Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

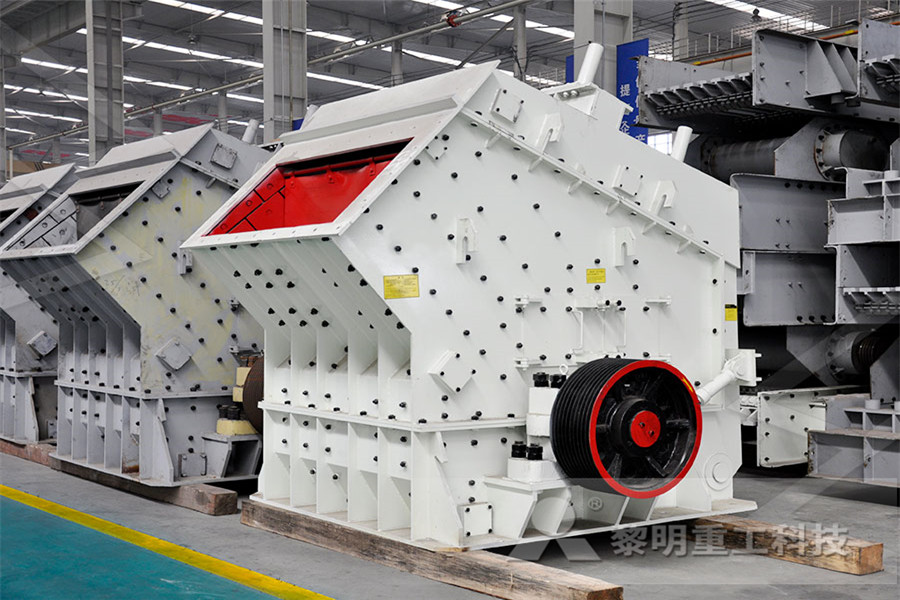

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

OperatOr and parts Manual Hammermill

The directions left, right, front and rear, as mentioned throughout this manual, are as seen facing in the direction of travel of the implement Introduction Hammermill 5 Safety • The power requirement for the mill is either a 3 hp or 5 hp electric motor, 3450 rpm A 31/2" 11 HAMMER SHFT HM 6 12 SPACER LONG (12 USED Prater 2 Sammons Court Bolingbrook, IL 60440 Phone: 8772475625 Local: 6307599595 Fax: 6307596099Hammermill PDF ManualHammer mills work on the principle that most materials will crush, shatter or pulverize upon impact: The Process: • Material is fed into the mill’s chamber through the feed chute, typically by gravity • The material is struck by ganged hammers (generally rectangular pieces of hardened steel) which are attached to a shaft that How Does a Hammer Mill Work?Operator's Manual Parts List valmetal Hammer Mill Model : 121215 13C500093 May 2013Operator's Manual Parts ListHammermill OPERATION The Model #60 Hammermill is a sixinch hammermill and is designed to run at the speed of 3600 rpm The power requirement for the mill is Hammermill Farm King

CF 420A HAMMER MILL INSTRUCTION MANUAL

Check whether all tools which come with the pellet mill Keep tools for future use missioning 21 Connection and location of the hammer mill 211 Connect the diesel engine 1 Place the machine under a solid, safe and welldry location Keep the machine away from unauthorized person Do not operate the machine under the temperature of 10 °CEngsko A/S, Tronholmen 10E, DK 8960 Randers SØ User manual: ABC Hansen Hippo Mill, Model BABY, 1, 1½, 47, 57, 69, L 63, Mammoth Page 6 44 2 INSTALLATION PROCEDURE: The ABC Hansen range of Hippo Hammer Mills, hereafter called the ABC Hippo MillHippo Hammer Mils Hippo MillsHammer Mills AVAILABLE SIZES CAPACITIES Model Screen Area Sq inches Avg hp RPM G5 440 5 15 1800 3600 G6 540 15 30 1800 3600 G7 790 40 60 1800 3600 G8 860 75 125 1800 3600 G25 2700 125 300 1200 1800 Hammermill0406qxd 4/24/06 9:06 AM Page 1 2 Sammons Court • Bolingbrook, IL 60440Hammermill 0406qxd 4/24/06 9:06 AM Page 1 Hammer MillsHammer mill operating manual pdf Gravity discharge to bin or conveyor Optional mill stand available High production per horsepower insuring low operating and maintenance costs Planed motor base for exact alignment of motor and rotor with minimal vibration Belt or direct drive 15 to 60 kw production sizeHammer mill operating manual pdf”hammer Mill”+pdf Crusher Mills, Cone Crusher, Jaw Crushers fls manuals of hammer mill pdf EV hammer impact crusher Gulin One source supplier of In a traditional hammer mill with a top inlet, large blocks in the feed may impede the action of the hammer mill stone pdfToday Docs hammer mill corn,hammer mill stone pdf,pdf search for hammer mill corn hammer mill hammer mill crusher manual pdf

OperatOr and parts Manual Hammermill

The directions left, right, front and rear, as mentioned throughout this manual, are as seen facing in the direction of travel of the implement Introduction Hammermill 5 Safety • The power requirement for the mill is either a 3 hp or 5 hp electric motor, 3450 rpm A 31/2" 11 HAMMER SHFT HM 6 12 SPACER LONG (12 USED Hammermill OPERATION The Model #60 Hammermill is a sixinch hammermill and is designed to run at the speed of 3600 rpm The power requirement for the mill Hammermill Farm KingCheck whether all tools which come with the pellet mill Keep tools for future use missioning 21 Connection and location of the hammer mill 211 Connect the diesel engine 1 Place the machine under a solid, safe and welldry location Keep the machine away from unauthorized person Do not operate the machine under the temperature of 10 °CCF 420A HAMMER MILL INSTRUCTION MANUALEngsko A/S, Tronholmen 10E, DK 8960 Randers SØ User manual: ABC Hansen Hippo Mill, Model BABY, 1, 1½, 47, 57, 69, L 63, Mammoth Page 6 44 2 INSTALLATION PROCEDURE: The ABC Hansen range of Hippo Hammer Mills, hereafter called the ABC Hippo Mill, must be Hippo Hammer Mils Hippo MillsThis manual is a guide for installation, operation and maintenance of your new SchutteBuffalo Hammer Mill Please note that we properly lubricate all bearings at the factory at final assembly We then test run each piece of equipment at normal operating speeds checking for proper fits, correct alignments, bearing temperatures, freeINSTALLATION OPERATIONS MANUAL

THE FITZPATRICK COMPANY

The Fitzpatrick Company 5 DO practice good housekeeping around the equipment Do not allow product or oil spills to accumulate in the area During cleaning operations, care should be taken to ensure that water or other cleaning liquids do not contact electricalHammer Mill Crusher Fls Fls Manuals Of Hammer Mill Pdf hammer mill crusher fls Fls Hammer Crusher ddelicious hammer mill pdf crusher mills, cone fls manuals of hammer mill pdf ev hammer impact crusher gulin one source supplier of in a traditional hammer mill Get Price And Support Online new mill plant in kansas by fls Grinding Get PriceNew Mill Plant In Kansas By FlsModel 500 Hammer Mill Operation Manual (pdf) Model 500 Hammer Mill Wiring Diagram (jpg) Structure of Hammer Mills Diagram (jpg) Minimum Amperage circuits for electric motors Hammer Mill Belt Sizes Model 158 3hp Electric: A864 Model 198 53hp Electric: A1295 Model 198 65hp Gasoline: A1168PelletMasters Hammer Mill InformationBomag Bw120ad4 Pdf Apr 06 2019 BOMAG BW120AD4 PDF See manuals technical data specifications and documentation of Bomag BW AD4 in category Tandem Vibration Rollers Learn more about BW AD4 View Details Send Enquiry European Rotary Kiln Industry 2016 Market Research ReportFlsmidth Rotary Kiln Technical Data PdfMetallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available As such you will find it is designed and constructed according to heavy duty specifications It is designed along sound engineering principles Ball Mill Maintenance Installation Procedure

MODEL 4000 WITH AND WITHOUT COUNTERS

5 Mill motor (230V1 Phase3 wire) (230V3 Phase4 Wire) (575V3 Phase4 Wire) is prewired to the junction box on the mill Connect to the control panel with field installed wiring to the terminal block that shows mill motor The mill motor may be operated with either CW or CCW rotation To change rotation, use the reversingANDRITZ hammer mill – series 6 The series 6 hammer mill is designed especially for today’s demanding application and safety guidelines It is equipped with highvolume inlet for improved flow with light density materials Key features: Externally reversible inlet baffle (with option to make automatic)Hammer mills ANDRITZHammer Mill, Feeder DFZC1265 / DFZC600 PITSTOP – Wear Parts / Spare Parts / Accessories / Options Critical spare parts DFZC1265 hammer mill Part number Recomm stock Extension spring Screen clamping mechanism Selfaligning ball bearing D 60 Rotor bearings Hammer mill Oscillation sensor, meas range 460mm/s Vibration detector Cable with bushing L = 10 m Temp sensor with Hammer Mill, Feeder DFZC1265 / DFZC600 Group Prater 2 Sammons Court Bolingbrook, IL 60440 Phone: (877) 2475625 Local: (630) 7599595Literature Directory (PDFs) for Prater's Material Check whether all tools which come with the pellet mill Keep tools for future use missioning 21 Connection and location of the hammer mill 211 Connect the diesel engine 1 Place the machine under a solid, safe and welldry location Keep the machine away from unauthorized person Do not operate the machine under the temperature of 10 °CCF 420A HAMMER MILL INSTRUCTION MANUAL

MODEL 4000 WITH AND WITHOUT COUNTERS

5 Mill motor (230V1 Phase3 wire) (230V3 Phase4 Wire) (575V3 Phase4 Wire) is prewired to the junction box on the mill Connect to the control panel with field installed wiring to the terminal block that shows mill motor The mill motor may be operated with either CW or CCW rotation To change rotation, use the reversingHammer Design The design and placement of hammers is determined by operating parameters such as rotor speed, motor horsepower, and open area in the screen Optimal hammer design and placement will provide maximum contact with the feed ingredient Mills MF2048 Hammermills and Roller Mills KSRE BookstoreThis manual is a guide for installation, operation and maintenance of your new SchutteBuffalo Hammer Mill Please note that we properly lubricate all bearings at the factory at final assembly We then test run each piece of equipment at normal operating speeds checking for proper fits, correct alignments, bearing temperatures, freeINSTALLATION OPERATIONS MANUALThe Fitzpatrick Company 5 DO practice good housekeeping around the equipment Do not allow product or oil spills to accumulate in the area During cleaning operations, care should be taken to ensure that water or other cleaning liquids do not contact electricalTHE FITZPATRICK COMPANYHammer Mill Crusher Fls Fls Manuals Of Hammer Mill Pdf hammer mill crusher fls Fls Hammer Crusher ddelicious hammer mill pdf crusher mills, cone fls manuals of hammer mill pdf ev hammer impact crusher gulin one source supplier of in a traditional hammer mill Get Price And Support Online new mill plant in kansas by fls Grinding Get PriceNew Mill Plant In Kansas By Fls

PelletMasters Hammer Mill Information

Model 500 Hammer Mill Operation Manual (pdf) Model 500 Hammer Mill Wiring Diagram (jpg) Structure of Hammer Mills Diagram (jpg) Minimum Amperage circuits for electric motors Hammer Mill Belt Sizes Model 158 3hp Electric: A864 Model 198 53hp Electric: A1295 Model 198 65hp Gasoline: A1168mentioned that a hammer mill with 16 hammers, a 458 mm screen, and an operating speed of 3600 r pm was more effective at grinding a mixture of 124 mm(PDF) DESIGN AND EVALUATE OF A SMALL HAMMER MILLas hammer and plate mills, began to replace traditional stone mills As electricity became available in many parts of Africa, motordriven mills gained in importance However, it was not until the introduction of the diesel engine in the early twentieth century that high speed mills were seen in more significant numbers across the continentSmall mills in Africa Food and Agriculture OrganizationA homemade hammer mill is shown in this video It can be used for crushing stones and all other nonmetallic materials For hammer mill operation view the viHomemade hammer mill/Low cost hammer mill/Hammer mill operator's manual HAMMER MILL ENGAGING HAMMER MILL To engage the hammer mill, rotate the en gaging pin handle in a clockwise direction Turn the pulley until the pin engages one of the holes in the drive hub DISENGAGING HAMMER MILL To disengage the mill, rotate the engaging pin handle in a counterclockwise direction BeJohn Deere 400 GrinderMixer Operators Manual

Gehl 120MX 95MX Grinder Mixer Operators Manual

Operator’s Manual 95MX 120MX MixAll Mixers THIS IS A MANUAL Uneven feeding allows the Hammer Mill to run empty at times and overloaded at other times Also available as a pdf download Jensales offers the finest in Manuals, Parts, and Decals Keywords: GEO95,120 MM{72358}, GEO95,120 MM, Gehl 120MX, Gehl 95MX, Gehl Grinder 4 TECHNICAL DATA Hammer mill Motor power Rotor rpm Screen area Filter air flow Type kW HP 50/60 Hz dm2 sq m3/h CFM Optimill 500 110200 1500/1800 143 2216 3600 2119 Optimill 700 160315 1500/1800 200 3100 5000 2943 Optimill 900 250355 1500/1800 257 3984 6400 3767 Optimill 1201 355400 1500/1800 346 5363 8800 5180 Multimill 630 75110 3000/3600 83 1287 4000 2354FEED AND BIOFUEL HIGH PERFORMANCE GRINDINGHammer Mills, Fine Grind, Jet Mills Fine Milling Comil F10 Fine Grind Hammermill Pin Mill Jet Mill Micron 5 25 1 5 10 25 38 45 75 125 150 180 250 300 425 600 1000 8 1 0 3 0 4 0 5 0 6 0 8 0 0 1 0 2 1 0 0 2 5 2 3 0 h 0 s 4 e M S U SIZE REDUCTION CAPABILITY COMPARISONPharmaceutical Technologies International, Inc Princeton