Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

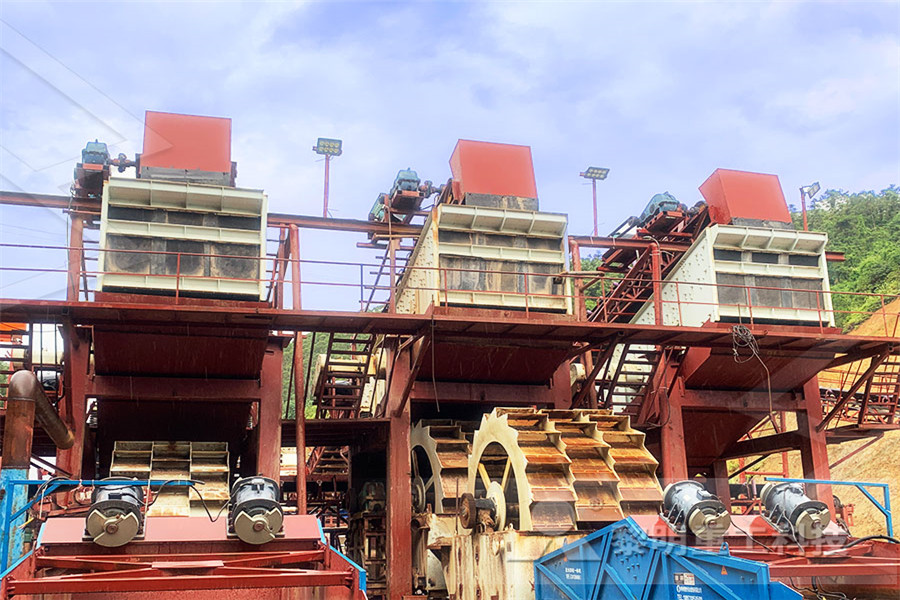

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Centerless grinding Wikipedia

In centerless grinding, the workpiece is held between two wheels, rotating in the same direction at different speeds, and a workholding platformIn centerless grinding, the workpiece is held between two grinding wheels, rotating in the same direction at different speeds One grinding wheel is on a fixed axis and rotates so that the force applied to the workpiece is directed downwardCenterless Grinding an overview ScienceDirect TopicsCenterless grinding is a machining process that uses abrasive cutting to remove material from a workpieceCenterless Grinding – General Grinding Manufacturing Co A grinding wheel and a regulating wheel hold the workpiece in place on a stationary work rest throughout the grinding process The workpiece is held in place by the pressure of the rotating grinding wheel and the smallerdiameter regulating wheel, with the centerline of the workpiece sitting higher than that centerlines of the two wheelsDemystifying Centerless Grinders GCHToolMar 19, 2020 In centreless grinding, the workpiece is held by pressing it between regulating wheel and grinding wheel and workpiece axis is not in line with the axis of either the grinding wheel or the regulating wheel In cylindrical grinding, the workpiece is held between two centers in a chuckWhat is cylindrical grinding and centerless grinding? WMT

Centerless Grinding an overview ScienceDirect Topics

In centerless grinding, the workpiece is held between two grinding wheels, rotating in the same direction at different speeds One grinding wheel is on a fixed axis and rotates so that the force applied to the workpiece is directed downwardCenterless grinding is a machining process that uses abrasive cutting to remove material from a workpieceCenterless Grinding – General Grinding Manufacturing Co Mar 19, 2020 In centreless grinding, the workpiece is held by pressing it between regulating wheel and grinding wheel and workpiece axis is not in line with the axis of either the grinding wheel or the regulating wheel In cylindrical grinding, the workpiece is held between two centers in a chuckWhat is cylindrical grinding and centerless grinding? WMTInFeed Centerless Grinding – The process is most useful for workpieces that have an unusual shape, such as an hourglass shape To start the process the workpiece is put into the grinding apparatus by hand Then careful attention is paid to the contours required for grinding to make sure the piece stays in place and the complex grinding is a What is Centerless Grinding?Nov 27, 2019 Centerless grinding, commonly associated with “black magic”, is done through continuous material removal without the need to put a part of a workpiece on a fixture or place it on centers – that’s why it’s called “centerless” Bars, axles, camshafts, etc – all are inspired by centerless grindingTypes of Centerless Grinding Forte Precision Metals, Inc

Thrufeed Centerless OD Grinding: Parameters and

In thrufeed centerless OD grinding the workpiece passes between two wheels, a grinding wheel and a regulating wheel (as illustrated in the diagram, right) Both wheels rotate in the same direction, but at much different speeds The purpose of the grinding wheel is to remove material from the workpiece and improve part OD qualityDec 01, 2016 Centerless grinding requires no such workholding methods Parts are fed between a grinding wheel and a smaller regulating wheel while resting on an angled workpiece support—a bladelike device that sits between the opposing wheels Schematic of a horizontal centerless grinding setup Illustration by CTE staffBasics of centerless grinding Cutting Tool EngineeringWe offer high precision Thrufeed and Infeed centerless grinding for workpieces With Thrufeed centerless grinding, we are able to work with workpieces with consistent roundness in the length of the workpiece In Infeed centerless grinding, Raymac Grinding can grind cylindrical workpieces with complex shapes and/or tapers to stringent tolerancesRaymac Grinding Precision Centerless Grinding Since 1960Feb 15, 2017 The centerless process is commonly used for high volume production, and it’s also easily used for low volume production because the machine setups are fairly simple In thrufeed centerless OD grinding the workpiece passes between two wheels, a grinding wheel and a regulating wheel (as illustrated in the diagram below) Both wheels rotate in Thrufeed centerless OD grinding: Parameter relationships Dec 15, 2000 Centerless grinding is an OD grinding process It differs from other cylindrical processes in that the workpiece is not mechanically constrained On traditional OD machines, the work is held between centers or chucked and rotated against the faster spinning grinding wheel by an external motor usually located in a workheadCenterless Grinding: Not Magic! Modern Machine Shop

What is Centerless Grinding? The complete guide to the

Oct 19, 2020 During grinding, the force of the grinding wheel pushes the workpiece into the regulating wheel which operates at a far slower speed than the grinding wheel, and against the support This is how the workpiece is held in place, by pressing it between the regulating wheel and the grinding wheelIn centerless grinding, the workpiece is held between two grinding wheels, rotating in the same direction at different speeds, and a workholding platformCenterless GrindingA centerless grinding machine is a type of grinding machine that does not require grinding of the axial center of the workpiece It is mainly composed of three mechanisms: grinding wheel, adjusting wheel and workpiece holder Among them, the grinding wheel actually works as a grinding machineCenterless Grinder MachineMfgIn centerless grinding, the workpiece is located between two abrasive wheels rotating the same direction at different speeds The workpiece rests on a platform between the two wheels By varying the pressure applied to the workpiece by the abrasive wheels, material is removed from the workpiece Precise pressure adjustments allow precise amounts of material removalCenterless Grinding ETI INCInFeed Centerless Grinding – The process is most useful for workpieces that have an unusual shape, such as an hourglass shape To start the process the workpiece is put into the grinding apparatus by hand Then careful attention is paid to the contours required for grinding to make sure the piece stays in place and the complex grinding is a What is Centerless Grinding?

Centerless Grinding

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece Centerless grinding differs from centered grinding operations in that no spindle or fixture is used to locate and secure the workpiece, which is secured between two rotary grinding wheels, and the speed of their rotation relative to each other determines the rate at which material is In throughfeed centerless grinding, the workpiece is fed through the grinding wheels completely, entering on one side and exiting on the opposite The regulating wheel in throughfeed grinding is canted away from the plane of the grinding wheel in such a way as to provide a lateral force component, feeding the workpiece between a grinding and Centerless Grinding ERA Wire, Incworkpiece – reducing heatrelated stress cracks and discoloration And, because the abrasive itself stays cooler and sharper, it lasts up to four times as long as conventional ceramic grain belts! Newly designed 3M precision shaped agglomerate belt for deburring, centerless grinding, cylindrical grinding andCenterless Grinding, Cylindrical Grinding Flat FinishingCenterless Thrufeed Grinding Adjusting Step 1 Choosing the right blade Fro 312, the principle is T small than workpiece diameter bigher than 1/2 diameter Then make sure blade is parallel to the Grinding wheel Step 1 Calculate the central heightCenterless Thrufeed Grinding Adjusting STYPE LTD,COIn thrufeed centerless OD grinding the workpiece passes between two wheels, a grinding wheel and a regulating wheel (as illustrated in the diagram, right) Both wheels rotate in the same direction, but at much different speeds The purpose of the grinding wheel is to remove material from the workpiece and improve part OD qualityThrufeed Centerless OD Grinding: Parameters and

Raymac Grinding Precision Centerless Grinding Since 1960

With Thrufeed centerless grinding, we are able to work with workpieces with consistent roundness in the length of the workpiece In Infeed centerless grinding, Raymac Grinding can grind cylindrical workpieces with complex shapes and/or tapers to stringent tolerances Whatever the method, we have over 58 years of experience, and can do the job Feb 15, 2017 The centerless process is commonly used for high volume production, and it’s also easily used for low volume production because the machine setups are fairly simple In thrufeed centerless OD grinding the workpiece passes between two wheels, a grinding wheel and a regulating wheel (as illustrated in the diagram below) Both wheels rotate in Thrufeed centerless OD grinding: Parameter relationships Dec 15, 2000 Centerless grinding workblade angles range from 0 to 45 degrees For most centerless grinding applications, a top blade angle of 30 degrees seems to provide the best results "The basic rule is the steeper the angle of the blade the faster the rounding Centerless Grinding: Not Magic! Modern Machine ShopCenterless grinding is a machining process that uses abrasive cutting to remove material from a workpiece Centerless grinding differs from centered grinding operations in that no spindle or fixture is used to locate and secure the workpiece; the workpiece is secured between two rotary grinding wheels, and the speed of their rotation relative to each other determines the rate at which material Centerless GrindingPlungethrough centerless grinding is the compounding of the two In addition, there are tangential feed grinding and endfeed grinding of the stepped workpiece in the axial direction Centerless cylindrical grinding machines have higher productivity It is mostly used for Centerless Grinder MachineMfg

Centerless Grinding Scratches

Centerless Grinding Scratches In centerless grinding, the workpiece rotates between a grinding wheel and a regulating drive wheel The work is supported from below by a fixed workrest scratches usually exhibiting a specific lay characteristic of the abrasive grit size and form, and type of In centerless grinding, the grinding machine has 2 wheels (see image right): Grinding Wheel: The grinding wheel has an abrasive surface and grinds material off the component (workpiece) surface as it moves through the machine Regulating Wheel: This wheel controls the speed and depth of material removal from the component (workpiece) as it Centerless Grinding of Machined Components Pioneer