Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

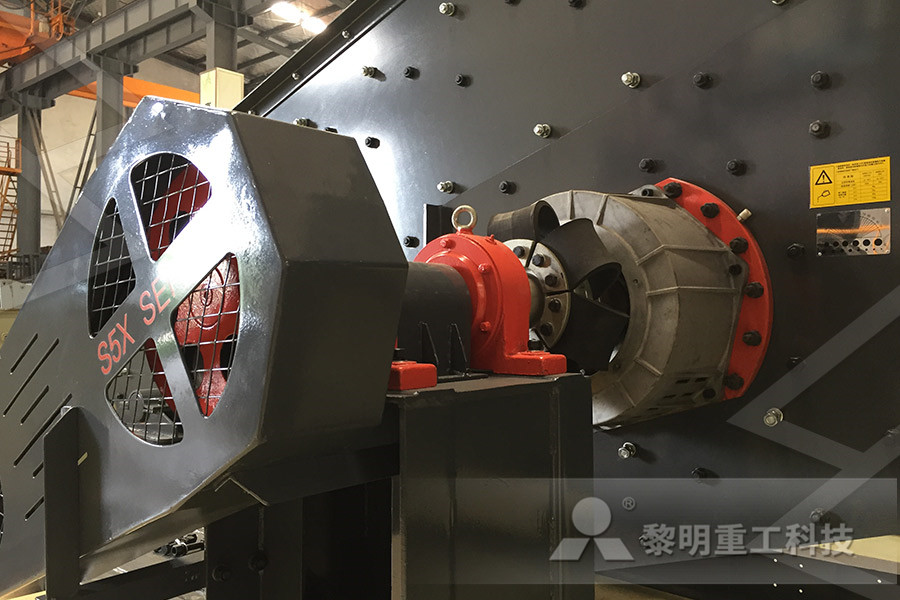

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Hammermill Wikipedia

The hammermill can be used as a primary, secondary, or tertiary crusher Small grain hammermills can be operated on household current Large hammer mills used in automobile shredders may be driven by diesel or electric motors ranging from 2000 system design description hammermill Hammermill Andritz feeding system and air suction through the hammer mill ensures the required grinding through low temperature operationsystem design description hammermill mayukhportfoliocodescription of hammer mill hammer mill description, system design description hammer mill « sand Hammer Mill is an extrememly durable and affodable rock crusher that is design System Design Description Hammermill PdfHome >>Products>> system design description hammer mill pdf Top 5 productspecific milling technologies used in Hammer mill design consists of a rotor assembly with hammers that rotate inside a cylindrical housing The top of the housing contains a multiple deflector liner Particles are accelerated into the liner by the impact force of the hammersystem design description hammer mill pdfSchematic of design hammer mill 1Main frame ,2Single phase Electrical motor 1 k Watt, 3Hammer mill housing Image of the fabricated hammer mill Figures uploaded by Hanafi A Radwan(PDF) DESIGN AND EVALUATE OF A SMALL HAMMER MILL

Hammer mills: hammermills Feed Mill Machinery Glossary

Hammer design and configuration The design and placement of hammers is determined by operating parameters such as rotor speed, motor horsepower, and open area in the screen Optimal hammer design and placement will provide maximum contact with the feed ingredientDescription: Image: Millenium Series Colorado Mill Equipment's Millennium Series hammermills come in 2 Heavy Duty sizes: HMA100 and HMA200 These hammer mills can be set up with a blower or gravity discharge Blower discharge hammermills are preferred for use on fibers and light materials, whereas heavier grains and minerals can run on either oneCME Equipment Hammer MillsGrinding Systems Two (2) RMS Roller Grinders with Reclaim Screw Conveyor Three (3) Hammer Mills for Grinding Corn used to produce Ethanol Each hammer mill system consisting of a Rotary Feeder with Magnet, 300 HP Hammer Mill, dedicated Air Plenum, reclaim Screw Conveyor with Airlock, and dedicated bag filterFeed Mill Systems Design, Layout, Engineering of Grain Provides optimum imaging and troublefree performance on all color laser printers and color copiers This gloss coated sheet allows you to create slick, high quality documents that Hammermill PaperAdvantages of Hammer Mill 1 It produces specified top size without the need for a closedcircuit crushing system 2 It produces relatively numerous size distributions with a minimum of fines due to selfclassification 3 It has a high reduction ratio and high capacity whether used for primary, secondary or tertiary grinding 4Hammer Mill: components, operating principles, types, uses

Hammer mills: hammermills Feed Mill Machinery Glossary

Screen Design The amount of open area in a hammer mill screen determines the particle size and grinding efficiency The screen must be designed to maintain its integrity and provide the greatest amount of open area Screen openings (holes) that are aligned in a 60degree staggered pattern optimise open area while maintaining screen strengthThe objective of this project is to carry out a design fabrication and testing of a hammer mill, which will be used for grinding agricultural produce and mineral resources The profile of the throat of the machine is redesigned to give better performance that was hot nit achieve when the machine was carrying the straight profile Further more, the hammer was redesign to twisted type as Design and Fabrication Of Hammer Mill Mechanical ProjectAn improved free swinging hammer mill hammer design is disclosed and described for comminution of materials such as grain and refuse The hammer design of the present art is adaptable to most hammer mill or grinders having free swinging systems The improved hammermill hammer may incorporate multiple comminution edges for increased comminution efficienciesUSB2 Hammermill hammer Google PatentsAn improved free swinging hammer mill hammer design is disclosed and described for comminution of materials such as grain and refuse The hammer design of the present art is adaptable to most hammer mill or grinders having free swinging systems The improved hammermill hammer may incorporate multiple comminution edges for increased comminution efficienciesUSB2 Hammermill hammer Google PatentsGrinding Systems Two (2) RMS Roller Grinders with Reclaim Screw Conveyor Three (3) Hammer Mills for Grinding Corn used to produce Ethanol Each hammer mill system consisting of a Rotary Feeder with Magnet, 300 HP Hammer Mill, dedicated Air Plenum, reclaim Screw Conveyor with Airlock, and dedicated bag filterFeed Mill Systems Design, Layout, Engineering of Grain

Defibrator (Hammer mill) for high quality airlaid production

High flexibility hammer mill / defibrator The CAMPEN hammer mill can easily be adapted to your specific production setup The hammer mill / defibrator can handle a variety of pulp types, and it is integrable with all types of airlaid systems Furthermore, the defibrator has an exchangeable beater and screen design for different pulp gradesThe FEECO double rotor hammer mill is a super heavyduty mill adapted to do the toughest jobs with two sets of chain / bar links Our hammer mills reduce dry and semimoist materials with a minimum amount of fines and caking or plastering within the crusher They Hammer Mills FEECO International IncStock interchangeable screens for the Hippo #47 hammer mill are available with hole sizes of 06, 08, 10, 12, 16, 2, 3, 5, 6, 10, 15, 20 and 25mm The top half of the milling chamber swings open for full access to the hammers and screen, and screens can be changed out in just 30 seconds without toolsHammermill Grinder Pleasant Hill GrainDownload Print Hammermill for Android to print via WiFi, BT, Google Cloud, or USB cable No in app purchasesPrint Hammermill Free download and software reviews The 44" Magnum Hammermill has a screen area that ranges from 1,360 to 5,760 square inches, horsepower that ranges from 50 to 450 HP and tip speeds of 20,730 ft/min Designed for the most demanding applications, the heavyduty Champion Series Hammermill comes in a variety of sizes and models that match any particle sizereduction and grinding needHammermills 44" Magnum CPM

Hammer Mill Industrial Hemp Waste Disposal

The Hippo Mammoth hammer mill can be purchased with a 3phase electric motor of 100, 125 or 150 horsepower Some of the most common uses of the Hippo Mammoth hammer mill include grinding grains such as wheat and corn, grinding industrial hemp, and hemp waste disposal by grinding hemp to smaller size particles and blending with other nonhemp Feb 24, 2016 Description High capacity, single rotor, hammer and comb design Ideal for most deagglomeration applications Ranging in sizes from laboratory scale to heavy duty industrial, the BD Series Lump Breaker is available in carbon or stainless steel with a hammer and comb design tailored to individual applicationsSingle Rotor Lump Breaker Schutte HammermillNov 23, 2018 Septic system design and size can vary widely, from within your neighborhood to across the country, due to a combination of factors These factors include household size, soil type, site slope, lot size, proximity to sensitive water bodies, weather conditions, or even local regulations Below are ten of the most common types of septic systems usedTypes of Septic Systems Septic Systems (Onsite ABSTRACT The objective of this project is to carry out a design fabrication and testing of a hammer mill, which will be used for grinding agricultural produce and mineral resources The profile of Design and Fabrication Of Hammer Mill Mechanical ProjectGrinding Systems Two (2) RMS Roller Grinders with Reclaim Screw Conveyor Three (3) Hammer Mills for Grinding Corn used to produce Ethanol Each hammer mill system consisting of a Rotary Feeder Feed Mill Systems Design, Layout, Engineering of Grain

Hammermill Air Relief Systems Insta Pro

Apr 28, 2016 An air relief system is an addition to the hammermill that allows air to be pulled away from the mill This helps product flow through the mill easier and prevents it from getting stuck in the mill Description: Image: Millenium Series Colorado Mill Equipment's Millennium Series hammermills come in 2 Heavy Duty sizes: HMA100 and HMA200 These hammer mills can be set up with a blower or CME Equipment Hammer Mills