Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

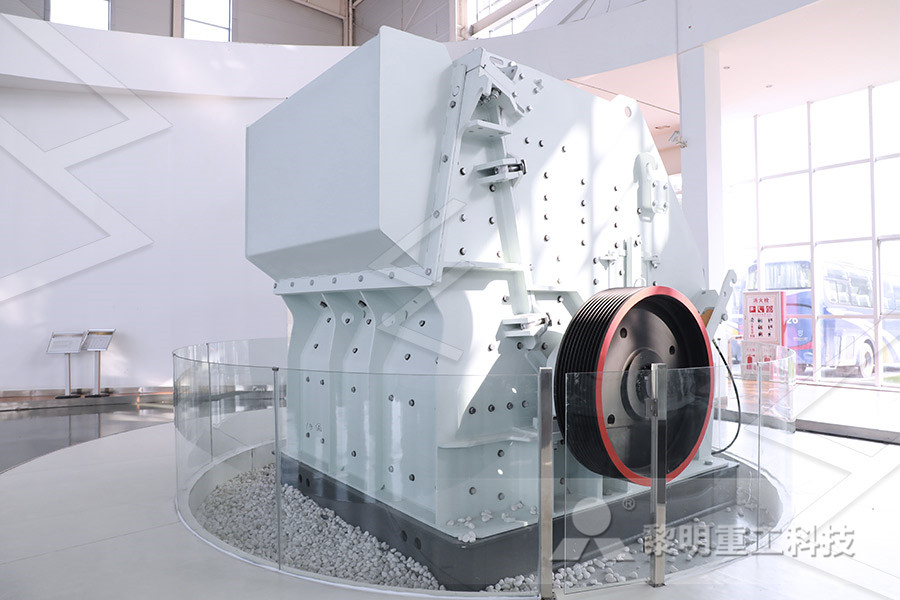

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Acid Leaching Copper Ore Treatment Method

Metallurgical ContentAcid Leaching Process FlowsheetCHEMISTRY OF COPPER DISSOLUTIONPREPARATION OF THE COPPER ORESTORAGE AND FEEDING THE ORECOPPER LEACHINGCHARGING THE TANKSCOPPER PRECIPITATIONACID SUPPLYPRODUCTION OF SULPHURIC ACID The treatment of copper oresHeap leaching is an industrial mining process used to extract precious metals, copper, uranium, and other compounds from oreusing a series of chemical reactions that absorb specific minerals and reseparate them after their division from other earth materials Similar to in situ mining, heap leach mining differs in that it places ore on a liner, then adds the chemicals via drip systems to the ore, whereas in situ mining lacks these liners and pulls pregnant solution up to obtain the minerals Heap leaching is widely used iHeap leaching Wikipediacase for testing the possibility of leaching the copper tailings The ore used,was a low grade copper tailing The are is highly si1icous, which fact is favorable to leaching, as the Si02 does not interfere with the re actions between the copper in the ore and the solution The screen analysis of the ore is as fol10ws;On 80 mesh =Leaching copper tailingsThe coarser ore goes to the heap leach, where the copper is subjected to a dilute sulfuric acid solution to dissolve the copper Then the leach solution containing the dissolved copper is subjected to a process called solvent extraction (SX)Copper ore leaching processing agnqtechActually, the current heap leaching process at mining companies involves a curing stage with the addition of 12 kg of sulfuric acid per ton of ore and a determined amount of Intermediate Pregnant Leach Solution (IPLS) The agglomerated ore is transported by conveyor belts to form 107 leach pads weighing a total of approximately 200,000 tonsLeaching of Primary Copper Sulfide Ore in ChlorideFerrous

Leaching Mining Fundamentals

Mar 05, 2014 Leaching is a chemical process in mining for extracting valuable minerals from ore Leaching also takes place in nature, where the rocks are dissolved by water Post leaching, the rocks are left with a smaller proportion of minerals than they originally containedcase for testing the possibility of leaching the copper tailings The ore used,was a low grade copper tailing The are is highly si1icous, which fact is favorable to leaching, as the Si02 does not interfere with the re actions between the copper in the ore and the solution The screen analysis of the ore is as fol10ws;On 80 mesh =Leaching copper tailingsTable of ContentsBringing Copper Metal into SolutionRecovering Copper Metal from Leach LiquorsCopper Leaching EquipmentCopper Leaching CostsCopper Leaching Practices The advance made in recent times in this branch of metallurgy is indicated by the attention the subject is receiving from important American Copper producing companies Reference to the files of publications devoted to Copper Leaching MethodHeap leaching is an industrial mining process used to extract precious metals, copper, uranium, and other compounds from ore using a series of chemical reactions that absorb specific minerals and reseparate them after their division from other earth materials Similar to in situ mining, heap leach mining differs in that it places ore on a liner, then adds the chemicals via drip systems to the Heap leaching WikipediaJul 01, 2020 The most obvious leaching differences among the three communities occurred in the leaching process of primary copper sulfide DXore, during which, the pH decreased to 145, 157 and 174 at 8th day All the results demonstrated that the native communities had the strongest ability of sulfur oxidizing to their local ore samplesEffective bioleaching of lowgrade copper ores: Insights

Copper Mining and Extraction: Oxide Ores

Most of the copper ores mined today are oxide or sulfide ores Extraction of sulfide ores is covered in more detail in Copper Mining and Extraction: Sulfide Ores (11–14), but is introduced here because an important byproduct of this process is used for the extraction of oxide ores Pyroprocessing Sulfide Ores Provides Acid for LeachingHeap leaching relies on a leaching agent moving through a bed of heaped ore to extract the metallic components: Crushed ore is stacked on a leaching pad and irrigated with the leaching agent The leaching agent chemically reacts with the metal in the ore to dissolve the copper into the solution as it percolates through the heapAgglomeration technique improves heap leaching process In this process copper ore is mined, crushed, ground, concentrated, smelted and refined While copper bacterial leaching thus far has been confined to the leaching of ore, pilot plant tests are underway for the leaching of chalcopyrite concentrates that would normally be processed by smeltingHow Hydrometallurgy and the SX/EW Process Made Copper leaching of copperbearing ores in the US The dissolved copper recovered by this operation was derived from the natural oxidation and leaching of sulfide mineralization in a major porphyry copper deposit located in the headwaters of Bingham Creek This is the present site of the largescale, open pit operation at Bingham Canyon, whichRecovery of Copper by Solution Mining MethodsAug 20, 2015 Copper Heap Leaching (Solvent ExtractionElectrowinning – SXEW) In 2014, more than 50 major HLSXEW operations worldwide recovered approx 3 million tonnes of copper, which represents roughly Heap Leach: Mining's breakthrough technology

Recent Developments in Copper Hydrometallurgy

Morenci Enhanced Stockpile Leaching Lowgrade ore from Western Copper deposit yBelow mill cut off grade material yMixed sulfide minerals – chalcopyrite, chalcocite y188 million ton stockpile to be constructed yAir injection yBacteria augmentation yControlled solution application Largest engineered chalcopyrite stockpile leach in the worldSelective leaching Glycine The presence of copper minerals with gold is known to lead to many challenges during the cyanidation of gold ores, such as high consumption of cyanide with low gold extraction and undesirable impacts on gold recovery during the downstream processes An alternative selective leaching process for copper minerals from The selective leaching of copper from a gold–copper The first process, vat leaching of highgrade copper oxide ore followed by EW of copper from the leach solution, produced low quality copper cathode at relatively high cost In 1968 the tonnage of highgrade oxide ores was decreasing and vat leaching was on the decline The second process, heap and dump leaching of lowCopper recovery using leach/solvent extraction Aug 27, 2020 Examples of microbial ore leaching Copper leaching: If chalcocite, chalcopyrite, or covellite are used for the production of copper, several metals are usually found together For example, chalcopyrite contains 26% copper, 259% iron, 25% zinc, and 33% sulphur Chalcopyrite is Microbial leaching Online Biology Notessection, referred to as raffinate in copper leaching or the barren in gold leaching, is refortified with the lixiviant chemicals and pumped to the top of the heap Heap leaching is often broken into two principle distinctions, runofmine or ROM dump leaching and crushed ore heap leaching Dump leaching consists of truck enddumpingDump and Heap Leaching HydroJex

Copper Leaching Method

Table of ContentsBringing Copper Metal into SolutionRecovering Copper Metal from Leach LiquorsCopper Leaching EquipmentCopper Leaching CostsCopper Leaching Practices The advance made in recent times in this branch of metallurgy is indicated by the attention the subject is receiving from important American Copper This invention relates to a process whereby recovery of copper from copper ores using leaching and solvent extraction techniques can be increased The process generally comprises leaching to obtain a pregnant leach liquor, washing ore residues with an extra quantity of water to obtain extra dissolved copper values, recovering said copper values, combining the extra wash water with the pregnant USA Leaching copper ores and solvent extraction The first process, vat leaching of highgrade copper oxide ore followed by EW of copper from the leach solution, produced low quality copper cathode at relatively high cost In 1968 the tonnage of highgrade oxide ores was decreasing and vat leaching was on the decline The second process, heap and dump leaching of lowCopper recovery using leach/solvent extraction section, referred to as raffinate in copper leaching or the barren in gold leaching, is refortified with the lixiviant chemicals and pumped to the top of the heap Heap leaching is often broken into two principle distinctions, runofmine or ROM dump leaching and crushed ore heap leaching Dump leaching consists of truck enddumpingDump and Heap Leaching HydroJexExtraction of copper from sufidic ores, either by pyrometallurgy or hydrometallurgy, has various limitations In this study, a solvometallurgical process for the extraction of copper from sulfidic ore minerals (chalcopyrite, bornite, chalcocite and digenite) was developed by using an organic lixiviant (FeCl 3 as oxidizing agent and ethylene glycol (EG) as organic solvent)Solvometallurgical process for extraction of copper from

Heap Leaching Mining Techniques, Metals Mining, Copper

Heap leaching is an industrial mining method to dig out precious metals and copper compounds from ore Process of heap leaching The mined ore is crushed into tiny chunks and heaped on an impermeable plastic and/or clay lined leach pad where it may be irrigated with a leach solution to melt the valuable metalsHeap leaching, a process by which metals such as gold and copper are recovered from ore, has long been a method of choice in ore beneficiation, with applications growing all the time While this process has proven to be efficient, often chosen for its costeffectiveness, the efficiency of the heap leaching process can be further improved through the addition of an agglomeration drumAgglomeration Drums in the Heap Leaching ProcessHeap leaching relies on a leaching agent moving through a bed of heaped ore to extract the metallic components: Crushed ore is stacked on a leaching pad and irrigated with the leaching agent The leaching agent chemically reacts with the metal in the ore to dissolve the copper into the solution as it percolates through the heapAgglomeration technique improves heap leaching process leaching of copperbearing ores in the US The dissolved copper recovered by this operation was derived from the natural oxidation and leaching of sulfide mineralization in a major porphyry copper deposit located in the headwaters of Bingham Creek This is the present site of the largescale, open pit operation at Bingham Canyon, whichRecovery of Copper by Solution Mining MethodsMorenci Enhanced Stockpile Leaching Lowgrade ore from Western Copper deposit yBelow mill cut off grade material yMixed sulfide minerals – chalcopyrite, chalcocite y188 million ton stockpile to be constructed yAir injection yBacteria augmentation yControlled solution application Largest engineered chalcopyrite stockpile leach in the worldRecent Developments in Copper Hydrometallurgy

Leaching of Copper Sulphides SAIMM

POX in a copper heap leach circuit Figure 2 Simplified ferric leaching flowsheet Figure 3 Copper chloride leach process Leaching Chemistry As outlined earlier, the leaching chemistry that takes place within a total POX autoclave is very complex and will vary from case to case according to the mineralogy of the concentrate fed to theHeap leaching is a metal extraction process from low grade ores where crushed ore is stacked on an impermeable pad and irrigated from the top with a solution of chemical reagents An enriched solution containing the targeted metal is collected at the bottom This technique involves complex chemical/electrochemical reactions and transport processes Among the main features of this method Studies on the curing and leaching kinetics of mixed Microbial leaching is the process by which metals are dissolved from ore bearing rocks using microorganisms For the last 10 centuries, microorganisms have assisted in the recovery of copper dissolved in drainage from waterMicrobial Leaching (Bioleaching, Biomining Sep 26, 2019 Copper processing is a complex process that involves many steps as the manufacturer processes the ore from its raw, mined state into a purified form for use in many industries Copper is typically extracted from oxide and sulfide ores that contain between 05 and 20% copperCopper Production: How Is Copper Made? ThoughtCo