Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

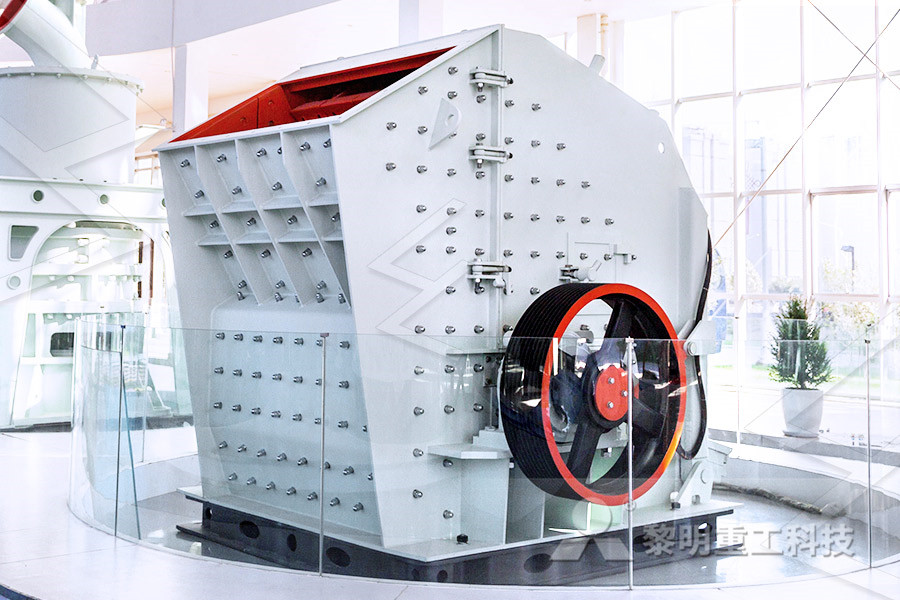

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

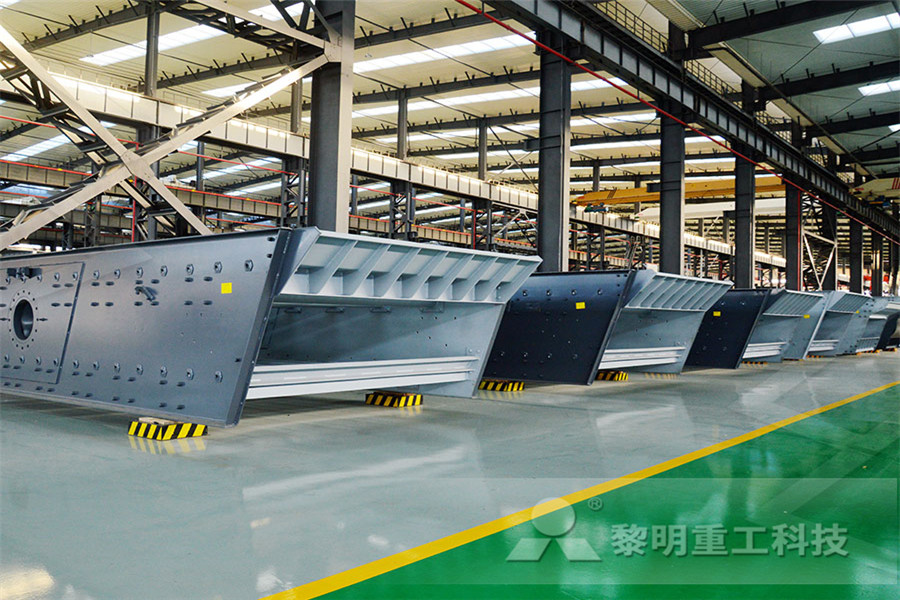

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

cement clinker grinding mill europe

Europe?s largest grinding plant built for HeidelbergCement Europes largest grinding plant in Grade, Poland, built for HeidelbergCement (Poland) — In April of this year, Christian Pfeiffer has planned, built and commissioned for HeidelbergCement in the cement plant Grade, Poland, a ball mill with a diameter of 52 m and a grinding path length of 1675 m, making it thus the largest grinding (Poland) — In April of this year, Christian Pfeiffer has planned, built and commissioned for HeidelbergCement in the cement plant Grade, Poland, a ball mill with a diameter of 52 m and a grinding path length of 1675 m, making it thus the largest grinding plant in EuropeEurope?s largest grinding plant built for HeidelbergCement Cement Plant, Clinker Grinding Unit: Capacity: 21155 t/h: Motor Power: 8003550 kw: Fineness: 3300~3800 cm²/g: Overview The ball mill for clinker is an efficient tool for fine powder grinding It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other ball mill for grinding cement clinkerCement ball mill is a kind of cement grinding equipment commonly used in cement plants It is mainly used for grinding materials in cement clinker section Cement ball mill is widely used in cement production, silicate products, new building materials, refractories, fertilizers, black and nonferrous metal mineral processing, glass, ceramics, and other industriesUse Cement Ball Mill Grinding Cement Clinker Cement Ball Clinker Plant Equipments, Clinker Plant Equipments Suppliers Directory Find variety Clinker Plant Equipments Suppliers, Manufacturers, Companies from around the World at water treatment equipment plant ,cement clinker ,iran clinker, Seeders Transplanters Cost of mini cement plant ball mill crusher other mining equipment World Leading Clinker Plant Equipments Suppliers, all Quality Clinker

Greywacke Cement Factory For Clinker Mixing Crusher

cement clinker factory fisher price coal price tractors prices clinker plant prices cement price bitumen price clinker price Suppliers : ~: MI Cement Factory Ltd 525 N Crown Portland Cement is an Ordinary Cement prepared by mixing clinker 95100% and gypsum 05% The ball mill for cement clinker grinding plant is an efficient tool for fine powder grinding It is mainly used to grind the cement clinker and raw materials in cement plant and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of oresChina High Capacity Cement Clinker Grinding Plant with Cement Clinker Grinding PlantZK Ball MillCement Mill There are three procedures of the cement grinding plant: raw material preparation, clinker burning and cement making The production technology of the silicate cement is regarded as the representative one in the cement industry It uses the limestone and clay as the main raw materials which are crushed, dosed and ground to be the primary raw ball mill cement clinker grinding plantCement Plant Equipment: We Manufacture all type of Cement Plant Equipment including Clinker Plant, Mill Headers, Conveyor Belts and supply to all over world including UAE, Europe, Cement Plant Equipment Cement Process Equipment Cement Cement clinker is a solid material produced in the manufacture of Portland cement as an intermediary product Clinker occurs as lumps or nodules, usually 3 millimetres (012 in) to 25 millimetres (098 in) in diameter It is produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilicate materials such as clay during the cement kiln stageCement clinker Wikipedia

Europe?s largest grinding plant built for HeidelbergCement

Europes largest grinding plant in Grade, Poland, built for HeidelbergCement (Poland) — In April of this year, Christian Pfeiffer has planned, built and commissioned for HeidelbergCement in the cement plant Grade, Poland, a ball mill with a diameter of 52 m and a grinding path length of 1675 m, making it thus the largest grinding plant in EuropeCement Plant, Clinker Grinding Unit: Capacity: 21155 t/h: Motor Power: 8003550 kw: Fineness: 3300~3800 cm²/g: Overview The ball mill for clinker is an efficient tool for fine powder grinding It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other ball mill for grinding cement clinkerJiangsu Pengfei Group Haian Building Material Equipment Co, Ltd, Experts in Manufacturing and Exporting Complete cement making machinery,ball mill and 132 more Products A Verified CN Gold Supplier on AlibabaJiangsu Pengfei Group Haian Building Material Equipment Co Cement Clinker Ball Mill Working Principle Center drive and side drive are two common drive modes for a cement clinker ball mill Center drive grinding mill means the motor shaft extends along the axis of mill body while side drive has a motor located on the side of the mill and torque is transmitted via the large girth gear which is bolted on the flange of the mill body High Capacity Cement China High Capacity Cement Clinker Grinding Plant with A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsCement mill Wikipedia

China Factory Cement Ball Mill Price for Cement Clinker

Cement Clinker Grinding Plant, Cement Ball Mill, Ball Mill Price manufacturer / supplier in China, offering Factory Cement Ball Mill Price for Cement Clinker Grinding Plant, Cement Clinker Grinding Equipment with Cement Ball Mill Sapre Part Price, Health Design Study Desks Adjustable Student Children School Tables and Chairs and so onThe preheating and partial precalcining of the raw material are completed by the cyclone preheater, instead of the partial function of the rotary kiln, shorten the length of the rotary kiln, and the gas heat exchange process in the kiln is carried out in a stacked state, and moved to the preheater in a suspended stateUnder the process, the raw material can be fully mixed with the hot gas Clinker Production Clinker Plant Cement Plant Equipmentrefractories – 9 Clinker cooling – 10 Kiln mechanical – 11 Emergency power – 12 Plant control systems 6 Cement milling process summary data – 8 Typical equipment downtime 110 1 Storage of clinker and other components – 2 Cement milling – 3 Separators (classifiers) – 4 Ball mill circuit control – 5 Cement storage – 6The Cement Plant Operations HandbookCement clinker is a solid material produced in the manufacture of Portland cement as an intermediary product Clinker occurs as lumps or nodules, usually 3 millimetres (012 in) to 25 millimetres (098 in) in diameter It is produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilicate materials such as clay during the cement kiln stageCement clinker WikipediaSpecializing in the sale of second hand cement plant equipment, and complete used cement plants In addition to used and new surplus Cement Plant Equipment (rotary kilns, ball mills, vertical roller mills), NMI deals in many other types of machinery, including used equipment for Bulk Material Handling, Crushing, Grinding, Industrial Mineral Processing, and Power PlantsNELSON MACH Sellers of SecondHand Cement Plant

cement epccement production lineCement grind millcement

10000t/d Cement Clinker Production Line Cement clinker making plant we use in this whole production line are vibrating feeder, jaw crusher, impact crusher, cement ball mill, lifer, preheating system, cement rotary kiln and packing machine and so onclinker sieve analysis for cement making plant ball mill Optimization of Cement Grinding Operation in Ball Mills Optimization of The Cement Ball Mill OperationOperation and Elements of A Closed Circuit Ball Mill SystemAuditing The OperationResults of Optimization Optimization addresses the grinding process, maintenance and product qualityclinker sieve analysis for cement making plant ball mill25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, cement silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations 25 años en la industria del cemento suministrando ingenieria y equipos para montaje y puesta en marcha de moliendas de cemento y clinker, silos Project for “Cement Australia” in Port KemblaEcorporates GmbH has been prominent supplier of key heavy equipment and complete systems for cement manufacturing We are in partnership with renowned workshops and fabrication facilities for manufacturing of cement plant equipment Kiln, Cooler, Crusher, Cement mill, Roller pressCement Plant Equipment EcorporatesCement Plant, Clinker Grinding Unit: Capacity: 21155 t/h: Motor Power: 8003550 kw: Fineness: 3300~3800 cm²/g: Overview The ball mill for clinker is an efficient tool for fine powder grinding It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other ball mill for grinding cement clinker

China Factory Cement Ball Mill Price for Cement Clinker

Cement Clinker Grinding Plant, Cement Ball Mill, Ball Mill Price manufacturer / supplier in China, offering Factory Cement Ball Mill Price for Cement Clinker Grinding Plant, Cement Clinker Grinding Equipment with Cement Ball Mill Sapre Part Price, Health Design Study Desks Adjustable Student Children School Tables and Chairs and so onCement clinker is a solid material produced in the manufacture of Portland cement as an intermediary product Clinker occurs as lumps or nodules, usually 3 millimetres (012 in) to 25 millimetres (098 in) in diameter It is produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilicate materials such as clay during the cement kiln stageCement clinker Wikipediarefractories – 9 Clinker cooling – 10 Kiln mechanical – 11 Emergency power – 12 Plant control systems 6 Cement milling process summary data – 8 Typical equipment downtime 110 1 Storage of clinker and other components – 2 Cement milling – 3 Separators (classifiers) – 4 Ball mill circuit control – 5 Cement storage – 6The Cement Plant Operations Handbookcement ball mill manufacturers in germany Cement mill Wikipedia A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ballcement clinker ball mill manufacturer germanyclinker sieve analysis for cement making plant ball mill Optimization of Cement Grinding Operation in Ball Mills Optimization of The Cement Ball Mill OperationOperation and Elements of A Closed Circuit Ball Mill SystemAuditing The OperationResults of Optimization Optimization addresses the grinding process, maintenance and product qualityclinker sieve analysis for cement making plant ball mill

cement clinker grinder ball mill tube mill for cem

what is the process of cement plant ball tube mills Ball Mill Vertical Roller Mill Cement Mill Crusher Mills Cement grinding process,Vertical roller mills and ball mills Around 110 years ago a Danish engineer, M Davidsen, patented a pioneering invention in France which involved a tube mill with a charge of steel balls or flint get priceCement Clinker Milling Plants Cement Clinker Grinding Plants Cement Clinker Grinding Alibaba offers 1112 cement clinker grinding plants products About 44 of these are mine mill 42 are cement making machinery and 1 are grinding equipment A wide variety of cement clinker grinding plants options are available to you such as raymond mill ball mill Cement Clinker Mill PriceBall Mill Maintenance In Cement Plants Cement Ball Mill Maintenance Kaartje Sturen Met Cement mill Wikipedia A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills in cement plant palmtransportservicescozaThis week, Cemtech reviewed recent advances in clinker reduction technologies in its latest webinar A topquality lineup of leading experts saw Professor Karen Scrivener of EPFL, Joel Maia, CEO of FCT Combustion and Leo Fit, product manager of activated clays at thyssenkrupp Industrial Solutions (TKIS) outline how they see the future development of clinker reduction, from the introduction of Calcined clays are redefining the cement sectorEcorporates GmbH has been prominent supplier of key heavy equipment and complete systems for cement manufacturing We are in partnership with renowned workshops and fabrication facilities for manufacturing of cement plant equipment Kiln, Cooler, Crusher, Cement mill, Roller pressCement Plant Equipment Ecorporates

Ball Mill Cement Plant

Ball Mill Cement Plant Our company mainly produces five series of products, including crushing equipment, sand making equipment, mineral processing equipment, grinding equipment and building materials equipment 40 years of mining machinery manufacturing history, three production bases, exported to more than 160 countries and regions, We are your trusted partner and service provider25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, cement silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations 25 años en la industria del cemento suministrando ingenieria y equipos para montaje y puesta en marcha de moliendas de cemento y clinker, silos Project for “Cement Australia” in Port KemblaSourcing Guide for Cement Ball Mill: China manufacturing industries are full of strong and consistent exporters We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: ball mill, grinding mill, cement millChina Cement Ball Mill, Cement Ball Mill Manufacturers