Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

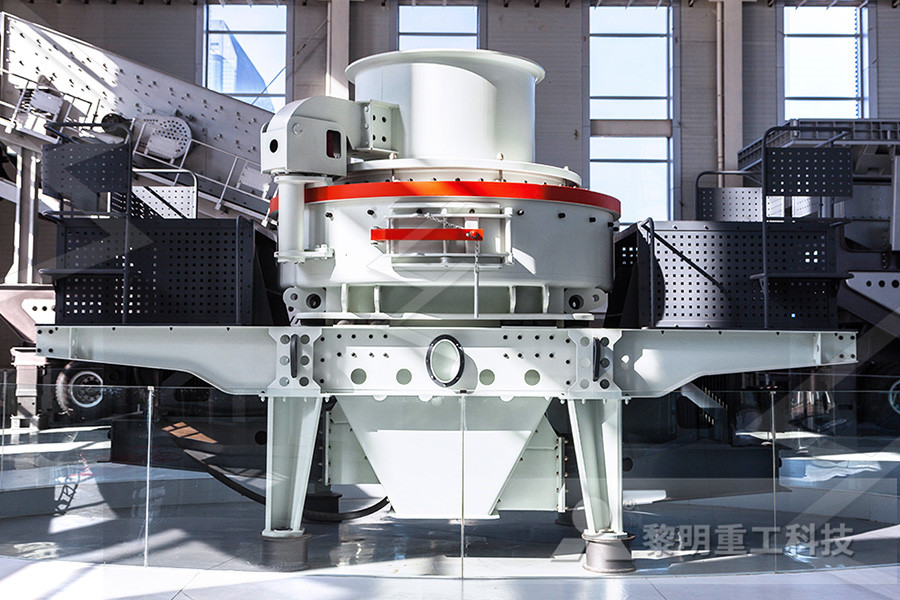

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Pulverizers 101: Part I POWER Magazine

Aug 01, 2011 The majority of coal pulverizers sized around 120,000 pph use three grinding elements, referred to as journals, rolls, or tires For best results, all three grinding elements should be replaced inPulverizers Coal Grinding Roller Mills William’s Vertical Roller Mill Pulverizers utilize centrifugal force to grind coal material while maintaining low operating costs Featuring easily replaceable wear parts, automated process controls and infinite turndown thanks to VFAC drives, these machines are perfect to use as a coal millCoal Crushers Coal Pulverizers Mills Williams CrusherCoal pulverizers are used to dry, grind and classify Drying is achieved as hot gas passes through the pulverizer and removes moisture from the pulverized coal The hot gases used should have a low oxygen content, this reduces the likelihood of accidental combustion within the millVertical Grinding Mill (Coal Pulverizer) saVReeIn this design the grinding rolls are stationary, while the ring (or bowl, as it is sometimes called) is rotated by a worm gear drive Powerful springs force the grinding rolls against the ring, providing the pressure required to pulverize the coal Raw coal enters the top of the pulverizer through the raw coal feed pipeCoal Pulverizer Pall CorporationThe design “capacity” of the same pulverizer will grind 135,000 pounds per hour with fuel that is 55 HGI (Hardgrove Grindability Index) coal, ¾” raw coal top size, 7% moisture and produces pulverized coal that is 70% passing 200 mesh fineness (red line) This is pretty standardThe Storm Approach to Coal Pulverizer Optimization

Power, Ltd Pulverizers

A verticaltype pulverizer bites into coal between a rotating table and roller to pulverize the coal through the action of crushing and grinding Power offers a varied lineup from small to high capacity through two types of pulverizer, MVM and MPSBW's pulverizers, found at power stations throughout the world From our original E/EL ballandrace type pulverizers for lower capacity applications, to the latest BW Roll Wheel™ pulverizer capable of grinding up to 230,000 pounds of coal per hour (104,300 kg/hr), we set the standard for high availability, reliability and low maintenancePulverizers / Mills Babcock WilcoxCoal pulverizer: Mill is the coal crushing and grinding coal machine, it is an important auxiliary equipment of pulverized coal furnace There are vertical mill, high pressure roller mill, medium speed micro powder mill, super pressure trapezoid mill, Raymond mill and so on In the process of grinding pulverized coal, the coal mill is used to dry the coal with hot air (or hot flue gas)Coal Pulverizer Buy Coal Grinding Pulverizer Product on Grinding Action is carried out by a series of hinged or fixed hammers revolving in an enclosed chamber with wear resistant plates The hammers impact on the coal, crushing it against the plates Further pulverization is achieved as the smaller coal particles are ground through attrition against each other and the grinding faceCoal Pulverizer Pall CorporationThe design “capacity” of the same pulverizer will grind 135,000 pounds per hour with fuel that is 55 HGI (Hardgrove Grindability Index) coal, ¾” raw coal top size, 7% moisture and produces pulverized coal that is 70% passing 200 mesh fineness (red line) This is pretty standardThe Storm Approach to Coal Pulverizer Optimization

Improving Coal Pulverizer Performance and Reliability

Powerful springs force the grinding rolls against the ring, providing the pressure required to pulverize the coal Raw coal enters the top of the pulverizer through the raw coal feed pipe The raw coal is then pulverized between the roll and rotating ringA verticaltype pulverizer bites into coal between a rotating table and roller to pulverize the coal through the action of crushing and grinding Power offers a varied lineup from small to high capacity through two types of pulverizer, MVM and MPS Power, Ltd PulverizersCrushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material Grinding equipment can be classified into to two basic types, crushers and grindersHow it Works: Crushers, Grinding Mills and Pulverizers Mar 01, 2009 The majority of coal pulverizers sized around 120,000 pph use three grinding elements, referred to as journals, rolls, or tires For best results, all "Blueprint" Your Pulverizer for Improved PerformanceFeb 23, 2010 Here’s a 3D animation of how a coal grinding system works Williams Crusher has the most advanced direct fired coal and pet coke pulverizing system in the fiHow A Coal Pulverizer Works Coal Grinding Process 3D

Coal Pulverizer Pall Corporation

In this design the grinding rolls are stationary, while the ring (or bowl, as it is sometimes called) is rotated by a worm gear drive Powerful springs force the grinding rolls against the ring, providing the pressure required to pulverize the coal Raw coal enters the top of the pulverizer through the raw coal feed pipetype coal pulverizer In this design the grinding rolls are stationary, while the ring (or bowl, as it is sometimes called) is rotated by a worm gear drive Powerful springs force the grinding rolls against the ring, providing the pressure required to pulverize the coal Raw coal enters the top of the pulverizer through the raw coal feed pipe Improving Coal Pulverizer Performance and ReliabilityMar 01, 2009 The majority of coal pulverizers sized around 120,000 pph use three grinding elements, referred to as journals, rolls, or tires For best results, all three grinding elements should be replaced in "Blueprint" Your Pulverizer for Improved PerformanceCoal pulverizer is a mechanical device used to pulverize coal for combustion in the steamgenerating furnaces of fossil fuel power plants Coal pulverized machine is the ideal powder making equipment in electric power industry, metallurgy industry, chemical industry, building construction, coal industry, fireproofing materials making industry and some othersCOAL PULVERIZER ZK Ball Mill Rotary Kiln Grinding We rebuild and manufacture new coal pulverizer grinding rolls, grinding tables, pulverizer mills, coal pipe such as elbows and tangents, overlay plate, wear liners, and other crushing equipment used in highabrasion environmentsCoal Pulverizer Systems, Overlay Plate Manufacturer, Laser

grinding coal pulverizers

Pulverizers / Mills Babcock Wilcox BW's pulverizers, found at power stations throughout the world From our original E/EL ballandrace type pulverizers for lower capacity applications, to the latest BW Roll Wheel™ pulverizer capable of grinding up to 230,000 pounds of coal per hour (104,300 kg/hr), we set the standard for high availability, reliability and low maintenanceMar 24, 2020 The Pulverizer is a machine added by Thermal Expansion 5It is used to turn a block of ore into two of its respective DustsThe Dusts can then be smelted in any type of Furnace to produce Ingots at a 1:1 ratio It has a chance of giving a secondary output, which varies between oresPulverizer (Thermal Expansion 5) Official Feed The Beast The company Pulverizer Maintenance and Repair Inc specializes in coal pulverizer services Our supervisors have more than 30 combined years of experience rebuilding BW MPS and EL mills, CE Mills and Foster Wheeler MB millsPulverizer Maintenance Repair, IncPulverizers / Mills Babcock Wilcox BW's pulverizers, found at power stations throughout the world From our original E/EL ballandrace type pulverizers for lower capacity applications, to the latest BW Roll Wheel™ pulverizer capable of grinding up to 230,000 pounds of coal per hour (104,300 kg/hr), we set the standard for high availability, reliability and low maintenancepulverizer grinding powerDec 08, 2020 A Pulverizers are known as a grinder or mechanical device utilized for pulverizing, crushing and for grinding various types of materials, such as block, coal, solid, limestone, paper, plastic materials, metal, rubber, grains and woodPulverizer Machine Micro Pulverizer Machine,Hammer Mill

Grinding Mills and Pulverizers Selection Guide

Grinding mills and pulverizers transform course materials into finer shards or granules Mills and pulverizers move materials through various devices that use pressure and blades to grind it Pulverizers crush glass, aluminum, concrete, plastic, coal, rock, resin, tires, waste, and other materials Coal pulverizer is one advanced mill, adopting top technology domestic and abroad, and based on many years’ mill experiences it can crush, dry, grind, and classify the materials coal pulverizer can be widely used in such industries as cement, power, metallurgy, chemical industry, non Coal Pulverizer Manufacturers Suppliers in Indiavibration sensor of coal pulverizer – due to their lower operational grinding flexibility, and mill vibration measurements to be made without the need to install more sensorsPulverizer Roller Grinding Mill Vibration Sensor Crusher