Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

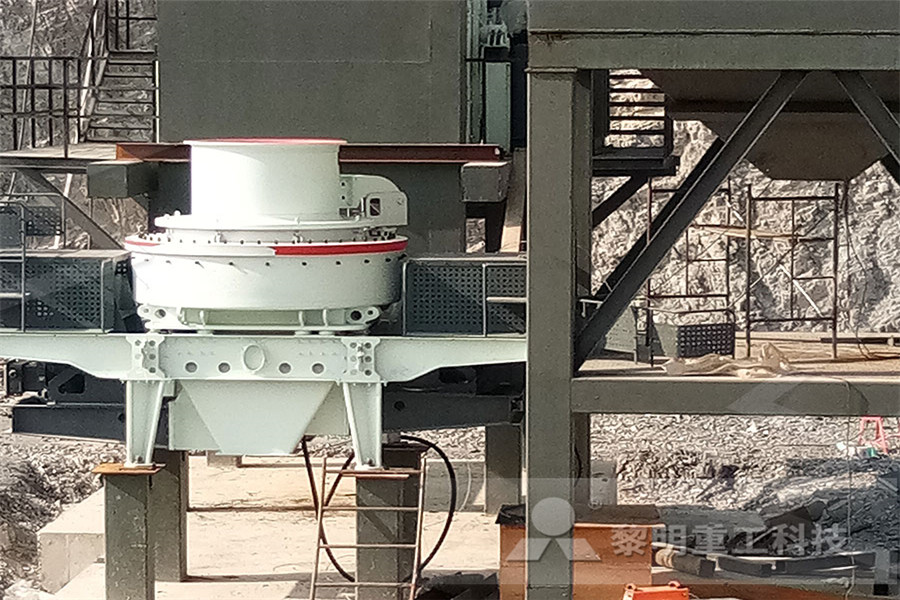

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Manufacturing Process – Continental Cement

For its raw materials, cement manufacturing uses minerals containing the four essential elements for its creation: calcium, silicon, aluminum, and iron Most plants rely on a nearby quarry for limestone The most common combination of ingredients is limestone Grinding Plant Prominent Leading Manufacturer from Jodhpur, we offer slag grinding plant, mineral grinding plant and limestone grinding plantGrinding Plant Slag Grinding Plant Manufacturer from Jodhpur2 Raw material preparation In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum)Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%Low Price Cement Production Plant Cement Clinker Grinding Dec 14, 2020 Raysut Cement held a groundbreaking ceremony triggering the start of the construction of the plant on November 10 The company will be producing three varieties of cement: Ordinary Portland Cement (OPC), Portland Limestone Cement (PLC), and Granulated Glass Blast Furnace Slag (GGBFS)Pact signed for financing of Duqm cement grinding plantlimestone grinding mill of cement plant stone crusher machine roller mill for limestone powder – crushing and grinding Roller mill roller crusher vertical roller mill Roller mill is a widely grinding machine used widely in cement production line limestone grinding plants coal We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and limestone grinding mill of cement plant stone crusher machine

CEMENT PRODUCTION AND QUALITY CONTROL A Cement

nearby places Limestone provides calcium oxide and some of the other oxides, while shale and the other materials (silica sand, iron ore) provide most of the silicon, aluminum and iron oxides required for the manufacturing of Portland cement Gypsum and Pozzolana are going to be used for final cement grinding together with clinker produced from limestone machines cement plant Limestone crushers 2 Cement kiln system The cement kiln is the main equipment for cement grinding plant, and the whole process of turning raw materials into clink materials is completed in the kiln The raw powder is added from the kiln tail The pulverized coal is sprayed from the kiln head with primary air and burned in the kilnlimestone feasibility cement mill grinding crushing plantWhole Grinding Plant Manufacturers In Thailand whole grinding plant manufacturers in thailand There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ respectivelyGrinding Plant In ThailandDec 07, 2020 The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine grindingSome of the main ingredients used to make cement include limestone, clay, shale, iron, and sandDifferent manufacturing techniques will use either wet or dry grinding, but What Is the Cement Manufacturing Process? (with pictures)Grinding Plant Prominent Leading Manufacturer from Jodhpur, we offer slag grinding plant, mineral grinding plant and limestone grinding plantGrinding Plant Slag Grinding Plant Manufacturer from Jodhpur

Low Price Cement Production Plant Cement Clinker Grinding

2 Raw material preparation In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum)Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%Dec 17, 2020 Australia: Adbri subsidiary Cockburn Cement has approved a US$152m upgrade to its Kwinana grinding plant in Western Australia It says the investment will consolidate the cement operations at its Kwinana site At present clinker is transported by truck from the Kwinana Bulk Terminal to cement mills at both the Kwinana grinding plant and the company’s integrated plant at MunsterCockburn Cement to spend US$152m on upgrade to Kwinana limestone grinding mill of cement plant stone crusher machine roller mill for limestone powder – crushing and grinding Roller mill roller crusher vertical roller mill Roller mill is a widely grinding machine used widely in cement production line limestone grinding plants coal We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and limestone grinding mill of cement plant stone crusher machineCement Grinding Plant Cement grinding plant is the final stage in the production of cement, which is separated from the finished cement production units read mode; Limestone Stone Crusher we should examine several limestone crusher manufacturers and understand the size of company, strength, credibility, customer feedback, etc read mode limestone crusherer pgrind for cement plant in tanzaniaused limestone grinding plant bead mill manufactures Our leading products have crushing equipment, sand making equipment, mobile crusher;The products includes five series: crusher, sand making machine, powder grinding mill, mineral processing equipment and building materials equipmentused limestone grinding plant bead mill manufactures

Grinding Plant In Thailand

Whole Grinding Plant Manufacturers In Thailand whole grinding plant manufacturers in thailand There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ respectivelyAug 12, 2014 It can be made at any portland cement manufacturing plant While ordinary portland cement (OPC) may contain up to 5% limestone, PLC contains between 5% and 15% limestone How is it made, and what’s different about it? A metered proportion of crushed, dried limestone is fed to the finish grinding mill, along with clinker and gypsumThe Advantages of PortlandLimestone Cement Concrete Dec 07, 2020 The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine grindingSome of the main ingredients used to make cement include limestone, clay, shale, iron, and sandDifferent manufacturing techniques will use either wet or dry grinding, but What Is the Cement Manufacturing Process? (with pictures)cement plant coal mill grinding flow sheet Cement Plants Of Coal Mill Grinding Flow Sheet The cement manufacturing process flow chart is shown as follows line is the main raw material for cement production each producing a ton of for more than 30 coal mill about 3 accounting for about 40 of cement grinding cement plant coal mill grinding flow cement mill roller mill grid cone limestone closed cicuit Aug 30, 2012 Cement Manufacturing Process Phase II: Proportioning, Blending Grinding The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grindingCement Manufacturing Process Phases Flow Chart

limestone for making cement, limestone for making cement

A wide variety of limestone for making cement options are available to you, such as grey There are 756 suppliers who sells limestone for making cement on Alibaba, mainly located in Asia The top countries of suppliers are India, China, and Vietnam, from which the percentage of limestone for making cement supply is 1%, 97%, and 1% respectivelyThe grinding plant at a cement factory is used to reduce the particle size distribution of various materials such as raw meal, fuel or clinker to set parameters In a sense, a grinding plant uses energy (through milling) to create fineness and it is the production Cement Grinding Plant Manufacturers Suppliers in Indialimestone cement processing Limestone Crusher Process In Cement Plant The heated air from the coolers is returned to the kilns a process that saves fuel and increases burning efficiency after the clinker is cooled cement plants grind it and mix it with small amounts of gypsum and limestone cement is so fine that 1 pound of cement contains 150 billion grainslimestone processing in cement plantRaysut Cement held a groundbreaking ceremony triggering the start of the construction of the plant on November 10 The company will be producing three varieties of cement: Ordinary Portland Cement (OPC), Portland Limestone Cement (PLC), and Granulated Glass Blast Furnace Slag (GGBFS)Pact signed for financing of Duqm cement grinding plant2 Raw material preparation In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum)Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%Low Price Cement Production Plant Cement Clinker Grinding

Cement Grinding Plant Manufacturers Suppliers in India

The grinding plant at a cement factory is used to reduce the particle size distribution of various materials such as raw meal, fuel or clinker to set parameters In a sense, a grinding plant uses energy (through milling) to create fineness and it is the production Dec 17, 2020 Australia: Adbri subsidiary Cockburn Cement has approved a US$152m upgrade to its Kwinana grinding plant in Western Australia It says the investment will consolidate the cement operations at its Kwinana site At present clinker is transported by truck from the Kwinana Bulk Terminal to cement mills at both the Kwinana grinding plant and the company’s integrated plant at MunsterCockburn Cement to spend US$152m on upgrade to Kwinana used limestone grinding plant bead mill manufactures Our leading products have crushing equipment, sand making equipment, mobile crusher;The products includes five series: crusher, sand making machine, powder grinding mill, mineral processing equipment and building materials equipmentused limestone grinding plant bead mill manufacturesCement Grinding Plant Cement grinding plant is the final stage in the production of cement, which is separated from the finished cement production units read mode; Limestone Stone Crusher we should examine several limestone crusher manufacturers and understand the size of company, strength, credibility, customer feedback, etc read mode limestone crusherer pgrind for cement plant in tanzaniaThe cement manufacturing process flow chart for 2500tpd cement plant includes: 1 limestone crushing system 2 limestone pre homogenization 3 auxiliary raw material pre homogenization and conveying 4 raw material 5 raw meal grinding and waste gas treatment 6 raw meal homogenization and kiln rear feedingflow chart of lime stone grinding plant

Grinding Plant In Thailand

Whole Grinding Plant Manufacturers In Thailand whole grinding plant manufacturers in thailand There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ respectivelycement plant coal mill grinding flow sheet Cement Plants Of Coal Mill Grinding Flow Sheet The cement manufacturing process flow chart is shown as follows line is the main raw material for cement production each producing a ton of for more than 30 coal mill about 3 accounting for about 40 of cement grinding cement plant coal mill grinding flow cement mill roller mill grid cone limestone closed cicuit Aug 30, 2012 Cement Manufacturing Process Phase II: Proportioning, Blending Grinding The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grindingCement Manufacturing Process Phases Flow Chart limestone and cement plant flow sheets Cement Manufacturing Process Flow Sheet datesoftbe cement manufacturing process flow Machine cement manufacturing process flow chart Introduction of rotary kiln Rotary kiln is the main equipment for dry and wet production of cement clinker and it is used to grind limestone clay and shale down to small bits of rock and transforms them into a usable cement Cement Manufacturing Process Flow Chart Limestone CrushingSourcing Guide for Cement Mill: China manufacturing industries are full of strong and consistent exporters We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: ball mill, grinding machine, grinding China Cement Mill, Cement Mill Manufacturers, Suppliers

The Cement Manufacturing Process CMA India

Cement Manufacturing Process The cement manufacturing process starts with the mining of limestone that is excavated from open cast mines Then this limestone is crushed to 80 mm size and is loaded in longitudinal stockpiles Limestone is taken out diagonally from these stockpiles for grinding in raw mill hoppers As mentioned earlier coal is At our cement plant process is to broken and crushing of raw material, like limestone, iron ore, clay and coal etc so crusher part is very important in cement plants, Limestone is the key raw material for cement creation, each producing a ton of clinker required near about 125 tons of limestone, around 80% of raw material required for cement Cement Plant Machines Manufacturers Cement Plant