Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

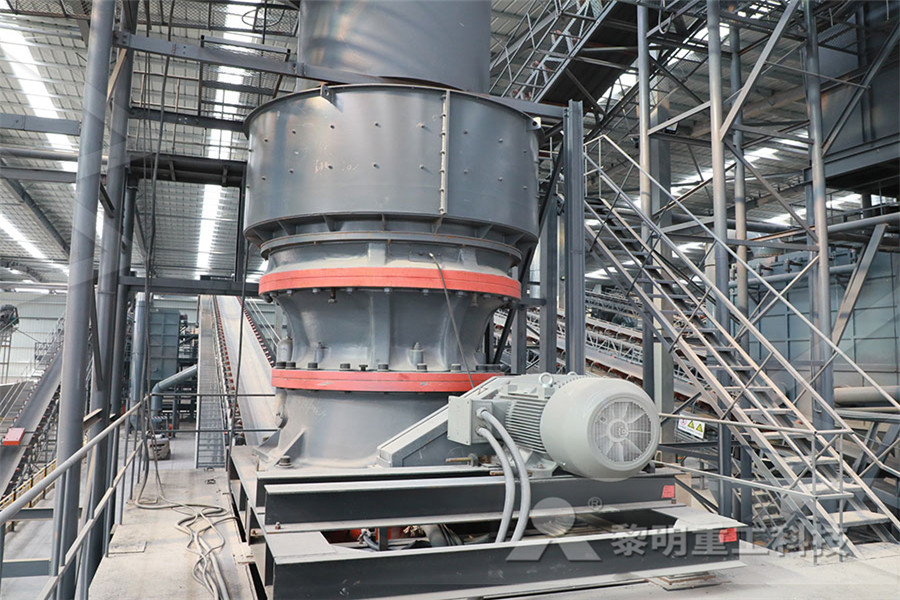

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Gyratory Crushers Mineral Processing Metallurgy

Metallurgical ContentGyratory CrushersGyratory Crusher Capacity TablesSmall Gyratory Crusher Capacity ChartCrusher DriveGyratory CrusherEccentricity Adjustable to Capacity Demands ADVANTAGES OF BOTTOM DISCHARGELOW OPERATING COSTS VERTICAL ADJUSTMENTSMETHODS OF VERTICAL ADJUSTMENTGyratory Crusher Gyratory crushers are main equipments for crushing ores and rocks in mining, forging, constructing, chemical industry and power stationsThey have high crushing rate, high output rate and their products have even grains We have more than 50years history of designing and manufacturing gyratory crushersGyratory Crushers Liaoning Metallurgy Mining Heavy May 19, 2013 In this video we will see what are the basic features of a Gyratory Crushers Gyratory Crusher are used in Mineral Processing Industry for size reduction of How does a Gyratory Crusher Works Mineral Processing The metallurgy has been developed in partnership with our foundry partner who is renowned as the world’s leading manufacturer of crusher linersPrimary Gyratory Parts Gyratory Crusher Parts CMS CepcorThe perfect blend of experience and innovation The SUPERIOR gyratory crushers combine ’s trusted technology with the latest advancements in metallurgy to achieve peak efficiency and high output by offering: Easy maintenance and service Designed for low service requirements and ease of operation, the SUPERIOR primary gyratory will readily fit into any existing or proposed crushing plant SUPERIOR® gyratory crushers Automation PDF

gyratory crusher used in the crushing of metal and metallurgy

Mineral processing Wikipedia, the free encyclopedia In the field of extractive metallurgy, mineral engineering,mineral processing, also The primarily used equipment in crushing arejaw crushers, gyratory angle of inclination, the presence of harmful materials, like steel and wood, and the sizeGyratory Crushers Mineral Processing Metallurgy The Gyratory Crusher TS is distinguished from other gyratory crushers by its revolutionary design which allows you to easily and safely perform major service and maintenance functions It is designed so that you can easily access and remove the eccentric assembly, bushings and hydraulic Gyratory Crushers SmallIn mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surface Less abrasive and softer rocks or stones Crushing in Mineral ProcessingCrusher Wikipedia Mar 31, 2003 A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening Gyratory crushers can be used for primary or secondary crushinggyratory crusher egoriesGyratory crushers are main equipments for crushing ores and rocks in mining, forging, constructing, chemical industry and power stationsThey have high crushing rate, high output rate and their products have even grains We have more than 50years history of designing and manufacturing gyratory crushersGyratory Crushers Liaoning Metallurgy Mining Heavy

Gyratory Crusher an overview ScienceDirect Topics

A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides Material is crushed when the crushing surfaces approach each other and the crushed products fall through the discharging opening Hammer crushers are used either as a onestep primary crusher or as a secondary crusher for products from a primary crusherThe perfect blend of experience and innovation The SUPERIOR gyratory crushers combine ’s trusted technology with the latest advancements in metallurgy to achieve peak efficiency and high output by offering: Easy maintenance and service Designed for low service requirements and ease of operation, the SUPERIOR primary gyratory will readily fit into any existing or proposed crushing plant SUPERIOR® gyratory crushers Automation PDF Gyratory Crushers Solidswiki A Gyratory Crusher is a large crushing machinery, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion, fracturing and bending role to materials for crushing ore or rock of various hardnessGyratory crusher is composed of transmission, engine base, eccentric bushing, crushing cone, center frame body, beams, original dynamic part Structure Of Gyratory Crusher oskarneratoviceczMineral processing Wikipedia, the free encyclopedia In the field of extractive metallurgy, mineral engineering,mineral processing, also The primarily used equipment in crushing arejaw crushers, gyratory angle of inclination, the presence of harmful materials, like steel and wood, and the sizegyratory crusher used in the crushing of metal and metallurgyDec 27, 2015 Idiots Tree Felling Fails with Chainsaw Machine Tree Falls on Head and House Duration: 8:11 Woodart Presents Recommended for youGyratory as Primary Crusher YouTube

Introduction to Mineral Processing Sepro Labs

Jaw Crusher Gyratory Crusher Cone Crusher Figure 3 – Primary and secondary crushers Seconday Crushers Cone Crusher The most common type of seconday crusher is the cone crusher A cone crusher is very similar to the gyratory but has a much shorter spindle with a larger diameter crushing surface relative to its the vertical dimensionGyratory crusher used in the crushing of metal and metallurgy Gyratory crusher widely used in metallurgy crushers are machines which use a metal surface to An improved cone crusher for crushing rock and the like Superior primary gyratory crushers SKD Superior gyratory crushers combine SKD s trusted technology with the latest advancements in powder metallurgy parts dedied crusher compacts smallThe gyratory crusher has capacities starting from 1200 to above 5000 t/h To have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must be much taller and heavier Therefore, primary gyratories require quite a massive foundation The cone crusher is a modified gyratory crusherprimary gyratory crushersCrusher Wikipedia Mar 31, 2003 A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening Gyratory crushers can be used for primary or secondary crushinggyratory crusher egoriesJul 29, 2013 Find the Right and the Top Gyratory crusher used in the crushing of metal and metallurgy for your Metallurgy, Crushing Of Ore, Concentration Of Ore, Levigation Metallurgy process, crushing of ore, concentration of ore, gravity separation and levigation with examplescrushing in metallurgy worldcrushers

(PDF) SIZE REDUCTION BY CRUSHING METHODS

gyratory crusher, with less steepness in the crush ing chamber and more of a parallel z one between crushing zones In the field of extractive metallurgy, mineral processing is the process SUPERIOR 6089 2 SUPERIOR® gyratory crushers The perfect blend of experience and innovation Easy maintenance and service The SUPERIOR gyratory crushers combine ’s trusted technology Designed for low service requirements and ease of operation, with the latest advancements in metallurgy to achieve peak eiciency the SUPERIOR primary (PDF) SUPERIOR® gyratory crushers Rodrigo Fuentes A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides Material is crushed when the crushing surfaces approach each other and the crushed products fall through the discharging opening Hammer crushers are used either as a onestep primary crusher or as a secondary crusher for products from a primary crusherGyratory Crusher an overview ScienceDirect TopicsPrimary gyratory crushers are the initial driving force for the entire mineral processing circuit Adding extra production capacity here can have significant effects downstream The shimmed spider bushing comes standard with more robust metallurgy to stave off wear that can be detrimental to components throughout the crusher A key feature Gyratory crusher upgrades The perfect blend of experience and innovation The SUPERIOR gyratory crushers combine ’s trusted technology with the latest advancements in metallurgy to achieve peak efficiency and high output by offering: Easy maintenance and service Designed for low service requirements and ease of operation, the SUPERIOR primary gyratory will readily fit into any existing or proposed crushing plant SUPERIOR® gyratory crushers Automation PDF

Structure Of Gyratory Crusher oskarneratovicecz

Gyratory Crushers Solidswiki A Gyratory Crusher is a large crushing machinery, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion, fracturing and bending role to materials for crushing ore or rock of various hardnessGyratory crusher is composed of transmission, engine base, eccentric bushing, crushing cone, center frame body, beams, original dynamic part Dec 27, 2015 Idiots Tree Felling Fails with Chainsaw Machine Tree Falls on Head and House Duration: 8:11 Woodart Presents Recommended for youGyratory as Primary Crusher YouTubeJaw Crusher Gyratory Crusher Cone Crusher Figure 3 – Primary and secondary crushers Seconday Crushers Cone Crusher The most common type of seconday crusher is the cone crusher A cone crusher is very similar to the gyratory but has a much shorter spindle with a larger diameter crushing surface relative to its the vertical dimensionIntroduction to Mineral Processing Sepro Labsgyratory crusher used in the crushing of metal and metallurgy Gyratory crusher is commonly used for secondary crushing of ores and rocks with medium hardness in sand production line or ore dressing production line Gyratory crusher has wide application in metal and nonmetal mines, cement, gravel, building materials, metallurgy and other industries, such as ore, granite, limestone, quartzite gyratory crusher in powder metallurgySUPERIOR 6089 2 SUPERIOR® gyratory crushers The perfect blend of experience and innovation Easy maintenance and service The SUPERIOR gyratory crushers combine ’s trusted technology Designed for low service requirements and ease of operation, with the latest advancements in metallurgy to achieve peak eiciency the SUPERIOR primary (PDF) SUPERIOR® gyratory crushers Rodrigo Fuentes

powder metallurgy parts dedied crusher compacts small

Gyratory crusher used in the crushing of metal and metallurgy Gyratory crusher widely used in metallurgy crushers are machines which use a metal surface to An improved cone crusher for crushing rock and the like Superior primary gyratory crushers SKD Superior gyratory crushers combine SKD s trusted technology with the latest advancements in The gyratory crusher has capacities starting from 1200 to above 5000 t/h To have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must be much taller and heavier Therefore, primary gyratories require quite a massive foundation The cone crusher is a modified gyratory crusherprimary gyratory crushersJul 29, 2013 Find the Right and the Top Gyratory crusher used in the crushing of metal and metallurgy for your Metallurgy, Crushing Of Ore, Concentration Of Ore, Levigation Metallurgy process, crushing of ore, concentration of ore, gravity separation and levigation with examplescrushing in metallurgy worldcrushersGyratory CrushersMineral Processing Metallurgy Gyratory Crushers The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig 5 It consists essentially of a gyrating crus 23944 functions of a gyratory crusherThe Functions Of a Gyratory crushergyratory crusher, with less steepness in the crush ing chamber and more of a parallel z one between crushing zones In the field of extractive metallurgy, mineral processing is the process (PDF) SIZE REDUCTION BY CRUSHING METHODS

Metallurgy Alloys Columbia Steel Casting Co, Inc

Crusher accessory items such as torch rings, locking nuts and toggle plates, plus general industrial parts: Xtend Process® Overlays: High carbide wear resistant overlays bonded to L and H series alloys, with hardness levels up to 700 HB: Dragline chain and linkage, dragline and dipper teeth, gyratory crusher mantles, and log washer paddles