Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

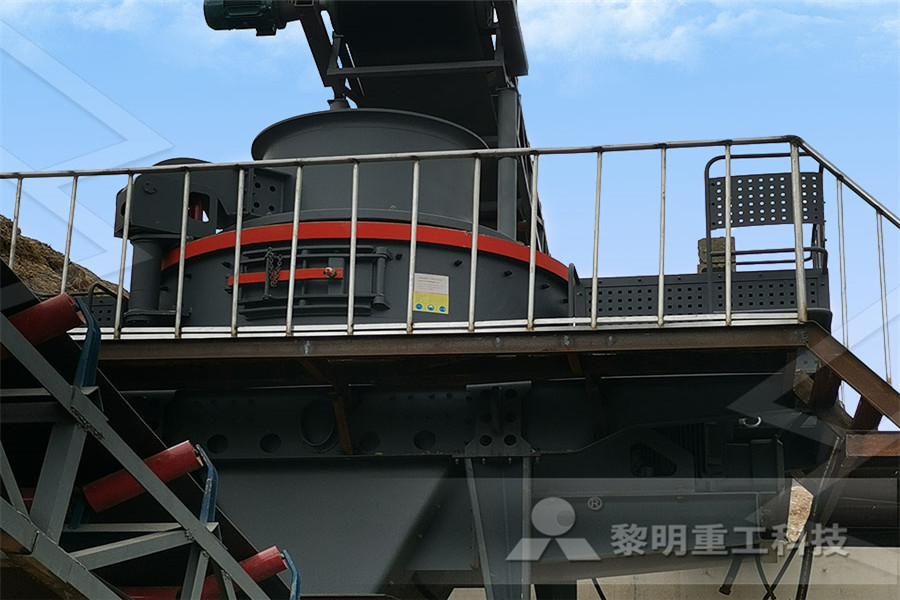

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

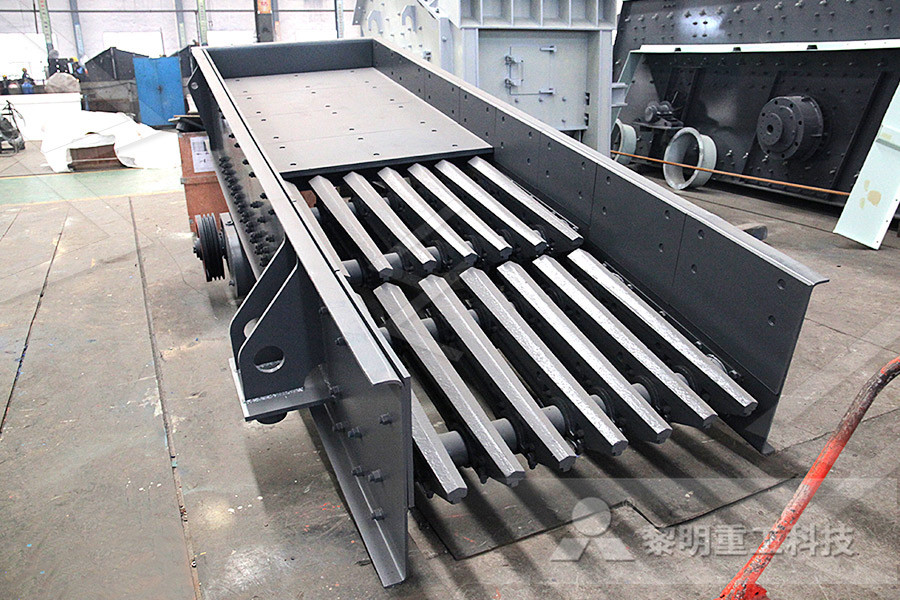

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Separation in mineral processing Minerallurgy

The adsorption or not of water on the surface of mineral particles is exploited to achieve separation between valuable minerals and gangue This separation technique is named froth flotation, and it is widely used for almost all types of ores For this process, the material ground into a fine powder is mixed with water and chemicalsA successful separation of a valuable mineral from its ore can be determined by heavyliquid testing, in which a singlesized fraction of a ground ore is suspended in a liquid of high specific gravity Particles of less density than the liquid remain afloat, while denser particles sinkMineral processing metallurgy BritannicaMagnetic separation is an ore dressing process, in which magnetically susceptible minerals are separated from a mixture using a magnetic force It is a method of concentrating the mined material by the application of a magnetic field We use MS to concentrate a valuable ore that contains a mixture of magnetic and nonmagnetic minerals;Magnetic Separation For Ore Dressing and Metallurgy With using traditional methods of the mineral separation, typically ore rises to the surface for further processing In this case, can use any method of separation, or a combination thereof to produce the expected results at any stage of the project readiness There is the possibility of changes in processing technology and equipmentHow to choose a method for the separation of minerals Gravity separation, also known as gravity concentration in mineral processing, is a technique of separating valuable minerals from gangue, based on their specific weight differences It is applied using water, particular liquids, or even air The process of concentrating ores Gravity Separation Principle, Uses and Applications

Manganese oxide ore beneficiation method and process flow

Among the ironcontaining manganese oxide ores, the iron minerals are mainly limonite It is difficult to separate iron and manganese by gravity separation, flotation or strong magnetic separation, and a reduction roasting magnetic separation method is requiredmethod of mineral separation; it was used 2,000 y ears before Gravity separation is one of the efficient m ethods of separating minerals from barren rock s by using the difference in densities(PDF) GRAVITY SEPARATION IN ORE DRESSINGAug 03, 2015 Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals It is done in order to produce a concentrate containing most of (PDF) Overview of Mineral Processing MethodsFigure 1 depicts the basic magnetic separation technologies now available in the marketplace in terms of field intensities and modes of processing LIMS and scalper magnets are not detailed in this paper The selection of magnetic separation technology depends on many processing factors, including particle size, and the specific assemblage of minerals and grades as well as their corresponding [PDF] A discussion of magnetic separation techniques for Gravity separation, also known as gravity concentration in mineral processing, is a technique of separating valuable minerals from gangue, based on their specific weight differences It is applied using water, particular liquids, or even air The process of concentrating ores using gravity separation has many advantagesGravity Separation Principle, Uses and Applications

How to choose a method for the separation of minerals

With using traditional methods of the mineral separation, typically ore rises to the surface for further processing In this case, can use any method of separation, or a combination thereof to produce the expected results at any stage of the project readiness There is the possibility of changes in processing technology and equipmentGravity Separation is used to separate mineral and gangue with a large difference in their Specific Gravities Chromite, tin, tantalite and various heavy metals are amenable to this principle Some gold ores contain Free Gold which can be recovered by gravity separation and this is the traditional method used in artisanal gold miningSeparation and Concentration Mineral Processing Floatation Separation Floatation is a main method to separate the ores by the different natures of wetting by water The hydrophobic mineral will be gathered on the bubbles and floats on the surface However, the hydrophilic minerals will stay in the water Applies for the following ores:Floatation Separation, Mining Flotation Process, Flotation In ore/mineral beneficiation, froth flotation is a method by which commercially important minerals are separated from impurities and other minerals by collecting them on the surface of a froth layer Flotation is the process of separation of beneficial minerals from a mixture by creating froth on which minerals Froth Flotation Process Detailed Explanation With How to choose a method for the separation of minerals There are more than 20 types of mineral flotationUniversal separation method, because by using flotation can be separated almost all mineralsIt is used for all types of ores and minerals (chalcopyrite, molybdenite, galena, sphalerite, gold, talc, mica, carbon, rare earth mineral, uranium minerals, and others)Separation Of Feldspar And Other Minerals By Flotation Methods

Chemical separation CONCENTRATION OF MINERALS

The chemical and mineral composition of the ore and host rocks (It should be ensured maximum extraction under economically acceptable reagent consumption Useful components should not be in the form of isomorphic impurities) The structure and texture of ores (This method is used in permeable sandy deposits of loose and well penetrated ores)Such ore generally uses gravity separation, flotation, strong magnetic separation or a combined process to recover iron minerals, and flotation to recover phosphorus or sulfide The above are mainly the common separation methods and technological processes of strong and weak magnetic iron oreIron ore beneficiation technology and process,gravity and now found in the recovery of heavy minerals from beach sand deposits in the separation of cassiterite, and recently in the upgrading of specular hematitic iron ores 2 Table 1 gives the types of electrical separation equipments used and the examples of the typical mineral separations for Electrical Separation of Mineral Raw Materials DD Misramethod of mineral separation; it was used 2,000 y ears before Gravity separation is one of the efficient m ethods of separating minerals from barren rock s by using the difference in densities(PDF) GRAVITY SEPARATION IN ORE DRESSINGnetic separation of iron ore have been in the field of dry processing, where a major revolution in iron ore beneficiation may be taking place But now consider an area of magnetic separation where dry methods have never lost their attractiveness Table I Iron Analysis of Crude and Beneficiated Minerals Used in the Ceramic Industry BeneflcistedADVANCES IN MAGNETIC SEPARATION OF ORES

Gold Processing Methods Gold Ore Extraction

Of all the methods of extracting gold processing it from its ore, I used a few to evaluate two principal flowsheets in this case study The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration Tests that mirror each of these unit operations were utilized to evaluate the principal flowsheets This page offers a comparative review of gold recovery Froth flotation is a process for selectively separating hydrophobic materials from hydrophilicThis is used in mineral processing, paper recycling and wastewater treatment industries Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th centuryFroth flotation WikipediaIn actual production, the fluorite beneficiation method needs to be formulated according to various factors such as the nature of the ore and the required concentrate grade Generally, the beneficiation of metallurgical grade fluorite concentrate can only require manual and gravity separationFluorite ore beneficiation process,ore grinding technology With using traditional methods of the mineral separation, typically ore rises to the surface for further processing In this case, can use any method of separation, or a combination thereof to produce the expected results at any stage of the project readiness There is the possibility of changes in processing technology and equipmentHow to choose a method for the separation of minerals How to choose a method for the separation of minerals There are more than 20 types of mineral flotationUniversal separation method, because by using flotation can be separated almost all mineralsIt is used for all types of ores and minerals (chalcopyrite, molybdenite, galena, sphalerite, gold, talc, mica, carbon, rare earth mineral, uranium minerals, and others)Separation Of Feldspar And Other Minerals By Flotation Methods

(PDF) Physical separation methods, Part 1: A Review

H erein, the importance of physical separation methods of ores in mineral processing is widely acknowledged Of interest is the magnetic separation, gravity concentration and The chemical and mineral composition of the ore and host rocks (It should be ensured maximum extraction under economically acceptable reagent consumption Useful components should not be in the form of isomorphic impurities) The structure and texture of ores (This method is used in permeable sandy deposits of loose and well penetrated ores)Chemical separation CONCENTRATION OF MINERALSnetic separation of iron ore have been in the field of dry processing, where a major revolution in iron ore beneficiation may be taking place But now consider an area of magnetic separation where dry methods have never lost their attractiveness Table I Iron Analysis of Crude and Beneficiated Minerals Used in the Ceramic Industry BeneflcistedADVANCES IN MAGNETIC SEPARATION OF ORESAnother method for the separation of gold and silver is the socalled cyanide process The Parkes process, which is based on silver being soluble in molten zinc while lead is not, is used to free silver from lead oresmetallurgy: Separation of the Metal Infopleasemethod of mineral separation; it was used 2,000 y ears before Gravity separation is one of the efficient m ethods of separating minerals from barren rock s by using the difference in densities(PDF) GRAVITY SEPARATION IN ORE DRESSING

Electrical Separation of Mineral Raw Materials DD Misra

now found in the recovery of heavy minerals from beach sand deposits in the separation of cassiterite, and recently in the upgrading of specular hematitic iron ores 2 Table 1 gives the types of electrical separation equipments used and the examples of the typical mineral separations for separation method for iron ore As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals We can provide you the complete stone crushing and beneficiation plantWe also supply standalone separation method for iron oreMineral processing or mineral beneficiation or upgradation involves handling of three primary types of ROM ore material which has been blasted, fragmented and brought out from in situ position These materials can be used directly or by simple or complex processing and even applying extractive metallurgy like hydrometallurgical or pyrometallurgical methodsMineral Processing an overview ScienceDirect TopicsScreened ores are upgraded by various methods to produce concentrates The most common physical separation methods are washing, highintensity magnetic separation, separation by gravity concentration, and separation by flotation, which makes use of the different surface properties of the mineralsHeavy Media Separation an overview ScienceDirect TopicsAnother method of concentration of ores is the Froth Flotation Method This is the process for concentration of primarily sulphide ores It has the advantage over gravity separation because it can collect even the extremely fine particles of minerals The process uses the difference in the wetting characteristics of minerals and gangueConcentration of Ores: Hydraulic Washing, Froth Flotation

mineral separation methods in srilanka

mineral separation methods in srilanka Mineral liberation analysis on coal components separated The mineral separation process was found to be affected by the type of comminution method as well as the disseminated grain size and dissemination states of the component mineralsMineral composition: TiO2 grade of raw ore: Processing method: Reagent: Concentrate index #1: Rutile, garnet, alalite: 130%: Gravity separation – magnetic separation – flotation – acid pickling / TiO2 9005%, recovery rate 50% #2: Rutile, ilmenite: 24%: Gravity separation – magnetic separation – flotation – acid pickling: Liquid Rutile Ore Titanium Flotation Mineral Processing Methods