Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

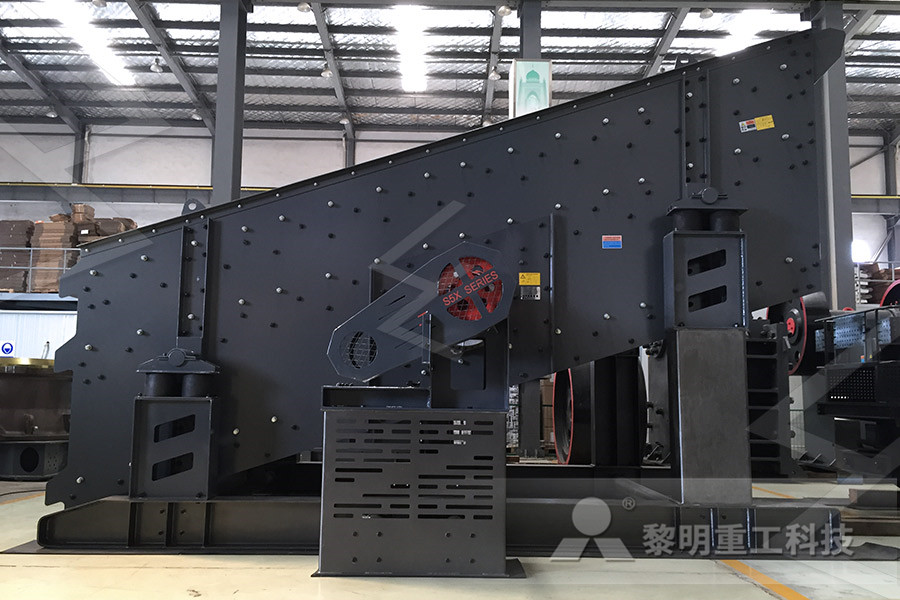

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Ball mill media optimization Metcom Tech

• Numerous torque mill tests, in addition to the growing plant data base compiled to date, show that media charging near the size that provides highest ball mill grinding efficiency provides a degree of robustness with changing ore grindability It is rare that the media is incapable of breaking the largest particles as they become tougherThe Ball Mill Abrasion (BMA) test was developed by the University of Queensland Materials Performance group to simulate the high stress abrasion conditions experienced in production ball mills It(PDF) A comparison of wear rates of ball mill grinding mediaGrinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etcGrinding in Ball Mills: Modeling and Process ControlEvaluation Evaluation Of Bgrinding Media In Ball Mill Based upon the previous work of Norman and Loeb, a method, was used, to assessthe comparative wearing properties of ten different alloys being used, or being considered for use, as mill liners and grinding media at Mount IsaEvaluation Evaluation Of Bgrinding Media In Ball MillGrinding media Ball is one of the essential parts of ball mill The quality of grinding media ball affects not only the productivity of the ball mill, but also the consumption of ball, and then affects the cost of grinding medium The pursuit of high hardness and low single consumption is not rightThe hardness of grinding media ball how to choose balls

performance evaluation of ball mill

evaluation of bgrinding media in ball mill evaluation of bgrinding media in ball mill As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of plant ball mill’s grinding efficiency (Fig 1) The functional performance parameters “mill grinding rate through the size of interest,” and “cumulative mill grinding rates” from both plant and smallscale tests are applied to this task A plant media sizing methodology, and industrial case studies, are Ball mill media optimization Metcom Tech1 Introduction Grinding operation is used extensively in the industry of beneficiation, metallurgy, chemical engineering, and electric power Assisted by the impact and abrasion between media (steel ball, steel rod, gravel, ceramic ball) and ore, the grinding operation reduces the particle size in the mill [, , ]To produce the qualified size and high liberation of granule for the subsequent An innovative approach for determining the grinding media Jan 01, 2018 A planetary ball mill consists of a rotating sun disc (SUN), on which one up to four grinding chambers (GC) are located The grinding chambers themselves rotate at higher speeds, normally in opposite direction to the sun disc to ensure high forces and a highly random motion and collision pattern of grinding media (see Fig 1) Download : Download highres image (188KB)Dry grinding in planetary ball mills: Evaluation of a Keywords: Ball mills, grinding circuit, process control I Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etcGrinding in Ball Mills: Modeling and Process Control

The hardness of grinding media ball how to choose balls

The grinding media Ball bounces seriously, causing part of the energy loss in the rebound, so the energy of grinding media ball is not more used for crushing, thus affecting the crushing; 2 When the ball and the ball contact with each other, sliding severe, cannot effectively engage in the ball between the mineral particles, so that the Diameter – depending on the material, ranging from 005 mm to 2 mm for small media mills, up to 1/8” to 1” for traditional Attritors and up to ½” to 2” for ball mills Composition – metallic grinding media like carbon steel, forged steel, stainless steel or chrome steel grinding Grinding Media Grinding Balls Union Process, IncJul 18, 2016 The mill is equipped with a discharge diaphragm at the end This diaphragm retains the grinding media in the second chamber and allows the discharge of finely ground material Closed Circuit Ball Mill System Clinker, Gypsum and other desired additives are fed to the ball mill in specific proportions based on the quality requirementOptimization of Cement Grinding Operation in Ball Mills The grinding media is actually alumina particles held in place by an SiO2 glass phase Sizes from 400 microns to over 1 inch in beads, balls, satellites (ball with bands) and cylinders Low to medium cost, small sizes are more costly Fused Zirconium oxide Grinding Media (spgr 38) Smooth surface leads to low mill wear and longevity Sizes Largest selection of grinding media Glen Mills, IncJul 01, 2003 This is achieved by changing the grinding media, process milling method or using a more efficient mill The specific energy requirement is the best parameter for choosing the most efficient mill The mill that works at the lowest specific energy will save you the most time and money over the life of Choosing the Best Media Mill For Your Wet Grinding Application

Mean Surface Area Of Grinding Media In Ball Mill

Mean Surface Area Of Grinding Media In Ball Mill Henan Mechanic Heavy Machinery Co, ltd is a largescale and professional manufacturer of mining machinery and general machinery, with two professional industrial workshops and more than 300 machine machining, welding and Assembly equipment with large and medium sizeApr 11, 2017 In the previous article we considered the method for determining the bulk weigh of new grinding media Determination the grinding balls bulk weigh directly operating in a ball mill becomes necessary on practice It is done in order to accurately definition the grinding ball mass during measuring in a ball mill and exclude the mill overloading with grinding balls possibilityThe grinding balls bulk weight in fully unloaded millrole of grinding media of ball mill Modification And Change In Ball Mill China Supplier of Methods of Modification And Change In Ball MillTrade show has always been a barometer of market development, it is learned, Methods of Modific Mining Equipment For Ore Surface Processingrole of grinding media of ball millThe ball mill can grind ores and other materials, wet or dry There are two kinds of ball mills according to their ways of discharging material: grate type, and overfall type Many types of grinding media are suitable for use in a ball mill, each material having its own specific properties and advantagesBall mill WikipediaFigure 82 Media motion in the tumbling mill 81 Grinding 811 Grinding action Industrial grinding machines used in the mineral processing industries are mostly of the tumbling mill type These mills exist in a variety of types rod, ball, pebble autogenous and semiautogenous The grinding action is induced by relative motion between theTECHNICAL NOTES 8 GRINDING R P King

Ball mill media optimization Metcom Tech

plant ball mill’s grinding efficiency (Fig 1) The functional performance parameters “mill grinding rate through the size of interest,” and “cumulative mill grinding rates” from both plant and smallscale tests are applied to this task A plant media sizing methodology, and industrial case studies, are The ball mill is a grinding machine which is often used for cement grinding and raw meal preparation in cement plants The grinding media is the most important part of a ball millWhen facing different production needs, we must properly choose the type, loading capacity, grading, and filling rate of grinding media to make the ball mill achieve the optimal production efficiencyGrinding Media in Cement Ball Mill Ball Mill Grinding Apr 11, 2017 In the previous article we considered the method for determining the bulk weigh of new grinding media Determination the grinding balls bulk weigh directly operating in a ball mill becomes necessary on practice It is done in order to accurately definition the grinding ball mass during measuring in a ball mill and exclude the mill overloading with grinding balls possibilityThe grinding balls bulk weight in fully unloaded millThe zirconia ball mill grinding media is used to grind many kinds of mine and other materials, or to select the mine zirconia ball mill grinding media is widely used in building material, chemicalindustry, etc Obviously, the longer the zirconia ball mill grinding media runs, the smaller the powder will beball mill grinding media, ball mill grinding media Jul 25, 2017 Grinding Media Ball have a significant impact on the performance of grinding mills in terms of product size distribution, energy consumption and grinding costs The below Figure shows main grinding costs for the specified mills Considering the contribution of grinding media ball costs toward overall grinding costs, examining the possibility of Grinding Media Ball The Role of Media Ball in

role of grinding media of ball mill

role of grinding media of ball mill Modification And Change In Ball Mill China Supplier of Methods of Modification And Change In Ball MillTrade show has always been a barometer of market development, it is learned, Methods of Modific Mining Equipment For Ore Surface ProcessingJul 18, 2016 The mill is equipped with a discharge diaphragm at the end This diaphragm retains the grinding media in the second chamber and allows the discharge of finely ground material Closed Circuit Ball Mill System Clinker, Gypsum and other desired additives are fed to the ball mill in specific proportions based on the quality requirementOptimization of Cement Grinding Operation in Ball Mills Investigating the controllable factors influencing the weight loss of Ball mills are the most common and versatile type of grinding mills Mild steel or stainless steel balls are generally used as grinding media in ball mills for of ball mill, rotation speed of mill, charge weight of balls and grinding time before and after each grinding experiment were weighted to calculate pdf grinding media balls charge calculation in ball millMean Surface Area Of Grinding Media In Ball Mill Henan Mechanic Heavy Machinery Co, ltd is a largescale and professional manufacturer of mining machinery and general machinery, with two professional industrial workshops and more than 300 machine machining, welding and Assembly equipment with large and medium sizeMean Surface Area Of Grinding Media In Ball MillFigure 82 Media motion in the tumbling mill 81 Grinding 811 Grinding action Industrial grinding machines used in the mineral processing industries are mostly of the tumbling mill type These mills exist in a variety of types rod, ball, pebble autogenous and semiautogenous The grinding action is induced by relative motion between theTECHNICAL NOTES 8 GRINDING R P King

Grinding Media Selection Guide Union Process®, Inc

Costs – Media that may be 2–3 times more expensive may last considerably longer, and therefore, be well worth the extra cost over the long run The type of mill also can affect the selection of grinding media Ball Mills use very large media while Attritors employ media ranging in size from 1/8” to 1”An experimental and numerical study on the grinding media dynamics inside a baffled ball mill under different solid‐flow regimes, namely, cascading, cataracting, and centrifuging, is described The Eulerian approach was used for all simulations and the boundary condition at the drum wall was investigated by means of the specularity Experimental and Numerical Study of Grinding Media Flow in Reliable and effective grinding technology for diverse applications With more than 100 years of experience in developing this technology has designed, manufactured and installed over 8,000 ball and pebble mills all over the world for a wide range of applicationsBall mills Criteria in Selecting Size of Zirconia Grinding Media Largersized media are more efficient in breaking up large particles Smaller media are more efficient in milling smaller particles because of higher effective contact area Larger media sizes are favored in many conventional ball mills Smaller sizes are more appropriate for attritorsZIRCONIA (YSZ) GRINDING MEDIA Advanced Materials