Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

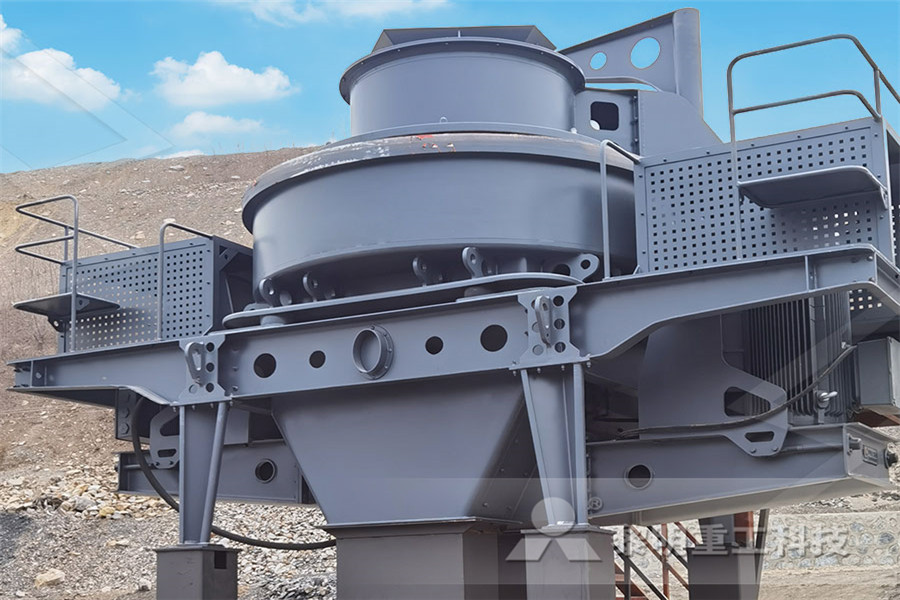

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Spiral Concentrator High Performance Gravity Concentration

DOVE Spiral Concentrators are costeffective, high performance gravity concentration separators used for separation and recovery of a wide range of minerals: zircon, ilmenite, rutile, iron ore, chromite, manganese, tin, tantalum and tungsten ore, silica sands, gold, copper and base metals and etc, as well as other nonferrous metals, rare metals and nonmetallic mineralsFor good separation, the density difference between the heavy minerals and the light minerals in the feedstock should be at least 1 g/cm 3; and because the separation is dependent upon size and density, spiral separators are most effective at purifying ore if its particles are of uniform size and shapeSpiral separator WikipediaThe spiral chute mainly uses the inertial centrifugal force generated by the minerals of different densities in the spiral rotation to achieve the separation of light and heavy minerals Because of its simple equipment structure, low power consumption, and large processing capacity, it is widely used in the gravity separation processSpiral Separators Mineral ProcessingMineral Iron Ore Concentrator Mineral Iron Ore Concentr Iron ore spiral concentrator for mineral processing multotecdesigned spiral concentrators are used across the world in coal gold iron ore mineral sands platinum and chrome processing plants and other minerals as a turnkey supplier of gravity concentration equipment across the world multotec can deliver endtoend spiral solutions from spiral separation machine for black ore processing plantThe fine mineral spiral series is used for fine feed with particles in the range of 30150 microns: WW Series: Utilises wash water addition for enhanced grade control in specific applications (ie iron ore, mineral sand) HC Series: These superhigh capacity spirals have been designed specifically for more economical and compact high tonnage Gravity Separation Mineral Technologies

Mineral processing Wikipedia

Gravity separation is one of the oldest technique in mineral processing but has seen a decline in its use since the introduction of methods like flotation, classification, magnetic separation and leaching Gravity separation dates back to at least 3000 BC when Egyptians used the technique for separation of goldmethod of mineral separation; it was used 2,000 y ears before Gravity separation is one of the efficient m ethods of separating minerals from barren rock s by using the difference in densities(PDF) GRAVITY SEPARATION IN ORE DRESSINGSpiral Chute For Ore Processing Line China Mineral Gravity Processing Machine Spiral Spiral Chute Application: Spiral Chute is suitable for the separation of 03002 mm fine iron ore, ilmenite, chromite, pyrite, zircon, rutile, monazite, phosphorite B, tungsten ore, tin ore, tantalum ore, niobium Sudan Barite Spiral Chute Mineral ProcessingThe spiral chute mainly uses the inertial centrifugal force generated by the minerals of different densities in the spiral rotation to achieve the separation of light and heavy minerals Because of its simple equipment structure, low power consumption, and large processing capacity, it is widely used in the gravity separation processSpiral Separators Mineral ProcessingCoal Spiral Separator is used for treating low grade ore, where large tonnages are processed such as Rutile, Ilmenite, Zircon and Garnet With seven turn units, the Coal Spiral Separator features splitter configuration designed for each application Also, it comes with concentrate diverter in order to obtain the highest concentrate product gradeMINERAL SPIRAL SEPARATOR Iron Ore Spiral Separator

Spiral classifier for mineral separation LZZG

The mineral separation spiral classifier is used in the dressing plant to match with the ball mill to distribute the ore sand, or in the gravity dressing plant to classify the ore and mud The particle size classification of the slurry in the metal beneficiation process and the desilting and dewatering of the washing Wait for homeworkHere is mainly introduce common types of spiral classifier used in mineral processing according to two aspects The height of overflow weir The number of screw shift Let's dive right in! In mineral processing, the ores need to be grinded into a certain size that the finegrained useful minerals and gangue minerals achieve full mon Types of Spiral Classifier Used in the Mineral Mineral Iron Ore Concentrator Mineral Iron Ore Concentr Iron ore spiral concentrator for mineral processing multotecdesigned spiral concentrators are used across the world in coal gold iron ore mineral sands platinum and chrome processing plants and other minerals as a turnkey supplier of gravity concentration equipment across the world multotec can deliver endtoend spiral solutions from spiral separation machine for black ore processing plantIn Mineral Processing, the SPIRAL Classifier on the other hand is rotated through the ore It doesn’t lift out of the slurry but is revolved through it The direction of rotation causes the slurry to be pulled up the inclined bed of the classifier in much the same manner as the rakes do As it is revolved in the slurry the spiral is constantly moving the coarse backwards the fine material Spiral Classifier for Mineral ProcessingUse Of Spiral Concentrator For Ore Benefication principle of operation of spiral for chrome ore benefication principle of spiral in chrome ore benefication principle of spiral in chrome ore benefication The ore beneficiation plant mainly includes magnetic separation plantcrusherjaw tertiary crusherball millspiral classifiermagneticThere is a theory that if the weights ofUse Of Spiral Concentrator For Ore Benefication

(PDF) Effects of operational parameters of spiral

Spiral separator is widely used in mineral processing operation for concentrating different minerals and coal The popularity of spiral separator is due to its simplicity, low operating cost and method of mineral separation; it was used 2,000 y ears before Gravity separation is one of the efficient m ethods of separating minerals from barren rock s by using the difference in densities(PDF) GRAVITY SEPARATION IN ORE DRESSINGMetallurgical ContentOptimum Operating Conditions of a Spiral ConcentratorThe Spiral’ Static DistributorThe Primary Spirals SeparatorThe Cleaner Spiral SeparatorMaintenance of the SpiralsHumphreys Spiral ConcentratorWhen to use a Gravity Spiral ConcentratorHumphreys Spiral Concentrator CapacitySpiral Concentrator The gravity spiral circuit is designed to extract and Gravity Spiral Concentrator Working PrincipleMineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other important operations Mineral processing metallurgy BritannicaThe Single Spiral Classifier is widely used to pregrading and inspection grading in closed circuits when used in the production flow of metal processing According to the difference in sedimentation rate of mineral particles and mud, the particle sizes of ores with 15mm003mm are classifiedOre Separation Spiral Classifier for Mineral Processing

Gravity Spiral Chute Used For Mineral Seperator Processing

Heavy Mineral Equipment Washing Plant Spiral Chute Gravity Separation Equipment Spiral chute is suitable for treatment of 0 6 0 03mm lode and placer but high mud content is bad for separation At present spiral chute has been widely used in the treatment of iron ore tungsten tin ore niobium tantalum ore Read MoreSpiral chute is suitable for the treatment of 06003mm lode and placer, but high mud content is bad for separation At present, spiral chute has been widely used in the treatment of iron ore, tungsten, tin ore, niobium tantalum ore, coastal and riverside placer and gold oreLL Series Spiral Chute Used In Gold Ore, Spiral Chute Therefore,the low weir spiral classifier is only used to wash the sand ore with less mud or coarse particles, rarely used in the grinding and classification operation mon Types of Spiral Classifier Used in the Mineral Iron Ore Spiral Separator is used for treatment of low grade ore where large tonnages are processed such as iron ore, manganese and chromite The Iron Ore Spiral Separator comes with precisely MINERAL SPIRAL SEPARATOR Iron Ore Spiral Separator The Single Spiral Classifier is widely used to pregrading and inspection grading in closed circuits when used in the production flow of metal processing According to the difference in sedimentation rate of Ore Separation Spiral Classifier for Mineral Processing

Spiral Classifier for Mineral Processing

In Mineral Processing, the SPIRAL Classifier on the other hand is rotated through the ore It doesn’t lift out of the slurry but is revolved through it The direction of rotation causes the slurry to be pulled up the inclined bed of the classifier in much the same manner as the rakes do As it is revolved in the slurry the spiral Alibaba offers 116 mineral use spiral separator products About 93% of these are Mineral Separator A wide variety of mineral use spiral separator options are available to you,mineral use spiral separator, mineral use spiral separator In the present study, effects of several operating parameters on the separation efficiency of mica from feldspar by spiral concentrator were investigated For this purpose, an albite ore containing(PDF) Effects of operational parameters of spiral Spiral Chute For Ore Processing Line China Mineral Gravity Processing Machine Spiral Spiral Chute Application: Spiral Chute is suitable for the separation of 03002 mm fine iron ore, ilmenite, chromite, pyrite, zircon, rutile, monazite, phosphorite B, tungsten ore, tin ore, tantalum oreSudan Barite Spiral Chute Mineral ProcessingGravity Separation Mineral Technologies The fine mineral spiral series is used for fine feed with particles in the range of 30150 microns: WW Series: Utilises wash water addition for enhanced grade control in specific applications (ie iron ore, mineral gravity mineral spiral classifier for ore

Gravity Spiral Chute Used For Mineral Seperator Processing

Heavy Mineral Equipment Washing Plant Spiral Chute Gravity Separation Equipment Spiral chute is suitable for treatment of 0 6 0 03mm lode and placer but high mud content is bad for separation At present spiral chute has been widely used in the treatment of iron ore tungsten tin ore niobium tantalum ore