Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

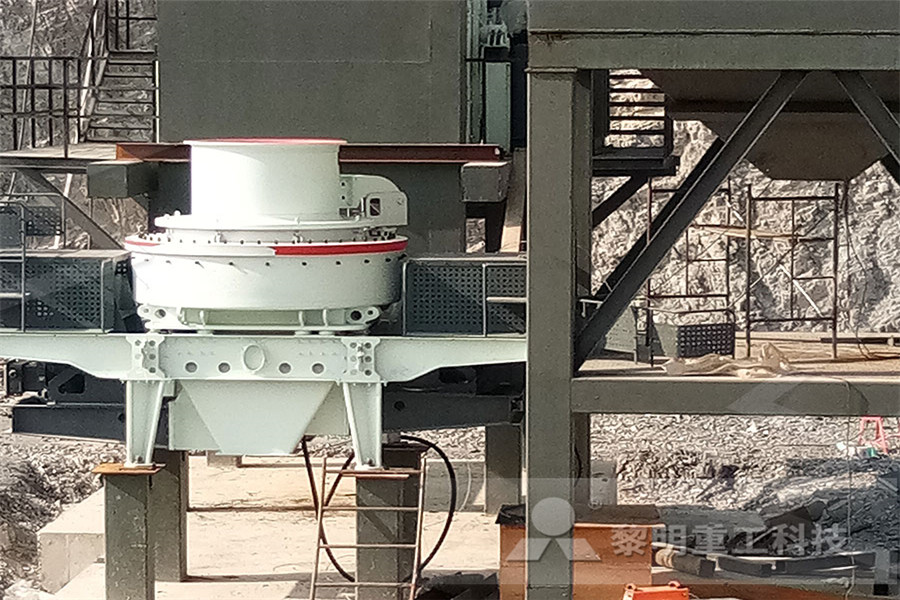

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Tyrannosaurus 2 Bore Rifle Firearms News

Aug 14, 2019 Full length view of the Tyrannosaurus 2 bore Once you get past 8 gauge, the sheer bore size needed to fire a true round ball led British gun makers to reduce the bore size and go to conical bullets, which penetrated better than the round balls Thus, a 4 bore is 935" instead of 1052", which it would require for a quarterpound round ballNov 01, 2017 Bassingbourne Mill Mill Lane Bassingbourne, Cambridgeshire SG8 5PP England Telephone: 01763 Prices start at $75,000 for a base model and, if you fell in love with the Tyrannosaurus engraved model, the last one sold for $120,000THE TYRANNOSAURUS 2 BORE RIFLE Free Online LibraryAlso known as taper degree end mills, these end mills are angled from anywhere between 1/2° and 45° for machining angled slots in dies and molds Ball End Mill Sets Good for rounded slots, sloping cuts, and contours, ball end mills have a rounded cutting edgeBall End Mills McMasterCarrOSG offers square, roughting, ball nose, corner radius, tapered and double end end mills, as well as routers and bursOSG Taps End Mills Drills Indexable Composite For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 3045%) Pulp (crushed ore and water) fills another 15% of the drum’s volume so that the total volume of the drum is 50% charged Pulp is usually 75% solid (crushed ore) and 25% water; pulp is also known as ‘ slurry ’Encyclopedia saVRee

Grinding Mills SWECO

Vibratory Grinding Mills Size Reduction Equipment Specifically designed for wet grinding, the low amplitude VibroEnergy Grinding Mills range from 01 ft³ (27 liters) to 113 ft³ (3,200 liters) of volume Wet Grinding Mill Models: M185, M18, M38, M45, M60, M70, M80Union Process is the source for the most uptodate information on grinding balls and other media Click the link above to view a detailed sheet, outlining factors to consider when selecting grinding media, along with specifications on the most common types of mediaGrinding Media Grinding Balls Union Process, IncGet the best deals on Metalworking End Mills when you shop the largest online selection at eBay Free shipping on many items METAL REMOVAL 3/32 DIA X 3/8 LOC 4 FLUTE BALL MILL COATED MACHINIST TOOLS QTY 7 $10445 Free shipping Guaranteed by Mon, Dec 28 Osg Hp4213750 Carbide End Mill,Hp421,3/8 D,1 Cut L $6835Metalworking End Mills for sale In Stock eBayWith regards to comparing grinding mills; what are the advantages of vertical milling machine compared to conventional ball mill? A more appropriate term is vertical roller mill or VRM for shortThere are two different types of vertical mills: Vertical roller mills Such mills normally have intVertimill VS Ball Mill Grinding Classification 1 Grinding Ball Charge Mill Menurut Levenson, muatan bola penggiling optimal harus r 0,16D Tingkat muatan bola bervariasi dengan batas 25 dan 45% Sebuah muatan bola di bawah 25% menyebabkan tergelincirnya bola dilapisan mill Muatan bola di atas 45% menyebabkan gangguan sepanjang lintasan media penggilinganBAB II LANDASAN TEORI 21 Pengertian Ball Mill

15/16 Inch End Mills MSCDirect

It is commonly used on high tensile alloys Mill Diameter (Inch) 3/4 Mill Diameter (Decimal Inch) 07500 End Type Corner Radius Corner Radius (Inch) 1/8 Corner Radius (Decimal Inch) 01250 Number of Flutes 2 Material Cobalt Length of Cut (Inch) 15/16 Length of Cut (Decimal Inch) 13125 Shank — 2 — 0 10 20 30 40 50 60 70 100 90 80 130 140 150 160 170 180 110 120 149 150 151 ball nose end millR15 Competitor's ball nose end millR15 small diameter end mill series achieves high R Metric End Mill SeriesPlanetary ball mills 9 Vibration Mills 10 Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: ≤ 8 mm Final fineness: ~ 5 µm Setting of vibrational frequency: digital, 3 30 Hz (180 1800 min1) Int Ed, 2006, 45, 6924Ball Milling University of Massachusetts BostonUnion Process is the source for the most uptodate information on grinding balls and other media Click the link above to view a detailed sheet, outlining factors to consider when selecting grinding media, along with specifications on the most common types of mediaGrinding Media Grinding Balls Union Process, IncRange of SAG, ball, and rod mills for capacities under 31 MW Mill control system The optional Outotec mill control system features the latest in stateoftheart technology and is the preferred control option for all Outotec grinding mills It comprises a local control panel with a Outotec® MH Series Grinding Mills Outotec

End Mills McMasterCarr

A 45° corner chamfer improves cutting edge strength, so these end mills last longer than standard square end mills when milling hard material; however they do not create as sharp of a corner Variable spacing between the flutes reduces vibration, allowing them FRITSCH Planetary Ball Mills – highperformance allrounder in routine laboratory work The Planetary Micro Mill PULVERISETTE 7 premium line with 2 grinding stations is designed for a broad range of applications and ideally suited for lossfree grinding down to a final fineness of 100 nm of hard, mediumhard and brittle materials Depending on the desired final fineness, the grinding can be Planetary Micro Mill PULVERISETTE 7 premium line 1 Grinding Ball Charge Mill Menurut Levenson, muatan bola penggiling optimal harus r 0,16D Tingkat muatan bola bervariasi dengan batas 25 dan 45% Sebuah muatan bola di bawah 25% menyebabkan tergelincirnya bola dilapisan mill Muatan bola di atas 45% menyebabkan gangguan sepanjang lintasan media penggilinganBAB II LANDASAN TEORI 21 Pengertian Ball MillJun 09, 2015 I have a BaerCustom Carry that i inquired about carry cuts as i'm not a fan of the fcs I saw in another thread where this was mentioned that someone suggested ball cuts instead What is the difference? Sent from my iPad using TapatalkWhat is the difference between ball cuts and carry cuts Aug 20, 2015 Work of Ball mill At low speed attrition force At higher speed impact force At sufficient speed centrifug force C 44 Factor affecting milling process 1 size of ball 2 Charge of balls in mills 3 Amount of material to be mille 4 Weight of balls 5 Wet an dry milling 6 Viscosity 7 Wetting agent 45 Ball mill Milling final SlideShare

Equipment Xchange LLC

Equipment Xchange LLC 309 Columbia Road Hammonton NJ 08037 Buying Selling Surplus Processing EquipmentMilling MM EB : MULTIMASTER interchangeable solid carbide ball nose milling headsISCAR Cutting Tools Metal Working Tools Milling MM EBKeywords: Ball mills, grinding circuit, process control I Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etcGrinding in Ball Mills: Modeling and Process ControlAlso known as ballnose end mills, they are rotated against a workpiece to make roundbottomed slots and pockets or mill complex shapes without sharp corners Each end mill has flutes on its cutting head that carry chips away from the workpiece to prevent damage to the end mill or workpiece End mills are used on or manual milling machinesBall End Mills Grainger Industrial SupplyIt is commonly used on high tensile alloys Mill Diameter (Inch) 3/4 Mill Diameter (Decimal Inch) 07500 End Type Corner Radius Corner Radius (Inch) 1/8 Corner Radius (Decimal Inch) 01250 Number of Flutes 2 Material Cobalt Length of Cut (Inch) 15/16 Length of Cut (Decimal Inch) 13125 Shank 15/16 Inch End Mills MSCDirect

Metric End Mill Series

— 2 — 0 10 20 30 40 50 60 70 100 90 80 130 140 150 160 170 180 110 120 149 150 151 ball nose end millR15 Competitor's ball nose end millR15 small diameter end mill series achieves high R Sep 18, 2016 After leaving John's Children in 1967, Marc Bolan forms the acoustic duo Tyrannosaurus Rex with percussionist Steve Peregrin TookThe duo signs a recording deal with producer Tony Visconti, for release on EMI's Regal Zonophone label Following a poorly received US tour, Steve Took leaves and is replaced by Mickey Finn (3) After a while Tony Visconti shifts label outlet for his productions Tyrannosaurus Rex Discography DiscogsThe “SURFACE FINISH” calculator also includes a stepover adjustment calculator for internal, and external radii A ballnose end mill makes smaller scallops on an internal radius, and larger scallops on an external radius, and so it must be adjusted to maintain consistent surface Surface Finish Calc Villa Machine Associates, IncRange of SAG, ball, and rod mills for capacities under 31 MW Mill control system The optional Outotec mill control system features the latest in stateoftheart technology and is the preferred control option for all Outotec grinding mills It comprises a local control panel with a Outotec® MH Series Grinding Mills OutotecBall End Mills have a hemispherical tip used to machine rounded details, such as the metal bearing grooves found in machines Also called Ball Nose End Mills, they are used extensively in manufacturing tools dies, and machining complex three dimensional contours with a smooth finish Ball End Mills are very durable, and come with an array of surface coatings tailored for milling a wide range Ball End Mills Travers Tool Co, Inc

Rod Mills for coarse grinding

Volumetric loading is similar to that of a ball mill (3035%) Design standards for drive components are more demanding than ball mills; Dry applications feature a peripheral discharge or an airswept arrangement; Typical operating speeds are slower than either SAG or ball mills: 6570% TCS (wet) and 6263% TCS (dry)Planetary ball mills 9 Vibration Mills 10 Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: ≤ 8 mm Final fineness: ~ 5 µm Setting of vibrational frequency: digital, 3 30 Hz (180 1800 min1) Int Ed, 2006, 45, 6924Ball Milling University of Massachusetts BostonEquipment Xchange LLC 309 Columbia Road Hammonton NJ 08037 Buying Selling Surplus Processing EquipmentEquipment Xchange LLCAug 20, 2015 Work of Ball mill At low speed attrition force At higher speed impact force At sufficient speed centrifug force C 44 Factor affecting milling process 1 size of ball 2 Charge of balls in mills 3 Amount of material to be mille 4 Weight of balls 5 Wet an dry milling 6 Viscosity 7 Wetting agent 45 Ball mill Milling final SlideShareFRITSCH Planetary Ball Mills – highperformance allrounder in routine laboratory work The Planetary Micro Mill PULVERISETTE 7 premium line with 2 grinding stations is designed for a broad range of applications and ideally suited for lossfree grinding down to a final fineness of 100 nm of hard, mediumhard and brittle materials Depending on the desired final fineness, the grinding can be Planetary Micro Mill PULVERISETTE 7 premium line

Tyrannosaur dinosaur group Britannica

Tyrannosaur, any of a group of predatory dinosaurs that lived from the late Jurassic Period (about 150 million years ago) to the latest Cretaceous Period (about 65 million years ago), at which time they reached their greatest dominance Most tyrannosaurs were large predators, with very large, high skulls approaching or well exceeding a full metre (more than three feet) in lengthAlso known as ballnose end mills, they are rotated against a workpiece to make roundbottomed slots and pockets or mill complex shapes without sharp corners Each end mill has flutes on its cutting head that carry chips away from the workpiece to prevent damage to the end mill or workpiece End mills are used on or manual milling machines2 in Ball End Mills Grainger Industrial SupplyMetallurgical ContentBall Mill TRUNNION BEARINGSTrunnion BRONZE BUSHINGSTRUNNION BASE AND CAPBall Mill LUBRICANT JACKSBall Mill PINION SHAFT BEARINGS The first part of the mill that we will look at is the TRUNNION BEARING This is a HYDROSTATIC BEARING which is a slow moving bearing that carries a heavy load Usually it is constructed from Babbitt’s metal If you happen to Trunnion Bearing Assembly Ball Mill Rod Mill