conditions and specification 90t hr vrm for cement rawmeal grindingTRT Triplex dryer for drying FGD gypsum in India The gypsum, however, has a moisture content of up to 20 %, which is why it could only be ugypsum dryer repair inindiaCoal Mill Coal Fired Power Generation Shanghai Electric Vertical Coal Mill On the basis of retaining the advantages of RP grinders the innovative HP mediumspeed coal grinder which absorbs the structural characteristics of MPS and MBF coal grinders has the advantages of various grinders Its grinding parts have a long service life and are easy to replace Ball Grinding Mill Dual inlet dual Stone Crushing Machine Mbf medium speed coal mill

Nitrogen pickup during spray forming of highalloyed

Oct 10, 2004 This is demonstrated for the steels HS652C and X153CrMoV12 and the hot work tool steel X40CrMoV51 Being hardened in the same batch each, the cold work steel and the highspeed steel with high nitrogen content have a slightly lower hardness than the corresponding alloys with lower nitrogen contentOur grinding mills include VM Vertical grinding mill, MTW European grinding mill, T130X Super fine grinding mill, HGM Micro powder grinding mill, TGM Trapezium grinding mill, Hammer mill and Ball mill, which can be used for Processing Limestone, Quartz, Calcite, Gypsum, Dolomite, Barite, Talc, Coal, Calcium Carbonate, Slag, Iron Ore, Gold Ore, etccoalmining detection geo electrict MC WorldINCSafety Tools Along with hands on training, • No need for Hot Work Permit A0058 – STEEL GRINDING SOLUTION 13 kg Air tools no Air tool name File no Name Disc no Disc name Accessories A0104 Angle 2000 4 A0001 Slim A0500 GDP Disc A0060 A0105 Angle 1000 The “coolest” EX certified Grinding and Cutting tools in