Solutions

Products

-

Primary mobile crushing plant

-

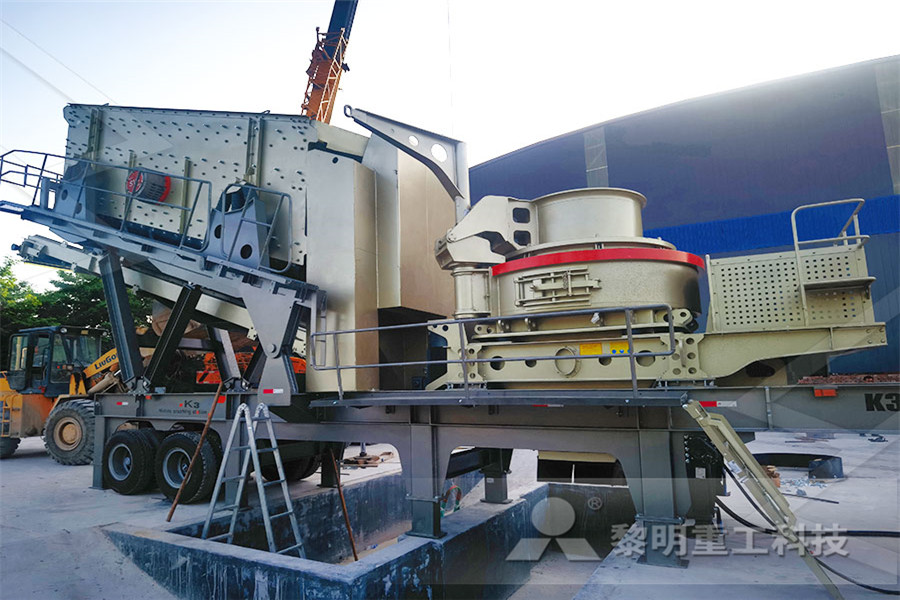

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Observation of iron ore beneficiation within a spiral

Feb 02, 2016 Spiral concentrators are used in the processing of ores composed of minerals with different densities A unit is composed of a profiled channel swept helically around a central post creating a spiralling trough Commonly used spirals have between three and seven turns, with a diameter between 04 and 1 m (Palmers and Vadeikis, 2010) The feed More than 300 kinds of iron ore are known However, there are only 20 types of iron ore raw materials used at this stage, the most important of which is magnetic Iron ore, magnetite, hematite, limonite and siderite, the following is an introduction to these four types of iron ore You may interest Buy magnetic separator machinesTypes of Iron Ore JXSC MachineIron processing, use of a smelting process to turn the ore into a form from which products can be fashionedIncluded in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties It constitutes 5 percent by weight of the Earth’s crust, and it is the Iron processing BritannicaSep 25, 2018 The reasons for choosing jigging for the iron ore beneficiation over other processes include (i) relatively easy separation, (ii) beneficial tradeoff between operating cost and reduced yield relative to dense medium processes, (iii) ability to treat ores requiring cut densities higher than a density of 40, and (iv) physical characteristics of Low grade Iron Ore Beneficiation and the Process of Analyzing The Differences Between Iron And Iron Ore Iron is found most abundantly on earth It has multifarious uses It is used as constructional and structural material It is used in many parts of the world for railings, furniture and as utensils tooAnalyzing The Differences Between Iron And Iron Ore

Iron in the Industrial Revolution ThoughtCo

Jul 26, 2019 Arguably, the key development came in 17834, when Henry Cort introduced the puddling and rolling techniques These were ways of getting all the impurities out of iron and allowing largescale production, and a vast increase in it The iron industry began to relocate to coal fields, which usually had iron ore Apr 12, 2017 How to Identify Iron Ore The earth's core is made up of iron ore Early man made tools and weapons from the iron ore they extracted from the earth and refined Only meteorites carry pure iron ore, and the deposits locked away within the Earth require mining and refining Layered deep in organic deposits, iron ore How to Identify Iron Ore Our PastimesApr 03, 2014 DSO, gravity separation, Iron ore, iron ore beneficiation, magnetic separation, Beneficiation of Iron Ores Iron ore is a mineral which is used after extraction and processing for the production of iron and steel The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron magnetite)Beneficiation of Iron Ores – IspatGuru–Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •The Latest Developments in Iron Ore ProcessingIron ore is a nonfungible commodity, and its quality varies To help facilitate price adjustment for differences between expected and delivered product specifications, PRAs have developed valueinuse (VIU) indices for the key priceaffecting chemical components of iron ore ironIron ore pricing explained Metal Bulletin

Different Types of Iron Ore 911metallurgist

Metallurgical ContentImpurities in Iron OresHematiteIron Ore FormationOrigin of Iron OreBodiesMagnetiteLimoniteSiderite The iron minerals that are at present used as There are differences in structure between high weir spiral classifier and submerged spiral classifier, so they are different in classification application The high weir classifier is more suitable for the coarse classification and the first classification with minerals grain size over 015mmTypes of Spiral Classifier in Mineral Processing XinhaiTypes of Ore: Two major varieties used for iron making are Haematite Ore( Containing Ferric Oxide Fe2O3) and Magnetite Ore (containing FerroFerric Oxide Fe3O4) When chemically pure, Haematite contains approximately 70% and Magnetite 724% iron But usually iron content of ores ranges between 5065/67% (rich ores) and 3035% (lean ores Glossary of Terms/ Definitions Commonly Used in Iron Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel—98% of the mined iron ore is used to make steel In 2011 the Financial Times has speculated that iron ore is "more integral to the global economy than any other commodity, except perhaps oil"Iron ore WikipediaDifferences Between Spiral Classifier and Hydrocyclone 16:33:24 XinHai Views (4026) Warm Tip: If you want to know more information, like quotation, products, solutions, etc, please Click here , and contact us onlineDifferences Between Spiral Classifier and Hydrocyclone

The Types of Coal: Composition, Usage, and Energy Value

Jan 29, 2020 The hot, purified, liquefied carbon solidifies into lumps called "coke" that can be fed into a blast furnace along with iron ore and limestone to produce steel Steam coal, also known as thermal coal, is suitable for electric power production Steam coal is ground into a fine powder that burns quickly at high heats and is used in power plants Nov 01, 2017 According to BAML, around 15 tonnes of iron ore is required to produce one tonne of steel In comparison to a blast furnace, an electric arc furnace predominantly uses This is how iron ore is turned into steel Business InsiderOct 23, 2018 S + O 2 → SO 2 4 P + 5 O 2 → 2 P 2 O 5 Roasting is the process of heating iron ore strongly in dry air for drying the ore and expelling humidity, It is used to increase the percentage of iron in the ore and for the oxidation of some impurities such as sulphur and phosphorus Roasting of iron is very important in the ore dressing process but this process pollutes the environment, Ore Extraction of Iron from its ores, Iron dressing, Reduction Iron ore is found in nature in the form of rocks, mixed with other elements By means of various industrial processes incorporating cuttingedge technology, iron ore is processed and then sold to steel companies The iron ore produced by Vale can be found in houses, cars and household appliancesIron Ore and Pellets Vale2 days ago Iron ore is a mineral block found underground It is smelted into iron ingots, which are used to make tools and armor 1 Obtaining 11 Breaking 12 Natural generation 2 Usage 21 Smelting ingredient 22 Note Blocks 3 Sounds 4 Data values 41 ID 5 Video 6 History 7 Issues 8 Trivia 9 Gallery Iron ore must be mined with a stone pickaxe or higher, or else it drops nothing Unlike most ores, iron Iron Ore – Official Minecraft Wiki

Iron Steel Facts Uses, Properties, Element Fe, Age

The amount of carbon is small (usually between 02% and 20%) but it makes a huge difference to the strength Steel can be around 1000 times stronger than iron in its pure form The Eiffel Tower in Paris, France is made from puddle iron Puddle iron is a form of wrought iron, an iron alloy with a very low level of carbon contentThe BFBOF route produces steel using raw materials such as iron ore, coal, limestone and steel scrap About 75% of steel is produced using the BFBOF route First, iron ores are reduced to iron, also called hot metal or pig iron Then the iron is converted to steel in the BOF After casting and rolling and/or coating, the steel is delivered as FACT SHEET Energy use in the steel industryPipe Taps are used to cut internal threads in parts or fittings that will be mated with threaded pipe or fittings to make a pressure tight jointPipe threads require higher cutting forces than regular machine thread tapping because the threads require 100% thread depth Pipe Taps Technical Information MSC Industrial Supply CoThe thick slag layer separates the ironcarbon melt and char from the oxidizing postcombustion products, providing a medium for heat transfer The exiting gas is then used to preheat and prereduce the iron ore feed materials The DIOS process uses a series of fluidized bed reactors for preheating and prereduction of iron ore finesEmerging Technologies for Iron and SteelmakingThere are differences in structure between high weir spiral classifier and submerged spiral classifier, so they are different in classification application The high weir classifier is more suitable for the coarse classification and the first classification with minerals grain size over 015mmTypes of Spiral Classifier in Mineral Processing Xinhai

Ironprocess spiral concentration for iron ore upgradation

Oct 01, 2012 Magnetite iron ore, limonite iron ore, Manganese ore,graphite etc mineral Hematite Iron ore beneficiation process Diagram energy saving ball mill, flotation Metallurgical ContentOptimum Operating Conditions of a Spiral ConcentratorThe Spiral’ Static DistributorThe Primary Spirals SeparatorThe Cleaner Spiral SeparatorMaintenance of the SpiralsHumphreys Spiral ConcentratorWhen to use a Gravity Spiral ConcentratorHumphreys Spiral Concentrator CapacitySpiral Concentrator The gravity spiral circuit is designed to extract and Gravity Spiral Concentrator Working PrincipleAug 21, 2020 Basic oxygen furnaces (BOF), which account for 70% of steel production worldwide, require iron ore, coke, and fluxes as feed material in steel production After the blast furnace is fed with these materials, hot air is blown into the mixture The air causes the coke to burn, raising temperatures to 1,700 degrees Celsius, which oxidizes impuritiesWhat You Should Know About Metallurgical CoalOct 23, 2018 S + O 2 → SO 2 4 P + 5 O 2 → 2 P 2 O 5 Roasting is the process of heating iron ore strongly in dry air for drying the ore and expelling humidity, It is used to increase the percentage of iron in the ore and for the oxidation of some impurities such as sulphur and phosphorus Roasting of iron is very important in the ore dressing process but this process pollutes the environment, Ore Extraction of Iron from its ores, Iron dressing, Reduction Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel—98% of the mined iron ore is used to make steel In 2011 the Financial Times has speculated that iron ore is "more integral to the global economy than any other commodity, except perhaps oil"Iron ore Wikipedia

Types of Iron Ore: Hematite vs Magnetite INN

For that reason, hematite ore is important for many mining companiesAs Australia’s Magnetite Network explains, “[d]irect shipping ores, when mined, typically have iron (Fe) content of between