Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

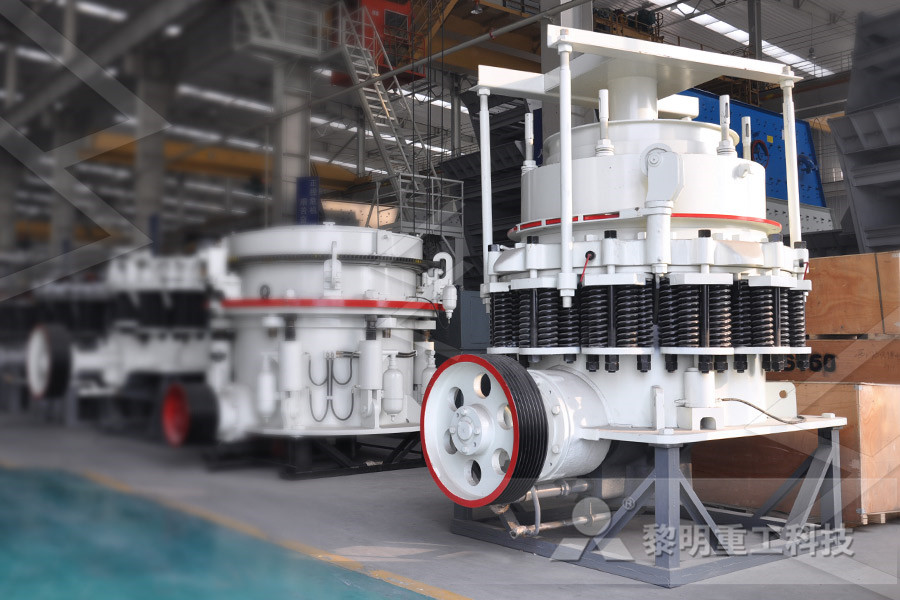

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Ball Mills Glen Mills, Inc

The extremely high centrifugal forces of planetary ball mills result in very high pulverization energy and therefore short grinding times The PM 400 is a robust floor model with 4 grinding stations You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy input The unique combination of high Specifications With more than 100 years of experience in ball mill technology, ’s ball mills are designed for long life and minimum maintenance They grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuitsBall mills Ball Mills Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applicationsBall Mill RETSCH powerful grinding and homogenizationApr 24, 2020 Ball mill and Rod mill is a tool used in modern mineral processing, coal chemical industry, sand making and other industries to grind ore into powder and then used in smelting industry to smelt gold, steel, etc Coal chemical industry coal water slurry is gasified to make chemical raw materials, and sand making is used for glass or building sandHistory of the Ball Mill and Rod Mill Grinding Balls Ball mill, which can also be called grinding mills, ball grinder or grinding ball, is the vital machine for crushing the materials after they are primarily crushedBall MillBall MillsGrinding MillsBall GrinderGrinding

HOW BALL MILL WORKS? energosteel

Oct 10, 2016 At the short ball mill grinding is a more rough and for grinding fineness a lot of material has to be returned from classifier to the mill, it leads to mill overload In long ball mills the grinding occurs only at the front and the rest of the balls in the drum only increases power consumptionDiameter – depending on the material, ranging from 005 mm to 2 mm for small media mills, up to 1/8” to 1” for traditional Attritors and up to ½” to 2” for ball mills Composition – metallic grinding media like carbon steel, forged steel, stainless steel or chrome steel grinding balls Grinding Media Grinding Balls Union Process, IncTo participate in the 911Metallurgist Forums, be sure to JOIN LOGIN Use Add New Topic to ask a New Question/Discussion about Grinding OR Select a Topic that Interests you Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent) Using Add Reply allows you to Attach Images or PDF files and provide a more complete input Use Add Comment = to comment on someone else’s Grinding time for ball mills Grinding Classification GRINDING MILLS – BALL Mills, SAG Mills, AG Mills ROD Mills We refurbish, design and manufacture an extensive range of highquality mills and mill components to exacting standards, offering you a turnkey service that’s backed by two decades of engineering expertiseGRINDING MILLS – BALL Mills, SAG Mills, AG HarcliffWith the constant efforts for more then a decade, we are successfully catering to the need of various industries with our extensive range of grinding machines, grinding mills, emulsifier mixerOur range includes attrition mills, ball mills, submersible basket mills, bead mills, pug mills, blending machines, ribbon blenders, sand mills, planetary mixers and othersGrinding Machines Grinding Mills and Industrial Grinding

Ball mills

Reliable and effective grinding technology for diverse applications With more than 100 years of experience in developing this technology has designed, manufactured and installed over 8,000 ball and pebble mills all over the world for a wide range of RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming Ball Mill RETSCH powerful grinding and homogenizationOct 10, 2016 Pipe ball mills have a drum length longer than three drum diameters Pic 2 Cylindrical balls mill A cylindrical ball mill used for grinding the coarse material This mill should have a short length because the balls distributed uniformly over the entire length of the mill and during rotation obtained the same pulseHOW BALL MILL WORKS? energosteelBall mill, which can also be called grinding mills, ball grinder or grinding ball, is the vital machine for crushing the materials after they are primarily crushed Ball mills can be divided into many types, such as tube mill, cement ball mill, superfine lamination grinding miller, horizontal ball mill, energysaving ball mill, overflow ball Ball MillBall MillsGrinding MillsBall GrinderGrinding DOVE Ball Mills are highly efficient size reduction machines, designed for grinding applications, where fine material is required Applicable for wet and dry grinding applications within the following branches of industries: Mining, Hard Rock (primary deposit) Gold Mining Application, as Ball Mill Ball Mills Wet Dry Grinding Up To 240

MATERIAL GRINDING BY MEANS OF BALL MILLS

2 PECULIARITIES OF BALL MILL AUTOMATION The process of solid material grinding in ball mills has been automated poorly, because there were no methods to measure the main parameters of the grinding process, such as amount of the material in the mill, grinding Grinding Mills Westpro’s heavy duty grinding mills are designed for durability and excellent grinding performance in mining applications 6ft Diameter x10ft Ball and Rod Mills at the Westpro Shop ADVANTAGES Sizes up to 49m (16tf) diameter and 4500hp (3356KW) Available with rubber, steel or ceramic liners; APPLICATIONS Size reduction of Grinding Mills Westpro MachineryDiameter – depending on the material, ranging from 005 mm to 2 mm for small media mills, up to 1/8” to 1” for traditional Attritors and up to ½” to 2” for ball mills Composition – metallic grinding media like carbon steel, forged steel, stainless steel or chrome steel grinding balls Grinding Media Grinding Balls Union Process, IncGRINDING MILLS – BALL Mills, SAG Mills, AG Mills ROD Mills We refurbish, design and manufacture an extensive range of highquality mills and mill components to exacting standards, offering you a turnkey service that’s backed by two decades of engineering expertiseGRINDING MILLS – BALL Mills, SAG Mills, AG HarcliffWith the constant efforts for more then a decade, we are successfully catering to the need of various industries with our extensive range of grinding machines, grinding mills, emulsifier mixerOur range includes attrition mills, ball mills, submersible basket mills, bead mills, pug mills, blending machines, ribbon blenders, sand mills, planetary mixers and othersGrinding Machines Grinding Mills and Industrial Grinding

Used Ballmills For Sale Grinding Mills, Crushers

GRINDING EQUIPMENT; BALL MILLS ; Buy Used Ball Mills 51 Items Available UNUSED FLSMIDTH 26’ x 43' Dual Pinion Ball Mill with 2 ABB 9,000 kW (12,069 HP) Motors w/ ABB VFD for Total Power of 18,000 kW (24,138 HP) Ball Mills, each with (2) GE Dual Pinion Synchronous 4,650 KW (6,250 HP) Motors (50 HZ) 1 Fixed Speed Drive and 1 Variable Industrial Ball Mills use horizontal rotating cylinders that contain the grinding media and the particles to be broken The mass moves up the wall of the cylinder as it rotates and falls back into the “toe” of the mill when the force of gravity exceeds friction and centrifugal forcesIndustrial Ball Mills for Sale 911MetallurgistPlanetary ball mills are smaller than common ball mills and mainly used in laboratories for grinding sample material down to very small sizes A planetary ball mill consists of at least one grinding jar which is arranged eccentrically on a socalled sun wheelLaboratory Ball Mills, Planetary Ball Mill, High Energy The mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a rod mill, ball mill or pebble mill AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball millAMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator Grinding Mills Westpro’s heavy duty grinding mills are designed for durability and excellent grinding performance in mining applications 6ft Diameter x10ft Ball and Rod Mills at the Westpro Shop ADVANTAGES Sizes up to 49m (16tf) diameter and 4500hp (3356KW) Available with rubber, steel or ceramic liners; APPLICATIONS Size reduction of Grinding Mills Westpro Machinery

Grinding Mills 911Metallurgist

Double Stage Ball Mills Occasionally, the liberation requirement for an ore requires very fine primary grinding Usually, the most expeditious way to accomplish this objective is by double stage ball milling Both mills are usually operated in closed circuit with separate classifiers In smaller plants, grinding mill drives should be as simple 19 rows DOVE Ball Mills are highly efficient size reduction machines, designed for grinding Ball Mill Ball Mills Wet Dry Grinding Up To 240 supported grinding mills up to the largest sizes SAG/ball mill circuit incorporating pebble crushers and a POLYCOM® highpressure grinding roll SAG and ball mill for gold ore grinding One of three SAG mills with 975 m diameter and 2 x 4000 kW drive power These mills operate in conjunction with ball mills for iron ore grinding in IranAutogenous mills, semiautogenous mills and ball mills for 2 PECULIARITIES OF BALL MILL AUTOMATION The process of solid material grinding in ball mills has been automated poorly, because there were no methods to measure the main parameters of the grinding process, such as amount of the material in the mill, grinding MATERIAL GRINDING BY MEANS OF BALL MILLSDiameter – depending on the material, ranging from 005 mm to 2 mm for small media mills, up to 1/8” to 1” for traditional Attritors and up to ½” to 2” for ball mills Composition – metallic grinding media like carbon steel, forged steel, stainless steel or chrome steel grinding balls Grinding Media Grinding Balls Union Process, Inc

Grinding Mills Nelson Machinery Equipment Ltd

Nelson Machinery sells new used grinding mills including ball mills, SAG mills, tower mills, Raymond roller mills Equip yourself with the gold standardThe mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a rod mill, ball mill or pebble mill AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball millAMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator With the constant efforts for more then a decade, we are successfully catering to the need of various industries with our extensive range of grinding machines, grinding mills, emulsifier mixerOur range includes attrition mills, ball mills, submersible basket mills, bead mills, pug mills, blending machines, ribbon blenders, sand mills, planetary mixers and othersGrinding Machines Grinding Mills and Industrial Grinding Regarding operations, in a ball mill, the grinding media has a higher rate of wear about the rollers and table in the VRM In ball mills, it is essential to monitor its performance via axial testing to ascertain that the media grading is right and that there are enough topsize media to grind the mill feed materialsBall Mills Or Vertical Roller Mills: Which Is Better For A ball mill crushes solids into a fine powder within a rotating drum, using balls as the grinding medium Applications Ball mills are found in settings as diverse as laboratories and mines, among others Technologies Ball mills can grind in either a wet or a dry environmentBall mill, Ball grinding mill All industrial

Ball Mills Economy Ball Mill in Tollesboro, KY

Economy Ball Mill, a division of JSB Industrial Solutions, Inc manufactures Ball Mills that are diverse in applications and uses Since we are an OEM and our product line has been around for over 50 years, we can provide the experience and knowledge to enhance your process capabilities by applying our procedural based manufacturing methods to your process knowledgeBall mills have been manufactured for over 150 years, and have become an industry standard for dry minerals grinding A ball mill is still the preferred solution for many types of dry grinding duty A ball mill consists of a rotating horizontal cylinder, containing a cascading grinding media, typically steel or ceramic balls, in the range of 10 Ball mills dry grinding systems fine powder processing