Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

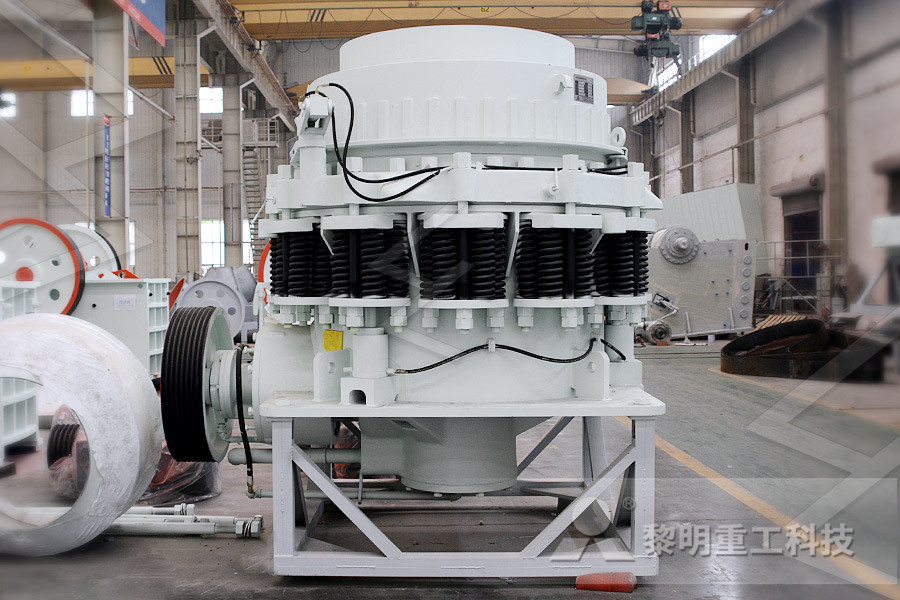

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

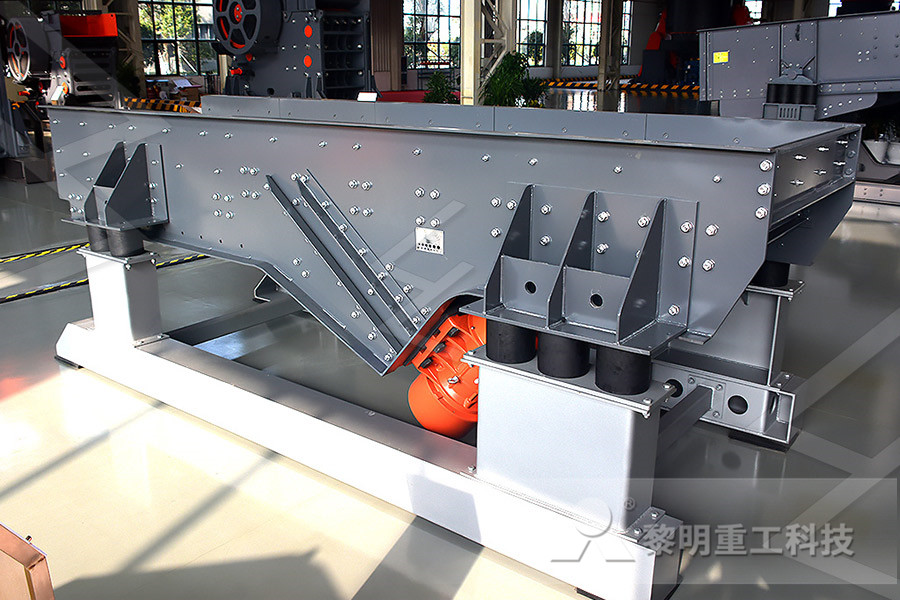

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

EIRICH TowerMill Vertical agitated media mill

The TowerMill quickly found applications in both wet and dry grinding plants nBrought to the market by the Japan Tower Mill Co, Ltd in the 1950’s, thereafter it was manufactured and marketed by the Kubota Corporation, from whom it was transferred to Nippon Eirich, Japan in 1999 TowerMill History – From INVENTION to global SUCCESSWet grinding – continuous Vertical agitated media mill for energy efficient fine grindingTowerMill Mischtechnik Mischer IntensivmischerTower mill grinding efficiency drops as feed material becomes finer then 25 microns due to high ball/particle size ratio Fine grinding efficiency greatly increases with finer media and slightly with denser slurries To achieve efficient grinding, closed circuit with hydrocyclones is neededTOWER FINE MILLING EXPERIENCE AT MOUNT ISA MINESStirred mills tower mills for efficient customised application For fine and ultrafine grinding, stirred mill and tower mill technology provides efficient solutions to meet your needs These mills operate at power intensities that give you unrestricted customization options for a wide range of industries and grinding applicationsStirred mills for milling grinding Design and Construction of a PedalPower Grinding mill To cite this article: Akande Stephen Oluwashola and Ayodele Mercy 2019 J Phys: Conf Ser 1378 View the (PDF) Design and Construction of a PedalPower Grinding mill

DESIGN AND OPERATION OF VERTIMILL® FOR SECONDARY

Tower mill grinding efficiency drops as feed material becomes finer then 25 microns due to high ball/particle size ratio Fine grinding efficiency greatly increases with finer media and slightly tower mill grinding design Stirred mills for milling grinding FL For fine and ultrafine grinding, stirred mill and tower mill technology provides efficient solutions to meet your needs These mills operate at power intensities that give you unrestricted customization options for a wide range of industries and grinding applicationstower mill grinding design ME Mining Machinerytower mill grinding design Second Hand Concrete Batching Plants For Sale In Malaysia Market of Second Hand Concrete Batching Plants For Sale In MalaysiaDevelopment of Second Hand Concrete Batching Plants are to largescale, automated, intelligen Raw Complex Gold Ore Processing Machinetower mill grinding designThe basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of circuit open/closed Ball Mill Design/Power Calculationimprove energy transfer to the grinding media and keeping the grinding chamber stationary This design proved successful in achieving small product sizes with reduced agitator screwenergy consumption The TowerMill quickly found applications in both wet and dry grinding plants n Brought to the market by the Japan Tower Mill Co, LtdEIRICH TowerMill Vertical agitated media mill

DESIGN AND OPERATION OF VERTIMILL® FOR SECONDARY GRINDING

Tower mill grinding efficiency drops as feed material becomes finer then 25 microns due to high ball/particle size ratio Fine grinding efficiency greatly increases with finer media and slightly Agitated Media Mill for wet amp; dry grinding of ores and minerals Nippon EIRICH, Japan, supplies the TowerMill, a vertical agitated media mill for wet grinding in the fineness range from 45 µm to 150 µm The machine concept is characterized by a far smaller space requirement and a 30 40 % lowerTowerMill Vertical Agitated Media Mill Eirich Machines Design and Construction of a PedalPower Grinding mill To cite this article: Akande Stephen Oluwashola and Ayodele Mercy 2019 J Phys: Conf Ser 1378 View the (PDF) Design and Construction of a PedalPower Grinding millJan 01, 2016 Vertical tower mill with pin stirrer The grinding action in the vertical mill is mostly by shear, torsion stresses and compression forces produced by the stirrer rotating at high velocities The result is abrasion by the grinding media on the mineral particles Some size reductions also occur by Stirred Mills – Ultrafine Grinding ScienceDirectgrinding mills (ball, SAG etc), fine grinding bead mills have a stationary shell, and a rotating central shaft with some form of mixing elements that agitates the beads The design of the mixing elements varies with proprietary design (Jankovic 2002, Radziszewski and Allen, 2014, Rahal et al, 2011):A Power Model For Fine Grinding HIGmills

Ball Mill Design/Power Calculation

Dec 12, 2016 If P is less than 80% passing 70 microns, power consumption will be Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is Eirich Tower mill™ • General characteristicsGravity keeps media in the millCharge weight aids grindingLow intensity, low tip speedHigh density mediaMedia sizes 38 –5 mmScrew agitator to lift charge 5 13 Nov 2013Stirred Milling machine development and application Swiss Tower Mills Minerals AG develops fine and ultrafine grinding mill products, using an innovative technology A range of services is available from consulting, conceptual and detail engineering to production, site assembly and lifecycle service supportSwiss Tower Mills Minerals AGThe basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of circuit open/closed Ball Mill Design/Power CalculationThe tower mill was more powerful than the water mill, able to generate roughly 20 to 30 horsepower There were many uses that the tower mill had aside from grinding corn Tower Mills fueled a society that was steadily growing in its need for power by providing a service to other industries as well: The production of pepper and other spicesTower mill Wikipedia

IsaMill

technology – the grinding volume of the IsaMill™ is one tenth of the equivalent ball or tower mill The high intensity means short residence times, preventing overgrinding and giving a sharp product size distribution » IsaMill™ advantages 7 Horizontal Design plug˚ow design This avoids short circuiting and makes the mill far lesstower mill grinding efficiency Second Hand Concrete Batching Plants For Sale In Malaysia Market of Second Hand Concrete Batching Plants For Sale In MalaysiaDevelopment of Second Hand Concrete Batching Plants are to largescale, automated, intelligen Raw Complex Gold Ore Processing Machinetower mill grinding efficiencyThe ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightGrinding Medium an overview ScienceDirect TopicsAgitated Media Mill for wet amp; dry grinding of ores and minerals Nippon EIRICH, Japan, supplies the TowerMill, a vertical agitated media mill for wet grinding in the fineness range from 45 µm to 150 µm The machine concept is characterized by a far TowerMill Vertical Agitated Media Mill Eirich Machines Jan 01, 2016 Vertical tower mill with pin stirrer The grinding action in the vertical mill is mostly by shear, torsion stresses and compression forces produced by the stirrer rotating at high velocities The result is abrasion by the grinding media on the mineral particles Some size reductions also occur by Stirred Mills – Ultrafine Grinding ScienceDirect

Ball Mill Design/Power Calculation

Dec 12, 2016 If P is less than 80% passing 70 microns, power consumption will be Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is design of iron ore grinding mill types design of iron ore grinding mill types Our Purpose And Belief LM Heavy Industry is committed to provide the global customers with the firstclass products and superior service, striving to maximize and optimize the interests and values of the customers, and build bright future with high qualitydesign of charNonMetallic Ore grinding millThe post mill gets its name from its construction: the body, which contains all of the gears and milling equipment, is balanced on a large post This crude design meant the entire windmill had to be turned into the wind On early post mills, this design was particularly cumbersome because the mill Mill Types illinoiswindmillsThe ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightGrinding Medium an overview ScienceDirect Topicstechnology – the grinding volume of the IsaMill™ is one tenth of the equivalent ball or tower mill The high intensity means short residence times, preventing overgrinding and giving a sharp product size distribution » IsaMill™ advantages 7 Horizontal Design plug˚ow design This avoids short circuiting and makes the mill far lessIsaMill

Stirred Milling machine development and application

Eirich Tower mill™ • General characteristicsGravity keeps media in the millCharge weight aids grindingLow intensity, low tip speedHigh density mediaMedia sizes 38 –5 mmScrew agitator to lift charge 5 13 Nov 2013Dec 20, 2016 The tower mill was an advancement of the post mill having multiple floors for storing grain, removing chaff, grinding grain, and living quarters for the windsmith and his family The most important feature of the tower mill was a cap (roof) that could What is a Windmill: Exploring What Windmills Do, And How Jun 07, 2016 DESIGN PARAMETER 5 Labor rooms s c a l e Vehicle space Worksho p 3 Offices (12×12ft) Laboratory Road Boiler Monitoring room (5×3ft) Boile r Warehous e Siloe s Gate 1 5*15 ft Gate2 Essentials of feed mill Facilities arrangementReceiving unit 6 ESSENTIALS OF FEED MILL 1 Fenced land 2 Building for warehouse 3Construction and designing of feed milltower mill grinding efficiency Second Hand Concrete Batching Plants For Sale In Malaysia Market of Second Hand Concrete Batching Plants For Sale In MalaysiaDevelopment of Second Hand Concrete Batching Plants are to largescale, automated, intelligen Raw Complex Gold Ore Processing Machinetower mill grinding efficiencyAuto enous Mill Ball Mill Re rind Mill Tower Mill M10 000 Table 1: Media Installed Power 6400 2600 740 1000 3000 Mill Volume (m ) 353 126 39 12 10 Power Intensity W/m3 18 21 19 42 300 Comparative Energy Intensity of Grinding Technologies The key to the energy efficiency of the IsaMillTM is the ability to use fine media While tower mills areimg4

ball mill grinding efficiency ball mill grinding

To determine mill power draw characteristics and capabilities for rod, ball and design vportable stone crushing machinesariables and operating conditions related to ball mill grinding efficiency Synopsis Ball mills are usually the largest consumers of energy within a media in the mill by looking at the mill grinding efficiencyEvery mining operation has a unique grinding process has experience of over 8,000 grinding mills globally, including manufacturing and delivering the largest SAG/AG mills in the world Our experts welcome the opportunity to assist you with circuit and circuit control design as well as startup, operation, and optimization of your millGrinding mills for mining and minerals processing