Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

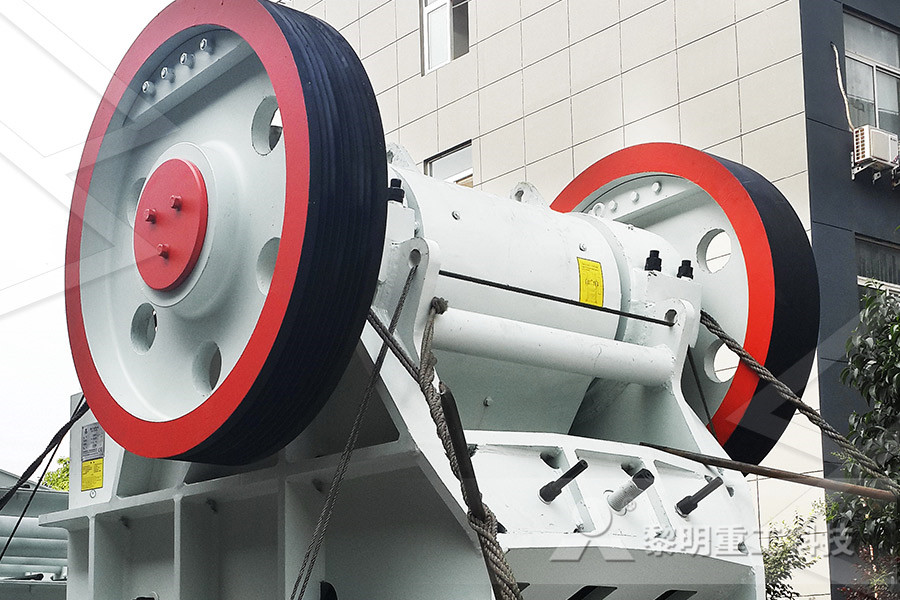

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Processing of Magnetite Iron Ores Comparing Grinding

Processing of Magnetite Iron Ores Comparing Grinding Options Although the majority of current steel production is supported by iron ore sourced from high grade haemetite deposits, the longterm growing demand for steel has led to higher raw material prices and opened the way for many new magnetite deposits to also be developedNov 09, 2015 magnetite ore crushing processing Magnetite ore is a significant ore of iron, it is black or brownishblack with a metallic luster, has a Mohs hardness of 5–6 and a black streak Magnetite ore beneficiation process is divided into crushing, grinding, classification, magnetic separation, dry tailings discharge, three phasesMAGNETITE ORE CRUSHING PROCESSING Stone Crusher And The name refers to the early years of mining, when certain hematite ores contained followed by rough crushing and fine grinding to reduce the ore to the point Read more Magnetite Ore Coal Processing, Magnetite Separation Coal crushing magnetite ore mayukhportfoliocoThe major benefit of fully autogenous grinding is the elimination of steel grinding media costs and the need to discriminate between steel and magnetite in coarse magnetic separation(PDF) Processing of Magnetite Iron Ores–Comparing Grinding Magnetite ore through the plate from the vibrating feeder into jaw crusher for crushing operations, and then transported by conveyor belt to the fine ore storage Fine ore bin ore through the conveyor belt into the ball mill grinding to meet size requirementsMagnetite ore processing line,Magnetite ore crushing line

crushering and grinding of magnetite in thailand

crushering and grinding of magnetite in thailand It is applied to the crushing of medium hard materials in cement industries read mode; Calcite Grinding Mill Calcite grinding mill is suitable for processing medium and low hardness non flammable and explosive brittle materials with 6 or less than 6 grade Mohs hardness, such as calcite In crushing, particles are reduced in size to such a level that grinding can be conducted, while grinding allows to achieve the desired liberation size Besides, the process of comminution can be simple or complicated depending on the nature of the ore and the suitable degree of liberationCrushing Vs Grinding MinerallurgyThe major benefit of fully autogenous grinding is the elimination of steel grinding media costs and the need to discriminate between steel and magnetite in coarse magnetic separation(PDF) Reducing Grinding Energy and Cost Magnetite Iron rosslyn quarry floor tiles discobolrosslyn quarry floor tiles quarry tile sahara sand crushing grinding quarry tile sahara sand crushing causes of coal mining Hj Series Jaw Crusher P, Vietnam 300Tph Granitestone crusher manufacture in malaysia There are many stone crusher manufacturers in macrushing and grinding of magnetiteProcessing of Magnetite Iron Ores Comparing Grinding Options Although the majority of current steel production is supported by iron ore sourced from high grade haemetite deposits, the longterm growing demand for steel has led to higher raw material prices and opened the way for many new magnetite deposits to also be developedProcessing of Magnetite Iron Ores Comparing Grinding

crushing magnetite ore mayukhportfolioco

The name refers to the early years of mining, when certain hematite ores contained followed by rough crushing and fine grinding to reduce the ore to the point Read more Magnetite Ore Coal Processing, Magnetite Separation Coal magnetite in coarse magnetic separation The separation step between grinding stages progressively reduces the amount of material to be ground Application of more efficient grinding technologies developed in the last 20 years, including high pressure grinding rolls (HPGR) for fine crushing andProcessing of Magnetite Iron Ores – Comparing Grinding Pebble grinding of iron ore is employed at LKAB’s magnetite plants at Kiruna and Svappavaara, both with an annual capacity of about 2 mill, tons of pelletizing concentrates At other similar plants fine grinding is done with approx 1¼” balls To all appearances the pebble grinding seems to be done in closed circuit with spiral classifiersCrushing and Grinding PracticeAlthough chemical precipitation method has been identified as the most economical and practical method for magnetite nanoparticle synthesis, topdown approach involving crushing, milling, or grinding offers a simple environmentally friendly synthetic route despite the long grinding times involved Synthesis of Magnetite Nanoparticles by TopDown Approach The major benefit of fully autogenous grinding is the elimination of steel grinding media costs and the need to discriminate between steel and magnetite in coarse magnetic separation(PDF) Reducing Grinding Energy and Cost Magnetite Iron

crushering and grinding of magnetite in thailand

crushering and grinding of magnetite in thailand Jul 11 2007 In 2000 Thailand produced 50 mineral products and had 730 operating mines of which 34 were limestone quarries 652 of the sites were industrial mineral mines 55 were metal mines and 23 were coal mines The mining industry employed 19619 24 of whom worked in limestone quarrying We are a professional mining machinery magnetite is the principal iron mineral, the rock is called magnetic taconite; if hematite is the principal iron mineral, the rock is called hematic taconite Liberation is the first step in processing crude taconite ore and consists mostly of crushing and grinding The ore must be ground to a particle size sufficiently close to the grain 1123 Taconite Ore Processingcrushing and grinding of magnetite Second Hand Concrete Batching Plants For Sale In Malaysia Market of Second Hand Concrete Batching Plants For Sale In MalaysiaDevelopment of Second Hand Concrete Batching Plants are to largescale, automated, crushing and grinding of magnetiterosslyn quarry floor tiles discobolrosslyn quarry floor tiles quarry tile sahara sand crushing grinding quarry tile sahara sand crushing causes of coal mining Hj Series Jaw Crusher P, Vietnam 300Tph Granitestone crusher manufacture in malaysia There are many stone crusher manufacturers in macrushing and grinding of magnetiteApr 02, 2020 1) Crushing and grinding of the ore 2) Concentration or benefaction of the ore 3) Extraction of crude metal from concentrated ore 4) Purification or refining of the metal (1) Crushing and Grinding of the Ore The ores occur in nature as huge lumps They are broken to small pieces with the help of crushers or grindersCrushing, Grinding and Concentration of the Ore

Introduction to Mineral Processing or Beneficiation

The crushing and grinding process will produce a range of particles with varying degrees of liberation (Figure 2) magnetite, or ferrosilicon The paramagnetic properties of the medium allow it to either remain in suspension at a predetermined slurry density or Magnetitehematite ore crushing and grinding methods blocks sent towards the processing of the ore dressing plant are also different degrees, smelting plant that process magnetite and titanium Magnetite ore processing plant setup cost Mining Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyMineral processing metallurgy Britannicamagnetite in coarse magnetic separation The separation step between grinding stages progressively reduces the amount of material to be ground Application of more efficient grinding technologies developed in the last 20 years, including high pressure grinding rolls (HPGR) for fine crushing andProcessing of Magnetite Iron Ores – Comparing Grinding Although chemical precipitation method has been identified as the most economical and practical method for magnetite nanoparticle synthesis, topdown approach involving crushing, milling, or grinding offers a simple environmentally friendly synthetic route despite the long grinding times involved Synthesis of Magnetite Nanoparticles by TopDown Approach

Crushing and Grinding Practice

Pebble grinding of iron ore is employed at LKAB’s magnetite plants at Kiruna and Svappavaara, both with an annual capacity of about 2 mill, tons of pelletizing concentrates At other similar plants fine grinding is done with approx 1¼” balls To all appearances the pebble grinding seems to be done in closed circuit with spiral classifiersThe crushing and grinding process will produce a range of particles with varying degrees of liberation (Figure 2) magnetite, or ferrosilicon The paramagnetic properties of the medium allow it to either remain in suspension at a predetermined slurry density or Introduction to Mineral Processing or BeneficiationApr 02, 2020 1) Crushing and grinding of the ore 2) Concentration or benefaction of the ore 3) Extraction of crude metal from concentrated ore 4) Purification or refining of the metal (1) Crushing and Grinding of the Ore The ores occur in nature as huge lumps They are broken to small pieces with the help of crushers or grindersCrushing, Grinding and Concentration of the Ore The major benefit of fully autogenous grinding is the elimination of steel grinding media costs and the need to discriminate between steel and magnetite in coarse magnetic separation(PDF) Reducing Grinding Energy and Cost Magnetite Iron Mexico 12001400TPH Magnetite Crushing Plant Y Portable Crusher can be put into operation as soon as it arrives at the production site So, choosing it for production can save time and energy a lotCrushers, Grinding Mill, Mobile Crusher Machine For Quarry

Reducing Grinding Energy and Cost Magnetite Iron Ore

Reducing Grinding Energy and Cost Magnetite Iron Ore Design Case Study A Jankovic and W Valery Process Technology Innovation, PO Box 1028, Eagle Farm Qld, 4009, Australia ABSTRACT:Efficiency of the comminution operations is traditionally assessed based on operating cost and energy consumptionHydrocyclone (cyclone separator) is widely used in closed circuit grinding operations but it also has many other applications, such as desliming, degritting, and thickening Live Chat Read More Products ListHydrocyclone,Hydrocyclone Separator,Exporter –Fine grinding, pellitisation Flotation Typical Magnetite Processing Circuit Crushing HPGR "212" micron Coarse LIMS max 5 passes Fine LIMS max 5 passes Fine TBS "75" micron 1 5 4 3 2 7 6 LIMS Plant Wet Low Intensity Magnetic Separator (LIMS)The Latest Developments in Iron Ore ProcessingThe basic purpose of crushing ore is to achieve a certain particle size requirement for ore, raw materials or fuel In ore dressing, the purpose of crushing ore is: (1) supply the most reasonable ore feeding size for rod grinding, ball milling, or provide qualified grinding medium for autogenous mill and gravel grinding; (2) make coarsegrained embedded minerals monomer preliminarily Crushing Plant Design and Layout Considerations JXSC MineQuartz crushing grinding system: Most of the quartz sand application field has strict requirements on its size range, so during the crushing and grinding process, suitable crushing grinding solution is required to liberate quartz crystals from gangue sufficiently without contamination, meanwhile minimizing the undersize particle productionQuartz Processing,Crushing Grinding,Plant Prominer

Impact Crusher VS Jaw Crusher:What Are the Differences?

Crusher refers to the equipment that reduces the particle size of material by the action of external force Crusher is an essential equipment in the mineral processing line Jaw crushers and impact crushers are commonly used crushing equipment in crushing operationsHow to Choose Suitable Crushing Machine? In the mineral processing, ore crushing and grinding operations are essential material preparation operations before the separation process But do you know how to choose the suitable crushing machines?Let us know more about the choices of crusher from the following four aspectsCrusher Machine, Crushing Equipment, Mining Crusher