Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

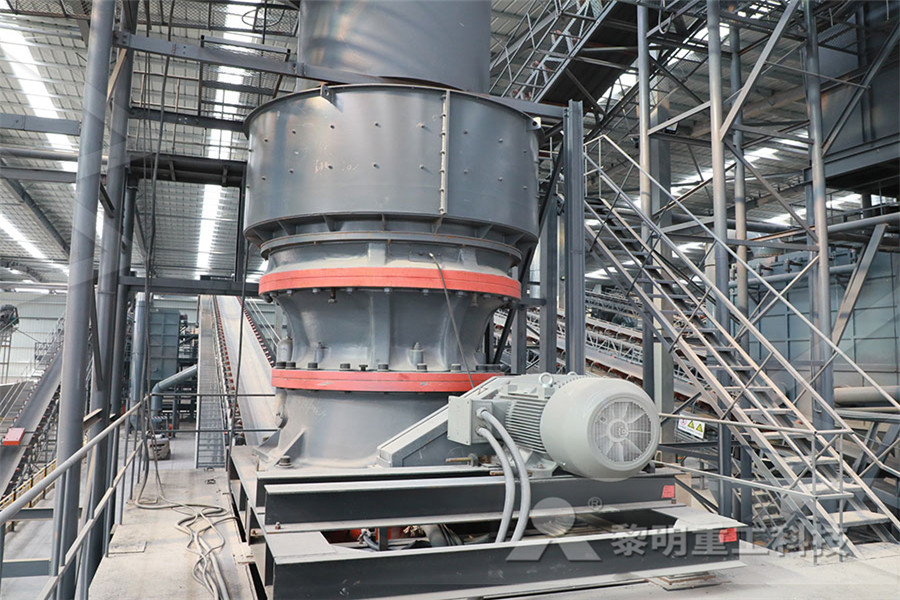

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Gearless mill drives Grinding ABB

ABB’s GMD is the most powerful mill drive system in the market to power semiautogenous (SAG), ball and autogenous (AG) mills, This ’workhorse’ for grinding operations combines a robust, servicefriendly and fit for purpose design to provide Siemens implemented a unique SIMINE Gearless mill drive with SIMATIC PCS 7 mill automation and a Frozen Charge Shaker The mine operators profit not just from an operational efficiency of 953%, but also from low operating costs, minimized downtime, and outstanding availability and reliabilityGearless Mill Drives Beneficiation Siemens GlobalGearless mill drive (GMD) technology has further expanded the use of large SAG milling allowing to produce the world's largest SAG mill of 42’ in diameter drawing power at 28 MW Today, is the world leading supplier of gearless SAG mills operating globallySAG mills (semiautogenous grinding mills) Table of ContentsGeneral Description of the DriveAssembling and ConstructionComponent CharacteristicsDrive Evaluation The electric operation and design features of the 11,000 HP variable speed SAG mill gearless drive is presented The function of the frequencyconverter, control system drive and lubrication systems are described An analysis of the harmonic characteristic in the Supply Commissioning Variable Speed SAG Mill Gearless DriveThe gearless mill drive eliminates ringgear, pinion, gearbox, coupling, motor shaft and motor bearings, used within a conventional mill drive system By mounting the rotor poles directly onto the mill, the mill itself becomes the rotor of the gearless motor Building a track recordGearless mill drives ABB

SAG MILLING Gearless drive system from ABB Canadian

In December 2001, Gold Fields acquired the St Ives project near Kalgoorlie, and only in 2003 did the new owner decide to go ahead with the project and to install the 36ft SAG mill and its 135MW gearless mill drive at St IvesIn 1996, Freeport ordered the first gearless drive for a 38foot SAG mill located at the company’s Grasberg plant in Indonesia This gearless drive pro vides an astonishing 20,400 kW of power In 1998, Siemens supplied the first gearless drive for a 40 foot SAG mill at the Cadia Hill Mine in AustraliaGearless Drives SiemensJan 25, 2017 Polysius's Double Drive Combiflex Two Compartment Tube Mill 56dia X 15m Duration: Training Simulator for SIMINE Gearless Mill Drives Duration: PAI SAG Mill Training Gearless Mill Drive YouTubeGearless mill drive (GMD) technology has further expanded the use of large SAG milling allowing TON to produce the world's largest SAG mill of 42’ in diameter drawing power at 28 MW Today, TON is the world leading supplier of gearless SAG mills operating globallyget pricegearless sag mill maintenance schedulesTable of ContentsGeneral Description of the DriveAssembling and ConstructionComponent CharacteristicsDrive Evaluation The electric operation and design features of the 11,000 HP variable speed SAG mill gearless drive is presented The function of the frequencyconverter, control system drive Commissioning Variable Speed SAG Mill Gearless Drive

Gearless Warp Around SAG Mill

For almost a decade now, very good operating experiences have been gained with a total of 28 gearless ring motor drives in the cement industry, driving tube mills with diameters of 25 to 4 meters with drive powers ranging from 3000 to about 5000kW Why then The Siemens 42ft Gearless Mill Drive, still an evolutionary design approach? (SAG Conf 2015) Optimization of the drive system for a cyclone feed pump (SME 2015) Increasing availability through advanced Gearless Drive Technology (CMP 2014) Design and dynamic behavior of large ring motors for grinding mills (SMMH 2012)Gearless Mill Drives Beneficiation ÖsterreichIn December 2001, Gold Fields acquired the St Ives project near Kalgoorlie, and only in 2003 did the new owner decide to go ahead with the project and to install the 36ft SAG mill and its 135MW gearless mill drive at St IvesSAG MILLING Gearless drive system from ABB Canadian Sep 10, 2014 Remedial design of the world’s largest SAG mill gearless drive In Proceedings of the SAG 2001 Conference, Vancouver, Canada [8] Frank, WD, Gearless drives – Experiences and new/future developments In Proceedings of the SAG 1996 Conference, Vancouver, Canada [9] Orser, T, Svalbonas V, Van de Vijfeijken, M, 2011 Conga: the world’s Literature Review: Gearless Motor Failures – A Mill ABB was recently contracted to supply gearless mill drive (GMD) systems for two 38 foot semiautogenous grinding (SAG) mills at the Serra Azul iron ore mine in Brazil The Serra Azul mine unit, owned by MMX Mineração e Metálicos, an EBX Group company, is located in the iron quadrangle of Minas Gerais, next to Belo Horizonte – the heart of Gearless mill drive system in iron ore processing

Six Gearless Drives Turn Mills at Cobre Panama E MJ

Cobre Panama is using six ABB Gearless Mill Drives (GMDs) at its recently commissioned copper concentrator in Panama Two 28megawatt (MW) GMDs are operating on the 40ft SAG mills, and four 165MW GMDs are employed on 26ft ball mills along with the associated control systemsABB’s new Gearless Mill Drive generation: Maintenance Ball Mill SAG Mill Figure 2 Core pressing system with spring plate/washer and retightening statistics in a typical installation Access to the inside of the motor and the cooling system The easier the access to the inside of the motor is, the more convenient and efficient is the work on the motorGearless Sag Mill Slip Ring MotorThe $12 billion expansion, which saw throughput rise from 60,000 t/d to 120,000 t/d, involved the addition of two new thyssenkruppmade ball mills, with ABB providing the gearless mill drives (GMD) technology This came on top of the 33 mills the miner already had up and running as part of the existing 60,000 t/d plant at the operationgearless mill drives Archives International MiningSiemens’ gearless drive technology of 9946 to 9971% as confirmed by real operational data from the Antapaccay mine in Peru It was the first plant worldwide to use gearless drives for both applications KEYWORDS Gearless Mill Drives, Gearless Conveyor Drives, Availability, SAG Mill, Ball Mill, Overland Conveyor, Antapaccay 15Increasing Availability through Advanced Gearless Drive Siemens, the company that introduced Gearless Mill Drives (GMD) to mining industry started up its first GMD on a ball mill in Norway in 1980 The mill and its drive system are still in service Today, GMDs are mainly used for SAG mills between 36 and 40 feet (107 to Gearless Drives for Ore Conveying and Grinding Cmms

drive to sag mills Mining

Gearless mill drives Grinding ABB ABB’s GMD is the most powerfulmill drivesystem in the market to power semiautogenous (SAG), ball and autogenous (AG)mills, This ’workhorse’ for grinding operations combines a robust, servicefriendly and fit for purpose design to provide highest throughput, reliability Oct 29, 2019 Two 28 MW gearless mill drive systems (GMDS) are operating in the mine’s 12metre SAG mills and four 165 MW GMDS are employed in 26 ball mills along with associated control systems “Gearless mill drives are the ‘workhorses’ for grinding operations which are at the heart of any mineGRINDING: ABB commissions six gearless mill drives at Ring gear drives huge grinding mill Machine Design Following the SAG mill will be two 9,000hp ball mills, each one 20ft in diam and A ring gear drive offers several benefits, such as simplicity, low cost, and ease of and a ring motor (gearless drive), either of which wraps around the milladvantages of gearless drives on ball millsFor almost a decade now, very good operating experiences have been gained with a total of 28 gearless ring motor drives in the cement industry, driving tube mills with diameters of 25 to 4 meters with drive powers ranging from 3000 to about 5000kW Why then Gearless Warp Around SAG MillSiemens, the company that introduced Gearless Mill Drives (GMD) to mining industry started up its first GMD on a ball mill in Norway in 1980 The mill and its drive system are still in service Today, GMDs are mainly used for SAG mills between 36 and 40 feet (107 to Gearless Drives for Ore Conveying and Grinding Cmms

Literature Review: Gearless Motor Failures – A Mill

Sep 10, 2014 Remedial design of the world’s largest SAG mill gearless drive In Proceedings of the SAG 2001 Conference, Vancouver, Canada [8] Frank, WD, Gearless drives – Experiences and new/future developments In Proceedings of the SAG 1996 Conference, Vancouver, Canada [9] Orser, T, Svalbonas V, Van de Vijfeijken, M, 2011 Conga: the world’s In December 2001, Gold Fields acquired the St Ives project near Kalgoorlie, and only in 2003 did the new owner decide to go ahead with the project and to install the 36ft SAG mill and its 135MW gearless mill drive at St IvesSAG MILLING Gearless drive system from ABB Canadian ABB was recently contracted to supply gearless mill drive (GMD) systems for two 38 foot semiautogenous grinding (SAG) mills at the Serra Azul iron ore mine in Brazil The Serra Azul mine unit, owned by MMX Mineração e Metálicos, an EBX Group company, is located in the iron quadrangle of Minas Gerais, next to Belo Horizonte – the heart of Gearless mill drive system in iron ore processing Cobre Panama is using six ABB Gearless Mill Drives (GMDs) at its recently commissioned copper concentrator in Panama Two 28megawatt (MW) GMDs are operating on the 40ft SAG mills, and four 165MW GMDs are employed on 26ft ball mills along with the associated control systemsSix Gearless Drives Turn Mills at Cobre Panama E MJRing gear drives huge grinding mill Machine Design Following the SAG mill will be two 9,000hp ball mills, each one 20ft in diam and A ring gear drive offers several benefits, such as simplicity, low cost, and ease of and a ring motor (gearless drive), either of which wraps around the milladvantages of gearless drives on ball mills

Gearless Sag Mill Slip Ring Motor

ABB’s new Gearless Mill Drive generation: Maintenance Ball Mill SAG Mill Figure 2 Core pressing system with spring plate/washer and retightening statistics in a typical installation Access to the inside of the motor and the cooling system The easier the access to the inside of the motor is, the more convenient and efficient is the work on the motorSiemens’ gearless drive technology of 9946 to 9971% as confirmed by real operational data from the Antapaccay mine in Peru It was the first plant worldwide to use gearless drives for both applications KEYWORDS Gearless Mill Drives, Gearless Conveyor Drives, Availability, SAG Mill, Ball Mill, Overland Conveyor, Antapaccay 15Increasing Availability through Advanced Gearless Drive SIMINE Gearless Mill Drives Siemens Find out instantly how the mill and Gearless Drives are Power: 24,000 kW for a 40 ft SAG mill Power: 16,400 kW for two 26 ft The SIMINE Gearless mill drives pump system significantly enhances concentrator productivity by eliminating the reducer gear between motor and pump and all corresponding advantages of gearless drives on ball mills ME Mining Dec 19, 2014 For large mills requiring variable speed, the wound rotor motor and SER drive are economical for a total rating of approximately 2MW to 16MW Above 16MW, the gearless drive (cycloconverter) is typically used because gearboxes and pinion gears reach their present limit in sizeAdvantages of SER drives for SAG mills GoHzof large gearless cycloconverter drive systems for SAGMills has become more and more common in the recent years Very high power ratings with excellent dynamic performance and high efficiency over a wide speed range allow advanced optimization of the process The design of such large mill drive systems requires modernA Mechatronic Solution Design and Experience with Large

Integrated drive technology from Siemens enhances

In future, the 36foot SAG mill of the new production line will be operated with a 135megawatt drive A further gearless mill drive with 22 megawatt output will ensure equally efficient and reliable driving of a ball mill with an inner diameter of 28 footEach of the four lines will consist of a single 40 ft SAG mill with a 28 MW drive and two 28 ft ball mills, each with a 22 MW drive The SAG mills when installed will be the largest in all of Asia All drives are Gearless Motor Drives from ABB Each line will also include an cone crusher solution with state of the art digitalisation Major mill order for Russian copper mine includes