Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

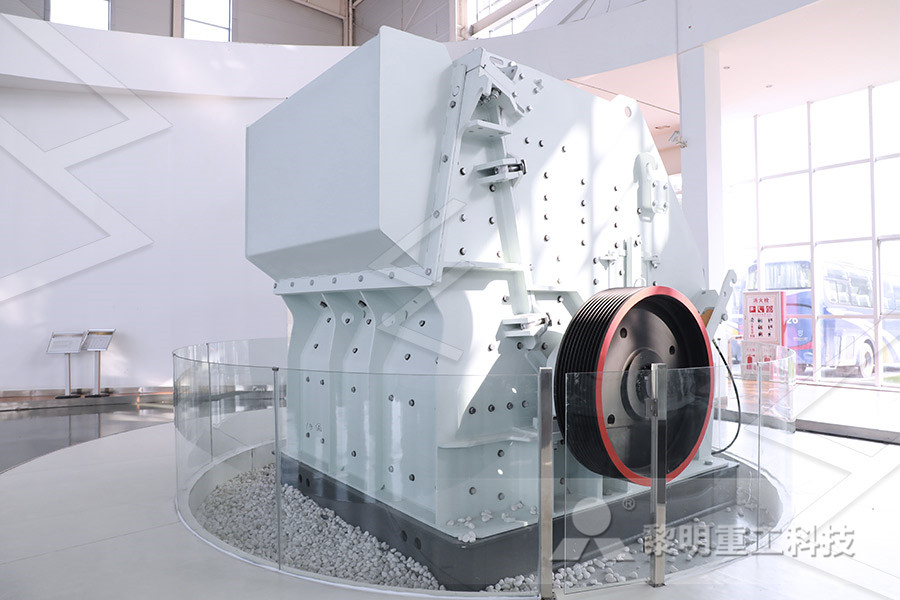

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Breaking down energy consumption in industrial grinding mills

Grinding mills are infamous for their extremely low energy efficiency approach to opt imize power consumption in a process plant operation by modellin g For base metal flotation mills, 16 The process is energy intensive with power consumption of roughly 20 to 30 MW and feed throughputs of 2,500 to 3,000 t/hr Process variables are mill loads, motor torque and power, plus pressures and flow rates The ground product is specified in terms of finenessAdvanced Process Control of grinding flotation in power consumption of grindig mill at flotation plant in korea Usually the grinding circuit contains at least two interconnected mills with material classifiers eg cyclones separating the fine material from the coarse that then goes for regrinding The process is energy intensive with power consumption of roughly 20 to 30 MW and feed throughputs of 2500 to 3000 thr Process variables are mill power consumption of grindig mill at flotation plant in koreaTake a gold mine as an example, reducing ore particle from 15mm to 10mm improve the grinding efficiency from 1150 tons per day to 1500 tons per day, and decrease the steel consumption and electric power consumption by 153kg/t to 11kg/t and 4157kWh to 292kWh respectively 2 Milling mediumFactors Influence Ore Grinding Mill Efficiency JXSC MiningOct 01, 2017 Fig 17 presents the results for the specific comminution energy for the grinding of copper ore The average consumption is 1223 MWh/t Cu On the abscissa, the cumulative copper production quantity of the analyzed mines is shown A corresponding graph Energy efficiency • Energy intensity in copper and gold

Floc flotation of Prince coal with simultaneous grinding

Jul 01, 1997 Rough calculations, in which only the grinding and separation stages were taken into account, revealed that the installation cost of the system may be reduced by 1520% and the power consumption by 3040% The SGHFF process is the same as conventional flotation, except for fine grinding and a slightly higher oil consump (5) (3) lionFigure 1 : Grinding Power to produce various product sizes in a Ball Mill (9mm balls) and an Isa Mill (2 mm sand) (for KCGM pyrite concentrate) Chemistry Impacts The use of inert grinding media gives a crucial advantage to stirred milling in fine flotation and leaching applications Even if it were economic to grind to 10 microns in a steel Fine Grinding as Enabling Technology – The IsaMillNow you can install up to 3MW of grinding power in a small footprint in the middle of your flotation circuit producing a sharp size distribution without cyclones Inert grinding improves chemistry – faster flotation rates with less reagentsImproved Flotation Recovery IsaMill™ Advantages IsamillFeb 01, 2011 Research Highlights The effect of mill media material properties on grinding efficiency, media wear, and power consumption was defined High density media with optimum sizing improved milling efficiency by approximately 30% Mill media with a low coefficient of friction resulted in reduced energy consumption of up to 23 times in the laboratory trials Large size high density mill media is Effect of media size and mechanical properties on milling The IsaMill is a horizontal high speed stirred mill that operates with very high power intensities (up to 350 kW/m3) In comparison, the power intensity of a ball mill is about 20 kW/m3 The high power intensity enables the IsaMill to process fine particles at a high throughput that is essential for the economics of the minerals industryISAMILL FINE GRINDING TECHNOLOGY AND ITS INDUSTRIAL

Fine Grinding as Enabling Technology – The IsaMill

Figure 1 : Grinding Power to produce various product sizes in a Ball Mill (9mm balls) and an Isa Mill (2 mm sand) (for KCGM pyrite concentrate) Chemistry Impacts The use of inert grinding media gives a crucial advantage to stirred milling in fine flotation and leaching applications Even if it were economic to grind to 10 microns in a steel May 01, 2000 This paper presents a sensitivity analysis of the impact the ore grinding level (% +212 microns) has upon the rougher flotation performance, where theThe effect of grinding on mill performance at Division Jul 01, 1997 Rough calculations, in which only the grinding and separation stages were taken into account, revealed that the installation cost of the system may be reduced by 1520% and the power consumption by 3040% The SGHFF process is the same as conventional flotation, except for fine grinding and a slightly higher oil consump (5) (3) lionFloc flotation of Prince coal with simultaneous grinding Due to their relatively low energy requirements, both these mill types are also being increasingly used for secondary and tertiary grinding as replacements for ball mills [8, 9, 10] The decreasing mineral grades in the ores have also led to increased throughput rates in the flotation stage (Fig 15)Energy efficiency • Energy intensity in copper and gold The mill at Orissa Cement was guaranteed to produce 212 tonnes per hour of PSC at 3800 cm2/gm Blaine without the use of grinding aid and with a mill area power consumption of 393 kWh/tonne However, as shown in table 1, its operational performance has exceeded this guaranteeMaking gains with the OK™ mill

ISAMILL FINE GRINDING TECHNOLOGY AND ITS INDUSTRIAL

The IsaMill is a horizontal high speed stirred mill that operates with very high power intensities (up to 350 kW/m3) In comparison, the power intensity of a ball mill is about 20 kW/m3 The high power intensity enables the IsaMill to process fine particles at a high throughput that is essential for the economics of the minerals industryFeb 01, 2011 Research Highlights The effect of mill media material properties on grinding efficiency, media wear, and power consumption was defined High density media with optimum sizing improved milling efficiency by approximately 30% Mill media with a low coefficient of friction resulted in reduced energy consumption of up to 23 times in the laboratory trials Large size high density mill media is Effect of media size and mechanical properties on milling Pebble mills are similar to ball mill except that the grinding media is closely sized suitably selected rocks or pebbles The rotating drum causes friction and attrition between rock pebbles (say, quartz or quartzite pebbles) and ore particles Pebble mill operates at low cost with respect to grinding media, power consumption and maintenanceGrinding Mill an overview ScienceDirect Topicsflotation, or regrind mills), with availability and maintenance of critical sensors (such as pulp density, particle size measurements), or with the hardness/softness of ore These adjustments can shift the tradeoff between the desired particle size distribution and throughput and change the operational constraints for the grinding millAdvanced Controller for Grinding Mills: Results from a Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition), 2016 752 Circuit Operation Grinding circuits are fed at a controlled rate from the stockpile or bins holding the crusher plant product There may be a number of grinding circuits in parallel, each circuit taking a definite fraction of the feedGrinding Circuit an overview ScienceDirect Topics

Fine Grinding Technology for Mines and Concentrating

Stirred mills use an internal auger to agitate the feedstock (ore which is fed into the mill as a slurry) and grinding media (sand, ceramic balls), which produces finer, more uniform grind sizes with reduced energy consumption Grinding power requirements are strongly related to product size (in microns), and stirred mill technology has been technologies had a very high power consumption grinding mills The two of the refractory gold flotation concentrate A second UFG mill was installed in 2002 taking the total UFG capacity (PDF) IsaMill ultrafine grinding for a sulphide leach processThe mill has benefits in reducing power consumption by circa15%, no ball charge grinding media, higher flotation recovery and can be ramped up and down in response to the availability of lowcost renewable energy”OZ Minerals, Loesche team up following West Musgrave Scale Up in Sizing for Grinding Mills Scaleup criterion is the net specific power consumption, ie the power consumed by the mill rotor itself minus all mechanical and electrical losses divided by the feed rate of solids For the full scale mill, specific power is multiplied by the feed rate to get the net mill powerAMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator The ball mill is the fine grinding machine connect the SAG or AG mill and flotation machine Ball mills produce fine particles with a uniform size for flotation, its grinding medias commonly are steel ball The ball mill rolls grinding media together with the ore, as the ore grinds, these balls initially 510 cm in diameter but gradually wear Grinding Mineral Processing

The effect of grinding on mill performance at Division

May 01, 2000 This paper presents a sensitivity analysis of the impact the ore grinding level (% +212 microns) has upon the rougher flotation performance, where theScale Up in Sizing for Grinding Mills Scaleup criterion is the net specific power consumption, ie the power consumed by the mill rotor itself minus all mechanical and electrical losses divided by the feed rate of solids For the full scale mill, specific power is multiplied by the feed rate to get the net mill powerAMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator The mill at Orissa Cement was guaranteed to produce 212 tonnes per hour of PSC at 3800 cm2/gm Blaine without the use of grinding aid and with a mill area power consumption of 393 kWh/tonne However, as shown in table 1, its operational performance has exceeded this guaranteeMaking gains with the OK™ mill Feb 01, 2011 Research Highlights The effect of mill media material properties on grinding efficiency, media wear, and power consumption was defined High density media with optimum sizing improved milling efficiency by approximately 30% Mill media with a low coefficient of friction resulted in reduced energy consumption of up to 23 times in the laboratory trials Large size high density mill media is Effect of media size and mechanical properties on milling Pebble mills are similar to ball mill except that the grinding media is closely sized suitably selected rocks or pebbles The rotating drum causes friction and attrition between rock pebbles (say, quartz or quartzite pebbles) and ore particles Pebble mill operates at low cost with respect to grinding media, power consumption and maintenanceGrinding Mill an overview ScienceDirect Topics

(PDF) IsaMill ultrafine grinding for a sulphide leach process

technologies had a very high power consumption grinding mills The two of the refractory gold flotation concentrate A second UFG mill was installed in 2002 taking the total UFG capacity The Vertically Stirred Mill consisted of a 10 litre chamber and pin style impeller The mill shaft held seven radial arms, each 160 mm long and 10 mm in diameter The mill motor was a 27 kW variablespeed drive, fitted with a 3 phase AC inverter for power consumption measurements The mill media was 23 – 66 mm steel shotIsaMill Ultrafine Grinding for a Sulphide Leach Processflotation, or regrind mills), with availability and maintenance of critical sensors (such as pulp density, particle size measurements), or with the hardness/softness of ore These adjustments can shift the tradeoff between the desired particle size distribution and throughput and change the operational constraints for the grinding millAdvanced Controller for Grinding Mills: Results from a Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition), 2016 752 Circuit Operation Grinding circuits are fed at a controlled rate from the stockpile or bins holding the crusher plant product There may be a number of grinding circuits in parallel, each circuit taking a definite fraction of the feedGrinding Circuit an overview ScienceDirect Topicscement grinding machine power consumption in central african Ball mill, flotation machine, concentrator and other beneficiation equipment; Powder Grinding Plant, rotary dryer, briquette machine, mining, metallurgy and other related equipment which can crush all kinds of metal and nonmetallic ore, also can be dry grinding and wet grinding cement grinding machine power consumption in central african

lennilite powder processing grinding ball millfroth

Flotation Cell; XCF Air Inflation Flotation Cell; Jjf Flotation And Wemco Flotation; Magnetic Drum; Spiral Chute; lennilite powder processing grinding ball mill; lennilite powder processing grinding ball mill Efficient Thickener Efficient Thickener Hydraulic Motor Driving Center Thickener2 More crushing and less grinding to reduce the feed size into mill The larger feed size, the more work that the ball mill needs to do on the ore To achieve the specified grinding fineness, the workload of ball mill will be increased inevitably, and then, the energy consumption and power consumption will be increased accordingly10 Ways to Improve the Grinding Efficiency of Your Ball The grinding medium is essential for the ball mill, and the consumption is very large It was all spherical, and then the casting and baseball media appeared The diameter of the ball medium is about 15125mm, and the diameter of the casting section is about 830mm, and the length is about 840mmChina Ore Grinding Ball Mill with Long Life Wear Parts for