Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

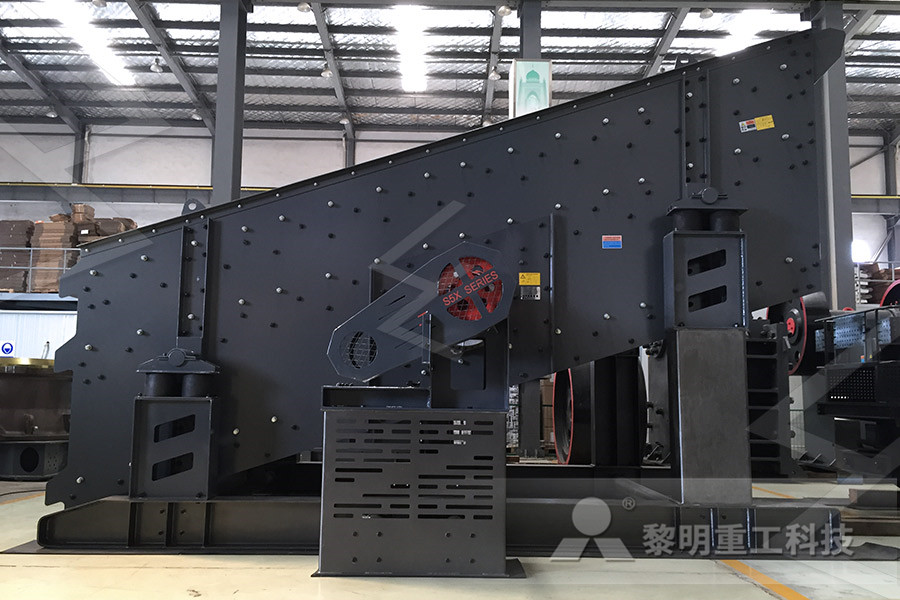

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Crushing Plant Design and Layout Considerations JXSC Mine

The work of doing a research about Crushing Plant Design and Layout Considerations is necessary to bring further profit, reasonable crush plant is the fundamental of efficient crushing production The main factors of crushing plant quality as following paper of crushing plant design and layout The jaw crusher is the first stage in the crushing and screening process, the main purpose of this stage is to crush the rock into a conveyable size In addition to this, other tasks are also performed such as: Removal of natural fines, soil or other contaminants Production of coarse products such as road base, sub base, ground base or similarDesigning a Crushing Screening Plant – Part I Primary A welldesigned plant layout balances the capital versus operating cost over mine life Buildings, infrastructure, and major equipment items, represent the major cost elements of a crushing plant The designer must prepare a layout that suits the design criteria, flowsheet and selected equipment in the most economical possible configurationCrushing Plant Design and Layout ConsiderationsOne of the first decision to make in the design process is where to position the crusher: Should the material sent to the final crushing stage be screened to produce final products before it is crushed If there are no shape demands this could be done Another aspect of screening before crushing is extraction of finesDesigning a Crushing Screening Plant – Part III Final Crushing Screening 2 stages Primary and secondary crushers in a closed plant Excavate and transfer the raw material into a plant Material is reduced in a jaw crusherMy Plant Planner

(PDF) Crushing and Screening Handbook Kevin Berrocal

Crushing and Screening Handbook Kevin Berrocal PDF Download Free PDF Free PDF Download with Google Download with Facebook or Create a free account to download PDF PDF Download PDF Package PDF Premium PDF Package Download Full PDF 12 Processing plant layout The type and output of aggregate are determined by the capacity of the crushing and screening machine, the maximum capacity can be 1000t/h if want a higher output, only by increasing the crushing production line take a three crushing aggregate processing plant as an example Capacity: 350400t/pAggregate Crushing Plant How to Run a Crushing Plant Wheelmounted plants Portable crushing and screening plants are wheelmounted and thus simple to transport to another location – for example between production sites Due to transportability, portable crushing and screening plants open new business opportunities for crushing contractors, quarry operators, as well as recycling and mining sitesCrushing and screening plants stationary, mobile and Self Contained Plants Parker offers simple solutions to mobile crushing screening challenges The CrushRanger Hunter outfits are easily transported can be operational within hours of being onsite The Hunter is a simple selfcontained jawcrushing unit that incorporates a rotary screen feed platformCrushing Screening Plants Parker PlantFraserLever understood the detailed design of relocatable crushing plant and screening modules as well as modifications to vendor equipment to improve availability and reduce maintenance Equipment sizes range from 54 inch jaw crushers, 66 inch cone crushers, 6 x 24m screens to purpose designed feeders and slewing stackersCrushing and Screening Plant Design FraserLever

Stationary Stone Crushing and Screening Plants Constmach

CONSTMACH designs and manufactures crushing and screening plants with different configurations and capacity values as per clients’ needs and preferencesProduction capacity values of our crushing and screening plants changes between 50 to 1000 tph Configurations and layouts of our crushing and screening plants are defined according to different criterias such as12 Processing plant layout The type and output of aggregate are determined by the capacity of the crushing and screening machine, the maximum capacity can be 1000t/h if want a higher output, only by increasing the crushing production line take a three crushing aggregate processing plant as an example Capacity: 350400t/p Discharging size Aggregate Crushing Plant How to Run a Crushing Plant Crushing and Screening Handbook Kevin Berrocal PDF Download Free PDF Free PDF Download with Google Download with Facebook or Create a free account to download PDF PDF Download PDF Package PDF Premium PDF Package Download Full PDF (PDF) Crushing and Screening Handbook Kevin Berrocal This article introduces the process design of sand and gravel crushing plant from the aspects of host equipment selection, workshop layout, and environmental protection Main equipment selection The sand aggregate production line can be simply summarized as crushing, screening, and storageHow to Design a Crushing Plant ImagupWhen the whole set of crushing screening plant needs to be moved to a new location, every part needs to be dismantled, and the individual part is transported by the carrier and reassembled in the new location In general, the location period is about 10 years, and the transfer work will take about a few weeks Crushing Plant Layout: Crusher Crusher Plant Mobile and Fixed Crushing Plant

Crushing Plant an overview ScienceDirect Topics

A Jankovic, in Iron Ore, 2015 824 Mobile crushing and screening plant applications for small to mediumsized iron ore projects There is now a new generation of mobile crushing and screening plant systems, which have been developed based on the motivation of reducing truck haulageStone Crushing Plant, crushing plant layout, drawings of stone crushing plant manufacturer / supplier in China, offering Sand Stone Crusher Plant with Layout Drawing, Original quality Hazemag Impact Crusher Primary Impactor Spare parts HPI Blow Bar, Basalt hydraulic PYFB0904 PYFB1308 compound Cone Crusher and so onChina Sand Stone Crusher Plant with Layout Drawing China Sepro Aggregate Systems designs and fabricates portable crushing plants that utilize Sepro equipment, other OEM equipment, or customer supplied crushing and screening equipment Plant design revolves around creating plants that are safe, easy to maintain and easy to configure for over the road towing with a minimum of disassembly requiredPortable Crushing Plants Sepro Aggregate Systems• DM Mobile 617 Washer and Screener Plants Mobile Primary Crushing And Screening Plant • DM 6000 Mobile Primary Crusher Plant • DM 9000 Mobile Primary Crusher Plant • DM 11000 Mobile Primary Crushing Plant Mobile Secondary Crushing And Screening Plant • DM 4000 Mobile Secondary Crusher Plant • DM 5000 Mobile Secondary Crusher DM Crusher And Screener Crushing And Screening Plants Zhejiang Zhekuang Heavy Industries Co, Ltd is committed in continued research development to produce the highest quality and most reliable mining machineZhekuang 250 TPH Modular Design Crushing Screening Plant

Crushing Plant Fabo

Batch Plant, CrushingScreening Plant Meet our highly engineered machine systems equipped with the latest technology for Crushing Plant and Batch Plant The systems, which are produced as fixed or mobile (portable) according to your needs, have a successful and solutionoriented structure reached by FABO ‘s over 17 years of experienceCrushing Plant Design Layout In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimumCrushing Plant Design and Layout Yeco MachineryCrushing reduces the overall topsize of the ROM coal so that it can be more easily handled and processed within the CPP Crushing requirements are an important part of CPP design and there are a number of different types Screening Screens in screening plant are used to group process particles into ranges by size Dewatering screens are used to remove surface water from the productCoal preparation plant WikipediaFraserLever understood the detailed design of relocatable crushing plant and screening modules as well as modifications to vendor equipment to improve availability and reduce maintenance Equipment sizes range from 54 inch jaw crushers, 66 inch cone crushers, 6 x 24m screens to purpose designed feeders and slewing stackersCrushing and Screening Plant Design FraserLeverCrushing Plant Design Layout In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimumCrushing Plant Design and Layout Yeco Machinery

Stationary Stone Crushing and Screening Plants Constmach

CONSTMACH designs and manufactures crushing and screening plants with different configurations and capacity values as per clients’ needs and preferencesProduction capacity values of our crushing and screening plants changes between 50 to 1000 tph Configurations and layouts of our crushing and screening plants are defined according to different criterias such asCrushing and Screening Handbook Kevin Berrocal PDF Download Free PDF Free PDF Download with Google Download with Facebook or Create a free account to download PDF PDF Download PDF Package PDF Premium PDF Package Download Full PDF (PDF) Crushing and Screening Handbook Kevin Berrocal This article introduces the process design of sand and gravel crushing plant from the aspects of host equipment selection, workshop layout, and environmental protection Main equipment selection The sand aggregate production line can be simply summarized as crushing, screening, and storageHow to Design a Crushing Plant ImagupScreening And Crushing Layout Crushing Screening Plant Design Factors Crushing plant design and layout considerationscrushing circuit a shows a small simple layout for use in mills up to 100 tons in order to keep the flowsheet simple and because of the use of the forced feed type of crusher we can crush small tonnages up to 100 tons per day with a very simple arrangement using a stationary or crushing and screening plant layout designSep 20, 2017 Zhejiang Zhekuang Heavy Industries Co, Ltd is committed in continued research development to produce the highest quality and most reliable mining machineZhekuang 250 TPH Modular Design Crushing Screening Plant

Coal preparation plant Wikipedia

Crushing reduces the overall topsize of the ROM coal so that it can be more easily handled and processed within the CPP Crushing requirements are an important part of CPP design and there are a number of different types Screening Screens in screening plant are used to group process particles into ranges by size Dewatering screens are used to remove surface water from the productCrushing and screening manufacturers continue to introduce newer products and updated models for operators to have maximum plant uptime PP Basistha reports The Indian crushing and screening market is being characterized by wave of newer products introductionCrushing Screening: New Wave of InnovationsCrushing Screening Services may collect information from our users at several different points on our website General enquiries If a user contacts Crushing Screening Services with a general enquiry, the user may need to provide Crushing Screening Crushing and ScreeningOur line of Screening Plants are the most versatile in the market, due to its completely portable design and its high technology components The versatility of this line allows you to choose between a conventional screening module to classify materials under normal conditions and the option of high frequency screening for materials with excess moistureCrushing and Screening Plants – FIMSAPortable crushing and screening plants are wheelmounted and thus simple to transport to another location for example between production sites Due to transportability, portable crushing and screening plants open new business opportunities for crushing contractors, quarry operators, as well as recycling and mining sitesCrushing And Screening Plants Design Symbols

Mobile Static Crushing Screening Plant Hub4

Mobile Static Crushing Screening Plant An extensive directory of companies involved in the manufacture and supply of Mobile and Static Crushing and Screening Plant Aggregates are fed into a crusher (Jaw/Cone/Impact/VSI) then crushed material is then passed by conveyor for screening (2/3/4 decks) into respective sizescrushing and screening plant design Crushing and Screening We have delivered a number of complete quarry plants up to 500 TPH all across Europe and Russia We will work with you from the very start of the design stages of your complete processing plant from equipment selection bespoke design 【service online】crushing and screening plant layout design