Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

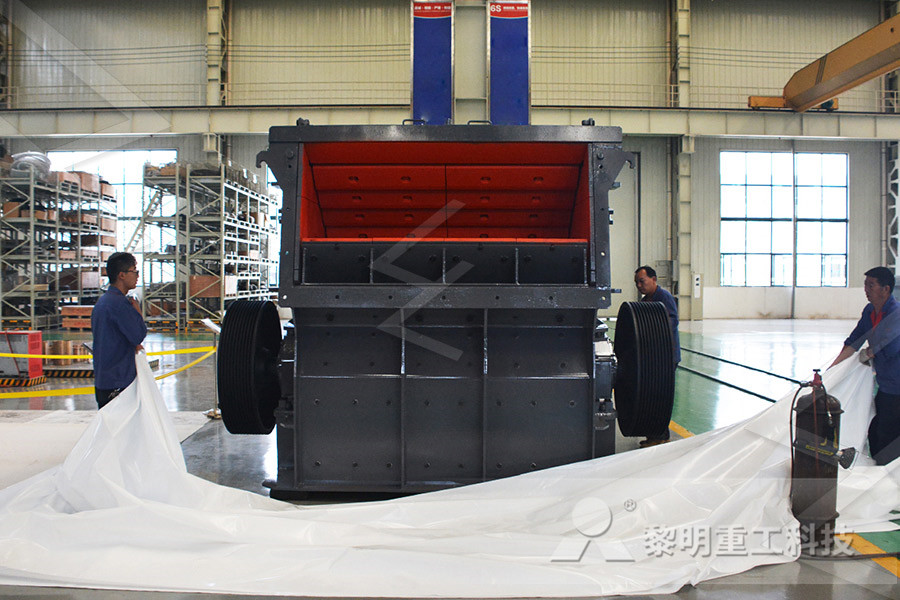

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Unlocking maximum value saleable tons from iron ore waste

Oct 14, 2019 Commissioned in late 2017, the two CDE processing plants wash, separate and gravity beneficiate about 17 Mt of low grade overburden iron ore that was stockpiled in waste dumps into a highgrade saleable product with a 63% iron content Nov 14, 2020 Waste gas mixture that exudes from the furnace contains majorly nitrogen, 30% carbon (II)oxide and about 10% carbon (IV)oxide These waste gas mixture is used in preheating the air blast and the iron ore at the initial stages of the extraction process READ MORE: Application of Le Chatelier's Principle In Chemical ReactionsProcesses and Procedures in the Extraction of Iron Tailings are finely ground rocks and other mineral waste as a result of mineral processing Due to the way minerals are processed, tailings can contain concentrations of processing chemicals This can make mine tailings an environmental concern, so proper transportation and disposal are crucialMine Waste Transfer and Disposal Methods Mine Tailings Aug 01, 2020 Throughout the ironmaking steelmaking process, ironcontaining solid wastes are produced and the production is about 10% of the crude steel (Gan et al, 2018) Usually, slags including iron slag and steel slag are used as the material for construction, cement production (Seo et al, 2019; Zhang et al, 2019)Resource utilization of municipal solid waste incineration “Some iron ore processing plants in the Pilbara experience issues separating valuable iron ore from undesired materials in wet processing situations,” he said “When separating the iron ore from the waste becomes too difficult, mining companies will Chemical additive boosts iron ore yield cuts waste The

Mine Waste Transfer and Disposal Methods Mine Tailings

Open pit mining has several stages of waste First, to access the actual seams or veins of ore, the top layers of rock, or overburden, must be removed Once the overburden has been removed, the seams can be extracted When extracting the seams, the additional waste rock will be removed to get to the actual ore, called gangueOctober 2, 1985—EPA proposes in the Federal Register (50 FR 40292) to reinterpret the scope of the mining waste exclusion as it applies to mineral and ore processing wastes, leaving only largevolume processing wastes excluded Other mineral and ore processing wastes that are hazardous would be subject to full RCRA Subtitle C (hazardous waste Mining Waste Special Wastes Wastes US EPASep 11, 2020 Ball mill for grinding iron ore Summary Mineral processing is performed to remove waste substances from useful products Throughout the mineral processing flow, care is taken to conserve the mass of valuable minerals and increase their proportion in the whole massMineral Processing Part 1 Geology for InvestorsThe ratio between waste rock and ore production is called the stripping ratio For example, a stripping ratio of 2:1 means that 2 tonnes of waste rock needs to be mined to mine 1 tonne of ore Generally, an open pit mine has a higher stripping ratio than an underground mine Waste rock is often stored close to the mine to minimize transportsLecture 4: Mining waste SGUAug 01, 2020 Min Gan, Zhiyun Ji, Xiaohui Fan, Xuling Chen, Yang Zhou, Guojing Wang, Ye Tian, Tao JiangClean recycle and utilization of hazardous ironbearing waste in iron ore sintering process J Hazard Mater, 353 (2018), pp 381392, 101016/jjhazmat201804032Resource utilization of municipal solid waste incineration

Extraction of Iron from its ores, Iron dressing, Reduction

Oct 23, 2018 S + O 2 → SO 2 4 P + 5 O 2 → 2 P 2 O 5 Roasting is the process of heating iron ore strongly in dry air for drying the ore and expelling humidity, It is used to increase the percentage of iron in the ore and for the oxidation of some impurities such as sulphur and phosphorus Roasting of iron is very important in the ore dressing process but this process pollutes the environment, Ore Jun 25, 2019 Steel and iron are the most recycled materials in the world due in part to the opportunity to recover large structures as well as the ease of reprocessing The use of magnets in the sorting process enables recyclers to easily separate them from the mixed waste stream Every year, around 400 million tons of metal are recycled worldwideMetal Types and Recycling ProcessAccording to the above discussion, RDF500 was used to replace coke breeze in the iron ore sinter process In this experiment, 0–40% coke breeze was replaced with RDF500 and the calorific value of the input fuel was equal The influence of RDF500 substitution ratio on the sintering speed was presented in Fig 2 It was found that the Refused derived fuel from municipal solid waste used as an The present work shows the results of Xray diffraction (XRD), Fourier transform infrared (FTIR), and thermal analysis of untreated (RMnt) and acidtreated red mud (RMa), a bauxite oreprocessing waste, exchanged with Pb2+, Cd2+, and Zn2+ cations These studies were performed in order to investigate the changes in the sorbent structure caused by the exchange with metals of different ionic radiiXRD, FTIR, and thermal analysis of bauxite oreprocessing At the processing plant, the taconite is crushed into very small pieces by rock crushing machines The crushers keep crushing the rock until it is the size of a marble The rock is mixed with water and ground in rotating mills until it is as fine as powder Separation The iron ore is Iron Mining Process Minnesota Iron

AMCOM LLC Solutions

Metallurgical slag processing complexes Iron ore enrichment Briquetting of fines and mill scale Municipal solid waste USA +1(516) iron ore concentrate (010 mm fraction with total Fe content 65%+) Municipal solid wasteTo efficiently process iron ore for high quality steel production, frequent ore grade monitoring, during all steps of downstream processing, is mandatory Independent from the ironmaking method, the optimal use of fuels and energy during sintering, pelletizing and direct reduction of iron ore (DRI) needs to be applied to stay competitive and Iron Ore Analysis Process Optimization Solutions Iron ore is converted into various types of iron through several processes The most common process is the use of a blast furnace to produce pig iron which is about 9294% iron and 35% carbon with smaller amounts of other elementsHow iron is made material, manufacture, making, history October 2, 1985—EPA proposes in the Federal Register (50 FR 40292) to reinterpret the scope of the mining waste exclusion as it applies to mineral and ore processing wastes, leaving only largevolume processing wastes excluded Other mineral and ore processing wastes that are hazardous would be subject to full RCRA Subtitle C (hazardous waste Mining Waste Special Wastes Wastes US EPASep 11, 2020 Ball mill for grinding iron ore Summary Mineral processing is performed to remove waste substances from useful products Throughout the mineral processing flow, care is taken to conserve the mass of valuable minerals and increase their proportion in the whole massMineral Processing Part 1 Geology for Investors

Extraction of Iron from its ores, Iron dressing, Reduction

Oct 23, 2018 S + O 2 → SO 2 4 P + 5 O 2 → 2 P 2 O 5 Roasting is the process of heating iron ore strongly in dry air for drying the ore and expelling humidity, It is used to increase the percentage of iron in the ore and for the oxidation of some impurities such as sulphur and phosphorus Roasting of iron is very important in the ore dressing process but this process pollutes the environment, Ore Leaching wastes are formed in the iron launders used to extract copper from oxide ore and to recover copper from tailings of sulphide ore, low grade ore and mine waters Because these operations are located mainly in the arid rocky area, treatment of this waste is necessary to prevent making streams unpotable and unfit for agricultural or How to Treat Wastewater from Iron and Steel Industry Metallurgical slag processing complexes Iron ore enrichment Briquetting of fines and mill scale Municipal solid waste USA +1(516) iron ore concentrate (010 mm fraction with total Fe content 65%+) Municipal solid wasteAMCOM LLC Solutionstypology of the mined substance(s), waste deposit(s) and mining systems and oreprocessing method(s), • an estimation, on the basis of the different processes employed throughout the production chain in mining operations and their management at each level, of the main types of waste generated over the last five or ten yearsMANAGEMENT OF MINING, QUARRYING AND ORE The taconite ore processing industry produces usable concentrations of ironbearing material by removing nonferrous rock (gangue) from lowgrade ore The sixdigit Source Classification Code (SCC) for taconite ore processing is 303023 Table 11231 lists the SCCs for taconite ore processing Taconite is a hard, banded, lowgrade ore, and is 1123 Taconite Ore Processing

Iron Ore HowStuffWorks

Most important, it releases oxygen from the iron ore, which makes up a high percentage of common iron ores The most primitive facility used to smelt iron is a bloomery There, a blacksmith burns charcoal with iron ore and a good supply of oxygen (provided by a bellows or blower) Charcoal is Iron ore is converted into various types of iron through several processes The most common process is the use of a blast furnace to produce pig iron which is about 9294% iron and 35% carbon with smaller amounts of other elementsHow iron is made material, manufacture, making, history Nov 01, 2017 Iron ore, coking coal, and limestone are added into the top of the blast furnace while heated air is blown into the bottom of the furnace to drive the combustion process The combustion of iron This is how iron ore is turned into steel Business Insider“Some iron ore processing plants in the Pilbara experience issues separating valuable iron ore from undesired materials in wet processing situations,” he said “When separating the iron ore from the waste becomes too difficult, mining companies will dispose of the tailings in a dam” The new chemical is added to a semiliquid mixture Chemical additive boosts iron ore yield cuts waste Gold Mine Ore Processing and Production (Area Sources) Taconite Iron Ore Processing; Asbestos Asbestos Laws and Regulations; Waste Industrial Waste: Mining Waste; TENORM: Mining Wastes: TechnologicallyEnhanced, NaturallyOccurring Radioactive Material (TENORM) produced from mining wastes Water Effluent Guidelines: Coal Mining Point Source Mining (except Oil and Gas) Sector (NAICS 212

Extracting iron Iron and aluminium GCSE Chemistry

Iron is extracted from iron ore in a huge container called a blast furnace Iron ores such as haematite contain iron(III) oxide, Fe 2 O 3 The oxygen must be removed from the iron(III) oxide in June 17, 2020 The US Environmental Protection Agency (EPA) has evaluated the risks remaining after fully implementing the 2003 National Emission Standards for Hazardous Air Pollutants (NESHAP) for Taconite Iron Ore Processing and determined that risks from this source category are acceptable EPA has determined the standards continue to provide an ample margin of safety to protect public Final Taconite Iron Ore Processing Risk and Technology