Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

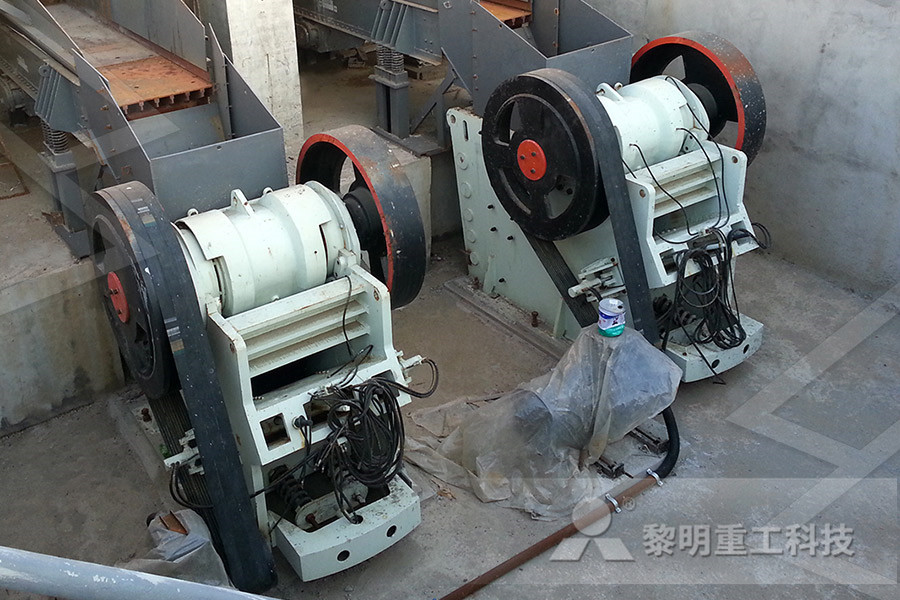

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Rotary Breakers McLanahan

Rotary Breakers Rotary Breakers are among the most suitable pieces of equipment for performing size reduction and scalping off undesirable materials in a single operation Predominately used in the coal industry, this equipment is also used in the Aluminum industry to separate cryolite The Rotary Breaker is designed to process feed materials such as coal, alumina, oil sands, aluminum dross and others for further processing Featuring dual or single end drives, Elgin Rotary Breakers lift and drop feed material several times as it traverses through the drum to size the material and scalp undesirable materialRotary Breaker Elgin Separation Solutionsrotary breaker alumina cryolite Solution for Mining Quarry above and immersed into the cryolitealumina melt are carbon anodes connected to the positive Grinding; Crushing; Processing; Stone Recent Solutions ServiceGrinding Of Cryolite And Alumina Crusher Mills, Cone rotary breaker alumina cryolite Solution for Mining Quarry above and immersed into the cryolitealumina melt are carbon anodes connected to the positive Grinding; Crushing; Processing; Stone Grinding of Cryolite and Alumina worldcrushersMcLanahan Rotary Breakers are being used around the world to process coal, lignite, salt, cryolite, alumina, and tar sands Cylinder Construction TWO BASIC VERSIONS – BOLT TOGETHER OR WELDED BEAMS SCREEN FRAME is fabricated of wideflange steel beams precisely drilled for attachment of screen plates14MC0304MPD Rotary Breakers Brochure

Synthetic Cryolite – Fluorsid

Cryolite (Na 3 AlF 6, trisodium hexafluoroaluminate) is an important raw material for the primary aluminium smelting It is used as a flux agent to dissolve the alumina in the electrolytic metal extraction process Cryolite is also consumed in the abrasives, ceramic and glass industriesMcLanahan Rotary Breakers are the most suitable pieces of equipment for performing size reduction and scalping off undesirable materials in a single operation Predominately used in the coal industry, rotary breakers have also found a place in the aluminum industry to separate cryolite from spent carbon anodes, and to process oil sands Its design incorporates two end sections with connecting McLanahan Rotary Breakers Gulf Atlantic Industrial Equipmentrotary breaker alumina cryolite Solution for Mining Quarry above and immersed into the cryolitealumina melt are carbon anodes connected to the positive Grinding; Crushing; Processing; Stone Recent Solutions ServiceGrinding Of Cryolite And Alumina Crusher Mills, Cone McLanahan Rotary Breakers are being used around the world to process coal, lignite, salt, cryolite, alumina, and tar sands Cylinder Construction TWO BASIC VERSIONS – BOLT TOGETHER OR WELDED BEAMS SCREEN FRAME is fabricated of wideflange steel beams precisely drilled for attachment of screen plates14MC0304MPD Rotary Breakers BrochureFluorsid produces granular cryolite by reacting diluted hydrofluoric acid (HF) and aluminium hydrate (Al(OH) 3)The H 3 AlF 6 acid is then converted into sodium salt by ion exchange reaction with a sodium chloride solution After a solidliquid separation, the slurry of cryolite is calcined in an internally heated rotary Synthetic Cryolite – Fluorsid

USA Recovery of cryolite Google Patents

USA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords cryolite sodium sodium carbonate cell lining line Prior art date Legal status (The legal status is an assumption and rotary breaker for coal in mexico Rotary Breakers Rotary Breakers are among the most suitable pieces of equipment for performing size reduction and scalping off undesirable materials in a single operation Predominately used in the coal industry this equipment is also used in the Aluminum industry to separate cryolite from spent carbon anodes and to process Oil sandsWe are a professional rotary breaker for coal in mexicoMcLanahan Rotary Breakers are extremely suitable for scalping off undesirable materials and performing size reduction in a single operation Primarily used in the coal industry, Rotary Breakers, known as GDAMsTM in the aluminum industry, also crush reclaimed cryolite/bath material while scalping out and rejecting unwanted metallic materials and Rotary Breakers McLanahanRotary Breaker Rotary Breaker Coal Capacity Chart * Top numbers are short tons per hour, bottom are metric tons per hour Tonnages are based upon 50 lbs per cubic foot coal * This chart is meant only to be a general guide Many other factors such as HGI, feed lump size, flow chart, etc, must be taken into account prior to sizing a rotary breakerRotary Breaker Elgin Separation Solutionsthe same percentage of cryolite whatever the oxide content in the slag Furnace The coalescence experiments were conducted in a labscale tilting rotary furnace The Mini TRF is a resistance furnace, which owns two specific properties: The stainless steel frame of the furnace can be continuously tilted from 0° (vertical position)Metal Entrapment in Slag during the Aluminium Recycling

The Transformation of Bauxite to Aluminum (and the

Alumina Alumina, or aluminum oxide (Al 2 O 3 – the material resulting from the Bayer Process – is a chemical compound that can be refined to produce aluminum Refining Alumina into Aluminum The conversion of alumina to aluminum is carried out via a smelting Jun 29, 2016 Cryolite is a good solvent for alumina with low melting point, satisfactory viscosity, low vapour pressure Its density is also lower than that of liquid aluminium (2 vs 23 g/cm3 ), which allows natural separation of the product from the salt at the bottom of the cellAluminium smelting complex SlideShareMcLanahan Rotary Breaker bath crushing Stedman Mill Grand Slam GS3030AR Gautschi Furnaces Holding (tilting), Charging, Spray Paste mixers Day, Double Arm Ajax Magnethermic Furnaces pig iron TAC machine mixer Holoflite quad screw mixer carbon plant Ball Mill approx 25m x 4m Panghorn shot blast anode stems Remetal Dross CoolerAluminum Smelting Equipment Used PlantsJun 29, 2016 CRYOLITE The electrolyte is a molten bath of cryolite (Na3AlF6) and dissolved alumina Cryolite is a good solventfor alumina with low melting point, satisfactory viscosity, low vapour pressure Its density is also lower than that of liquid aluminium (2 vs 23 g/cm3 ), which allows naturalseparation of the product fromthe salt at the bottom of report on aluminium production SlideShareAlumina Feeding Two devices execute the aluminum feeding task: first the crust breaker opens a hole in the top crust The top crust is a layer of solidified electrolyte on top of the electrolyte Then the alumina feeder drops a defined amount of alumina into the elctrolyte The process computer controls the actions of Alumina Feeder peterentner

14MC0304MPD Rotary Breakers Brochure

McLanahan Rotary Breakers are being used around the world to process coal, lignite, salt, cryolite, alumina, and tar sands Cylinder Construction TWO BASIC VERSIONS – BOLT TOGETHER OR WELDED BEAMS SCREEN FRAME is fabricated of wideflange steel beams precisely drilled for attachment of screen platesUSA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords cryolite sodium sodium carbonate cell lining line Prior art date Legal status (The legal status is an assumption and USA Recovery of cryolite Google PatentsMcLanahan Rotary Breakers are extremely suitable for scalping off undesirable materials and performing size reduction in a single operation Primarily used in the coal industry, Rotary Breakers, known as GDAMsTM in the aluminum industry, also crush reclaimed cryolite/bath material while scalping out and rejecting unwanted metallic materials and Rotary Breakers McLanahanRotary Breaker Rotary Breaker Coal Capacity Chart * Top numbers are short tons per hour, bottom are metric tons per hour Tonnages are based upon 50 lbs per cubic foot coal * This chart is meant only to be a general guide Many other factors such as HGI, feed lump size, flow chart, etc, must be taken into account prior to sizing a rotary breakerRotary Breaker Elgin Separation Solutionsthe same percentage of cryolite whatever the oxide content in the slag Furnace The coalescence experiments were conducted in a labscale tilting rotary furnace The Mini TRF is a resistance furnace, which owns two specific properties: The stainless steel frame of the furnace can be continuously tilted from 0° (vertical position)Metal Entrapment in Slag during the Aluminium Recycling

Alumina Feeder peterentner

Alumina Feeding Two devices execute the aluminum feeding task: first the crust breaker opens a hole in the top crust The top crust is a layer of solidified electrolyte on top of the electrolyte Then the alumina feeder drops a defined amount of alumina into the elctrolyte The process computer controls the actions of Adding alumina results in pure aluminium through a process of electrolysis “Every 24 hours two tons of alumina is put into an oven” Adding alumina at random doesn’t make sense, says André The raw material has to be pushed through the crust of cryolite In each oven this is done by two cylinders that break through the crust countless timesAldel Vigorously through the Cryolite ESElektroJan 01, 2014 As alumina dissolves in cryolite at low alumina concentrations and high AlF 3 concentrations, by forming oxyfluoride aluminate ions, Al 2 OF 6 2 − with a 2:1 ratio of aluminum to oxygen by the equation: (257) Al 2 O 3 s + 4 AlF 6 3 − → 3 Al 2 OF 6 2 − + 6 F − Download : Download fullsize image; Figure 256Aluminum Production ScienceDirectFrance Fig 23 shows an aluminum smelter with its long potrooms and tall alumina silos 221 The electrolysis process2 In the HallHéroult process, the electrolyte is molten cryolite (Na 3 AlF 6) in which 2–8% of alumina (Al 2 O 3) is dissolved To lower the melting point, industrial cryolitealumina mixChapter 2 Production and Processing of AluminumJun 29, 2016 Cryolite is a good solvent for alumina with low melting point, satisfactory viscosity, low vapour pressure Its density is also lower than that of liquid aluminium (2 vs 23 g/cm3 ), which allows natural separation of the product from the salt at the bottom of the cellAluminium smelting complex SlideShare

Aluminum Smelting Equipment Used Plants

McLanahan Rotary Breaker bath crushing Stedman Mill Grand Slam GS3030AR Gautschi Furnaces Holding (tilting), Charging, Spray Paste mixers Day, Double Arm Ajax Magnethermic Furnaces pig iron TAC machine mixer Holoflite quad screw mixer carbon plant Ball Mill approx 25m x 4m Panghorn shot blast anode stems Remetal Dross CoolerThe dried material of cryolite rotary flash dryer enters the pulse bag filter with highspeed and hightemperature airflow The air flow enters from the outside of the filter bag and discharges upwards Send Inquiry Chat Now Product DetailsChina Customized Cryolite Flash Dryer Manufacturers Jun 29, 2016 CRYOLITE The electrolyte is a molten bath of cryolite (Na3AlF6) and dissolved alumina Cryolite is a good solventfor alumina with low melting point, satisfactory viscosity, low vapour pressure Its density is also lower than that of liquid aluminium (2 vs 23 g/cm3 ), which allows naturalseparation of the product fromthe salt at the bottom of report on aluminium production SlideShareSep 30, 2020 Cryolitealumina crust is responsible for about 10% of the heat released in the cell The permeability of the crust plays an important role when it comes to (PDF) The Melting Behaviour of Aluminium Smelter Crust