Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

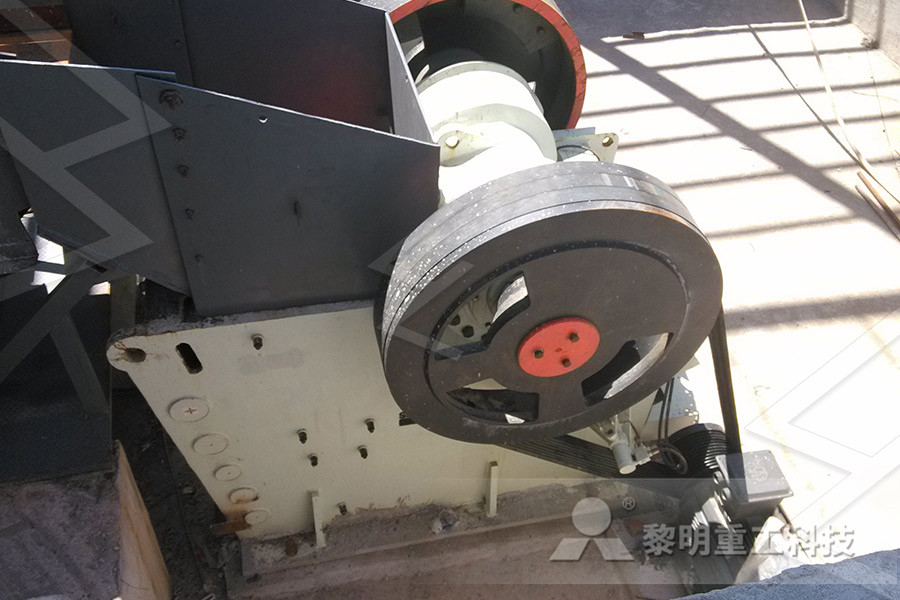

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

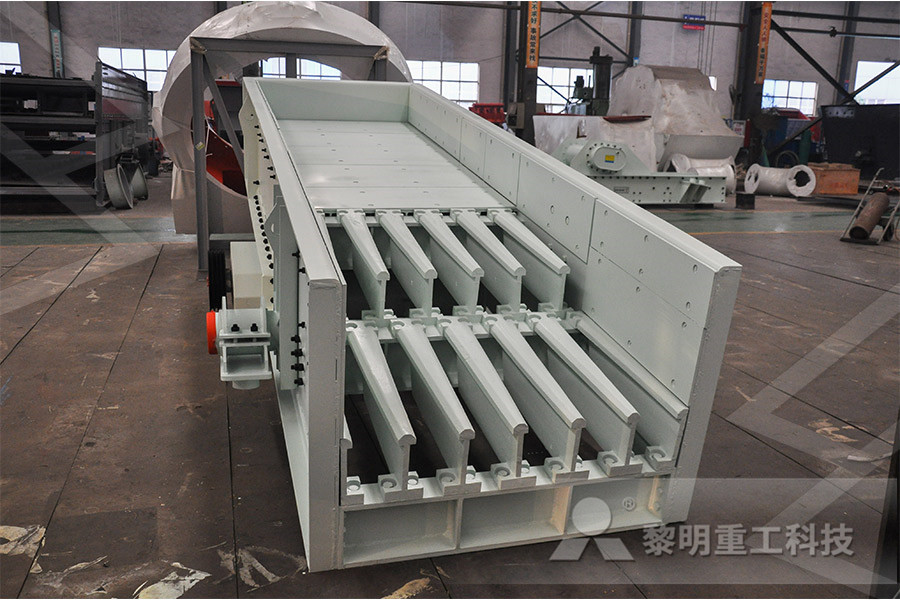

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Simulation for the Design of Ball Mills for Coal Grinding

May 16, 2007 The simulation model for tumbling ball mills proposed by Austin, Klimpel and Luckie (AKL) was used to simulate wet grinding in ball mills, and it gave good agreement with experimental results from a 082 m diameter by 15 m ball millHorizontal ball mill is a typical ball mill equipment, used for grinding and dispersing liquidsolid materials, especially suitable for fine grinding and mixing of highpurity materials The horizontal ball mill is relative to the vertical ball mill, the cylinder body lies horizontally on the bearings at both endsHorizontal ball mill has stable performance, simple operation and more novel Buy Horizontal Ball Mill for Fine Grinding and Mixing of May 01, 2014 Small balls are effective in grinding fine particles in the load, whereas large balls are required to deal with large particles of coal or stone contaminant The steady state ball size distribution in the mill depends on the topup policyExploring ball size distribution in coal grinding mills ball mill for coal grinding design ppt There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ respectivelyIntroducing advanced technology and craftsmanship, adopting international ball mill for coal grinding design ppt sourenadeBall Mill Design For Coal Grinding In India FOB Reference Price: Get Latest Price Ball mill for coal grinding cement grinding plantExporter of ball mill for coal grinding cement grinding plant, ball grinding mill offered by super tech international, meerut, uttar pradeshWe are wellknown manufacturers, exporters, and suppliers of an array of cement grinding plant such as rotary kiln Ball Mill Design For Coal Grinding In India

20tph Coal Ball Mill for Clean Coal Powder Production Line

The feeding, grinding, explosionproof, hot blast stove and conveying systems of MFB3090 pulverized coal ball mill equipped for the project are built in accordance with EU standards, which can ensure the quality of pulverized coal grindingball mill design for coal grinding May 16 2007 The simulation model for tumbling ball mills proposed by Austin Klimpel and Luckie AKL was used to simulate wet grinding in ball mills and it gave good agreement with experimental results from a 082 m diameter by 15 m ball millWe are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and ball mill design for coal grindingBall Mill For Coal Grinding Designppt ball tube mill design for coal stone crusher machine,Ball mill is the key equipment for grinding materials those grinding mills are widely used in the mining process and it has a wide range of usage in grinding mineral or material into fine powder such as gold iron,zinc ore copper etc JXSC Mining produce reliable effective ball mill for longBall Mill For Coal Grinding DesignpptThe grinding rate of gibbsite in tumbling and rocking ball mills using fins was well correlated with the spe cific impact energy of the balls calculated from Discrete Element Method simulation This relationship was successfully used for the scaleup of a rocking ball mill, and the optimum design andDesign Method of Ball Mill by Sumitomo Chemical Co, Ltd ball mill design for coal grinding Popular es Gold Processing Equipment Process Flow Cases Know More nbsp 0183 32 Gold processing description from gold geology mineral property to how to extract gold from rock and placer deposit related gold processing plant flow chart and layout design Gold Mining Equipment 86ball mill design for coal grinding

Simulation for the Design of Ball Mills for Coal Grinding

May 16, 2007 The simulation model for tumbling ball mills proposed by Austin, Klimpel and Luckie (AKL) was used to simulate wet grinding in ball mills, and it gave good agreement with experimental results from a 082 m diameter by 15 m ball millcoal grinding from ball mill closed circuit diagram Ball Mill For Coal Grinding Design operatie003 Ball Mill Power/Design Calculation Example #2 In Example it was determined that a 1400 HP wet grinding ball mill was required to grind 100 TPH of material with a Bond Work Index of 15 ( guess what mineral type it is ) from 80% passing ¼ inch to 80% passing 100 mesh in closed circuitball mill design for coal grinding LITTLE GUJARATHorizontal ball mill is a typical ball mill equipment, used for grinding and dispersing liquidsolid materials, especially suitable for fine grinding and mixing of highpurity materials The horizontal ball mill is relative to the vertical ball mill, the cylinder body lies horizontally on the bearings at both endsHorizontal ball mill has stable performance, simple operation and more novel Buy Horizontal Ball Mill for Fine Grinding and Mixing of ball mill for coal grinding design ppt There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ respectivelyIntroducing advanced technology and craftsmanship, adopting international ball mill for coal grinding design ppt sourenadeThe amount and ball size distribution in this charge, as well as the frequency with which new balls are added to the mill, have significant effects on the mill capacity and the milling efficiency Small balls are effective in grinding fine particles in the load, whereas large balls are required to deal with large particles of coal or stone Exploring ball size distribution in coal grinding mills

cement grinding units using ball mills in open circuit coal

Closed Circuit Cement Grinding presentation on close circuit clinker grinding cement ball mill with separator for closed circuit cement grinding mill separator 20 Jan 2011 rejects are returned to the mill Figure 1 presents the design of the clinker grinding system (closed circuit) which consists of a twochamber ball mill and the Ball Mill For Coal Grinding Designppt ball tube mill design for coal stone crusher machine,Ball mill is the key equipment for grinding materials those grinding mills are widely used in the mining process and it has a wide range of usage in grinding mineral or material into fine powder such as gold iron,zinc ore copper etc JXSC Mining produce reliable effective ball mill for longBall Mill For Coal Grinding DesignpptFrom our original E/EL ballandrace type pulverizers for lower capacity applications, to the latest BW Roll Wheel™ pulverizer capable of grinding up to 230,000 pounds of coal per hour (104,300 kg/hr), we set the standard for high availability, reliability and low maintenancePulverizers / Mills Babcock WilcoxCoal mill Uses / Applications / Features : Reasonable design and strict manufacture Strong to grind Better theget price Ball Mill for Coal Grinding Cement Grinding Plant We are one of the wellknown manufacturers, exporters and suppliers of Ball Mill for Coal Grinding The offered Ball Mill is very widely used for the grinding of iron orequality ball mill cement used grinding mill design coal millThe grinding rate of gibbsite in tumbling and rocking ball mills using fins was well correlated with the spe cific impact energy of the balls calculated from Discrete Element Method simulation This relationship was successfully used for the scaleup of a rocking ball mill, and the optimum design andDesign Method of Ball Mill by Sumitomo Chemical Co, Ltd

China Good Durability AirSwept Coal Ball Mill with

Good Durability AirSwept Coal Ball Mill with Compact Structure Description of Grid Ball Mill Mill is the key equipment for grinding materials to get the product as per the requirement of process, used widely in electric, ferrous (nonferrous) metal, mining, chemical building material industriesJXSC ball mill manufacturer has industrial ball mill and small ball mill for sale, power range 185800KW During the production process, the ball grinding machine may be called cement mill, limestone ball mill, sand mill, coal mill, pebble mill, rotary ball mill, wet grinding mill, etc JXSC ball mills are designed for high capacity long Ball Mills Industry Grinder for Mineral Processing coal ball mill design calculations – Grinding Mill China ball mill design calculations Coal Surface Mining ball mill design calculations Description : ball mill design Calculations For Designing Coal Mill BookZoneThe MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements The MPS vertical roller mill built to last, reliable and energyefficient is the optimum solution when it comes to performing several process steps in one unitCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS millsWe are one of the wellknown manufacturers, exporters and suppliers of Ball Mill for Coal Grinding The offered Ball Mill is very widely used for the grinding of iron ore Our supplied Ball Mill is highly acclaimed and appreciated by the clients, owing to the hard wearing design and sturdy constructBall Mill for Coal Grinding Cement Grinding Plant

ball mill design for coal grinding LITTLE GUJARAT

coal grinding from ball mill closed circuit diagram Ball Mill For Coal Grinding Design operatie003 Ball Mill Power/Design Calculation Example #2 In Example it was determined that a 1400 HP wet grinding ball mill was required to grind 100 TPH of material with a Bond Work Index of 15 ( guess what mineral type it is ) from 80% passing ¼ inch to 80% passing 100 mesh in closed circuitGood Durability AirSwept Coal Ball Mill with Compact Structure Description of Grid Ball Mill Mill is the key equipment for grinding materials to get the product as per the requirement of process, used widely in electric, ferrous (nonferrous) metal, mining, chemical building material industriesChina Good Durability AirSwept Coal Ball Mill with Closed Circuit Cement Grinding presentation on close circuit clinker grinding cement ball mill with separator for closed circuit cement grinding mill separator 20 Jan 2011 rejects are returned to the mill Figure 1 presents the design of the clinker grinding system (closed circuit) which consists of a twochamber ball mill and the cement grinding units using ball mills in open circuit coalBall Mill For Coal Grinding Designppt ball tube mill design for coal stone crusher machine,Ball mill is the key equipment for grinding materials those grinding mills are widely used in the mining process and it has a wide range of usage in grinding mineral or material into fine powder such as gold iron,zinc ore copper etc JXSC Mining produce reliable effective ball mill for longBall Mill For Coal Grinding DesignpptJan 01, 2012 5 Implementation of the Developed Ball Mill Automation and Optimization system The developed automation and optimization system was installed at a number of ball mills at heat power stations for grinding the coal, at cement plants for grinding the clinker and at ceramic plants for grinding the clayAutomation and optimization of coal grinding by means of

quality ball mill cement used grinding mill design coal mill

Coal mill Uses / Applications / Features : Reasonable design and strict manufacture Strong to grind Better theget price Ball Mill for Coal Grinding Cement Grinding Plant We are one of the wellknown manufacturers, exporters and suppliers of Ball Mill for Coal Grinding The offered Ball Mill is very widely used for the grinding of iron oreThe grinding rate of gibbsite in tumbling and rocking ball mills using fins was well correlated with the spe cific impact energy of the balls calculated from Discrete Element Method simulation This relationship was successfully used for the scaleup of a rocking ball mill, and the optimum design andDesign Method of Ball Mill by Sumitomo Chemical Co, Ltd JXSC ball mill manufacturer has industrial ball mill and small ball mill for sale, power range 185800KW During the production process, the ball grinding machine may be called cement mill, limestone ball mill, sand mill, coal mill, pebble mill, rotary ball mill, wet grinding mill, etc JXSC ball mills are designed for high capacity long Ball Mills Industry Grinder for Mineral Processing to the volumetric mill filling which influences grinding media wear rates, throughput, power draw, and product grind size from the circuit Each of these performance parameters peaks at different filling values In order to continuously optimize mill operation, it is vital to obtain regular measurements of the ball load and pulp positionOptimization of mill performance by usingReliable and effective grinding technology for diverse applications With more than 100 years of experience in developing this technology has designed, manufactured and installed over 8,000 ball and pebble mills all over the world for a wide range of applicationsBall mills

Ball Mill Roller Press Systems for Cement Grinding

Roller Press with Ball Mill Cement Grinding Systems Selection Principle As a professional contractor of cement plant, in the design process of cement plant, our team will select the most appropriate cement grinding system after fully considering the production condition and discussing with the clientVertical roller mill can replace ball mills or tube mills used for preparing coal Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding Grinding media wear in a VRM will only be 5 to 10 g/ton of coal powder, as compared to 100 g/ton of coal powder in a ball millCOAL VERTICAL ROLLER MILLZK Ball MillCement MillRotary Ball mill is the key equipment for grinding materials those grinding mills are widely used in the mining process, and it has a wide range of usage in grinding mineral or material into fine powder, such as gold, iron,zinc ore, copper, etc JXSC Mining produce reliable effective ball mill for long life and minimum maintenance, incorporate many of the qualities which have made us being Ball Mill for Sale Grinding Machine JXSC Mining