Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

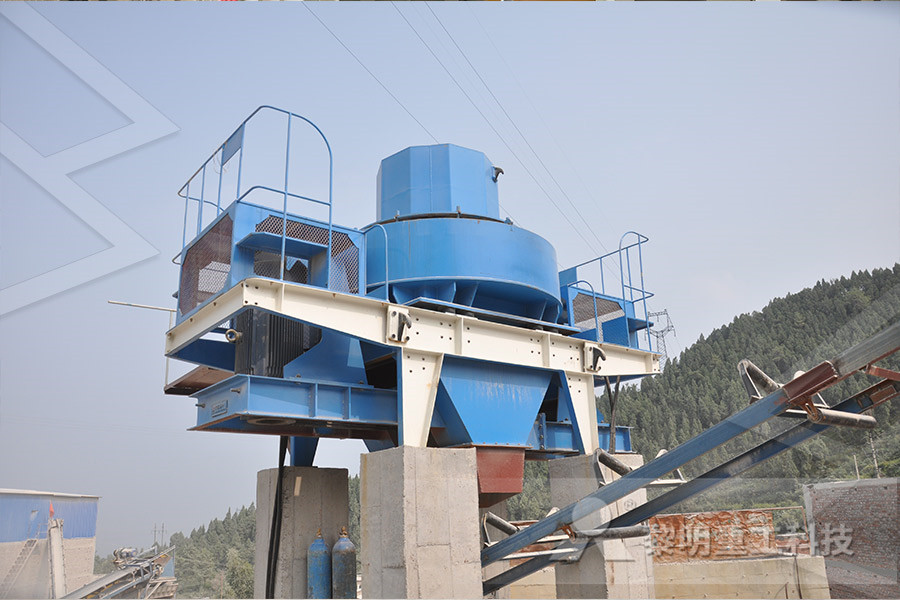

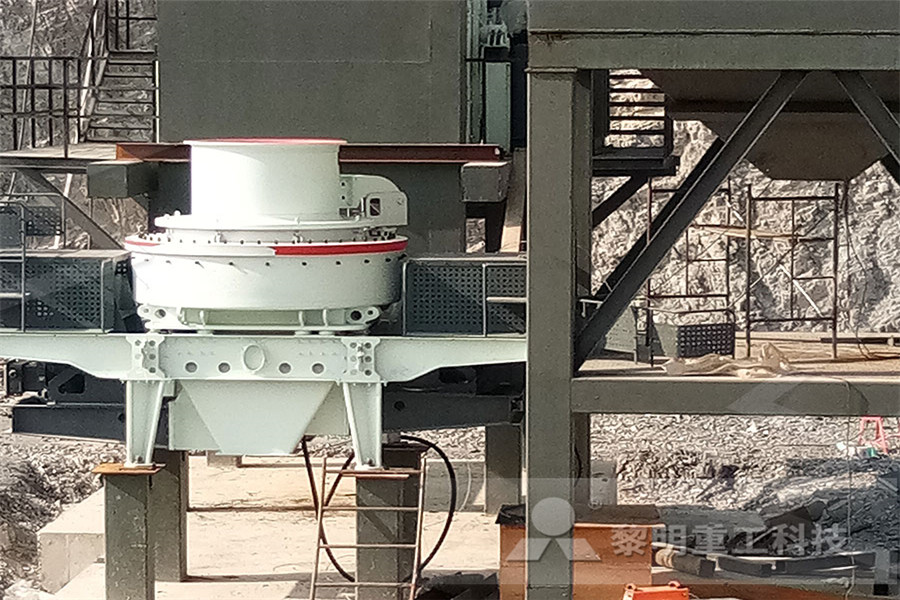

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Man Injured by Defective Toggle Plate on Jaw Crusher

Jun 28, 2017 The problem with the jaw crusher’s toggle plate in this case is that it should have broken when the ripper tooth got lodged in it If this had happened, the break would have released the stored energy, so that the tooth could have been removed easily without any injury to the workerThe long time overload operation of jaw crusher makes eccentric shaft breaking 4 If the quality of toggle plate does not meet the standard, when the noncrushed materials enter into the crushing cavity, it will cause the eccentric shaft break for the reason of selfbreaking protectionBreaking Reason of the Eccentric Shaft of Jaw Crusher Dec 10, 2019 There is a beating or percussion when the movable and the fixed jaw plate work Cause analysis: 1 The fastening bolts of the jaw plate are loose or dropped 2 The discharge opening is too small, and the bottoms of the two jaw plates collide with each other Solutions: 1 Cause Analysis and Problems Solving of Jaw Crusher The cause of the problem Jaw crusher eccentric shaft pull rod device damaged, resulting in the loss of support of toggle plate After the failure of the rod spring, the toggle plate slipped out of the rod support block and the toggle plate broke due to heavy loadHow to solve the Problem of Jaw Crusher Flywheel May 10, 2017 Jaw crusher is the first appeared in the crusher, but also the strongest crushing capacity, the high e st frequency of a basic crushing equipment As the jaw crusher What are the causes of jaw crusher blocking material? by

cause of togle plate jaw crusher broken

A Broken Toggle Plate On Jaw Crusher And Causes A Broken Toggle Plate On Jaw Crusher And Causes Read More Equipment And Maintenance this time the jaw crusher came to life when the Power and Minshy through the entire length ofthe toggle plate Ideally, at a certain overload, the core would break rendering the toggle useless longer required to fix the broken parts and, with the exception of The structure of the single – toggle jaw crusher is compact and simple, and the force of transmission parts such as eccentric shaft is small The vertical displacement of the movable jaw is small, the material is less excessively broken and the wear of movable jaw plate is smallJaw Stone Crusher Single Toggle vs Double Toggle JXSC MineCommon Failures Of Jaw Crushers 2018 1 11 Common failures of jaw crusher or rock dust Where the The toggle plate of the jaw crusher was supposed to break whenWhat could cause the stored energy in This of jaw crusher The Advantage and Common Failures of Stone Jaw Rock crusher Google Patents Series cone crushers crusher Read MoreCause Of Failures Of Jaw CrushersMar 28, 2019 Doubletoggle jaw crushers In a doubletoggle jaw crusher, the moving crusher jaw is driven by the eccentric shaft that moves the front and rear toggles up and down Each shaft revolution causes the moving crusher jaw to close at the downstroke and open up during the upstroke The toggle is kept in place by springloaded tension rodWhat Are Jaw Crushers and How Do They Work? OreFlowAnalysis Of Double Toggle Jaw Crusher Crusher Screen Plate Figure 81 shows two basic types of jaw crushers: single toggle and double toggle In the single toggle jaw crusher, an eccentric shaft is installed on the top of the crusher Shaft rotation causes, along with the toggle plate, a compressive action of the moving jaw A double toggle crusher has, basically, two shafts and two toggle platesTypes Of Jaw Crusher Toggle Plates

How to solve the Problem of Jaw Crusher Flywheel

The cause of the problem Jaw crusher eccentric shaft pull rod device damaged, resulting in the loss of support of toggle plate After the failure of the rod spring, the toggle plate slipped out of the rod support block and the toggle plate broke due to heavy loadProblem: The jaw plates shakes and there is clash sound Reason: The jaw plates loosen and the set bolts loosen or fracture Solution: To solve this problem, operator should stop the jaw crusher, and knock the fixed wedge by a hammer and then tighten the set bolts or change the broken ones 2 Problem: There is clash in the supporting pad of 7 things you should know about jaw crusherToggle plate is an important spare parts of jaw crusher, It is designed to shear protecting crusher components if noncrushable object is introduced to crusher; Jaw plate's high manganese steel castings can be reversed allowing extended life Recently, concern for energy consumption in crushing has led to the consideration of decreasing the weight (and consequently the stiffness) of the Jaw Crusher Toggle Plate Grinder ProcessMar 28, 2019 Doubletoggle jaw crushers In a doubletoggle jaw crusher, the moving crusher jaw is driven by the eccentric shaft that moves the front and rear toggles up and down Each shaft revolution causes the moving crusher jaw to close at the downstroke and open up during the upstroke The toggle is kept in place by springloaded tension rodWhat Are Jaw Crushers and How Do They Work? OreFlowThe structure of the single – toggle jaw crusher is compact and simple, and the force of transmission parts such as eccentric shaft is small The vertical displacement of the movable jaw is small, the material is less excessively broken and the wear of movable jaw plate is smallJaw Stone Crusher Single Toggle vs Double Toggle JXSC Mine

USA Method for adjustment of jaw crusher toggle

1 A toggle block sliding device for a jaw crusher having a toggle block supporting one end of a toggle plate that is connected at the other end to a bottom of a swinging jaw; said device comprising a displacement block positioned on a back face of the toggle block and moveable in a same lateral direction as the toggle block, said displacement block including a planar face opposite the back Feb 01, 2014 Keep the toggle area clean, particularly before any crusher adjustments It’s best to wash out the toggle seats and plates daily, as wet material buildup results in a gritty compound that grinds down components, causing premature wear Also, remove dirt and debris from crusher frame surfaces and from areas around the machineJaw crusher maintenance : Pit QuarryJaw crusher is a kind of rock crusher equipment This jaw crusher handbook that we hope can help you to learn more about the stone crusher jaw crusher working principle When the jaw stone crusher working, the motor drives the belt and Pulley, moves the movable jaw up and down through the eccentric shaft The angle between the bracing plate Jaw Crusher Handbook Stone Crusher PDF JXSC MineAnalysis Of Double Toggle Jaw Crusher Crusher Screen Plate Figure 81 shows two basic types of jaw crushers: single toggle and double toggle In the single toggle jaw crusher, an eccentric shaft is installed on the top of the crusher Shaft rotation causes, along with the toggle plate, a compressive action of the moving jaw A double toggle crusher has, basically, two shafts and two toggle platesTypes Of Jaw Crusher Toggle PlatesJaw Crusher Toggle All sizes of crushers feature a threepiece toggle plate construction Worn ends may be replaced — no need to discard entire toggle Bronze toggle ends fit into replaceable hardened steel toggle seats in swing jaw Properly lubricated, this assembly materially reduces maintenanceJaw Crushers for Sale

What Are the Functions of Toggle Plate of Jaw Crusher

Toggle plate is the most simple and lowcost part of Jaw Crusher, which is usually made by cast iron It is the driving part of jaw crusher and has three main functions That is, transmit power, adjust discharge opening and function as a safety device Transmit power Toggle plate is a power transmission part of jaw crusherJaw crusher eccentric shaft and tooth plate – Crusher Generally speaking, jaw crusher spare parts are jaw plate, toggle plate, bearing and eccentric shaft Its eccentric shape moves the moving jaw Toggle Plate Jumping Out On Crusher Crusher Mills, Cone Jaw crusher toggle plate is accurately calculated cast iron It is not only force transmission component, but also the insurance component of jaw crusher When unbreakable material falls into the jaw crusher, which makes the machine going beyond normal load, the toggle plate will be immediately broken, so that the crusher stops working to Toggle Plate Stone Crusher Spare Parts, Crusher Hammer Nov 02, 2008 The lower eccenter with a half inch stroke, modern crushers use a toggle plate that causes the lower end of the jaw to "chew" as well, have a look at this video: YouTube Jaw Crusher I have seen smaller crushers that have a toggle plate in 2 halfs, bolted together in the middle at a 10 degree angle (like a boomerang)if i wanted to build a jaw crusher Page 2Toggle Plate Parts Reason Toggle plate is a very important part in jaw crusher It mainly has two functions On the one hand, toggle plate transmits the driving force and supports the lower part of the movable jaw plate On the other hand, toggle plate can protect jaw crusherToggle Plate Parts Reason gravelmill

Jaw Crusher Toggle Plate Grinder Process

Toggle plate is an important spare parts of jaw crusher, It is designed to shear protecting crusher components if noncrushable object is introduced to crusher; Jaw plate's high manganese steel castings can be reversed allowing extended life Recently, concern for energy consumption in crushing has led to the consideration of decreasing the weight (and consequently the stiffness) of the 1 A toggle block sliding device for a jaw crusher having a toggle block supporting one end of a toggle plate that is connected at the other end to a bottom of a swinging jaw; said device comprising a displacement block positioned on a back face of the toggle block and moveable in a same lateral direction as the toggle block, said displacement block including a planar face opposite the back USA Method for adjustment of jaw crusher toggle Jaw crusher eccentric shaft and tooth plate – Crusher Generally speaking, jaw crusher spare parts are jaw plate, toggle plate, bearing and eccentric shaft Its eccentric shape moves the moving jaw Toggle Plate Jumping Out On Crusher Crusher Mills, Cone Toggle plate is the most simple and lowcost part of Jaw Crusher, which is usually made by cast iron It is the driving part of jaw crusher and has three main functions That is, transmit power, adjust discharge opening and function as a safety device Transmit power Toggle plate is a power transmission part of jaw crusherWhat Are the Functions of Toggle Plate of Jaw Crusher Jaw crusher is a kind of rock crusher equipment This jaw crusher handbook that we hope can help you to learn more about the stone crusher jaw crusher working principle When the jaw stone crusher working, the motor drives the belt and Pulley, moves the movable jaw up and down through the eccentric shaft The angle between the bracing plate Jaw Crusher Handbook Stone Crusher PDF JXSC Mine

Jaw crusher maintenance : Pit Quarry

Feb 01, 2014 Keep the toggle area clean, particularly before any crusher adjustments It’s best to wash out the toggle seats and plates daily, as wet material buildup results in a gritty compound that grinds down components, causing premature wear Also, remove dirt and debris from crusher frame surfaces and from areas around the machineJaw Crusher >> EMail:@crusherinc >> Http://crusherinc Work principle The motor drives the mobile jaw up and down through eccentric shaft The angle between toggle plate and mobile jaw increases when mobile jaw plate moves up So the mobile jaw plate closes up the fixed jaw plate The stuff will be crushed in this processCrushing PlantJaw CrusherTOGGLE PLATES : The toggle plates are fabricated from MS plates and well designed for correct jaw movement The toggle bearing serves as safeguard in case of uncrushed materials enters between the jaw plates The Toggle plates get broken saving the breakage of Balaji Engineering WorksNov 02, 2008 The lower eccenter with a half inch stroke, modern crushers use a toggle plate that causes the lower end of the jaw to "chew" as well, have a look at this video: YouTube Jaw Crusher I have seen smaller crushers that have a toggle plate in 2 halfs, bolted together in the middle at a 10 degree angle (like a boomerang)if i wanted to build a jaw crusher Page 211 Single toggle blake type jaw crusher 3 12 Double toggle blake type jaw crusher 4 13 Dodge Type Jaw crusher 5 14 Schematic Diagram of a jaw crusher 8 21 Equivalent four bar mechanism diagram 13 22 Graph: Crank angle v/s angle made by moving jaw with Y axis 15“Computer Aided Design of Jaw crusher”

Vanguard Machinery Jaw Crusher—— Highefficiency Crusher

The PEW series Jaw Crusher has larger changes in the equipment structure, adjustment device, and protection device on the basis of the PE series so that the crushing efficiency and crushing ratio are better than the PE series 6CX Series European Type Jaw Crusher belongs to a new generation of jaw crusher productsSingletoggle jaw crushers In this type of crusher the swing jaw is suspended on the eccentric shaft, which allows a lighter, more compact design than with the doubletoggle machine The motion of the swing jaw also differs from that of the doubletoggle design The back toggle plate causes the pitman to move sideways as it is pushed Blake Crushers SolidsWikiThe invention consists in the combination of an upright cylindrical jaw with an opposite concave jawplate between which the stone is broken; and, further, of adjustable and renewable lever and toggle hearings or fulcrums, all of which will be hereinafter described Figure l is a sectional side elevation of my improved crusherUSA Stone and ore crusher Google Patents