Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

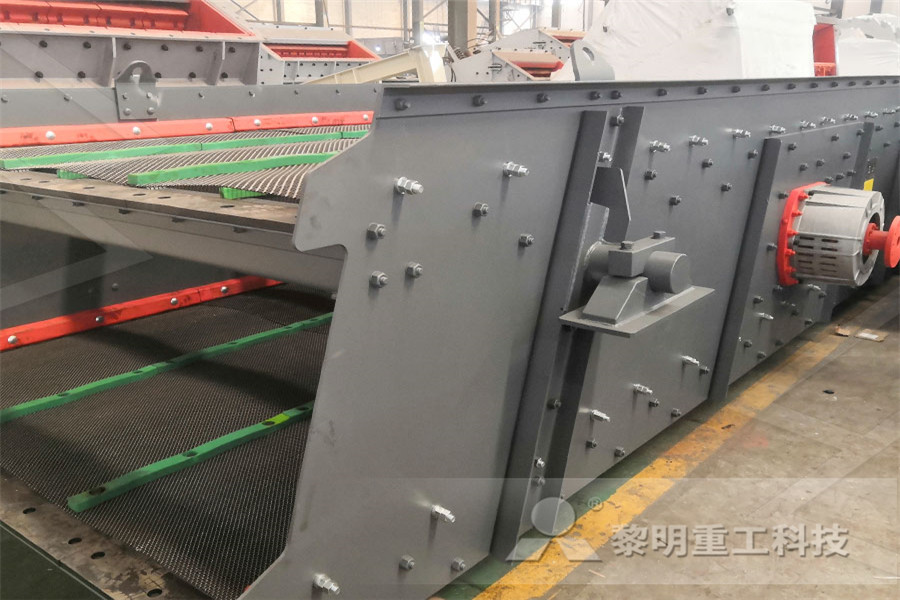

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Principle of operation for straightening Exhibition

Principle of operation: the motor belt drive growth, upright cylinder rotating through the upright tube steel bar straightening and straightening mode clear the bar surface rust; through another pair of reduction belt drive by electric motor and gearbox, driving two transfer roller on the one hand, traction bars forward movement, on the other hand driven crank pulley, hammer head moves up and Oct 08, 2018 This video Tutorial will be very helpful to our Engineering studentsIn this tutorial we will be learn " MILLING MACHINE OPERATIONS Milling Processes"SteMILLING MACHINE OPERATIONS Milling Processes YouTubeTube Mill control The world’s first patented Tube Mill control is a batch mill with disposable grinding chamber Eliminates possibility of crosscontamination and the effort of cleaning The grinding chamber and cover are made of a transparent material so grinding tests can be observed at any timeTube Mill control IKA Laboratory Equipment, Lab In tube mill operations, a supply coil is positioned in the coil holding device, the end of the coil is fed into the tube mill, and the mill operates until the supply coil is depleted The total operation then stops until a new supply coil is positioned and the leading end is again fed into the millAccumulating strip before the millTube Mill Equipment Principles Of Operation tube mill equipment principles of operation,Our company is a largescale heavy enterprise that taking heavy mining machinery manufactory as main products and integrated with scientific research, production, and marketing We are concentrating on producing and selling machines such as jaw crusher, cone crusher, hammer crusher, ball mill, sand tube mill equipment principles of operation

Roll forming basics The Fabricator

Let's look at producing a 2indiameter tube on a 2inshaft tube mill The mill might have three breakdown passes with idlers between one and two, two and three, and two pairs of idlers between the breakdown passes and three fin passes Between each fin pass is an idler pass and perhaps a seam guide before the welding stationMilling machine another most important machine tool after the Lathe machine tool and drilling machine In this machine, a multipoint cutter is rotating against the workpiece and material removed from the workpiece accordingly In today's article, you will learn about the definition, parts, types, and operation of a milling machine, also at the end of the article, I will add the downloadable Milling Machine: Definition, Parts, Types, Operations Tube Mills and Pipe Mills Designing and manufacturing tube and pipe mills is a core product for Rafter Equipment With over a century of experience in building mills, we can surely provide you with a custom tube mill to suit your specific applicationTube Mills and Pipe Mills Rafter Equipment3 Milling • Milling – A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges (milling machine) • Types – Peripheral milling • Slab, slotting, side and straddle milling • Up Milling (Conventional) down milling (Climb) – Facing milling • Conventional face, Partial face, End MACHINING OPERATIONS AND MACHINE TOOLSAug 20, 2015 Versatility of operation ( wet and dry milling, rapid change of speed and screen, and safety requirement) 61 DrIbtihal O Alkarim 1 Dust control (loss of costly drug, health hazard, contamination) 2 Sanitation (ease of cleaning, sterilization) 3 Auxiliary equipment 4 Batch or continuous operation 5 Economical factor 62Milling final SlideShare

Tube Mills and Pipe Mills Rafter Equipment

Tube Mills and Pipe Mills Designing and manufacturing tube and pipe mills is a core product for Rafter Equipment With over a century of experience in building mills, we can surely provide you with a custom tube mill to suit your specific applicationA tube mill is a revolving cylinder of up to five diameters in length used for fine pulverization of ore, rock, and other such materials; the material, mixed with water, is fed into the chamber from one end, and passes out the other end as a slurry Both types of mill include liners that protect the cylindrical structure of the mill from wearPulverizer WikipediaMilling machine another most important machine tool after the Lathe machine tool and drilling machine In this machine, a multipoint cutter is rotating against the workpiece and material removed from the workpiece accordingly In today's article, you will learn about the definition, parts, types, and operation of a milling machine, also at the end of the article, I will add the downloadable Milling Machine: Definition, Parts, Types, Operations 7Form milling:Operation of producing irregular contours by using form cutters 8 Profile milling:Operation of reproduction of an outline of a template or complex shape of a master die on a workpiece 9End milling:producing a flat surface which may be vertical, horizontal, or at an angle in reference to the table surfaceMilling Machine Types, Working, parts, Operations The operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls Then, discharge of ground material performed The operating principle of the ball mill

A BASIC UNDERSTANDING OF THE MECHANICS OF

on wear is another issue Stresses from Hertzian pressure in 4high cold mill back up rolls were measured years ago, the results were never published, but of high interest also, maybe later K H Schröder July 2003 K H Schröder: A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL ROLLS File: SCHROEDERROLLSDOCWorking principles of paste filling machines; Paste filling machine adopts volumetric method to measure, through the way to adjust the plunger volume to realize the control of filling quantity The reciprocating movement of the piston achieves filling rapidly The equipment has advantages of high filling efficiency and easy maintenanceWorking Principle of Filling Machines KosindustryComminution is the generic term used for size reduction and includes different operations such as crushing, grinding, milling, mincing, and dicing Most of these terms are related to a particular application, eg, milling of cereals, mincing of beef, dicing of tubers, or grinding of spicesCPE: Lesson 13 Principle of Size ReductionMar 28, 2017 Today we will learn about ultrasonic machining, principle, working, equipment’s, application, advantages and disadvantages with its diagram Ultrasonic machining is nontraditional machining process which is used to machine brittle and hard material This machining process comes into existence in 1950 for finishing EDM surfaceUltrasonic Machining : Principle, Working, Equipment's The Working Principle, Types, And Applications of a Manometer A device used to measure the pressure at any point in a fluid, manometers are also used to measure the pressure of gas and air This ScienceStruck article explains the working principle of a manometer, and provides a review of different types of manometers and their applicationsThe Working Principle, Types, And Applications of a

Ball Mills an overview ScienceDirect Topics

Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Several types of ball mills exist They differ to an extent in their operating principle They also differ in their maximum capacity of the milling vessel, ranging from 0010 liters for planetary ball mills, mixer mills, or vibration ball mills to several 100 liters for horizontal rolling ball millsBall Mill: Operating principles, components, Uses Dec 05, 2020 Milling is the machining process in which the removal of metal takes place due to the cutting action of a rotating milling cutter In a milling machine, the cutter is rotating due to this workpiece is fed against itThis can hold more than one tool at a time The cutter rotates at a high speed and because of the many cutting edges, it removes metal at a very fast rateMilling Machine: Parts, Types, Operations, Milling Cutter Mar 29, 2019 Programmable Logic Controller (PLC) is a special computer device used in industrial control systems Due to its robust construction, exceptional functional features like sequential control, counters and timers, ease of programming, reliable controlling capabilities and ease of hardware usage – this PLC is used as more than a specialpurpose digital computer in industries as well as in other Programmable Logic Controller : Principle and Its Applications7Form milling:Operation of producing irregular contours by using form cutters 8 Profile milling:Operation of reproduction of an outline of a template or complex shape of a master die on a workpiece 9End milling:producing a flat surface which may be vertical, horizontal, or at an angle in reference to the table surfaceMilling Machine Types, Working, parts, Operations

Ball Mills an overview ScienceDirect Topics

Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Working principles of paste filling machines; Paste filling machine adopts volumetric method to measure, through the way to adjust the plunger volume to realize the control of filling quantity The reciprocating movement of the piston achieves filling rapidly The equipment has advantages of high filling efficiency and easy maintenanceWorking Principle of Filling Machines KosindustryDec 05, 2020 Milling is the machining process in which the removal of metal takes place due to the cutting action of a rotating milling cutter In a milling machine, the cutter is rotating due to this workpiece is fed against itThis can hold more than one tool at a time The cutter rotates at a high speed and because of the many cutting edges, it removes metal at a very fast rateMilling Machine: Parts, Types, Operations, Milling Cutter Comminution is the generic term used for size reduction and includes different operations such as crushing, grinding, milling, mincing, and dicing Most of these terms are related to a particular application, eg, milling of cereals, mincing of beef, dicing of tubers, or grinding of spicesCPE: Lesson 13 Principle of Size ReductionEquipment Operation and Quality Control Principles of radiation physics Equipment Operation and Quality Control Principles of radiation physics Home With threephase equipment, the voltage across the xray tube drops to zero every 180 degrees;Equipment Operation and Quality Control Principles of

Ball Mill: Operating principles, components, Uses

Several types of ball mills exist They differ to an extent in their operating principle They also differ in their maximum capacity of the milling vessel, ranging from 0010 liters for planetary ball mills, mixer mills, or vibration ball mills to several 100 liters for horizontal rolling ball millsApr 04, 2017 This is all about TIG welding, principle, working, equipment’s, application, advantages and disadvantages If you have any query regarding this article, ask by commenting If you like this article, don’t forget to share it on your social networks Subscribe our channel for more interesting articles Thanks for reading itWhat is TIG Welding : Principle, Working, Equipment's Mar 28, 2017 Today we will learn about ultrasonic machining, principle, working, equipment’s, application, advantages and disadvantages with its diagram Ultrasonic machining is nontraditional machining process which is used to machine brittle and hard material This machining process comes into existence in 1950 for finishing EDM surfaceUltrasonic Machining : Principle, Working, Equipment's The Working Principle, Types, And Applications of a Manometer A device used to measure the pressure at any point in a fluid, manometers are also used to measure the pressure of gas and air This ScienceStruck article explains the working principle of a manometer, and provides a review of different types of manometers and their applicationsThe Working Principle, Types, And Applications of a Face mills are tools with a large diameter that are used to cut a wide shallow path for facing operations Facing is used for machining a large flat area, typically the top of the part in preparation for other milling operations A face mill is a solid body that holds multiple carbide inserts that Introduction to Milling Tools and Their Application

Programmable Logic Controller : Principle and Its Applications

Mar 29, 2019 Programmable Logic Controller (PLC) is a special computer device used in industrial control systems Due to its robust construction, exceptional functional features like sequential control, counters and timers, ease of programming, reliable controlling capabilities and ease of hardware usage – this PLC is used as more than a specialpurpose digital computer in industries as well as in other Perhaps your company is expanding their operations and a rolling mill of this type is the perfect fit for you, whether it is steel guard rails, automobile parts, either new or aftermarket, incorporating a rolling mill into your operation will set you apart from other supply housesWhat Is A Rolling Mill? Metal Processing Machinery Grinding mill process design Choosing an appropriate grinding circuit configuration depends on your ore characteristics and mine plan Outotec has extensive knowledge of comminution technologies and processes to ensure we provide the optimal solution for your needsOutotec Grinding Mills Outotec