Solutions

Products

-

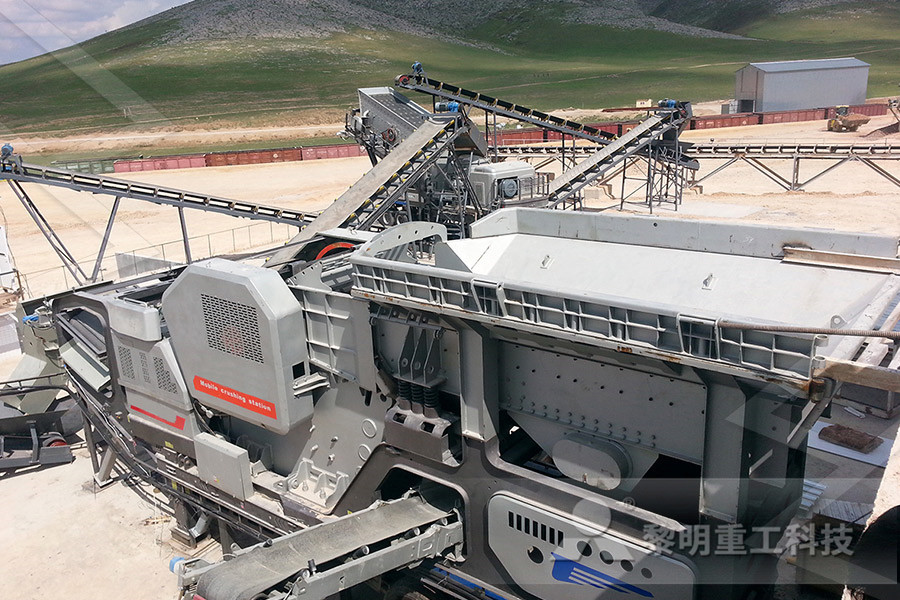

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

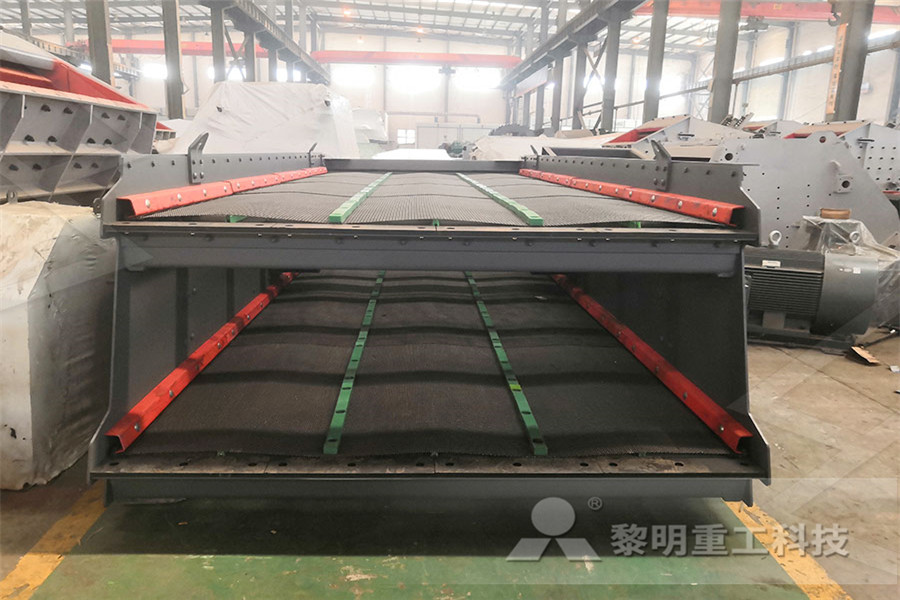

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

(DOC) BALL MILL STANDARD OPERATING PROCEDURE: SL NO

BALL MILL STANDARD OPERATING PROCEDURE: SL PROCEDURES STATUS REMARK NO 1 Ensure that all the items mentioned in the prerequisites are available 2 Connect the power supply (3 Phase) [415 V, 50/ 60 HZ] AC with Earthing (use 5 core cable to draw earthing from the input supply) 3The operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media The material grinding occurs during impact falling grinding balls and abrasion the particles between the ballsThe operating principle of the ball mill Primo PizzaBall Mill and Grinding Circuit Preparation for StartUP The following items must be checked before the equipment in the Grinding Circuit is started Check the ore slot feeder for obstruction or hang—ups Check the ball mill belt feeder for undue buildup of material Check oil level in ball mill lube oil tanks Also, check grease level in the mill ring gear spray lube drum Ensure that the Ball Mill Operation Grinding Circuit Startup Shutdown Operating Procedure for Ball miller Note: Internal Timer has been modified to time for 9,999 minutes –Extended time This ball mill was designed to run 15 minutes, Average Time The original total time was 999 minutes maximumOperating Procedure for Ball millerThe trial operation of the ball mill should be carried out by a skilled ball mill operator and strictly abide by the safety operation regulations of the ball mill The continuous operation time of the ball mill in dry operation shall not be less than 1224 hours Any problems found during operation shall be Analyze the operating rules of the ball mill prominetech

Variables in Ball Mill Operation Paul O Abbe®

Ball milling is one of the few unit operation that improves with increasing mill diameter If acceptable results can be obtained with a 12” jar mil, then good result will certainly be Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available As such you will find it is designed and constructed according to heavy duty specifications It is designed along sound engineering principles Ball Mill Maintenance Installation ProcedureUltrafine Powder Ball Mill Operating Procedures ultrafine powder ball mill operating procedures nbsp 0183 32 Powder nanostructured by ball milling displays a particle size of the order of micrometres being much less susceptible to oxidation Varying the ball milling parameters also leads to powders with diverse characteristics such as morphology size and microstructure i e crystallite Procedures Ball Mill Powder With A Ball MillerA ball mill is a type of grinder used to grind materials into extremely fine powder 7 Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speed 8 Types of Ball MillsBall Milling University of Massachusetts BostonBall Mill Operating Procedure Operating Procedure for Ball miller Note Internal Timer has been modified to time for 9999 minutes Extended time This ball mill was designed to run 15 minutes Average Time The original total time was 999 minutes maximum Now it is 9999 minutes Ie 160 hoursBall Mill Operating Procedure gmkrawcowepl

Ball Milling University of Massachusetts Boston

A ball mill is a type of grinder used to grind materials into extremely fine powder 7 Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speed 8 Types of Ball MillsOperating Procedure for Ball miller Note: Internal Timer has been modified to time for 9,999 minutes –Extended time This ball mill was designed to run 15 minutes, Average Time The original total time was 999 minutes maximumstandard operating procedure of ball millBall mills operations and maintenance seminar Learn how to optimise your ball mill systems in this 5day training seminar focused on best practices for operations and maintenance (preventive and reactive) to achieve energy savings, reduced maintenance costs and overall improved productivity of the ball mill Operations and maintenance training for ball millsBall Mill Operating Procedure Duocarpediem Operating procedure for ball miller note internal timer has been modified to time for 9999 minutes extended time this ball mill was designed to run 15 minutes average time the original total time was 999 minutes maximum now it is 9999 minutes ie 160 hours to operate longer times two cooling fans have been installed and anBall Mill Relining Standard Operating ProcedureUltrafine Powder Ball Mill Operating Procedures ultrafine powder ball mill operating procedures nbsp 0183 32 Powder nanostructured by ball milling displays a particle size of the order of micrometres being much less susceptible to oxidation Varying the ball milling parameters also leads to powders with diverse characteristics such as morphology size and microstructure i e crystallite Procedures Ball Mill Powder With A Ball Miller

Ball Mill Operating Procedure hotelcelanoit

Dem Simulation Of Mill Charge In 3d Via Gpu Computing the ball mill simulation with 1 million spheres is completed in 27 hoursn the near future, these compute times can be halved with the advances in graphic card hardwareinitially the mill design and operating variables are set in the coden particular, the interior envelop of the sphere calculation procedure is mapped to the gpuget Procedure For Installation Of Ball Mill Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grindable materialsprocedure for in stallation of wet ball millDec 30, 2018 BALL MILL STANDARD OPERATING PROCEDURE 1 Open one side of vessel by opening the screw situated over the both sides of the vessel and remove the cap from vessel 2 Pour the ingredients desired no and size of balls into the vesselSOPs for SOPs for Scientific Instruments Gpatindia McCloskey Equipment can service machines worldwide to make sure your operation runs smoothly +7(927)687 07 58 [ protected] Piskunov street, Irkutsk Russian Federation Any of your enquiry will be highly appreciated contact us balling procedure for ball mill T01:04:53+00:00balling procedure for ball mill MC WorldINCAug 23, 2020 A Standard Operating Procedure (SOP) is a document consisting of stepbystep information on how to execute a task An existing SOP may need to just be modified and updated, or you may be in a scenario where you have to write one from scratch It sounds daunting, but it's really just a checklist See Step 1 to get the ball How to Write a Standard Operating Procedure: 15 Steps

Ball Milling University of Massachusetts Boston

A ball mill is a type of grinder used to grind materials into extremely fine powder 7 Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speed 8 Types of Ball MillsMill operating proceduresShangHai Bailing Machinery Co,Ltd Mill operating procedures Ball mill is widely used in industrial production of highfine grinding machine These are the correct ball mill operating rules, »More detailed Standard Operation Procedures (SOPs) for BallMill Standard Operation Procedures for BallMill safe operating procedures for ball mill – Crusher Machine Ball mill has features of high operation rate, grinding effect, and we must follow close to the line of the operation procedures and maintenance procedures of ball mill 1Before the start ball mill, you should check whether the connection bolts are tightened, and tightening condition of the spoon head of the ore feeder, and key of gears, couplings And, you should check that whether the Ball Mill Operation and MaintenanceOperating Procedure for Ball miller Note: Internal Timer has been modified to time for 9,999 minutes –Extended time This ball mill was designed to run 15 minutes, Average Time The original total time was 999 minutes maximumstandard operating procedure of ball millA ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating about its axis TBall mill Wikipedia

(PDF) Grinding in Ball Mills: Modeling and Process Control

depending on the type of the mill, the operating conditions and the type of the a procedure to determine the exact Penggerusan dengan ball mill replika menghasilkan indeks kebundaran 0 Ball Mill Operation Ball Mill Maintenance Procedures Ball be aware many service and repair procedures should be done only by authorized personnelhe service technicians at your haas factory outlet hfo have the training, experience, and are certified to do these tasks safely and correctlyBall Mill Operation Ball Mill Maintenance Procedures BallProcedure For Installation Of Ball Mill Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grindable materialsprocedure for in stallation of wet ball millThe mill performance is evaluated and recommendations are formulated based on the past history of the mill operations, inspections, process measurements, feed/product characteristics and grinding performance, in order to improve mill output and reduction in power consumptions in the ball mill system DIAGNOSTIC STUDY History of mill operationsPROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL Cement Ball Mill Operation Procedure Ball mill relining standard operating procedure xsm ball mill operating procedures ball mill crasher installation procedure ball mill wikipedia the ball mill is a key piece of equipment for grinding crushed materials and it is widely used in production lines for powders such as cement silicates 247Disassembly Procedure For Calcium Ball Mill

Optimizing your SAG mill operation International Mining

In the past, when primary, secondary and tertiary crushers fed material directly to large ball mills, the energy efficiency of the concentrator was determined for the most part by the ball mill operation, whereas now the energy efficiency of a plant often rests largely on the SAG mill operationMILLING OPERATIONS Milling is the process of machining flat, curved, orMilling machines are basically classified as vertical or irregular surfaces by feeding the workpiece against a rotating horizontal These machines are also classified as kneetype, cutter containing a number of cutting edges The milling ramtype, manufacturing or bed type MILLING OPERATIONS TYPES OF MILLING MACHINESSIMINE MILL end of the inching operation, the SIMINECIS MILL GD stops the mill with balanced Whether SAG or Ball Mill, space is a sensitive subject, especially in the conprocedure for inching ball mill pochirajucoprocedure for ball mill operationLeBron, NOOOOO deadspin In the third quarter of Game 4 of the Eastern Conference Finals, Kevin Love heaved an incredible outlet pass the length of the court to a waitinprocedure for ball mill operation homeideascentrecoza