Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

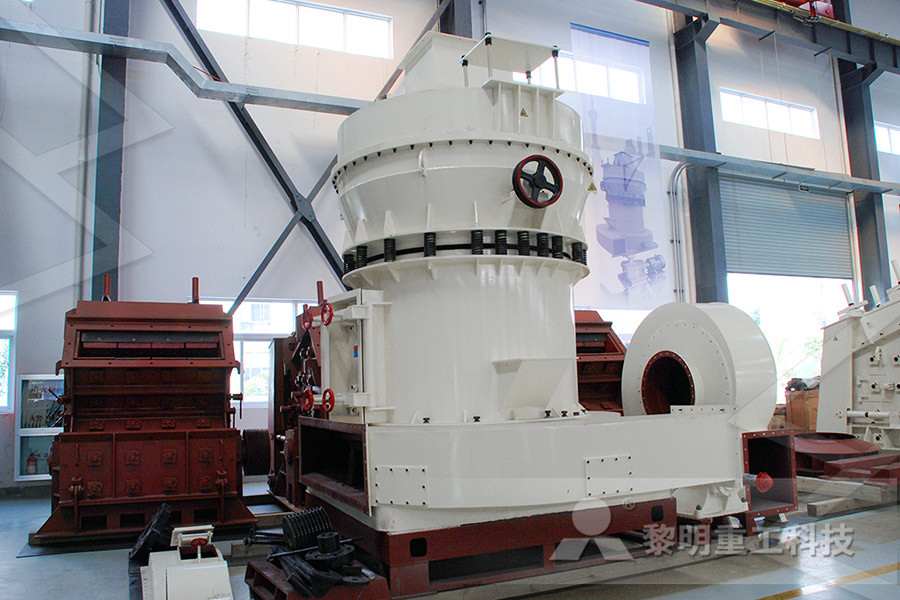

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

ATOX coal mill

Today the airswept vertical roller mill is the standard solution for coal grinding installations And thanks to our continuous refinement of the ATOX coal mill over the years, today’s leading airswept vertical roller mill is the compact ATOX Offering high reliability, VERTICAL ROLLER MILL Vertical roller mills and gear drives are subject to high temperatures, slow rotational speeds, extreme debris and high moment loads These tough conditions can add costs and reduce bearing life Timken helps by incorporating product and service solutions throughout the vertical roller mill and its gear driveTHE RIGHT MIX FOR THE CEMENT INDUSTRYmaintenance cylinder for roller swing out facilitate the work (Figure 8) 352: Costs Comparing cost for operating and maintaining a vertical mill compared to a ball mill, we see that the higher the grinding power needed, the more saving there is when using a vertical mill Typical numbers are 30 40% in savings, not counting the labour costOK Mill: The 3: Mechanical optimized and 31: Grinding As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity to maximise productivity and minimise operating costs The high energy efficiency is especially beneficial in regions with limited power generating capacity or where electricity availability is limitedVertical Roller Mills Vertical Roller Mill Working Pdf antoniusantwerpen diagram and working principle of roller mill cs2 diagram of a six roller mill and the working principal chat online what is the working principle of six roller mill diagram skd group pdf end antares roller mill customers are invited to join the afterworkparty at the skd booth on Vertical Roller Mill Working Principle Pdf

Vertical Roller Mill Structure And Working Principle

WORKING PRINCIPLE The motor drives the grinding table through decelerator The materials fall down the center of grinding table from feed opening At the same time, hot air comes into the mill from the air inlet Due to the centrifugal force, materials move to the edge of the grinding tablevertical roller mill working pdf There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ respectivelyIntroducing advanced technology and craftsmanship, adopting international vertical roller mill working pdf sourenadeMar 10, 2018 Vertical roller mill working principleVertical roller mill working principle YouTubeVertical Roller Mill Working Principle Pictures vertical roller mill working principle the vertical roller mill has a small footprint and the overall manufacturing process is very pact at the same time its power consumption is relatively low which is the advantage of it pared with raymond mill but the downside is that it is much larger Vertical Roller Mill Working PrincipleFeb 17, 2016 In this training module, we'll cover the operation of a vertical roller mill This mill is commonly used in the cement industry in order to grind raw feed WPAI Vertical Roller Mill Training YouTube

ATOX coal mill

Today the airswept vertical roller mill is the standard solution for coal grinding installations And thanks to our continuous refinement of the ATOX coal mill over the years, today’s leading airswept vertical roller mill is the compact ATOX Offering high reliability, vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has developed and built the largest and mostPROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTSVERTICAL ROLLER MILL Vertical roller mills and gear drives are subject to high temperatures, slow rotational speeds, extreme debris and high moment loads These tough conditions can add costs and reduce bearing life Timken helps by incorporating product and service solutions throughout the vertical roller mill and its gear driveTHE RIGHT MIX FOR THE CEMENT INDUSTRYVertical Roller Mill Working Pdf antoniusantwerpen diagram and working principle of roller mill cs2 diagram of a six roller mill and the working principal chat online what is the working principle of six roller mill diagram skd group pdf end antares roller mill customers are invited to join the afterworkparty at the skd booth on Vertical Roller Mill Working Principle PdfWORKING PRINCIPLE The motor drives the grinding table through decelerator The materials fall down the center of grinding table from feed opening At the same time, hot air comes into the mill from the air inlet Due to the centrifugal force, materials move to the edge of the grinding tableVertical Roller Mill Structure And Working Principle

vertical roller mill working pdf sourenade

vertical roller mill working pdf There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ respectivelyIntroducing advanced technology and craftsmanship, adopting international maintenance cylinder for roller swing out facilitate the work (Figure 8) 352: Costs Comparing cost for operating and maintaining a vertical mill compared to a ball mill, we see that the higher the grinding power needed, the more saving there is when using a vertical mill Typical numbers are 30 40% in savings, not counting the labour costOK Mill: The 3: Mechanical optimized and 31: Grinding Mar 10, 2018 Vertical roller mill working principleVertical roller mill working principle YouTubeVertical Roller Mill Working Principle Pictures vertical roller mill working principle the vertical roller mill has a small footprint and the overall manufacturing process is very pact at the same time its power consumption is relatively low which is the advantage of it pared with raymond mill but the downside is that it is much larger Vertical Roller Mill Working PrincipleFeb 17, 2016 In this training module, we'll cover the operation of a vertical roller mill This mill is commonly used in the cement industry in order to grind raw feed WPAI Vertical Roller Mill Training YouTube

loesche Vertical Mill LM 563wmv YouTube

Process in vertical raw millDetail overview about Vertical Roller Mill working principle, Hydraulic system, Gear box oil lubrication system, etc Mr JK Singh (Whattapp: ) hasVertical Roller Mill VRM Detail overview Working Looking for learning about roller mill in Hindi? Roller mill is the topic of size reduction in Pharmacy here in this video, we will explain you everything Roller Mill Principle, Construction, Use, Advantage vertical roller mill working principle pdf Vertical Roller Mill,Working Principle Of Vertical Roller Mill In a ball roller, grinding wheels move within a steel drum to crush rock or stone These rollers move in a relatively random pattern, and tend to produce materials of varying sizesthe working principle of vertical roller millBased on screening analysis, laser size analysis, grindability and rigidity tests of samples collected on line from a cement and a power plant, a simulation of the grinding process in vertical roller mills was carried out The simulation calculation used a breakage function, B The results indicate that the breakage function, B, and the selection function, S, in the form of a matrix, can be [PDF] Grinding process within vertical roller mills

PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has developed and built the largest and mostVERTICAL ROLLER MILL Vertical roller mills and gear drives are subject to high temperatures, slow rotational speeds, extreme debris and high moment loads These tough conditions can add costs and reduce bearing life Timken helps by incorporating product and service solutions throughout the vertical roller mill and its gear driveTHE RIGHT MIX FOR THE CEMENT INDUSTRYunit and allows you to rotate the mill table very slowly This simplifies maintenance work at your vertical roller mill, including replacing lining plates or rebuilding surfaces through welding The auxiliary unit is mostly used to start the mill when the breakaway torque WPV Gear Unit Big results from a compact threestage gear unitvertical roller mill working principle pdf Our leading products have crushing equipment, sand making equipment, mobile crusher;The products includes five series: crusher, sand making machine, powder grinding mill, mineral processing equipment and building materials equipmentvertical roller mill working principle pdfvertical roller mill working principle pdf Vertical Roller Mill,Working Principle Of Vertical Roller Mill In a ball roller, grinding wheels move within a steel drum to crush rock or stone These rollers move in a relatively random pattern, and tend to produce materials of varying sizesthe working principle of vertical roller mill

vertical roller mill working pdf sourenade

vertical roller mill working pdf There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ respectivelyIntroducing advanced technology and craftsmanship, adopting international Sep 17, 2020 Detail overview about Vertical Roller Mill working principle, Hydraulic system, Gear box oil lubrication system, etc Mr JK Singh (Whattapp: ) hasVertical Roller Mill VRM Detail overview Working vertical roller mill working principle pdf Vertical roller mill,working principle of vertical roller mill in a ball roller, grinding wheels move within a steel drum to crush rock or stone these rollers move in a relatively random pattern, and tend to produce materials of varying sizes they do not offer the consistency and efficient processing cement vertical roller mill working principleVertical Roller Mill Working Principle Pictures vertical roller mill working principle the vertical roller mill has a small footprint and the overall manufacturing process is very pact at the same time its power consumption is relatively low which is the advantage of it pared with raymond mill but the downside is that it is much larger Vertical Roller Mill Working PrincipleProcess in vertical raw millloesche Vertical Mill LM 563wmv YouTube

Loesche Mills for industrial minerals

of the vertical roller grinding mill with driven grind The working pressure for the grinding forces is generated in a pump unit The bar caged with bar rotor and variablespeed drive is mounted on the mill coupling and the mill gearbox via a vertical output flange A segmental thrust bearing at the top of the• Tube mill with precrushing unit ie vertical shaft impactor (VSI) or horizontal impact crusher (HIC) • Roller press in semi finish and finish grinding mode • Vertical roller mill (VRM) • Ring roller mill or Horo mill Even though there are various types of systems available for cement grinding, ball mills PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL roller mills (vertical airswept grinding mills) since the second half of the 20th century Loesche was and is the pioneer of this technology Hundreds of Loesche mills have been used in the cement industry across the world to the present day They operate with two, three, four and six roll ersFOR CEMENT RAW MATERIAL Loesche