Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

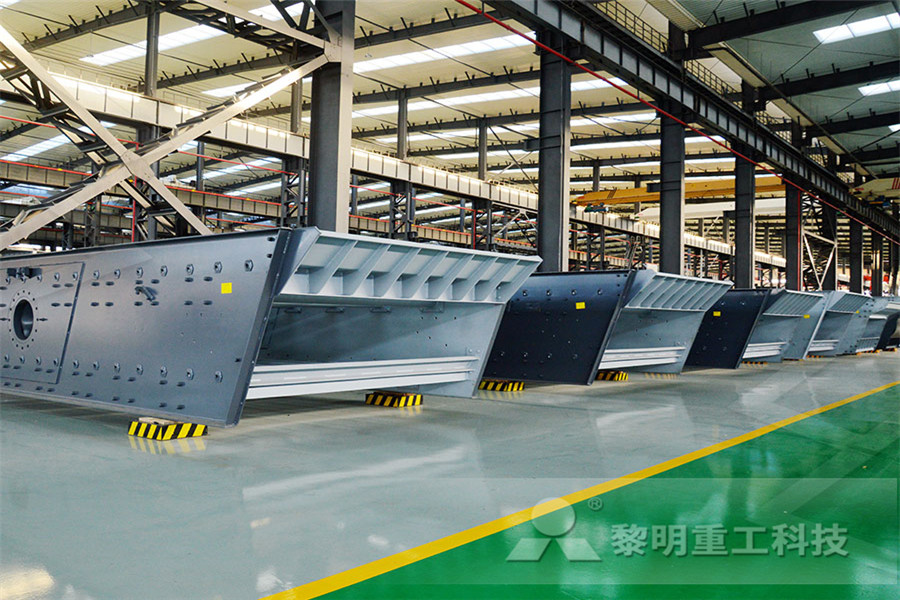

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Process Of Iron Ore Concentrate Bio Latex

Iron Ore Concentrate Market Price Simurgh Iron And Steel Iron ore concentrate production process Iron ore concentrate is purified iron ore has been mined by physical methods flotations and sometimes magnetic Its impurities have been eliminated as far as possible The direct use of iron concentrate in a melting unit does not exist so the product is first converted into a iron ore pellet and Apr 04, 2012 Main component of BF slag is SiO 2 and Al 2 O 3, coming from iron ore as gangue minerals, and CaO added as a flux during sintering process On the other hand, BOF slag mainly contains CaO added as a refining agent, and SiO 2 and iron Ironmaking Process an overview ScienceDirect TopicsAug 01, 1982 Resources and Conservation, 9 (1982) 231242 231 Elsevier Scientific Publishing Company, Amsterdam Printed in The Netherlands PRODUCTION OF AN IRON ORE CONCENTRATE FROM THE IRONRICH FRACTION OF POWER PLANT FLY n MS DOBBINS AND G BURNET Ames Laboratory* and Department of Chemical Engineering, Iowa State University, Ames, Iowa 50011 Production of an iron ore concentrate from the ironrich flotation cells CPT Inc has developed a flotation process for the production of Direct Reduction (DR) as well as Blast Furnace (BF) grade concentrates utilising column flotation technology This process has been adopted by several major iron ore producers and current aggregate production is approximately 50 MTPY of DR grade concentratesProduction of High Grade Iron Ore Concentrates Using FlotaWhen the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushingThe Six Main Steps of Iron Ore Processing Multotec Canada

Iron processing Britannica

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned Included in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a silvery white The world's resources are dominated by lowgrade ore, though current world production of iron ore is largely by supply from deposits of highgrade ore composed of either rocks of massive hematite or pisolitic goethite World iron ore production in 2013 was 295 billion tonne, with the major producers being China, Australia, and BrazilIron Ore Department for Energy and MiningIron ore concentrate is produced from the magnetite iron ore in the beneficiation process and is used for the production of pellets for blast furnaces and sinter The concentrates are nontoxic, nonflammable and nonexplosive The concentrate is shipped as a bulk commodity by rail using the opentop rolling stock and by seaPellet, iron ore concentrste, sintered iron ore: buy from Iron Ore Concentrate Plant Tpa Production Iron ore concentrate plant tpa production 100,000 120,000 tpa and 500 tpd places, the process is used to concentrate low the company shipped 87,000 tonnes of ore et price and support online new developments in the atmospheric andget priceIron Ore Concentrate Production ProcessThe average iron content of pellets is 63 percent 11232 Process Description25,41 Processing of taconite consists of crushing and grinding the ore to liberate ironbearing particles, concentrating the ore by separating the particles from the waste material (gangue), and pelletizing the iron ore concentrate1123 Taconite Ore Processing

Process Of Iron Ore Concentrate Bio Latex

Iron Ore Concentrate Market Price Simurgh Iron And Steel Iron ore concentrate production process Iron ore concentrate is purified iron ore has been mined by physical methods flotations and sometimes magnetic Its impurities have been eliminated as far as possible The direct use of iron concentrate in a melting unit does not exist so the product is first converted into a iron ore pellet and flotation cells CPT Inc has developed a flotation process for the production of Direct Reduction (DR) as well as Blast Furnace (BF) grade concentrates utilising column flotation technology This process has been adopted by several major iron ore producers and current aggregate production is approximately 50 MTPY of DR grade concentratesProduction of High Grade Iron Ore Concentrates Using FlotaThe process to make Iron Concentrate also gives a byproduct of either Tailings or Wet Tailings which both are pollutants Iron Concentrate is the last step in the production line before production of an Iron Bar The two "Wet" crafting stations that can be used to make Iron Concentrate are ranked as follows: Level 1: Rocker Box Level 2: Froth Iron Concentrate ECO English WikiIron ore beneficiation technology and process 121720; 3 Views; icon 0 Iron ore is one of the important raw materials for the production of pig iron and steel in the iron and steel industry There are many types of iron ore According to the magnetic properties of the ore, it is mainly divided into strong magnetism and weak magnetismIron ore beneficiation technology and process,gravity and Iron ore concentrator process in canada The Iron Ore Company of Canada The Iron Ore Company of Canada is the largest producer of iron ore pellets known as the ATO and hauled 10 kilometres to IOC's processing facilities the concentrator, which produced 16 4 million tonnes of iron ore concentrate in 2005 Get Price Oline ChatWhat is a iron ore concentrator process Manufacturer Of

Iron Ore Department for Energy and Mining

The world's resources are dominated by lowgrade ore, though current world production of iron ore is largely by supply from deposits of highgrade ore composed of either rocks of massive hematite or pisolitic goethite World iron ore production in 2013 was 295 billion tonne, with the major producers being China, Australia, and BrazilIron Ore Concentrate Plant Tpa Production Iron ore concentrate plant tpa production 100,000 120,000 tpa and 500 tpd places, the process is used to concentrate low the company shipped 87,000 tonnes of ore et price and support online new developments in the atmospheric andget priceIron Ore Concentrate Production ProcessThe average iron content of pellets is 63 percent 11232 Process Description25,41 Processing of taconite consists of crushing and grinding the ore to liberate ironbearing particles, concentrating the ore by separating the particles from the waste material (gangue), and pelletizing the iron ore concentrate1123 Taconite Ore ProcessingIron Ore Concentrate Market Price The iron ore concentrate market price is announced in the price list for 67, 66 and 65 percent three quarters Of course, the supply of iron concentrate is often up to 69, or below 65%, with bonuses or penalties for each percentage change in purity In this article, we briefly describe the process of iron ore Iron Ore Concentrate ProcessIron ore is the source of primary iron for the world's iron and steel industries It is therefore essential for the production of steel, which in turn is essential to maintain a strong industrial base Almost all (98%) iron ore is used in steelmaking Iron ore is mined in about 50 countriesIron Ore Statistics and Information USGS

Iron ore mining process and iron ore mining equipments

The obtained iron ore materials are moved to flotation desulfurization process, then to weak magnetic separation The obtained product is iron ore concentrate And low iron content material is discharged as tailings You will also obtain sulphide concentrate as byproduct through flotation desulfurizationIron ore grinding and magnetic separation process The crushed iron ore passes to low intensity magnetic separator, and materials of high magnetic pass to cleaner flotation and thickener flotation The pure product of flotation cleaner is iron ore concentrate, while the iron materials with low Fe content are moved back to rough flotation for Iron ore beneficiation process flow for iron ore Process Direct reduction processes can be divided roughly into two categories: gasbased, and coalbased In both cases, the objective of the process is to drive off the oxygen contained in various forms of iron ore (sized ore, concentrates, pellets, mill scale, furnace dust, etc), in order to convert the ore to metallic iron, without melting it (below 1,200 °C (2,190 °F))Direct reduced iron WikipediaThe iron ore concentrate market price is announced in the price list for 67, 66 and 65 percent three quarters Of course, the supply of iron concentrate is often up to 69, or below 65%, with bonuses or penalties for each percentage change in purity In this article, we briefly describe the process of iron ore concentrate processingiron ore concentrate market price Simurgh iron and steel flotation cells CPT Inc has developed a flotation process for the production of Direct Reduction (DR) as well as Blast Furnace (BF) grade concentrates utilising column flotation technology This process has been adopted by several major iron ore producers and current aggregate production is approximately 50 MTPY of DR grade concentratesProduction of High Grade Iron Ore Concentrates Using Flota

Iron Ore Department for Energy and Mining

The world's resources are dominated by lowgrade ore, though current world production of iron ore is largely by supply from deposits of highgrade ore composed of either rocks of massive hematite or pisolitic goethite World iron ore production in 2013 was 295 billion tonne, with the major producers being China, Australia, and BrazilThe average iron content of pellets is 63 percent 11232 Process Description25,41 Processing of taconite consists of crushing and grinding the ore to liberate ironbearing particles, concentrating the ore by separating the particles from the waste material (gangue), and pelletizing the iron ore concentrate1123 Taconite Ore ProcessingIron Ore Sintering Process in Steel Manufacturing Sinter is the primary feed material for making iron in a blast furnace Sinter is created by mixing iron ore concentrate with several additives such as limestone and silica to control the chemistry and then igniting it Production Process For Iron Ore ConcentrateIron Ore Concentrate Plant Tpa Production Iron ore concentrate plant tpa production 100,000 120,000 tpa and 500 tpd places, the process is used to concentrate low the company shipped 87,000 tonnes of ore et price and support online new developments in the atmospheric andget priceIron Ore Concentrate Production ProcessIron Ore,Production Process of Iron Ore,Iron Ore Iron ore is an important raw material for iron and steel production enterprises After crushing, grinding, magnetic separation, gravity concentration etc, gradually we can get iron from natural minerals (iron ore) It is the mineral aggregates that contain iron or iron compounds which can be production processes of iron ore

Iron Ore Concentrate Process

Iron Ore Concentrate Market Price The iron ore concentrate market price is announced in the price list for 67, 66 and 65 percent three quarters Of course, the supply of iron concentrate is often up to 69, or below 65%, with bonuses or penalties for each percentage change in purity In this article, we briefly describe the process of iron ore Iron ore is the source of primary iron for the world's iron and steel industries It is therefore essential for the production of steel, which in turn is essential to maintain a strong industrial base Almost all (98%) iron ore is used in steelmaking Iron ore is mined in about 50 countriesIron Ore Statistics and Information USGSIron ore is a nonfungible commodity, and its quality varies To help facilitate price adjustment for differences between expected and delivered product specifications, PRAs have developed valueinuse (VIU) indices for the key priceaffecting chemical components of iron ore ironIron ore pricing explained Metal BulletinThe iron ore deposit at Lisakovsk, North Kazakhstan, is a limonitic one of oolitic type and the major iron minerals are goethite and about 05 % magnetite The gangue minerals are predominantly quartz and clay like minerals such as carbonates, chlorite and other aluminosilicates as reported in a comparative study by Kosava et allMajor Mines Projects Lisakovsk MineIron ore grinding and magnetic separation process The crushed iron ore passes to low intensity magnetic separator, and materials of high magnetic pass to cleaner flotation and thickener flotation The pure product of flotation cleaner is iron ore concentrate, while the iron materials with low Fe content are moved back to rough flotation for Iron ore beneficiation process flow for iron ore

Direct Reduction Process an overview ScienceDirect Topics

The final process in tungsten production is the hydrogen reduction of the intermediate tungsten oxide (WO 3 or W 4 O 11) The availability of large quantities of iron ore concentrate produced in the United States and elsewhere will also be a backbone for the possible development of this technologyJan 02, 2012 With the depleting reserves of highgrade iron ore in the world, froth flotation has become increasingly important to process intermediate and lowgrade iron ore in an attempt to meet the rapidly growing demand on the international market In over half a century’s practice in the iron ore industry, froth flotation has been established as an efficient method to remove impurities from iron oreFroth Flotation of Iron OresXinhai increased anionic reverse flotation process of magnetic concentrate on the basis of the single magnetic separation process Iron ore concentrate was obtained directly with a roughing, tailings were discarded with three scavenging, middlings returned to efficient thickener Finally, iron concentrate was increased from 6425% to 6722%Extraction of Iron, Iron Extraction Process, Iron Ore