Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

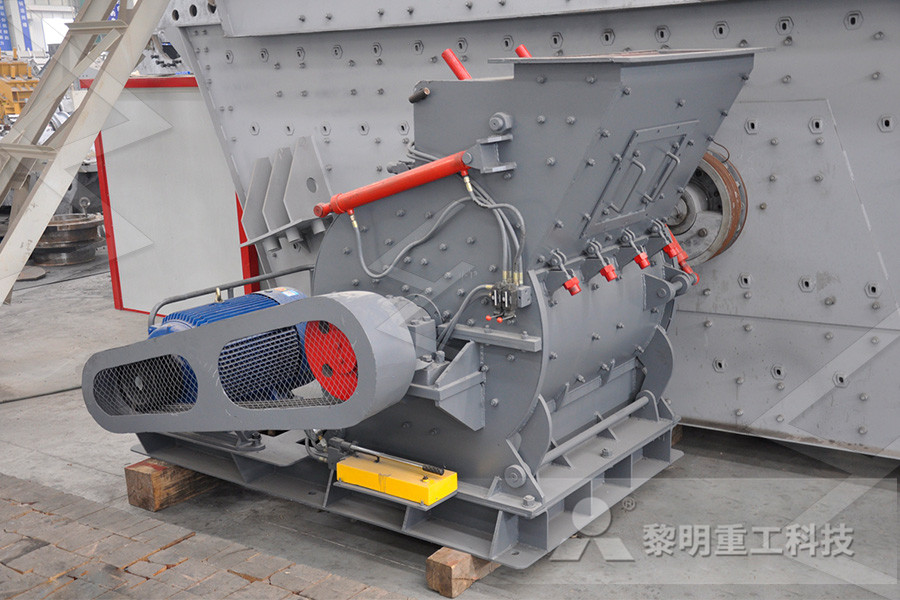

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Maintenance of the Mobile Crusher

Mobile crusher need to be routinely maintained to ensure efficient operation Equipment should be lubricated as required, small and mediumsized equipment is mainly lubricated with grease and lubricating oil, generally have a forced lubrication system, we should always pay attention to observe the oil temperature, oil pressure, flow and other parametersHere just take some problems that may happen in mobile crushing plant sometime for example, to know more, please consult the engineer Caiman, the professional mobile crusher manufacturer, have various mobile crushers, tire ones and track ones These mobile crushing machines well satisfy the customers’ demands and get high reputation from themUsed mobile crusher plant troubleshooting and maintenance repair and maintenance of impact crushers Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment repair and maintenance of impact crushers Mobile Impact crusher is a new and efficient crushing equipmentSuitable for coarse,medium, and fine crushing of materials with particle size not more than 500mm and compressive strength not exceed 350MPaMaterials can be crushed by impact crusher are mainly slag, clinker, limestone, coal, coke, etc, Impact crusher designed in YIFAN is widely used in energy, cement fields,and railways, highways Tips for impact crusher's operation and daily maintenanceYou can get advanced new and used mobile impact crusher from Features Of Mobile Impact Crusher This impact crusher features reasonable structure, high productivity, easy operation and maintenance and safe performanceThe most outstanding advantage of this machine is that its finished powder is in good, cubic shape and without tensity Used Mobile Impact Crusher For Sale

Portable Crushers Maintenance Costs GitHub Pages

Different from the traditional crusher machine fixed, complete functions, good flexibility, large processing quantity mobile crushing coal, of course, the portable crusher maintenance is a relatively complex Maybe many customs be consider to portable crusher amintenance costs, This is different base on different equipmentBefore the maintenance of jaw crusher machine, all electrical control devices and electric motors should be power outages, locked, and posted with maintenance of identity When the equipment operation, not to carry out lubrication, cleaning, repair or maintenance work Jaw Crusher Maintenance Dragon MachineryWorking Impact Crusher is the main machine of the Mobile Impact Crusher Plant,it’s used as secondary equipment after in the Jaw Crusher Mobile Impact Crusher Plant is mainly used for metallurgy, chemical industry, building materials, water and electricity’s materials processing which often requires to relocate, especially for highways, railways, water and electricity projects mobility Mobile Impact Crusher PlantShunky MachineryDec 08, 2020 Browse our inventory of new and used Crusher Aggregate Equipment For Sale near you at MachineryTrader Top manufacturers include KINGLINK, , POWERSCREEN, MCCLOSKEY, CEDARAPIDS, SANDVIK, KLEEMANN, KPIJCI, TEREX PEGSON, and RUBBLE MASTER Page 1 of 101Crusher Aggregate Equipment For Sale 2516 Listings Principle, it is possible for RM impact crushers to be operated by one person Following a short training session, you can get the most from your compact crusher All maintenance points are accessible from ground level Nothing could be simplerMobile Impact Crusher RUBBLE MASTER

Maintenance of the Mobile Crusher

Mobile crusher need to be routinely maintained to ensure efficient operation Equipment should be lubricated as required, small and mediumsized equipment is mainly lubricated with grease and lubricating oil, generally have a forced lubrication system, we should always pay attention to observe the oil temperature, oil pressure, flow and other parametersHere just take some problems that may happen in mobile crushing plant sometime for example, to know more, please consult the engineer Caiman, the professional mobile crusher manufacturer, have various mobile crushers, tire ones and track ones These mobile crushing machines well satisfy the customers’ demands and get high reputation from themUsed mobile crusher plant troubleshooting and maintenance repair and maintenance of impact crushers Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment repair and maintenance of impact crushers Mobile Impact crusher is a new and efficient crushing equipmentSuitable for coarse,medium, and fine crushing of materials with particle size not more than 500mm and compressive strength not exceed 350MPaMaterials can be crushed by impact crusher are mainly slag, clinker, limestone, coal, coke, etc, Impact crusher designed in YIFAN is widely used in energy, cement fields,and railways, highways Tips for impact crusher's operation and daily maintenanceThe crawler type mobile stone crusher plant is a new type of crushing equipment with high productivity and high efficiency The crawler mobile crusher station is a widely used mobile crusher in the machinemade sand production line It has a selfdriven form, advanced technology and perfect mon problems and maintenance of crawler mobile stone

Portable Crushers Maintenance Costs GitHub Pages

Different from the traditional crusher machine fixed, complete functions, good flexibility, large processing quantity mobile crushing coal, of course, the portable crusher maintenance is a relatively complex Maybe many customs be consider to portable crusher amintenance costs, This is different base on different equipmentAug 19, 2015 Impactor Maintenance Program Crusher Training Get IMPACT! Stedman Machine offers a full training program that can help increase efficiency with your impactors or crushers Learn from the industries best, and find out how you can save valuable time and money Reduce spare parts replacement; Reduce size reduction steps; Reduce or eliminate Impactor Maintenance Programs Crusher Training Stedman Moreover, the mobile impact crusher adopts module parts, which is easy to make maintenance and operation Mobile cone crusher Mobile cone crusher crushing hard material in secondary or tertairy crusher The mobile cone crusher is an ideal device for secondary and tertiary crushing The device is equipped with an automatic setting and adjustment Environmental Protection Mobile Crusher Fote Machinery(FTM)Working Impact Crusher is the main machine of the Mobile Impact Crusher Plant,it’s used as secondary equipment after in the Jaw Crusher Mobile Impact Crusher Plant is mainly used for metallurgy, chemical industry, building materials, water and electricity’s materials processing which often requires to relocate, especially for highways, railways, water and electricity projects mobility Mobile Impact Crusher PlantShunky MachineryMobile Impact Crushers are used as primary,secondary,tertiary crushers in aggregate quarries, recycling applications on construction sites and also in mining operations The mobile impact crushers are used for crushing medium hardness materials as well as Boratas mobile crushers mobile crushers mobile screens

MR 170 Z Mobile impact crushers

Impact crusher In contrast to pressure crushing, the impact crusher operates according to the impact crushing principle In this process, the crushed material is picked up by a fast moving rotor, greatly accelerated and smashed against a fixed impact plate ("impact toggles") From there, it falls back within range of the rotorDepending on the application, impact crushers can have higher wear costs, higher maintenance, and produce more fines Impact crushers may be used as a primary, secondary, or tertiary crusher depending on the producer’s finalproductsize needs These crushers are available in stationary, track and mobile designsWhat is the difference between a Cone Crusher and an Aug 01, 2019 The structure of the mobile concrete crusher The mobile concrete processing station produced by Machinery adopts multistage combination mode, which includes jaw crusher, impact crusher, cone crusher and vibrating screening equipment, conveyor belt, etc2 Types of Concrete Crushers It has the characteristics of high crushing capacity, high crushing ratio, stable finished product quality, low production cost and convenient operation and maintenanceThe wheel type mobile impact crushing plant is mainly used in construction waste disposal, metallurgy, chemical industry, building materials, hydropower and other relocation Mobile Impact Crusher Plant manufacturer,Mobile Impact Impact crusher is a new and efficient crushing equipmentSuitable for coarse,medium, and fine crushing of materials with particle size not more than 500mm and compressive strength not exceed 350MPaMaterials can be crushed by impact crusher are mainly slag, clinker, limestone, coal, coke, etc, Impact crusher designed in YIFAN is widely used in energy, cement fields,and railways, highways Tips for impact crusher's operation and daily maintenance

How to maintain jaw crusher mobile crushers

Here are the most common maintenance methods for you: Lubrication: (1) Always pay attention and do a good job of lubricating the friction surface in time to ensure the normal operation and extend its service life (2) The grease used in the jaw crusher should be determined according to the location of use and the temperatureJaw crusher is often used as the first crushing equipment, its workload can be imagined, so the maintenance of the machine is very important The following is a brief introduction to the maintenance rules and maintenance of jaw crusher: 1Repair and maintenance of jaw crusher1979 ELJAY RC45STD Portable Cone Crusher Toshiba, 20 hp, elec, 18 in x 8 ft 6 in cross conv, w/10 hp, 5 ft x 16 ft 2 deck screen, 29 in x 21 ft under screen disch conv, w/Weg 10 hp moreNew and used Crushers for sale Ritchie BrosMobile Crushers Innovation Advantages Our mobile crusher can be used in one stage of crushing for separate operation or complete joint operations with other crushing and screening portable plants to achieve twostage, threestage or fourstage crushing, so that various crusher screening requirements could be satisfiedMobile Crushers Mobile Crushing PlantReliable Performance Pcx 800x400 High Efficiency Impact Crusher , Find Complete Details about Reliable Performance Pcx 800x400 High Efficiency Impact Crusher,Highefficiency Fine Crusher,Cheap Rock Crusher,Fine Crusher Stone from Crusher Supplier or ManufacturerBaichy Heavy Industrial Machinery Co, LtdReliable Performance Pcx 800x400 High Efficiency Impact

What is the difference between a Cone Crusher and an

Depending on the application, impact crushers can have higher wear costs, higher maintenance, and produce more fines Impact crushers may be used as a primary, secondary, or tertiary crusher depending on the producer’s finalproductsize needs These crushers are available in stationary, track and mobile designsFuel efficiency and electric power Traditionally, mobile impact crushers have used a dieselhydraulic engine for the trackdrive and power to the crusherThe advent of electricdrive and hybrid systems is one of the main advancements that has occurred over the last decade, and its development is seen by many as one of the most significant trends going forward, especially considering the The rise of mobile impact crushers for recycling The Lokotrack® LT1110™ Mobile Impact Crusher always provides high capacity and a high reduction rate The LT1110 is commonly used for crushing medium hard rocks and for recycling though it can crush any recycled material from asphalt to concrete and bricks Engine and hydraulic pump speeds are optimised for the best efficiency Lokotrack® LT1110™ Mobile Impact Crusher Tutt BryantImpact Crushers – VSIs and HSIs Impactstyle crushers include VSIs, as well as horizontal shaft impactors (HSIs), and are best used with less abrasive rock types, like limestone These types of machines break apart material by the impacting forces of certain wear parts known as blow bars and impact plates or toggles Some operations also use impactstyle crushers after they have already Types of Rock Crushers Quarry Crushing Equipment KemperFig 9 shows a semimobile plant equipped with a reversible impact crusher being prepared for transport 4 Typical applications 41 Vertical impact crusher A typical application for the verticalshaft impact crusher is the crushing of smallsize offspec material for the production of sand (Fig 10)Semimobile crushers for oversize comminution Mineral

2020 EvoQuip Cobra 290R Mobile Impact CrusherOAGAD

TEREX EVOQUIP COBRA 290R MOBILE IMPACT CRUSHER The Cobra 290R is a versatile and easy to use Track Mounted Impact crusher that can operate in the most demanding of applications such as Reinforced Concrete, Recycled Asphalt, Construction and Demolition waste and Natural RockThe ® Finlay I120 is a midsized trackmounted mobile impact crusher, commonly used for processing medium to hard natural aggregates and recycling materials such Impact Crushers Heavy Duty FinlayThese crushers are used in aggregates production, mining operations as well as in recycling applications, normally as stationary crushers However, some models are also available as mobile or portable versions Vertical shaft impact crushers Vertical shaft impact crushers take the full advantage of socalled rockonrock crushing process In Impact crushers highquality impactors Outotec