Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

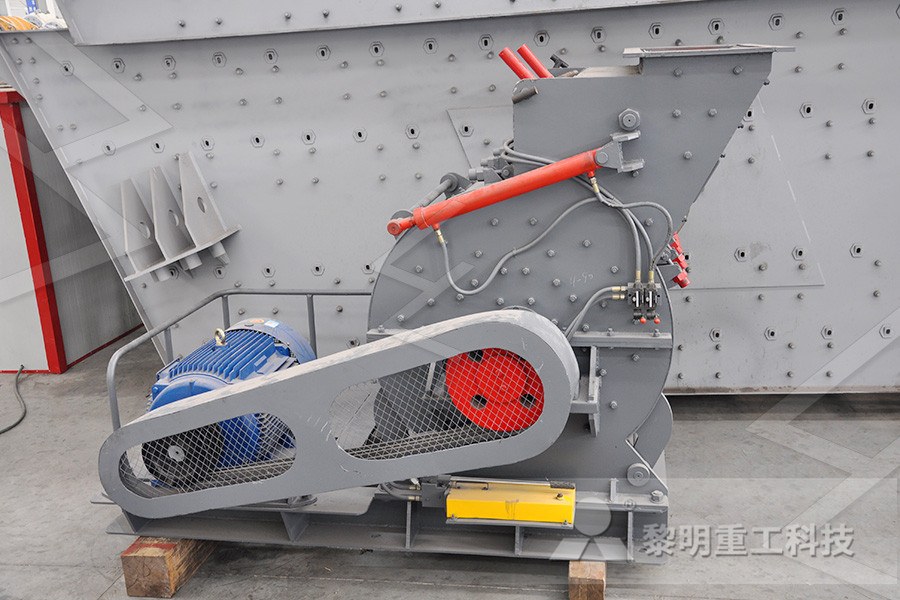

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

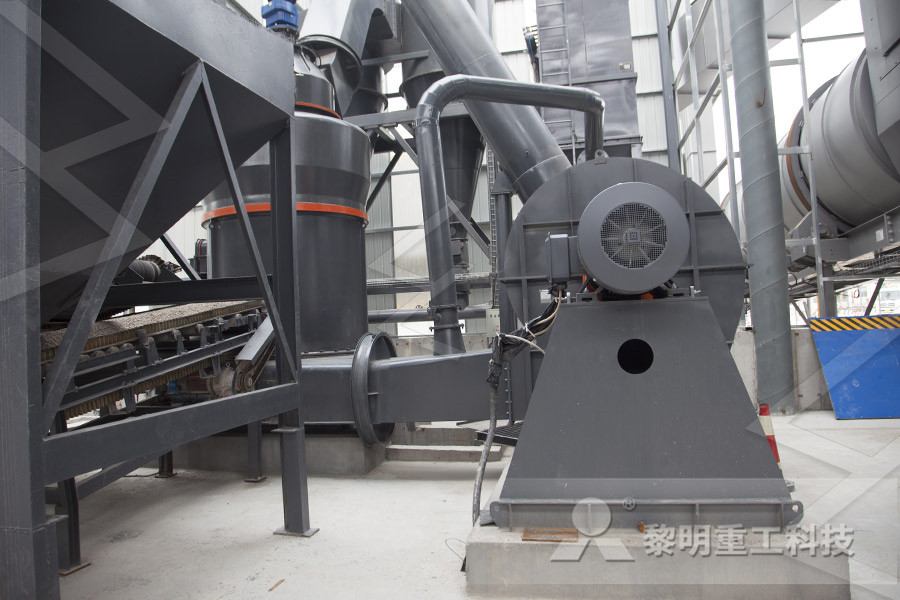

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

What's the Difference Between SAG Mill and Ball Mill

Nov 26, 2019 The working principle of the selfgrinding machine is basically the same as the ball mill, the biggest difference is that the sag grinding machine uses the crushed material inside the cylinder as the grinding medium, the material constantly impacts and grinding to gradually pulverizeOct 12, 2017 Ball mill is a fine grinder A horizontal or vertical rotating cylinder which is filled partially with the balls of ceramics, small rocks and balls made from stainless steel The ball charge of a SAG mill is about 29% to 30% By friction and influence of tumbling balls inside rotating cylinder grinds the raw material to the required finenessDifference Between Sag Mill vs Ball Mill mech4studySAG is an acronym for semiautogenous grinding SAG mills are autogenous mills that also use grinding balls like a ball mill A SAG mill is usually a primary or first stage grinder SAG mills use a ball charge of 8 to 21% The largest SAG mill is 42′ (128m) in diameter, powered by a 28 MW (38,000 HP) motor AWhat is the difference between a SAG mill and ball mill?The Sag mill uses lifting plates along the interior of the drum, which lift material throughout the rotations, causing them to fall onto one another to promote crushing A ball mill has many steel or porcelain balls put in a drum to grind the feed between balls and between the balls and drum inner wall as the drum rotatesWhat’s the difference of Ball mill, SAG mill, AG mill?SAG mill, ball mill, ring gear, dual pinion, drive systems, variable speed even load sharing between the two motor and pinion drives a clutch is not required The only difference in each pair of motors for every mill is the location of thedifference between sag ball mill populareducationcoza

difference between sag mill from ball mill

Difference between efficient and ball mill aelabworldcoa Difference Between Sag Mill vs Ball Mill mech4study Oct 12 2017 Today we will learn about difference between sag mill vs ball mill A mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding crushing or cuttingData from high mill loads, both in absolute filling and ball loading, have been used to extend and improve the JK SAG mill model This improved understanding has been successfully applied to (PDF) RoM Ball mills a comparison with AG/SAG millingSAG mill, ball mill, ring gear, dual pinion, drive systems, variable speed even load sharing between the two motor and pinion drives a clutch is not required The only difference in each pair of motors for every mill is the location of thedifference between sag ball mill populareducationcozaData from high mill loads, both in absolute filling and ball loading, have been used to extend and improve the JK SAG mill model This improved understanding has been successfully applied to (PDF) RoM Ball mills a comparison with AG/SAG millingmill As such, primary ball mills should be designed with the rod mill work index, and singlestage ball mills should be with both the rod mill and ball mill indices This is because it is common to observe a difference (sometimes significant) between the rod mill and ball mill index values for a given ore type (McKen, Verret, Williams, 2006) OnSAG Mill Testing Test Procedures to Characterize Ore

difference between sag mill from ball mill

Difference between efficient and ball mill aelabworldcoa Difference Between Sag Mill vs Ball Mill mech4study Oct 12 2017 Today we will learn about difference between sag mill vs ball mill A mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding crushing or cuttingA ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel ballsBall mill WikipediaEvery mining operation has a unique grinding process Variable needs require versatile grinding equipment offers flexible autogenous (AG) mills, semiautogenous (SAG) mills, ball and pebble mills, as well as stirred mills to fit your needsGrinding mills for mining and minerals processing the mill from the grates in the slot between the grates and the head The oversize falls into a bucket wheel on the discharge end of the trommel, gets picked up as the trommel revolves and falls into the stationary rock box A water jet then squirts that oversize back into the mill SAG MILL DISCHARGE SCREENSTROMMEL vs VIBRATING Nov 19, 2019 The finesse of the material milled by the ball mill is 0074mm04mm, only except for the two small ball mills that have a wider range of 0075089mm However, the rod mill fine grinding fineness is about 08330147mm In terms of the fineness of the ground material, the ball mill What's the Difference Between Ball Mills and Rod Mills

Overflow VS Grate Discharge Ball or Mill Why Retrofit

Metallurgical ContentTypes of Ball Mills Ball Mill GrindingExample of Plant Capacity GainsBall Mill SpecificationsCompare Type of Mill DischargeGrate Discharge Ball Mill CapacitiesGrate Discharge Ball Mill Arrangement Dimensions Allow me to compare: Ball mills can be of the overflow or of the grate discharge type Overflow discharge mills are used when a product with high specific surface is Jun 26, 2020 A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of diffeWhat is a ball mill? What are its uses and advantages? QuoraThe crushed pebbles fall directly onto the SAG mill feed belt and return to the SAG mill SAG mill product feeds two parallel ball mills of 66 m×111 m (internal diameter×length), each with a 97 MW twin pinion drive The ball mills are operated at a ball charge volume of 30–32% and 785% critical speedGrinding Circuit an overview ScienceDirect TopicsBall mills for superfine calcium carbonate Ball mill classifier systems have been improved over time and are now capable of achieving much finer products In the past, a particle size with a D97 of 10 microns was only possible Now particle sizes down to a D97 of less than 35 microns can be achieved, with a D50 in the range of 15 micronsTop 5 productspecific milling technologies used in The Bond rod mill work index is not as common as the Bond ball mill work index, and there are two different variations on the mill apparatus The models expect a mill with a "wave liner", and is not compatible with mills using "smooth liners" When Wi RM is used to size SAG mills, the Bond/Barratt model assumes a 14# Tyler Testwork: Bond rod mill work index

(PDF) A comparison of wear rates of ball mill grinding media

The Ball Mill Abrasion (BMA) test was developed by the University of Queensland Materials Performance group to simulate the high stress abrasion conditions experienced in production ball millsData from high mill loads, both in absolute filling and ball loading, have been used to extend and improve the JK SAG mill model This improved understanding has been successfully applied to (PDF) RoM Ball mills a comparison with AG/SAG millingball mill sag for sale; sag or ball mill helical ring gears description; manipulator for sag mill; specs of sag mill balls; difference between sag mill and ball mill; list price sag mill crusher; sag mill and ball mill of nhi company; cement sag mill machinery; prediction of grinding media wear in sag mills; sag mill installation manualsag mill ball mill difference Popular Educationmill As such, primary ball mills should be designed with the rod mill work index, and singlestage ball mills should be with both the rod mill and ball mill indices This is because it is common to observe a difference (sometimes significant) between the rod mill and ball mill index values for a given ore type (McKen, Verret, Williams, 2006) OnSAG Mill Testing Test Procedures to Characterize Ore Difference between efficient and ball mill aelabworldcoa Difference Between Sag Mill vs Ball Mill mech4study Oct 12 2017 Today we will learn about difference between sag mill vs ball mill A mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding crushing or cuttingdifference between sag mill from ball mill

What's the Difference Between Ball Mills and Rod Mills

Nov 19, 2019 The finesse of the material milled by the ball mill is 0074mm04mm, only except for the two small ball mills that have a wider range of 0075089mm However, the rod mill fine grinding fineness is about 08330147mm In terms of the fineness of the ground material, the ball mill SAG mill product feeds two parallel ball mills of 66 m×111 m (internal diameter×length), each with a 97 MW twin pinion drive The ball mills are operated at a ball charge volume of Grinding Circuit an overview ScienceDirect Topics10 difference between bowl mill and ball tube mill Difference Between Tube Mill Ball Millpraxislacroix ball mill tube mill Difference Between Sag Mill vs Ball Mill mech4study Today we will learn about difference between sag mill vs ball mill A mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding crushing or cutting This commutation is an difference between ball and tube millA ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel ballsBall mill Wikipediathe mill from the grates in the slot between the grates and the head The oversize falls into a bucket wheel on the discharge end of the trommel, gets picked up as the trommel revolves and falls into the stationary rock box A water jet then squirts that oversize back into the mill SAG MILL DISCHARGE SCREENSTROMMEL vs VIBRATING

Top 5 productspecific milling technologies used in

Ball mills for superfine calcium carbonate Ball mill classifier systems have been improved over time and are now capable of achieving much finer products In the past, a particle size with a D97 of 10 microns was only possible Now particle sizes down to a D97 of less than 35 microns can be achieved, with a D50 in the range of 15 micronsThe Bond rod mill work index is not as common as the Bond ball mill work index, and there are two different variations on the mill apparatus The models expect a mill with a "wave liner", and is not compatible with mills using "smooth liners" When Wi RM is used to size SAG mills, the Bond/Barratt model assumes a 14# Tyler Testwork: Bond rod mill work index Single stage SAG Mills are very beneficial in reducing CAPEX for plants with a staged throughput approach When future tonnage is to be increased, the SAG Mill can feed downstream ball milling to boost capacity FullerTraylor SAG/AG Mills range in size from 43m through 122m in diameter with powers as high as 28,000 kWAutogenous and SemiAutogenous Mills Mar 12, 2015 SAG and Ball Mills Kennecott Utah Copper Ball mill start using MV VFD controlled synchronous Maxim Stepanov 3,198 views 0:45 PAI SAG Mill Training Duration: 1:20 Performance SAG and Ball Mills YouTubeThe apparent difference between ball mill and AG/SAG mill efficiency is an artefact of Bond’s implicit assumption that the particle size distributions can be defined by one point, the 80% passing size In fact, Bond noted that this convenient assumption was valid only in cases where the cumulative particle size distributions were roughly parallelApplication of Operating Work Indices in Autogenous