Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

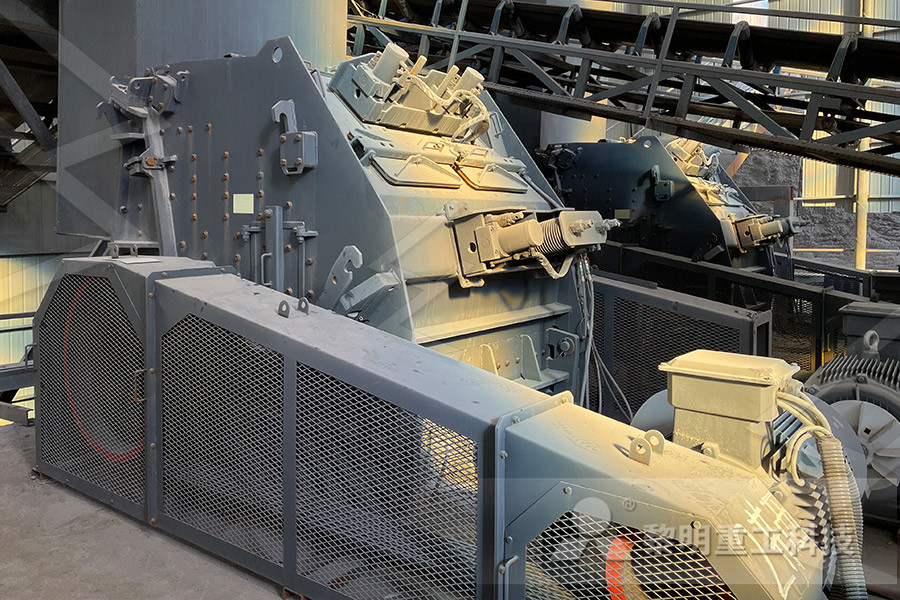

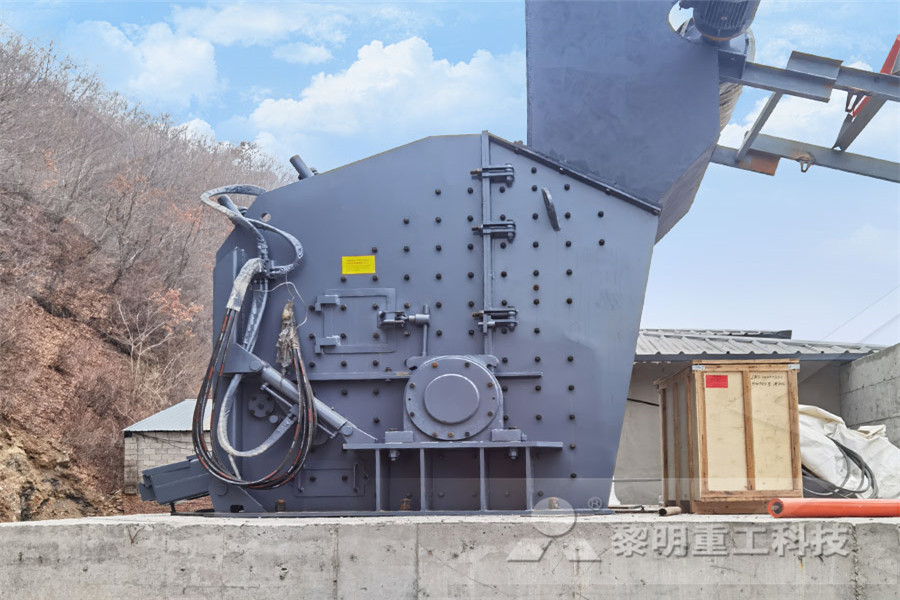

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

iron and steel mill layout schematics greenbeanscafecoza

process flow diagram for iron and steel crusher steel mill production process flow diagram Iron and Steel Plant Process Flow Diagrammental factors, to determine the overall layout of the various sites on the iron and steel plant, shown in figure 1 Fig 1 Steel plant general layout diagram of venues 3 Systematic Layout Planning of Iron and Steel Plant 31 SLP Method Introduction Systematic Layout Planning was proposed by Richard † Muther of American, and hadOverall Layout Design of Iron and Steel Plants Based on Dec 18, 2020 Explore John Lucas's board "Steel Mill Models" on Pinterest See more ideas about steel mill, steel, model railroad30+ Steel Mill Models ideas in 2020 steel mill, steel Modeling steel mill sites and operations Railmodel Journal, October 2000 page 45 Layout Tour: Bethlehem Steel at Sparrows Point, Maryland on NTRAK modules Railmodel Journal, October 2000 page 45 Heavy industry in a small space Model Railroader, January 1999 page 140 Three ways to model an interesting steel mill railroad Columbia Steel's Modeling Steel Mills 101 augusthealthservicesIroncarbon phase diagram To refine steel from either scrap or pig iron, the amount of carbon must be carefully controlled In MZ, Fig 32 shows a typical ironcarbon diagram This helps us to understand how this control is done A slightly more colorful version of the ironcarbon phase diagram follows 24 Ironcarbon phase diagramtermsIntroduction to Iron and Steel Texas AM University

OVERVIEW OF THE STEELMAKING PROCESS

Direct reduction Scrap Ladle (Refining) Electric arc furnace (Steelmaking) Iron Ore Pellets Electric Arc Furnace Steelmaking Continuous casting Design by Blisscommunication / Cover photo: ThyssenKrupp Steel / Tubes photo: Salzgitter The process shown above is illustrative only and is not designed to show the steelmaking process in detailThe production of steel in an EAF is a batch process Cycles, or "heats", range from about 11/2 to 5 hours to produce carbon steel and from 5 to 10 hours or more to produce alloy steel Scrap steel is charged to begin a cycle, and alloying agents and slag materials are added for refining Stages125 Iron And Steel ProductionStructural Shapes – standard steel configurations produced by steel mills such as wide flanges, channels, angles, pipe, tubes, etc Structural Steel – the structural elements that make up the frame that are essential to supporting the design loads, eg beams, columns, braces, plate, trusses, and fasteners It does not include for example STRUCTURAL STEEL DESIGN AND CONSTRUCTIONMy layout was first built before Walthers reproduced the HO scale Ashland Iron Steel complex of kits, but fortunately I had built a harbor at the end of my largest peninsula, that accommodates a ferry dock, and dock for a 3' ore boat, space for two Hulett unloaders, and space for the umpteen tracks to service the vastly compressed steel mill steel mill arrangement Model Railroader Magazine Model the iron and steel industry with respect to geographic distribution, plant size, and processes used Fourteen of the installations in the iron industry were operated as mineconcentration plant combinations, although in some places the distance from the mine to the concentra tion plant was a few miles Only one mine and one concentrationWater Requirements of the Iron and Steel Industry

OVERVIEW OF THE STEELMAKING PROCESS

Direct reduction Scrap Ladle (Refining) Electric arc furnace (Steelmaking) Iron Ore Pellets Electric Arc Furnace Steelmaking Continuous casting Design by Blisscommunication / Cover photo: ThyssenKrupp Steel / Tubes photo: Salzgitter The process shown above is illustrative only and is not designed to show the steelmaking process in detailIroncarbon phase diagram To refine steel from either scrap or pig iron, the amount of carbon must be carefully controlled In MZ, Fig 32 shows a typical ironcarbon diagram This helps us to understand how this control is done A slightly more colorful version of the ironcarbon phase diagram follows 24 Ironcarbon phase diagramtermsIntroduction to Iron and Steel Texas AM UniversityStructural Shapes – standard steel configurations produced by steel mills such as wide flanges, channels, angles, pipe, tubes, etc Structural Steel – the structural elements that make up the frame that are essential to supporting the design loads, eg beams, columns, braces, plate, trusses, and fasteners It does not include for example STRUCTURAL STEEL DESIGN AND CONSTRUCTIONModeling steel mill sites and operations Railmodel Journal, October 2000 page 45 Layout Tour: Bethlehem Steel at Sparrows Point, Maryland on NTRAK modules Railmodel Journal, October 2000 page 45 Heavy industry in a small space Model Railroader, January 1999 page 140 Three ways to model an interesting steel mill railroad Columbia Steel's Modeling Steel Mills 101 augusthealthservicesCutting Tool Materials: High Speed Steel (HSS) provides good wear resistance and costs less than cobalt or carbide end mills HSS is used for generalpurpose milling of both ferrous and nonferrous materials Vanadium High Speed Steel (HSSE) is made of high speed steel, carbon, vanadium carbide and other alloys designed to increase abrasive wear resistance and toughnessBasic End Mills Technical Information MSC Industrial

steel mill arrangement Model Railroader Magazine Model

My layout was first built before Walthers reproduced the HO scale Ashland Iron Steel complex of kits, but fortunately I had built a harbor at the end of my largest peninsula, that accommodates a ferry dock, and dock for a 3' ore boat, space for two Hulett unloaders, and space for the umpteen tracks to service the vastly compressed steel mill Feb 26, 2019 My layout has now been taken down, but the Mill still lives I have donated all my steel mill buildings and cars to the Garden State Central model railroad club of which I am a member We are building a new layout at the Info Age Learning Center at Camp Evans in Wall New Jersey There is room for Bethlehem Steel to be built with even more detailBethlehem Steel Home LayoutRolling mills are located at many steel mill complexes, but they can also be used as standalone facilities The Ashland Iron and Steel Rolling Mill is also similar to buildings used for vehicle and railcar assembly, metal smelting and fabrication, refractories and more, so this versatile structure will have a home on any layoutWalthers Rolling Mill Ashland Iron Steel Kit 32 Jul 09, 2014 Model Railroader is the world's largest magazine on model trains and model railroad layouts We feature beginner and advanced help on all model railroading scales, including layout track plans, model railroad product reviews, model train news, and model railroad forumssteel mill layout Model Railroader Magazine Model Recognized as a global leader in networking, education and steel industry sustainability programs, the Association for Iron Steel Technology (AIST) is a nonprofit organization with 16,000 members from more than 70 countries With 29 Technology Committees, 22 Local Members Chapters, and two major annual conference and expositions, AIST represents an incomparable network of steel industry Association for Iron Steel Technology

Steel Manufacturing Process Association for Iron Steel

The Association for Iron Steel Technology (AIST) is a nonprofit entity with 18,500 members from more than 70 countries AIST is recognized as a global leader in networking, education and sustainability programs for advancing iron and steel technologyFeC True Equilibrium Diagram Graphite formation promoted by •S> 1i %wt • slow cooling 1600 1400 1200 1000 800 600 400 0 12 3 490 L g+L a+ Graphite Liquid + Graphite (Fe) C o, wt% C 065 740°C T(°C) g+ Graphite 100 g 1153°C Austenite 42 wt% C a + g Cast iron 1 Gray iron 2 Nodular (ductile) iron 3 White iron 4 Malleable iron 5 steel and cast iron06 Malmö HögskolaIn a blast furnace, fuel (), ores, and flux are continuously supplied through the top of the furnace, while a hot blast of air (sometimes with oxygen enrichment) is blown into the lower section of the furnace through a series of pipes called tuyeres, so that the chemical reactions take place throughout the furnace as the material falls downwardThe end products are usually molten metal and Blast furnace WikipediaAug 21, 2020 The BOS method adds recycled scrap steel to the molten iron in a converter At high temperatures, oxygen is blown through the metal, which reduces the carbon content to between 015% The EAF method, however, feeds recycled steel scrap through highpower electric arcs (with temperatures of up to 1,650 degrees Celsius) to melt the metal and The Modern Steel Manufacturing Process ThoughtCoStructural Shapes – standard steel configurations produced by steel mills such as wide flanges, channels, angles, pipe, tubes, etc Structural Steel – the structural elements that make up the frame that are essential to supporting the design loads, eg beams, columns, braces, plate, trusses, and fasteners It does not include for example STRUCTURAL STEEL DESIGN AND CONSTRUCTION

Steel Pickling: A Profile

21 BASIC FLOW DIAGRAM OF IRON AND STEEL PRODUCTION 22 22 BASIC FLOW DIAGRAM OF STEEL ROLLING AND FINISHING 24 31 SHARE OF STEEL CONSUMPTION FOR 1982 AND 1992 BY can be classified as steel mill products The American Iron and Steel Institute (AISI) estimated 1991 US shipments of44 31 2014 Rev B – Substation Standards Switch Operating Platforms Steel Design and Details 45 31 2038 Rev B – Substation Standards ChainLink Fence Swing Gates 46 31 2044 Rev F – Substation Standards Equipment Cabinet Platforms Steel Design and Details 47CONSTRUCTION STANDARDS STANDARD DRAWINGSby design limits for maximum separation force, torque, Hertzian pressure etc, but these criteria are valid only under so called “normal rolling conditions” and even these change continuously with progressive wear in the contact zone Besides “normal rolling conditions” a stable, theoretical assumption mills experience many differentA BASIC UNDERSTANDING OF THE MECHANICS OF The EHS Guidelines for Integrated Steel Mills include information relevant to the manufacture of pig iron and raw or lowalloy steel from iron ore and ironbased alloys It is applicable to the manufacture of metallurgical cok e; primary iron and steel production in Blast and Basic Oxygen furnaces (BFFinal Integrated Steel Mills IFCOct 21, 2009 Walthers new Ashland Iron Steel series features upgraded versions of some of our most popular HO Scale steel series kits, an amazing all Product Video: Walthers HO Ashland Iron Steel Series

Steel plant ppt 1 SlideShare

Aug 07, 2015 •The iron whilst molten is poured into moulds and left to solidify this is called cast iron and is used to make railings and storage tanks •The rest of the iron is used to make steel 21 •Steel is made in steel melting shop in the refractory lined vessels called LD Converters by blowing oxygen through the hot metal bathAttendees at the recent Iron and Steel Exposition in Pittsburgh, Pennsylvania, had the opportunity to visit an operating hot strip mill without leaving the Lawrence Convention Center simply by putting on a helmet Like the winged sandals of Hermes, the helmet transported its Step Inside the Cyberworld of a Virtual Reality Steel MillSchematic World save Categories Arenas Castles Dungeons Entertainement Games Houses and shops Miscellaneous Redstone Temples Towers Towns Traps Floating Islands Gardens Islands Pixel art Boats Flying machines Ground VehiclesCreations and schematics searchRecognized as a global leader in networking, education and steel industry sustainability programs, the Association for Iron Steel Technology (AIST) is a nonprofit organization with 16,000 members from more than 70 countries With 29 Technology Committees, 22 Local Members Chapters, and two major annual conference and expositions, AIST represents an incomparable network of steel industry Association for Iron Steel TechnologyJune 24, 2019 September 26, 2019 Steel Mill Modelers Supply BOF Slag Pots Modeled one of the many prototypes available Trunnions are prototype width and size for use with J hooks and match our charging ladle and scrap box, along with many of the modeling industry manufacturersSteel Mill – Modelers Supply

Steel Primary steelmaking Britannica

Steel Steel Primary steelmaking: In principle, steelmaking is a melting, purifying, and alloying process carried out at approximately 1,600° C (2,900° F) in molten conditions Various chemical reactions are initiated, either in sequence or simultaneously, in order to arrive at specified chemical compositions and temperatures Indeed, many of the reactions interfere with one another The blast furnace is the first step in producing steel from iron oxides The first blast furnaces appeared in the 14th century and produced one ton per day Even though equipment is improved and higher production rates can be achieved, the processes inside the blast furnace remain the same The blast furnace uses coke, iron ore and limestone to Steel Production American Iron and Steel InstituteTata Steel, lowest cost steel producer, strives to make steel making process more economical, efficient and environmentally sustainable Adoption of bestinclass technology, operational efficiency and efficient optimal use of resources contribute to making the steel Tata Steel's Sustainable Steel Making Process