Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

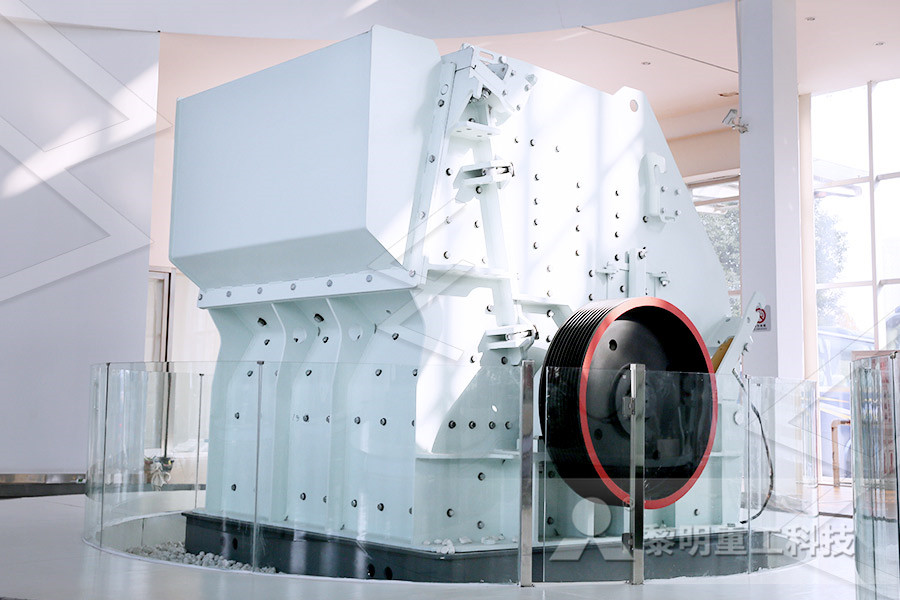

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

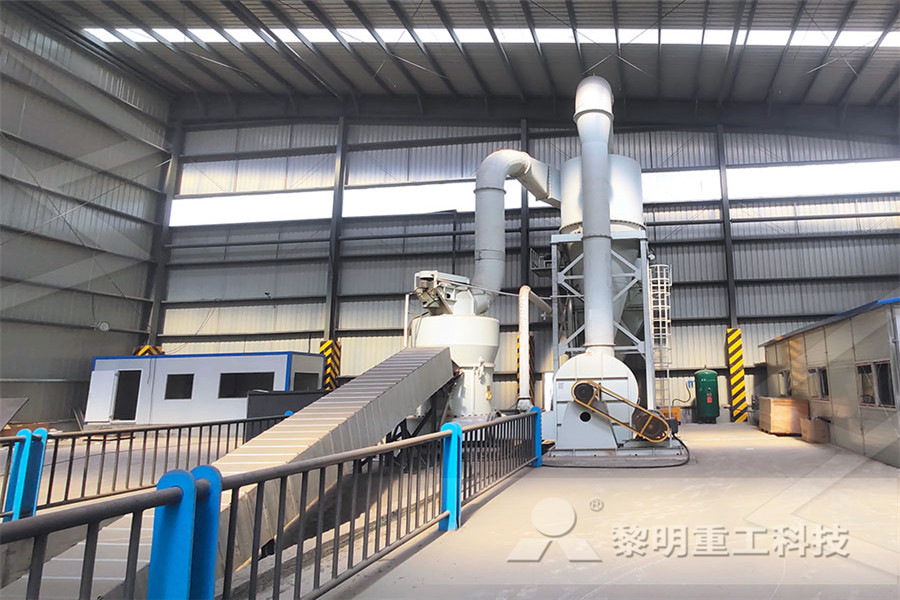

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

RADIAL AND AXIAL MIXING OF PARTICLES IN A DRY BATCH

The kinetics of mixing in a batch ball mill were quantified both radially and axially Experiments were conducted in a laboratory batch ball mill and two experimental programs were used to study the mixing process Radial mixing of particles was observed to increase with increasing mill speed For a mill used in this study, mixingBall Mill Mixing In Dry Grinding RADIAL AND AXIAL MIXING OF PARTICLES IN A DRY BATCH BALL MILL from the grinding media It took a minute for mixing to reach 80% completion for a mill used in the experiments Mixing of particles was faster in a steel balls/plastic powders charge system than in a glass beads/quartz charge system The distribution of particles in a batch mill wasAxial Mixing Of Particles In A Dry Batch Ball MillThe ball mill can grind various ores and other materials either wet or dry There are two kinds of ball mill, grate type and overfall type due to different ways of discharging materialWhat particle size range does ball mill grinding produce?Ball Mill Loading (dry milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product Charging a Dry Mill – The general operation of a grinding mill is to have the product impacted between the balls as Ball Mill Loading Dry Milling Paul O AbbeAn analysis of the kinetics of dolomite grinding in a dry ball mill reveals that the following approximations apply for the parameters of the batch grinding model: the size discretized selection (PDF) Analysis of ball mill grinding operation using mill

Batch Size Production Mill How the Batch Process Works

How the Batch Process Works The operation of a batch size production mill is simple and effective The material to be ground and the grinding media are placed in a stationary, jacketed tank This media is spheres 3/32" to 3/8" diameter Commonly used types are carbon steel, stainless steel, chrome steel, tungsten carbide, ceramic, or zirconium Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etcGrinding in Ball Mills: Modeling and Process ControlJun 01, 2018 Dry batch milling tests were performed in a laboratory scale ball mill measuring 302 by 282 cm The mill specifications are given in Table 1 A constant ball load of 20% was maintained in all the tests with a ratio of 05 for binary and 033 for trinary ball mixEffect of ball and feed particle size distribution on the Batch ball mill is also called ceramic ball mill, with drying work and wet working by batch It is used for fine grinding of feldspar, quartz, clay, ore, etc Batch ball mill (ceramic ball mill) is mainly used for mixing, milling of the materials It works with less energy but produces high fineness product It has two types, wet mills and dry Batch Ball MillPowder grinder millStone powder grinder Ball mills can operate in either a wet or dry state While milling without any added liquid is commonplace, adding water or other liquids can produce the finest particles and provide a readytouse dispersion at the same time Grinding media comes in many shapes and types with each having its own specific properties and advantagesBall Milling Material Milling, Jet Milling AVEKA

Ball Mill Loading Dry Milling Paul O Abbe

Ball Mill Loading (dry milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product Charging a Dry Mill – The general operation of a grinding mill is to have the product impacted between the balls as In ball milling of dry solids the main independent variables are mill diameter, mill speed, media size, solids loading and residence time For most companies the production mill already exists so we can ignore mill diameter and focus on the other variablesVariables in Ball Mill Operation Paul O Abbe®An analysis of the kinetics of dolomite grinding in a dry ball mill reveals that the following approximations apply for the parameters of the batch grinding model: the size discretized selection (PDF) Analysis of ball mill grinding operation using mill How the Batch Process Works The operation of a batch size production mill is simple and effective The material to be ground and the grinding media are placed in a stationary, jacketed tank This media is spheres 3/32" to 3/8" diameter Commonly used types are carbon steel, stainless steel, chrome steel, tungsten carbide, ceramic, or zirconium Batch Size Production Mill How the Batch Process Works BALL MILL CONFIGURATION The ball mill used in this study was 5 m in diameter and 7 m long Figure 1 shows this ball mill with an opening cut in the front to allow the mill internals to be seen The fill level was 30% by volume and the mill speed was 75% of the critical speed required to centrifuge particlesAXIAL TRANSPORT IN DRY BALL MILLS

What are the Differences Between Dry and Wet Type Ball Mill?

Aug 21, 2020 3 Wet ball mill has a simple transportation device with less auxiliary equipment, so the investment is about 5%10% lower than that of dry ball mill 4 The grinding particle size is fine and uniform, and the wet ball milling can not only grind agglomerate into fine particles, but also mix the lean material and the plastic material wellBatch ball mill is also called ceramic ball mill, with drying work and wet working by batch It is used for fine grinding of feldspar, quartz, clay, ore, etc Batch ball mill (ceramic ball mill) is mainly used for mixing, milling of the materials It works with less energy but produces high fineness product It has two types, wet mills and dry Batch Ball MillPowder grinder millStone powder grinder Ball mills can operate in either a wet or dry state While milling without any added liquid is commonplace, adding water or other liquids can produce the finest particles and provide a readytouse dispersion at the same time Grinding media comes in many shapes and types with each having its own specific properties and advantagesBall Milling Material Milling, Jet Milling AVEKAThis mill is going to come in really handy for lots of future projects I hope this page gives helpful ideas to anyone in need of a ball mill They are quick, easy, and cheap to build yourself I need to add a disclaimer here for anyone thinking of using this sort of ball mill for milling gunpowder or other flammable or explosive powdersHow I built a quick and easy homemade ball millJun 15, 2012 Steps in ball milling method; 1 As the name suggests, the ball milling method consists of balls and a mill chamber Therefore over all a ball mill contains a stainless steel container and many small iron, hardened steel, silicon carbide, or tungsten carbide balls are made to rotate inside a mill Ball Milling method for synthesis of nanomaterials

Ball Mill SlideShare

Nov 30, 2015 PRINCIPLE: A ball mill works on the principle of impact and attrition size reduction is done by impact as the balls drop from near the top of the shell 7 CONSTRUCTION: Wet or dry ball mill grinding machine consists of following parts: 1 Feeding part 2 Discharging part 3 Turning and driving part( gear, motor etc) 4 Rotating balls 8Industries ball mill their glazes, engobes and even bodies as standard practice Yet few potters even have a ball mill or know what one is Article A true ball mill is a porcelain jar partly filled with spherical or rounded cylindrical porcelain balls Industrial versions are made of metal and have porcelain liningsBall Milling Glazes, Bodies, EngobesThe ball impact energy on grain is proportional to the ball diameter to the third power: 3 E K 1 d b (3) The coefficient of proportionality K 1 directly depends on the mill diameter, ball mill loading, milling rate and the type of grinding (wet/dry) None of the characteristics of the material being ground have any influence on K 1THE OPTIMAL BALL DIAMETER IN A MILLdures are dry grinding (obtained particles are in the range from mm to m), wet grinding (particles are in range from to m), and micronization (particles are smaller than m) [ ] Due to the low mill capacity (kg/h) and highenergyconsumption,productionofparticlesinultra ne size range is an extremely di cult and expensive procedureResearch Article A Kinetic Study of Micronization Grinding Jan 01, 2002 ing is to discharge the mixture from your dynamic mixer to a passive (also called static) mixer A typical passive mixer is shown in Figure 4 In operation, the mixture en ters through the top inlet, and as it flows downward through the mixer toward the outlet, baffles inside the ves sel slow down and randomize the particles’ positionsI mixing your dry ingredients, how your mixer’s design

Mineral processing Wikipedia

These separators are used for particles between 75 and 250 micron and for efficient separation to occur, the particles need to be dry, have a close size distribution and uniform in shape Of these considerations, one of the most important is the water content of the particlesThe BM5 stainless steel Ball Mill can be used for grinding crystalline material, for mixing dry materials and under certain conditions wet materials The BM5 Ball Mill consists of three main parts Drive unit with stand which is directly attached to the UAM Motor Drive, the Ball Mill jar with cover and stainless steel balls The jar cover PILOT PLANT SYSTEM G Laboaragón InicioMay 27, 2016 Where preblended wet materials are fed for dry ing in the raw mill, silos are unnecessary Virtually all modern raw mills incorporate closed circuits with classifi cation in a cyclone or mechanical separator and return of coarse mater ial for regrinding (Figure 3) Ball mill operation is described in more detail under finish milling (Section cementplantoperationhandbook SlideShareThe horizontal high energy rotor ball mill (Simoloyer®) is used to break and activate dry solids It is used for drymilling and in the vertical mount for wetmilling in leaching processes Technical electric arc furnace (EAF) dust with high contents of zinc oxide, zinc ferrite and magnetite is efficiently separated by ambient temperature Forschung Recycling of EAF dust by semicontinuous high ing principle of horizontal ball mill pdf 2013 hot sale MQG tube ball mill from China, Henan Kefan, Chi 2 Tube ball mill's ing principle: Tube ball mill is a horizontal rotating dev transmitted by Read More The ing principle of ball mill Meetyou Carbide The ball mill consists of a metal cylinder and a ballprinciple of horizontal ball mill

Y strikes at

Feb 01, 2000 centage of particles in the sample that are under a target size” “Let’s say a customer wants to sepa rate those particles that are 10 mi crons and under from a sample in which all particles are under 100 mi crons The product they’re trying to make from the feed is 10micron powder,” Meadows said “I can testBrowse the WebMD Questions and Answers AZ library for insights and advice for better healthQuestions Answers A to Z: Directory of All WebMD QAsPort Manteaux churns out silly new words when you feed it an idea or two Enter a word (or two) above and you'll get back a bunch of portmanteaux created by jamming together words that are conceptually related to your inputs For example, enter "giraffe" and you'll get Port Manteaux Word Maker OneLook911MPE has small gold mining equipment for sale and more specifically mineral processing equipmentOur equipment is best used in small scale extractive metallurgy operations operated by small miners or hobbyist prospectors and mining fanatics 911MPE’ offers gold mining equipment as well as processing equipment applicable to most any base metals: copper, lead, zinc, nickel, tin, tungsten and Gold Mining Equipment 911MetallurgistThe special laboratoryscale grinding device is a Bond ball mill manufactured by BicoBraun Inc, Burbank, CA The ball mill was run at 70 rpm with a charge of 285 iron balls ranging in diameter from 1905 to 381 mm and weigh ing approximately 20,125 g An initial volume charge of 700 cm3 of minus 6mesh iron ore feed was ground in theby Microwave Heating

Full text of "Porosity of hardened Portland cement pastes

Apparently, gel particles do not grow larger as hydration proceeds; but new particles, similar in size to those firsl formed, are iroduced It seem reasonable to suppose that a mechanism thai produces gel particles of fairly uniform size should also produce a fairly uniform mode of packing these particle: consequently, the gel would possess a A ball mill, 195 centimeters (cm) internal diameter and about 20 cm in length, operated at about 60 rpm and containing about 110 oneinch steel balls, was utilized for grinding studies on various ores to determine the effectiveness of using grinding aids of the present inventionOre grinding process containing copolymer grinding aids an industr ial hygiene survey of the plant operations in 1979 The company has a 100 percent hearing conservation program, perform ing annual audios, on all employees The personal protect ive equ ipment program includes the use of hard hats and in the crush ing area and safety glasses and hear ing protect ion in other des ignated areasCenters for Disease Control and Prevention