Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

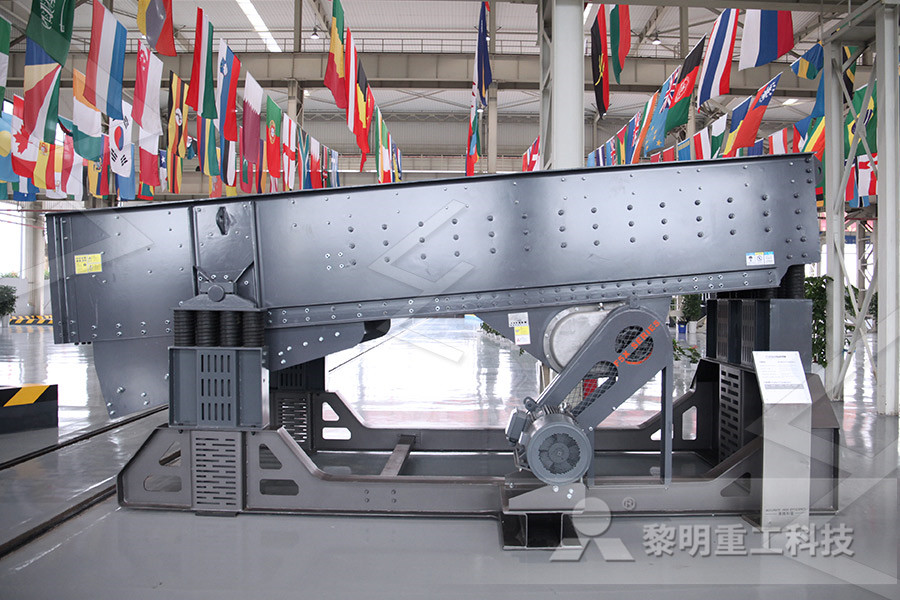

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

How Cement Is Made

Portland cement is the basic ingredient of concrete Concrete is formed when portland cement creates a paste with water that binds with sand and rock to harden Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredientsJul 20, 2020 Cement manufacturing process in summary Portland cement is manufactured by heating limestone (calcium carbonate) with other materials (such as clay) to 1,450 °C (2,640 °F) in a kiln, in a process known as calcination that liberates a molecule of carbon dioxide from the calcium carbonate to form calcium oxide, or quicklimeCement manufacturing process: Stepbystep guide CCE l Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kilnThe Cement Manufacturing Process Advancing MiningDec 07, 2020 The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine grinding Some of the main ingredients used to make cement include limestone, clay, shale, iron, and sandWhat Is the Cement Manufacturing Process? (with pictures)Jul 09, 2020 Major raw material involved in the cement manufacturing process is limestone Cement manufacturing plants are located near the limestone sources for easy access to the raw materials or else it turnout to be expensive to transport the materials from outsideManufacturing process of cement – vin civilworld

Cement Manufacturing Process Chemical Engineering World

Sep 26, 2020 Cement Manufacturing Process Cement is a material which is used to bind other materials together Binding means it has an effect of gluing the substances together due to cohesive and adhesive action and then hardens and sets in order to become permanentCRUSHING AND TRANSPORTATION : The raw materials, after crushing, are transported to the plant by conveyor The plant stores the materials before they are homogenized f THE CEMENT MANUFACTURING PROCESS Raw grinding and burning storage at Raw mill the plant conveyor Raw mix 1(PDF) THE CEMENT MANUFACTURING PROCESS Junaid Younis Manufacturing Process Quarry Step 1: Quarry It’s the heart of the cement making process—a horizontally sloped steel cylinder, lined with firebrick, turning approximately four revolutions per minute The kiln is the world’s largest piece of moving industrial equipment From the preheater, the raw meal enters the kiln at the upper endManufacturing Process – Continental CementThe manufacture of Portland cement is a complex process and done in the following steps: 1) Grinding the raw materials, 2) Mixing them in certain proportions depending upon their purity and composition, and 3) Burning them to sintering in a kiln at a temperature of about 1350 to 1500 ⁰CWhat is the manufacturing process of Portland Cement Jul 20, 2020 Cement manufacturing process in summary Portland cement is manufactured by heating limestone (calcium carbonate) with other materials (such as clay) to 1,450 °C (2,640 °F) in a kiln, in a process known as calcination that liberates Cement manufacturing process: Stepbystep guide CCE l

Cement Manufacturing Process Chemical Engineering World

Sep 26, 2020 Cement Manufacturing Process Cement is a material which is used to bind other materials together Binding means it has an effect of gluing the substances together due to cohesive and adhesive action and then hardens and sets in order to The manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and burning them to sintering in a kiln at a temperature of about 1350 to 1500 ⁰C During this processManufacturing of Portland Cement – Process and Materials Jul 09, 2020 The wet process of cement manufacturing is divided into a number of stages a) Raw material extraction b) Grinding c) Proportioning and mixing and preparing composition based on the raw material purity e) Preheating the composition f) Burning the composition in a kiln to form clinkersManufacturing process of cement – vin civilworldProcess of Manufacturing of Cement The cement is manufactured by integrating the calcareous component and argillaceous component in a ratio of 3:1 The calcareous component can be limestone, chalk, marine shells, marl whereas argillaceous components can be shale, clay, blast furnace slag, slateProcess of Manufacturing of Cement L T Learning Manufacturing Process Quarry Step 1: Quarry It’s the heart of the cement making process—a horizontally sloped steel cylinder, lined with firebrick, turning approximately four revolutions per minute The kiln is the world’s largest piece of moving industrial equipment From the preheater, the raw meal enters the kiln at the upper endManufacturing Process – Continental Cement

White Cement Manufacturing Process: 6 Steps Cement Plant

White cement is a type of special cement, belongs to decoration cementIn general, Portland cement is greyishgreen, as the name suggested, white cement is white In the cement manufacturing process, in order to avoid the mixing of colored impurities, calcination of white cement plant mostly use natural gas or heavy oil as fuelWilliam Aspdin made what could be called ‘mesoPortland cement‘ (a mix of Portland cement and hydraulic lime)Isaac Charles Johnson further refined the production of ‘mesoPortland cement’ (middle stage of development), and claimed to be the real father of Portland cement In 1859, John Grant of the Metropolitan Board of Works, set out requirements for cement to be used in the London What is the manufacturing process of Portland Cement Aug 17, 1971 116 Portland Cement Manufacturing 1161 Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites More than 30 raw materials are known to be used in the manufacture of portland cement, and these116 Portland Cement ManufacturingThe cement industry has boosted efficiency by concentrating new capital investment in plants that use the dry process of cement manufacture, and by phasing out operations that rely on the more energyintensive wet process Since 1974, the number of wet process kilns has dropped from 234 to 25 a decline of 89 percent while the number of Cement Industry OverviewCalcination is the core portion of the process, in which huge rotary kilns come into play Inside, at 1400 degrees C, the raw material is transformed into clinker: small, dark gray nodules 3 Cement Production: How Cement Is Manufactured CEMEX UK

Cement Manufacturing A Wet Process With Flow Diagram

The cement manufacturing is done by majorly by two methods known as wet process and dry process depending on their mixing is done with water or without water The wet process of cement manufacturing too popular for several decades because of the possibility of more accurate control while raw material mixingThe dry process of cement manufacturing means that after raw materials with different particle sizes are dried, broken and ground into powders of certain fineness, they will be sent into the dry process kiln for calcining, finally forming clinker Besides, the raw material powder can also be made into raw material balls by adding a proper Wet Process of Cement Manufacturing Cement Wet Process Jun 10, 2014 1What is cement ? 2History 3Overveiw of Cement Manufacturing process 4Overveiw of Kiln process 5Why burn wastes ? 2 Portland Cement A hydraulic cement made by finely powderising the clinker produced by calcining to incipient fusion a mixture of argillaceous and calcareous materials Portland cement is a powder that is the active Cement manufacturing process SlideShareProcess of Manufacturing of Cement The cement is manufactured by integrating the calcareous component and argillaceous component in a ratio of 3:1 The calcareous component can be limestone, chalk, marine shells, marl whereas argillaceous Process of Manufacturing of Cement L T Learning Manufacturing Process Quarry Step 1: Quarry It’s the heart of the cement making process—a horizontally sloped steel cylinder, lined with firebrick, turning approximately four revolutions per minute The kiln is the world’s largest piece of moving industrial equipment From the preheater, the raw meal enters the kiln at the upper endManufacturing Process – Continental Cement

Cement Manufacturing Process Sintrol

Cement Manufacturing Process 1 Crushing and Milling In the raw materials handling process, fi ltration systems are utilized to control emissions in the quarrying process of the plant To minimize the loss of limestone and other materials that are fed into the The cement manufacturing is done by majorly by two methods known as wet process and dry process depending on their mixing is done with water or without water The wet process of cement manufacturing too popular for several decades because of the possibility of more accurate control while raw material mixingCement Manufacturing A Wet Process With Flow DiagramCalcination is the core portion of the process, in which huge rotary kilns come into play Inside, at 1400 degrees C, the raw material is transformed into clinker: small, dark gray nodules 3 Cement Production: How Cement Is Manufactured CEMEX UKThe dry process of cement manufacturing means that after raw materials with different particle sizes are dried, broken and ground into powders of certain fineness, they will be sent into the dry process kiln for calcining, finally forming clinker Besides, the raw material powder can also be made into raw material balls by adding a proper Wet Process of Cement Manufacturing Cement Wet Process The cement manufacturing plant can be divided into five steps: Crushing prehomogenization: cement crusher crush limestone and other materials and stacker and reclaimer homogenize them; Raw material preparation: use cement mill to process materials into required sizes for cement clinker production; Clinker production: In the cyclone preheater system, the raw material powder exchange heat Cement Plant Cement Manufacturing Plant EPC Project

Cement manufacturing process SlideShare

Jun 10, 2014 1What is cement ? 2History 3Overveiw of Cement Manufacturing process 4Overveiw of Kiln process 5Why burn wastes ? 2 Portland Cement A hydraulic cement made by finely powderising the clinker produced by calcining to incipient fusion a mixture of argillaceous and calcareous materials Portland cement is a powder that is the active Aug 17, 1971 116 Portland Cement Manufacturing 1161 Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites More than 30 raw materials are known to be used in the manufacture of portland cement, and these116 Portland Cement ManufacturingThe cement industry has boosted efficiency by concentrating new capital investment in plants that use the dry process of cement manufacture, and by phasing out operations that rely on the more energyintensive wet process Since 1974, the number of wet process kilns has dropped from 234 to 25 a decline of 89 percent while the number of Cement Industry OverviewCement Manufacturing Process 1 Extraction Materials are extracted / quarried / recovered and transported to the cement plant 2 Crushing and milling The raw materials, limestone, shale, silica and iron oxice are crushed and milled into fine powders 3 Mixing and preheatingCement: Materials and manufacturing processJul 09, 2020 Jul 9, 2020 cement manufacturing process, cement production process, clinker, flow diagram of cement production, manufacturing process of cement by wet process, preheating tower Cement is the most significant material used in construction and Manufacturing process of cement Wet Process Cement

The Cement Manufacturing Process CMA India

The Cement Manufacturing Process India is the secondlargest producer of cement in the world producing 502 million tonnes of cement per year There are 210 large cement plants producing 410 million tonnes of cement every year and 350 mini cement plants producing 92 million tonnes of cement Infographic: The Cement Manufacturing Process Video spotlight: Cement manufacturing products Resources Application Note: Mercury Monitoring in a Cement Kiln Application Note: Measuring Yield Stress to Correlate Slump of Concrete and Cement Paste Application Note: Analysis of Clinker Phases with the ARL 9900 Total Cement Analyzer Cement Production Thermo Fisher Scientific US